Running servos in position mode instead of analog

- Dbsharp

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 2

18 Feb 2021 17:51 - 18 Feb 2021 17:53 #199312

by Dbsharp

Replied by Dbsharp on topic Running servos in position mode instead of analog

Yea I have not powered the drives yet, but the motors are installed. I have an empty cabinet on my bridgeport boss, a couple dyn4 drives siting in there.

Mesa hardware never plugged into anything.....

I wonder how much of this I can return? Had it for a while but never used.

I won't have it operational for probably 6 moths, but I said the same thing this time last year. I've been designing and enclosure for the mill and until I finish that, and start fab I won't have the electronics mounted. Picked up a "working" chnc lathe a few weeks ago.... I have a thread in cnc machines section where I am troubleshooting poor servo performance and resolver issues.

Anyways I could probably wire up one servo on bench and configure my Mesa hardware to test this. My oscilloscope is old so it may be tricky to capture this delay and measure it... no recording or freezing a frame here.

Mesa hardware never plugged into anything.....

I wonder how much of this I can return? Had it for a while but never used.

I won't have it operational for probably 6 moths, but I said the same thing this time last year. I've been designing and enclosure for the mill and until I finish that, and start fab I won't have the electronics mounted. Picked up a "working" chnc lathe a few weeks ago.... I have a thread in cnc machines section where I am troubleshooting poor servo performance and resolver issues.

Anyways I could probably wire up one servo on bench and configure my Mesa hardware to test this. My oscilloscope is old so it may be tricky to capture this delay and measure it... no recording or freezing a frame here.

Last edit: 18 Feb 2021 17:53 by Dbsharp.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

18 Feb 2021 18:01 #199315

by Michael

Replied by Michael on topic Running servos in position mode instead of analog

Linuxcnc has a built in halscope that you can use to capture the inputs and outputs.

DMM customer service was very helpful but denied their drives could have a delay despite being shown the scope plot. They also allowed me to return a 1 year old motor in exchange for one with a brake.

I would set everything up on the bench and see if it works and how well. Shouldn't take much time.

DMM customer service was very helpful but denied their drives could have a delay despite being shown the scope plot. They also allowed me to return a 1 year old motor in exchange for one with a brake.

I would set everything up on the bench and see if it works and how well. Shouldn't take much time.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

18 Feb 2021 18:41 - 18 Feb 2021 18:41 #199326

by bevins

Replied by bevins on topic Running servos in position mode instead of analog

I have DYN4 750 watt ac servos with planetary gear reduction and I am tapped at about 500ipm. Any faster and the drive gets overload error and shuts down. This sounds like the same issue and I am running in step/dir mode. I wont need them any faster that that but will never use them again.

Last edit: 18 Feb 2021 18:41 by bevins.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

18 Feb 2021 18:46 - 19 Feb 2021 02:58 #199327

by Michael

Replied by Michael on topic Running servos in position mode instead of analog

With higher than 45ips/s acceleration I can get them to over current at high speeds also in step/dir. I was definitely hoping for more out of them, the manual and tuning info wasn't helpful or easy for analog setup.

Bevin's, did you close the position loop back to Linux? If so care to share any info or hal files?

Bevin's, did you close the position loop back to Linux? If so care to share any info or hal files?

Last edit: 19 Feb 2021 02:58 by Michael.

Please Log in or Create an account to join the conversation.

- Dbsharp

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 2

19 Feb 2021 02:44 #199366

by Dbsharp

Replied by Dbsharp on topic Running servos in position mode instead of analog

I will hook up one servo to my lathe it has a 7i33ta board on it with open channels. I might reach out so you can walk me through the steps you were told, an we can check my response time

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

19 Feb 2021 02:56 #199367

by Michael

Replied by Michael on topic Running servos in position mode instead of analog

More than happy to help. What model motors and drives did you get from DMM?

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

20 Feb 2021 23:27 #199571

by Michael

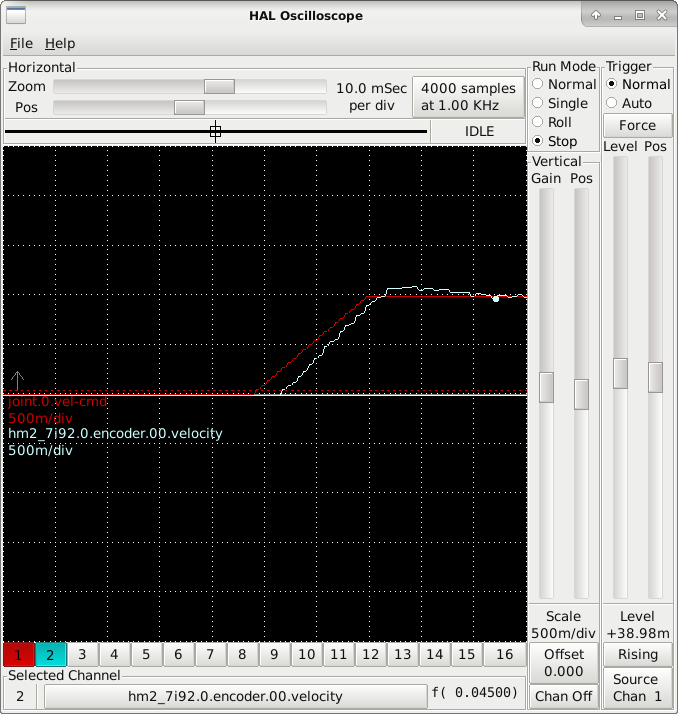

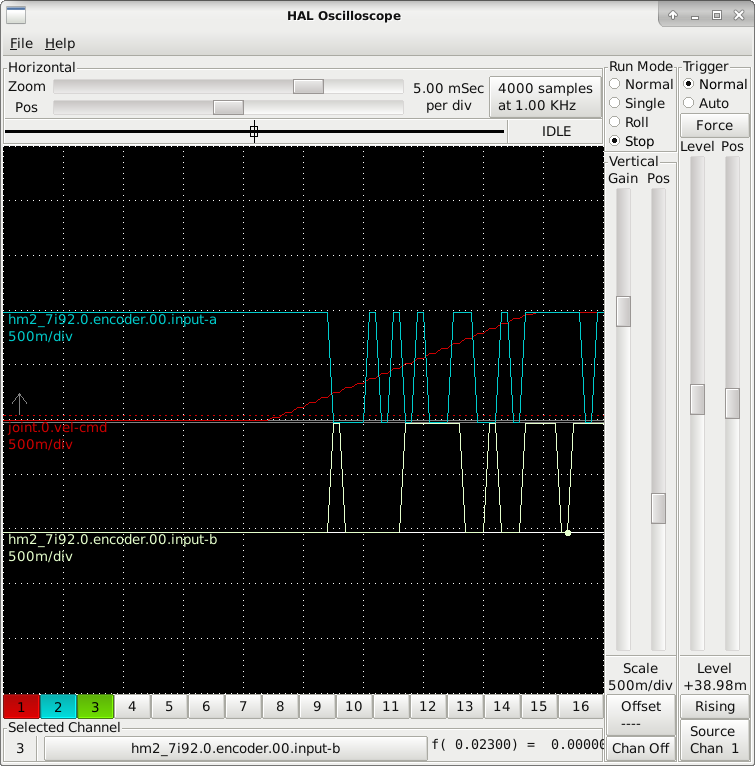

I hooked up the encoders in position mode and they still have a delay in response that can be seen in either of the attached pictures. If I use position mode will this also effect the ability to close the loop with linuxcnc and run consistently? If it does this only leave me the options to use different servos (+$$$) or to try a linear scale on each axis (+$$)

Replied by Michael on topic Running servos in position mode instead of analog

An interesting question is whether the 5 ms delay is present in position mode as well.

Connecting the encoders could answer this. This delay might cause issues with spindle

synced motion like rigid tapping.

This brings up a general observation, your errors are not huge, in fact you may have

never noticed them when machining and similar errors may also exist in step/dir

position mode.

A similar situation happens when people add linear encoders and discover all

the backlash and stick-slip errors that they had never noticed before.

Does the overcurrent alarm go away if you reduce the acceleration?

(200 IPS/S is likely beyond what the motors can do with a high inertial load)

I hooked up the encoders in position mode and they still have a delay in response that can be seen in either of the attached pictures. If I use position mode will this also effect the ability to close the loop with linuxcnc and run consistently? If it does this only leave me the options to use different servos (+$$$) or to try a linear scale on each axis (+$$)

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

20 Feb 2021 23:52 #199572

by jmelson

Replied by jmelson on topic Running servos in position mode instead of analog

I think a 5 ms delay between command and feedback from the encoder is going to make PID tuning pretty difficult. That's a 5 servo period delay.

Jon

Jon

The following user(s) said Thank You: Michael

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 567

- Thank you received: 108

21 Feb 2021 00:51 #199575

by JohnnyCNC

Replied by JohnnyCNC on topic Running servos in position mode instead of analog

I'm running a DYN4 1.8K as a spindle motor geared 1:1.8 using velocity mode and +/-10V control. I rigid tap 3mm to 6mm with no problem. Never tried a DYN on an axis though.

Please Log in or Create an account to join the conversation.

- arvidb

-

- Offline

- Platinum Member

-

Less

More

- Posts: 459

- Thank you received: 158

21 Feb 2021 09:47 - 21 Feb 2021 09:50 #199588

by arvidb

Edit: I'm thinking in EtherCAT terms now, where the position is sent directly to the servo drives. If you use e.g. Mesa cards as stepgens to generate step/dir signals, then you're still running in a kind of velocity mode I guess? So you might still have problems.

Replied by arvidb on topic Running servos in position mode instead of analog

If you run position mode there should be no loop to close with LinuxCNC? Well, I guess rigid tapping could suffer a bit? Also you might need to increase following error tolerance somewhat.I hooked up the encoders in position mode and they still have a delay in response that can be seen in either of the attached pictures. If I use position mode will this also effect the ability to close the loop with linuxcnc and run consistently? If it does this only leave me the options to use different servos (+$$$) or to try a linear scale on each axis (+$$)

Edit: I'm thinking in EtherCAT terms now, where the position is sent directly to the servo drives. If you use e.g. Mesa cards as stepgens to generate step/dir signals, then you're still running in a kind of velocity mode I guess? So you might still have problems.

Last edit: 21 Feb 2021 09:50 by arvidb.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.135 seconds