Home made encoder questions

- Scot

- Offline

- Elite Member

-

Less

More

- Posts: 170

- Thank you received: 5

05 Sep 2019 06:19 #144210

by Scot

Replied by Scot on topic Home made encoder questions

Ah, I understand now. I think the material I am getting is plastic coated on both sides. It's very possible to etch 304 with a substance called Adlers etchant. But the material must be mirror polished. They refer to it as a number 8 finish. But the MDF idea is a good thought. I think the MDF may be problematic with the etchant, since it is a liquid and will soak into the wood. I was planning to use a contact adhesive on the plastic and a glass plate. Then stick the two together, remove the top plastic coating then use the etchant. The plastic on the side stuck to the glass will stop the etchant and the glass was intended to keep it flat as you suggested with the MDF.

But thanks for that input. Good ideas, all around.

Scot

But thanks for that input. Good ideas, all around.

Scot

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

05 Sep 2019 06:23 #144211

by pl7i92

Replied by pl7i92 on topic Home made encoder questions

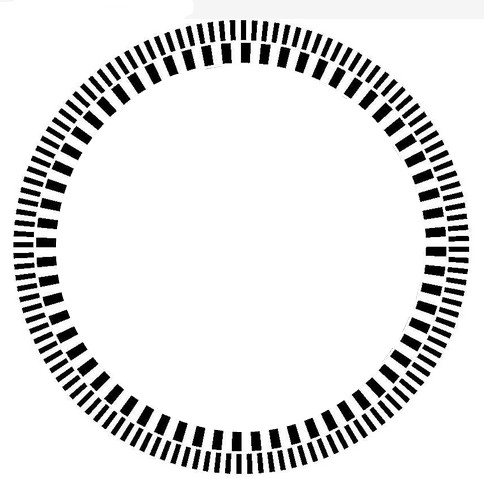

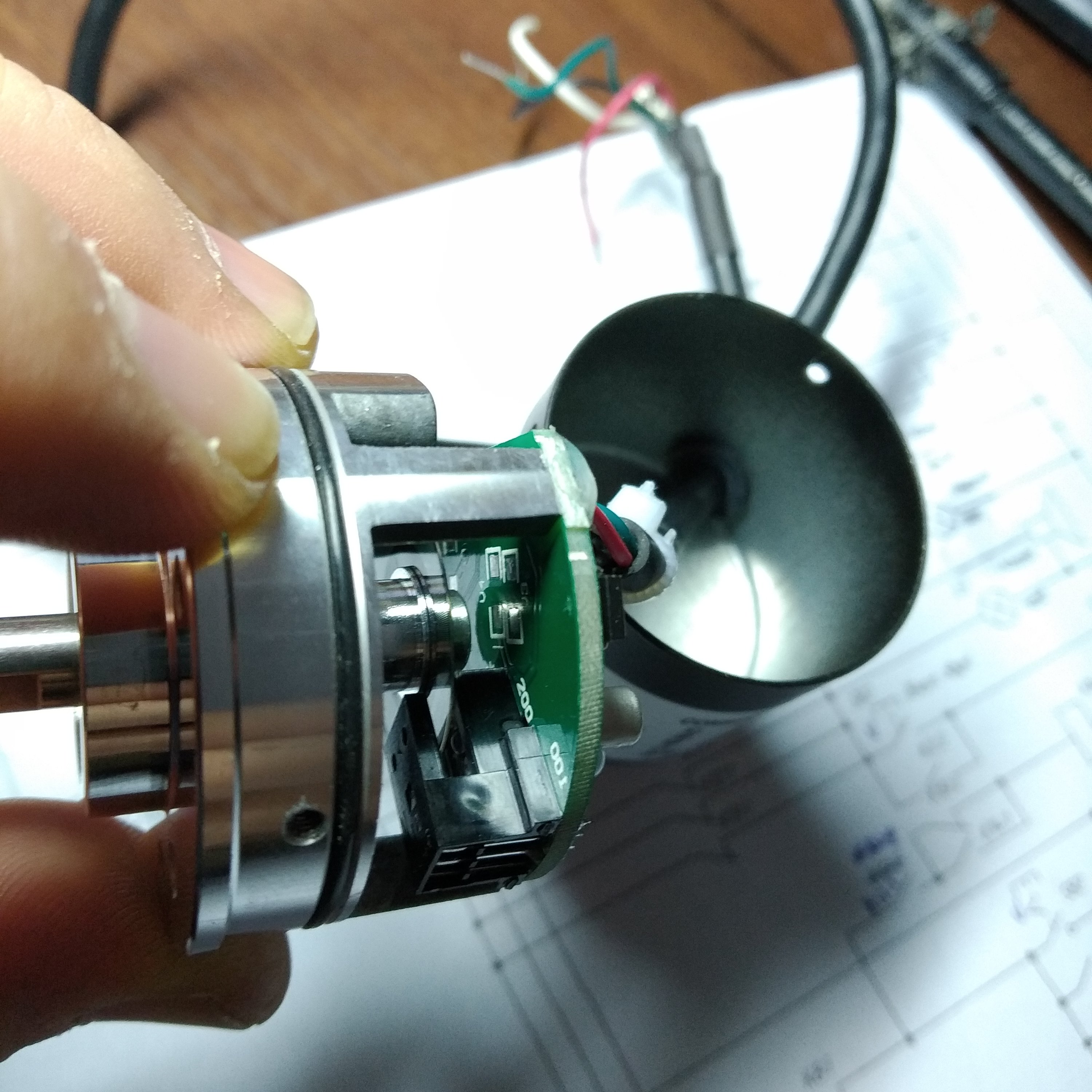

Attachments:

Please Log in or Create an account to join the conversation.

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

05 Sep 2019 07:10 #144222

by aleksamc

Replied by aleksamc on topic Home made encoder questions

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

05 Sep 2019 10:48 #144231

by pl7i92

Replied by pl7i92 on topic Home made encoder questions

this encoders are made to go on double Axis Motors

for a lathe you may want it direct on Spindle

for a lathe you may want it direct on Spindle

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17568

- Thank you received: 5140

05 Sep 2019 14:50 #144242

by PCW

Replied by PCW on topic Home made encoder questions

No, I was referering to the fact that most higher resolution quadrature encoders use a simple slotted (or photo lithographed) disk with only one ring of slots and the quadrature detection is done with Moire or Ronchi masks with an 1/4 slot pitch offset between the A and B masks.

Please Log in or Create an account to join the conversation.

- Scot

- Offline

- Elite Member

-

Less

More

- Posts: 170

- Thank you received: 5

05 Sep 2019 16:30 #144247

by Scot

Replied by Scot on topic Home made encoder questions

Okay. I think I understand now. The second ring of slits is 1/4 the distance past the leading edge of the first slits and 1/4 behind the trailing edge of the next slit. Am I correct?

Thanks,

Scot

Thanks,

Scot

Please Log in or Create an account to join the conversation.

- Scot

- Offline

- Elite Member

-

Less

More

- Posts: 170

- Thank you received: 5

05 Sep 2019 16:36 #144248

by Scot

Replied by Scot on topic Home made encoder questions

Thanks for the attempt! I appreciate you took out the time, for sure. It helps a bit to get an idea what's in the enclosure, too.

Please Log in or Create an account to join the conversation.

- Scot

- Offline

- Elite Member

-

Less

More

- Posts: 170

- Thank you received: 5

05 Sep 2019 16:37 #144249

by Scot

Replied by Scot on topic Home made encoder questions

I think I'm grasping it now. The only thing I have to make sure of is to pick the right reader for it. I know they sell kits with just a wheel and a reader which can be mounted as needed. If I can etch the wheel, pick the right reader and then mount it precisely enough, it should work. Well, I hope so at least.

Great info. Thanks a bunch.

Scot

Great info. Thanks a bunch.

Scot

Please Log in or Create an account to join the conversation.

- Dinuka_Shehan

-

- Offline

- Platinum Member

-

Less

More

- Posts: 333

- Thank you received: 26

05 Sep 2019 16:46 - 05 Sep 2019 16:53 #144250

by Dinuka_Shehan

Replied by Dinuka_Shehan on topic Home made encoder questions

Last edit: 05 Sep 2019 16:53 by Dinuka_Shehan.

Please Log in or Create an account to join the conversation.

- Scot

- Offline

- Elite Member

-

Less

More

- Posts: 170

- Thank you received: 5

05 Sep 2019 17:21 #144253

by Scot

Replied by Scot on topic Home made encoder questions

Thanks for the link. I have a questions, though. Is that encoder capable of reading in quadrature? I see the index and the single ring of slits is clear. But from what I'm getting about keeping accurate threading, this design may not work.

The lathe I'm retrofitting keeps pretty tight tolerances and I'll be using it in a commercial setting. The problem I'm running into is keeping those precise interactions between the spindle and tooling. I'm using Linuxcnc, as well, and not Mach.

Thanks again,

Scot

The basic idea of mounting the wheel to the back of the spindle on the lathe is the same, though. Albeit what I'm doing is on a bigger machine.

The lathe I'm retrofitting keeps pretty tight tolerances and I'll be using it in a commercial setting. The problem I'm running into is keeping those precise interactions between the spindle and tooling. I'm using Linuxcnc, as well, and not Mach.

Thanks again,

Scot

The basic idea of mounting the wheel to the back of the spindle on the lathe is the same, though. Albeit what I'm doing is on a bigger machine.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.279 seconds