Z axis is off by .010" over 1/2"

- Roland2161

- Offline

- Junior Member

-

Less

More

- Posts: 36

- Thank you received: 0

28 Jan 2019 02:20 #125001

by Roland2161

Z axis is off by .010" over 1/2" was created by Roland2161

Hi all,

So after reading a bunch I am stuck. My Z axis seems to be off exactly the same every time. Using a dial indicator I go to move .500, and it will only move .490. Then when it goes back to 0 it has moved an extra .001, every time. It keeps moving along. So it shifts as it repeats the same path. It will always travel .490", but it will always gain a .001 on one end and lose it on the other. I imagine its an step tuning issue. Any direction someone can point me in would be great. I do not know where I need to go to fix this.

I did not build this machine nor am I that experienced in linuxcnc past reading the manual, I purchased it to get a home shop running, and am using it as my learning tool so I can build my own machines. I am currently a novice learning as I go. Thanks for the understanding. Thank you.

So after reading a bunch I am stuck. My Z axis seems to be off exactly the same every time. Using a dial indicator I go to move .500, and it will only move .490. Then when it goes back to 0 it has moved an extra .001, every time. It keeps moving along. So it shifts as it repeats the same path. It will always travel .490", but it will always gain a .001 on one end and lose it on the other. I imagine its an step tuning issue. Any direction someone can point me in would be great. I do not know where I need to go to fix this.

I did not build this machine nor am I that experienced in linuxcnc past reading the manual, I purchased it to get a home shop running, and am using it as my learning tool so I can build my own machines. I am currently a novice learning as I go. Thanks for the understanding. Thank you.

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

28 Jan 2019 03:01 - 28 Jan 2019 03:04 #125005

by Leon82

Replied by Leon82 on topic Z axis is off by .010" over 1/2"

You can go into step config and look at the pitch of the axis screw. 5 rev per inch for example. If it's a metric screw like 5mm make sure the rev per inch goes out a bunch of decmial places. Exit without saving and Discard changes when you exit as it can overwrite some configurations done after

In the ini its listed as scale I believe. You can play with the value

In the ini see if they have a line backlash=.000. here you can adjust your backlash comp.

There should be a folder for your machine with about 10 files in it.

In the ini its listed as scale I believe. You can play with the value

In the ini see if they have a line backlash=.000. here you can adjust your backlash comp.

There should be a folder for your machine with about 10 files in it.

Last edit: 28 Jan 2019 03:04 by Leon82.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

28 Jan 2019 03:19 #125011

by Todd Zuercher

Replied by Todd Zuercher on topic Z axis is off by .010" over 1/2"

Loosing steps is the most likely of suspects. First you should look up the specifications for the step timings for your stepper drives. Then I would suggest setting them to 150-200% of the minimums specified. The next thing is to do a reality check on the acceleration limits in your configuration, and set them to something reasonable if they are too high.

Lost steps isn't the only possibility though. some kind of mechanical slippage is also possible. Check to be sure there couldn't be a coupling or pulley slipping anywhere.

Lost steps isn't the only possibility though. some kind of mechanical slippage is also possible. Check to be sure there couldn't be a coupling or pulley slipping anywhere.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

29 Jan 2019 22:34 #125215

by andypugh

Is the error proportional? Is 0.25" actually 0.245? 0.75 = 0.735?

If so then it looks like a simple scaling error. 5 TPI leadscrew and 5mm leadscrew are about the right error to account for this.

(0.5" / 5.08" * 5mm = 0.492..)

Replied by andypugh on topic Z axis is off by .010" over 1/2"

So after reading a bunch I am stuck. My Z axis seems to be off exactly the same every time. Using a dial indicator I go to move .500, and it will only move .490. .

Is the error proportional? Is 0.25" actually 0.245? 0.75 = 0.735?

If so then it looks like a simple scaling error. 5 TPI leadscrew and 5mm leadscrew are about the right error to account for this.

(0.5" / 5.08" * 5mm = 0.492..)

Please Log in or Create an account to join the conversation.

- Roland2161

- Offline

- Junior Member

-

Less

More

- Posts: 36

- Thank you received: 0

30 Jan 2019 00:40 #125232

by Roland2161

Andy,

Yes the error is proportional. I moved it a 1/4'' and it was off .005. Moved it a half inch and it was off almost exactly .492. and .75 was mor like .738 ish, but I have a half thousandth of backlash. Not sure if it is accounted for.

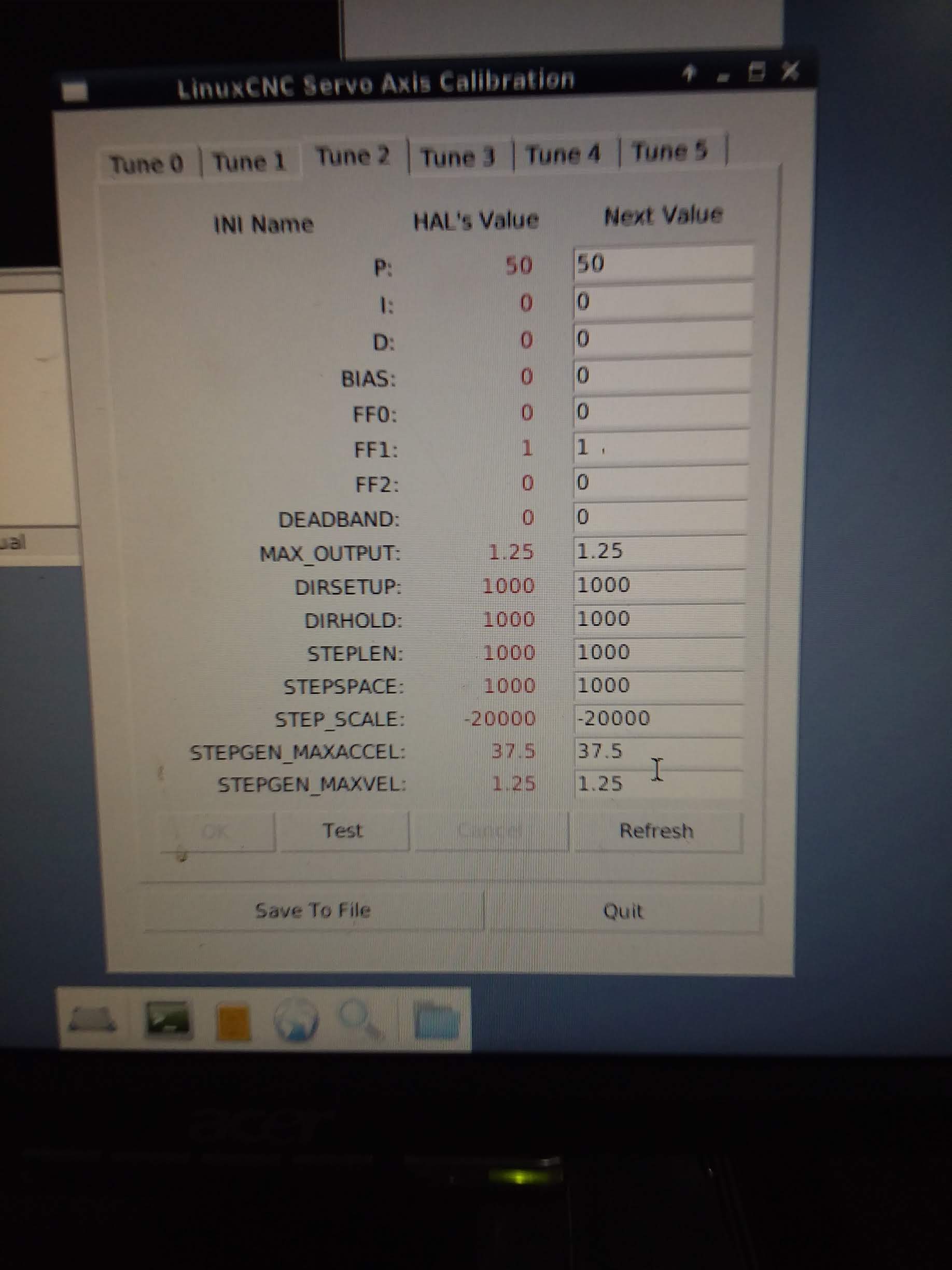

How would I fix this? What menu would I go in? Or where about's in the manual? I uploaded a picture of the servo tune. I think the acceleration might be to much? And it's missing a step as well?

Thank you.

Replied by Roland2161 on topic Z axis is off by .010" over 1/2"

So after reading a bunch I am stuck. My Z axis seems to be off exactly the same every time. Using a dial indicator I go to move .500, and it will only move .490. .

Is the error proportional? Is 0.25" actually 0.245? 0.75 = 0.735?

If so then it looks like a simple scaling error. 5 TPI leadscrew and 5mm leadscrew are about the right error to account for this.

(0.5" / 5.08" * 5mm = 0.492..)

Andy,

Yes the error is proportional. I moved it a 1/4'' and it was off .005. Moved it a half inch and it was off almost exactly .492. and .75 was mor like .738 ish, but I have a half thousandth of backlash. Not sure if it is accounted for.

How would I fix this? What menu would I go in? Or where about's in the manual? I uploaded a picture of the servo tune. I think the acceleration might be to much? And it's missing a step as well?

Thank you.

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Online

- Moderator

-

Less

More

- Posts: 17724

- Thank you received: 5186

30 Jan 2019 01:02 #125234

by PCW

Replied by PCW on topic Z axis is off by .010" over 1/2"

You could try setting your step_scale to -20320

Also you acceleration is very quick (1.25/37.5 = 1/30 second to full speed)

you might need to reduce this also

Also you acceleration is very quick (1.25/37.5 = 1/30 second to full speed)

you might need to reduce this also

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

30 Jan 2019 01:08 #125235

by andypugh

Replied by andypugh on topic Z axis is off by .010" over 1/2"

Yes, -20000 sounds like an assumed 5tpi on a metric machine and 20x microstepping (or gear ratio)

It is far more likely that ball screws are 5mm pitch, so that -20320 is the number.

Though, it has to be said, that 5tpi ball screws exist, I had exactly the opposite problem when I changed the ball screw on my milling machine Y axis. There is a very compact 16mm ball screw with a 5tpi pitch from Gten.

It is far more likely that ball screws are 5mm pitch, so that -20320 is the number.

Though, it has to be said, that 5tpi ball screws exist, I had exactly the opposite problem when I changed the ball screw on my milling machine Y axis. There is a very compact 16mm ball screw with a 5tpi pitch from Gten.

Please Log in or Create an account to join the conversation.

- Roland2161

- Offline

- Junior Member

-

Less

More

- Posts: 36

- Thank you received: 0

04 Feb 2019 23:15 #125703

by Roland2161

Thank you all for the advice, I finally got back to the machine and presto, -20320 was the magic number. I ended up lowering the acceleration to 19 and that also solved the missing step issue.

Now what is happening is that it moves .002 further than commanded everytime I move. So from 0 to .250 it moves .252. Then from 0 to .750 it moves .752. What could be causing this? I do have .0005" of back lash. could that be causing this?

Replied by Roland2161 on topic Z axis is off by .010" over 1/2"

You could try setting your step_scale to -20320

Also you acceleration is very quick (1.25/37.5 = 1/30 second to full speed)

you might need to reduce this also

Thank you all for the advice, I finally got back to the machine and presto, -20320 was the magic number. I ended up lowering the acceleration to 19 and that also solved the missing step issue.

Now what is happening is that it moves .002 further than commanded everytime I move. So from 0 to .250 it moves .252. Then from 0 to .750 it moves .752. What could be causing this? I do have .0005" of back lash. could that be causing this?

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

04 Feb 2019 23:29 #125704

by Leon82

Replied by Leon82 on topic Z axis is off by .010" over 1/2"

The tolerance of the ballscrew depending on class may affect it.

You could tweak the scaling a little bit. Also you can go all out and map the screw for errors. But I have only read about it. Not sure how you would executive it

You could tweak the scaling a little bit. Also you can go all out and map the screw for errors. But I have only read about it. Not sure how you would executive it

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

04 Feb 2019 23:31 - 04 Feb 2019 23:37 #125705

by Leon82

Also, perhaps fast descelleration could sent the "mass" of the table to load on the opposite side of the play in the screw

I'm not really sure why I quoted myself

Replied by Leon82 on topic Z axis is off by .010" over 1/2"

The tolerance of the ballscrew depending on class may affect it.

You could tweak the scaling a little bit. Also you can go all out and map the screw for errors. But I have only read about it. Not sure how you would executive it

Also, perhaps fast descelleration could sent the "mass" of the table to load on the opposite side of the play in the screw

I'm not really sure why I quoted myself

Last edit: 04 Feb 2019 23:37 by Leon82.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.287 seconds