Help configuring DM542A drivers

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

28 Nov 2020 16:44 #190527

by txtrone

Help configuring DM542A drivers was created by txtrone

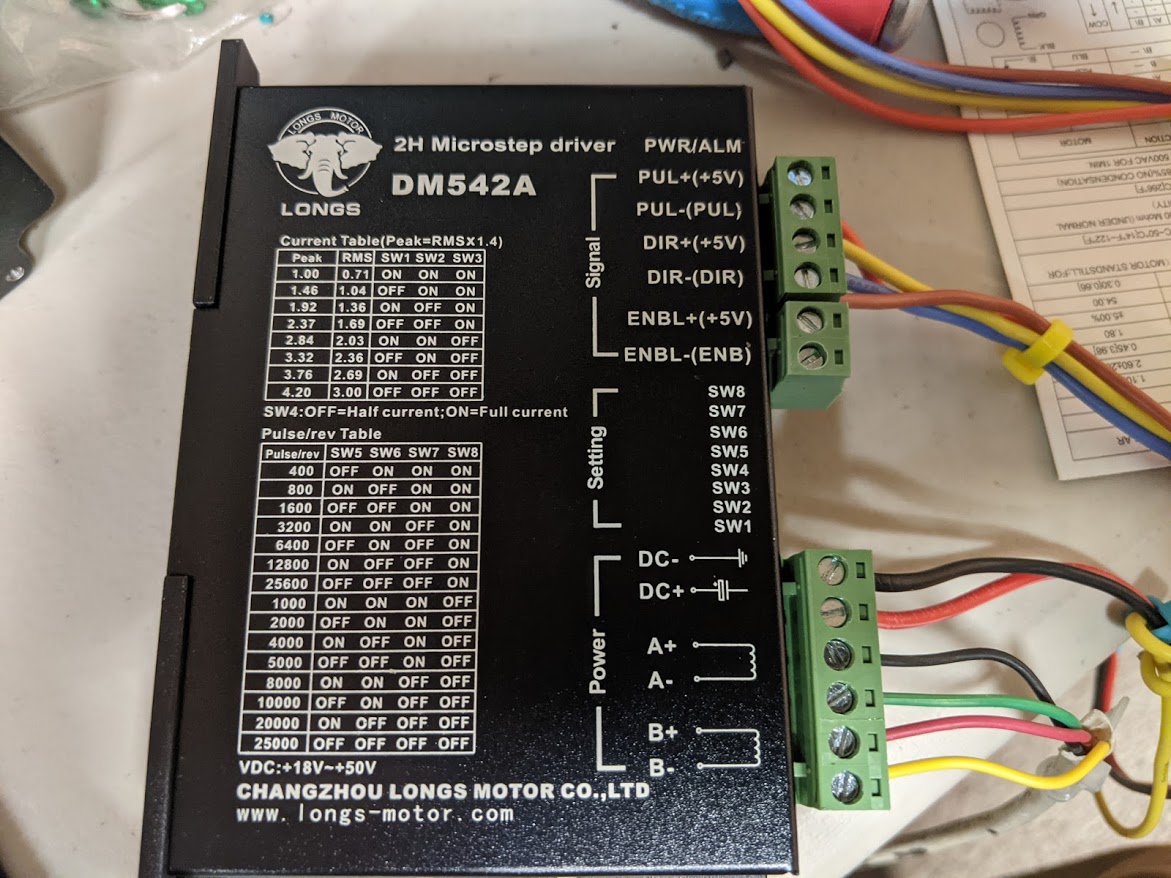

I have the driver, model DM542A, powered up but I am having a lot of trouble configuring it.Should I be using the 'custom' profile from the driver selection in stepconf? Any pointers are much appreciated.

I am attaching my motor spec sheet.

I am attaching my motor spec sheet.

Please Log in or Create an account to join the conversation.

- alkabal

- Offline

- Platinum Member

-

Less

More

- Posts: 476

- Thank you received: 52

28 Nov 2020 17:13 - 28 Nov 2020 17:14 #190530

by alkabal

Replied by alkabal on topic Help configuring DM542A drivers

I don't know if this can help you but here is my timing settings for this driver

DIRSETUP = 5500

DIRHOLD = 5500

STEPLEN = 2850

STEPSPACE = 2850

but for a second one i need to increase timing due to quality...

DIRSETUP = 6000

DIRHOLD = 6000

STEPLEN = 3000

STEPSPACE = 3000

DIRSETUP = 5500

DIRHOLD = 5500

STEPLEN = 2850

STEPSPACE = 2850

but for a second one i need to increase timing due to quality...

DIRSETUP = 6000

DIRHOLD = 6000

STEPLEN = 3000

STEPSPACE = 3000

Last edit: 28 Nov 2020 17:14 by alkabal.

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

28 Nov 2020 20:24 #190546

by txtrone

Replied by txtrone on topic Help configuring DM542A drivers

Thanks! What about the dip switches on the side?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11668

- Thank you received: 3931

29 Nov 2020 20:51 - 29 Nov 2020 20:52 #190627

by rodw

Replied by rodw on topic Help configuring DM542A drivers

Do your drivers have an elephant printed on them? (made by Longs Motors)

I've never had any problems with them and a mate as a CNC mill made by Syil quite a few years ago that uses them too.

I've got a feeling some other brands are not the same. I was able to get dirsetup and dirhold down to 500.

But PCW recommends you go up to 20000 or so when you are starting out.

One set of DIP switches sets the current limit (eg if you have a 2.8 amp motor you can reduce the current down from 3.5 amps to that.

The other set is for microstepping.

I run them at 25x microstepping with a Mesa 7i76e (5000 steps per rev,)

I've never used pncconf to set any thing up other than to build a basic working config without worrying about the correct scaling and edit my ini files by hand

I've never had any problems with them and a mate as a CNC mill made by Syil quite a few years ago that uses them too.

I've got a feeling some other brands are not the same. I was able to get dirsetup and dirhold down to 500.

But PCW recommends you go up to 20000 or so when you are starting out.

One set of DIP switches sets the current limit (eg if you have a 2.8 amp motor you can reduce the current down from 3.5 amps to that.

The other set is for microstepping.

I run them at 25x microstepping with a Mesa 7i76e (5000 steps per rev,)

I've never used pncconf to set any thing up other than to build a basic working config without worrying about the correct scaling and edit my ini files by hand

Last edit: 29 Nov 2020 20:52 by rodw.

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

29 Nov 2020 21:30 #190630

by txtrone

Replied by txtrone on topic Help configuring DM542A drivers

Hmm. I will have to check for the elephant.

There is another switch regarding 'full or half voltage' ... what do you use?

I thought the pncconf was the setup tool for Mesa boards and the drivers? How would you go about setting up a new 7I76e and the dm542a drivers for a plasma table. Can I just open LinuxCNC and fill in the parameters? Or do I need to use a wizzard to do that?

Also, do you choose 'other' as the step driver board type/manufacturer?

Thanks!

There is another switch regarding 'full or half voltage' ... what do you use?

I thought the pncconf was the setup tool for Mesa boards and the drivers? How would you go about setting up a new 7I76e and the dm542a drivers for a plasma table. Can I just open LinuxCNC and fill in the parameters? Or do I need to use a wizzard to do that?

Also, do you choose 'other' as the step driver board type/manufacturer?

Thanks!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21228

- Thank you received: 7249

29 Nov 2020 22:41 #190638

by tommylight

That would be the standstill current, that can be lowered when stationary to reduce motor heating.

Replied by tommylight on topic Help configuring DM542A drivers

I would guess it is current, not voltage, but who knows....

There is another switch regarding 'full or half voltage' ... what do you use?

That would be the standstill current, that can be lowered when stationary to reduce motor heating.

Use pncconf to set up a base machine, stepgens, switches, soft limits, homing, then check if everything works properly. Only after setting this up use the configurator to do a PlasmaC config by adding the encoder (THCAD) input, float switch and/or ohmic probing inputs and torch on output.How would you go about setting up a new 7I76e and the dm542a drivers for a plasma table.

Yes, and i also set the timings to 15000 (yes fifteen thousand) to be sure the drives work, after setting up everything i do lower that to 5000 for step time and step space.Also, do you choose 'other' as the step driver board type/manufacturer?

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

30 Nov 2020 20:58 #190709

by txtrone

Replied by txtrone on topic Help configuring DM542A drivers

Yes, you are correct... it is half/full current.

Thanks for the very helpful info! I hope tomorrow will allow enough time to get it going... today I had to do actually work at work.... I am not complaining about that though, lucky to have it.

I will follow up when I get the motors running.

Thanks for the very helpful info! I hope tomorrow will allow enough time to get it going... today I had to do actually work at work.... I am not complaining about that though, lucky to have it.

I will follow up when I get the motors running.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

01 Dec 2020 03:32 #190739

by txtrone

Replied by txtrone on topic Help configuring DM542A drivers

Attachments:

Please Log in or Create an account to join the conversation.

- txtrone

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 384

- Thank you received: 106

02 Dec 2020 01:49 #190823

by txtrone

25x microstepping is set by using a 'multiplier' of 5x within the software, correct?

Replied by txtrone on topic Help configuring DM542A drivers

YesDo your drivers have an elephant printed on them? (made by Longs Motors)

Do you set the current according to the RMS or Peak chart on the driver?One set of DIP switches sets the current limit (eg if you have a 2.8 amp motor you can reduce the current down from 3.5 amps to that.

So for switches 5-8 (on the driver itself) you are using OFF - OFF - ON - OFF ... to set it at 5000 steps per rev?The other set is for microstepping.

I run them at 25x microstepping with a Mesa 7i76e (5000 steps per rev,)

25x microstepping is set by using a 'multiplier' of 5x within the software, correct?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11668

- Thank you received: 3931

02 Dec 2020 02:24 #190824

by rodw

Replied by rodw on topic Help configuring DM542A drivers

Just looking at one of my drives.

I thought I saw you had a 3.5 amp motor so I would set SW1,SW2,SW3 for 3.32 amps peak (OFF,ON,OFF)

SW4 off to enable less current when idle.

I would not go too high with the microstepping to start with. Probably start at 2000 (10x microstep) SW5 Off, SW6 & SW7 On, SW8 Off

To get to the higher settings you probably need to reduce you timings which we don't want to do right now as the goal is reliable performance.

Are you using a parallel port or a mesa card?

I thought I saw you had a 3.5 amp motor so I would set SW1,SW2,SW3 for 3.32 amps peak (OFF,ON,OFF)

SW4 off to enable less current when idle.

I would not go too high with the microstepping to start with. Probably start at 2000 (10x microstep) SW5 Off, SW6 & SW7 On, SW8 Off

To get to the higher settings you probably need to reduce you timings which we don't want to do right now as the goal is reliable performance.

Are you using a parallel port or a mesa card?

The following user(s) said Thank You: txtrone

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.105 seconds