7i92TM pings but not recognised by mesaflash

- PCW

-

- Away

- Moderator

-

- Posts: 17503

- Thank you received: 5116

(also you need to power cycle the 7I92TM after re-flashing)

You can get the pinout at the breakout with:

mesaflash --device 7i92t --addr [CARD_IP_ADDR] --dbname1 5abob --readhmid

I should note that you may get the "motors not moving but clicking on reversals"

if step and dir are swapped.

Please Log in or Create an account to join the conversation.

- JT

-

- Away

- Administrator

-

- Posts: 1047

- Thank you received: 542

JT

Please Log in or Create an account to join the conversation.

- gothia

-

- Visitor

-

1/2: Main issue was partially fixed.:

The comunication problem between the mesa card 7i92 and the computer was finally the Parallel cable used to connect the 5ABoB was a Null-modem protocol cable.

This is to say, there are only 8 wires and connections instead of 25 on it.

After replacing the cable the engines start working automatically.

I also had the right firmware (Thanks PCW) and made a trial of MesaCT although the firmware update using mesaflash command in the console was really quick, just took a few seconds (Thanks JT)

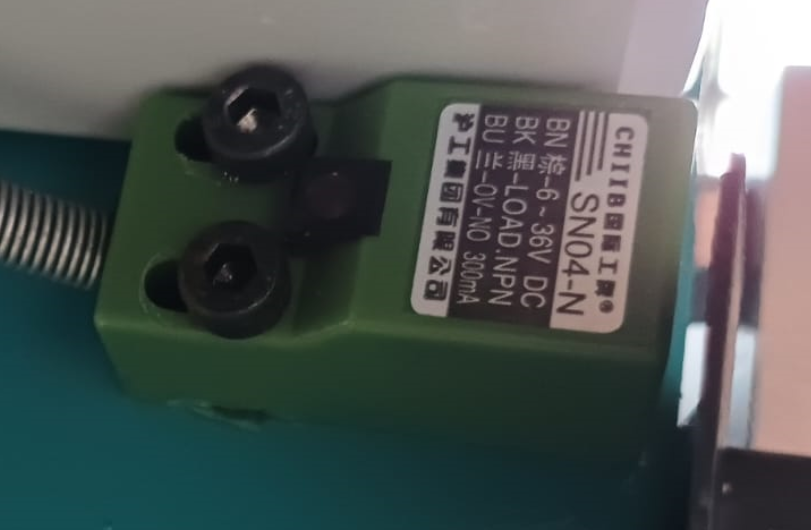

2/2: Inductive end stop limits and emergency stop button not detected

After configurating speed and acceleration of all engines i tried to set up the end stops and emergency stops.

Disafortunately they seem not to be detected once more.

The inductive end-stops have 3 wires ( Gnd, Vcc(+70v) and a signal cable of 24v)

When the end stop is not active the signal voltage is near 0v (200mV); when it is active the signal is +24V althouth there is noise on it (+/-5V at 20kHz)

As for the emergency stop interruptor, this is a mechanical switch.

Voltage is 9V when closed and near 0V when open

I tried all the GPIO combinations in the PncConf wizart including invert check box option.

But had no feed back

I used the Hal configuration screen to check if the XYZ-home and end stop gray balls turned into yellow when activating each end stop and emergency stop individually. But there was no change at all.

Questions:

a) Is it necessary to modify any Hal parameter in the configuration files due to the 24v voltage or the 20KHz/+/-5V noise?

Should I insert any resistance or Zehner Diod to reduce the voltage to 5V ??

(Let me remark the previous installation based upon linux2.6+5ABOB with a parallel connection works without issues)

b) Is there a right or ortodox way to wire the end stop ??

Let me remark i am upgrading a cnc machine normaly in production from monday to friday.

All sensors and engines work fine under an old computer working having linuxcnc 2.6 and a direct parallel connection to a 5 axis bob.

So i am keeping all the wiring and the connections in the old 5abob.

I am currently inserting the mesa 7i92TM card and a new computer with 2.9.2 Linuxcnc set up, when the machine is not working.

Once the machine must be back to production just remove the Mesa 7i92 card and I connect the 5abob to the older computer.

Thanks in advance again for all your assistance

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17503

- Thank you received: 5116

I hope you mean Gnd,Vcc, (+24V) ...The inductive end-stops have 3 wires ( Gnd, Vcc(+70v) and a signal cable of 24v)

When the end stop is not active the signal voltage is near 0v (200mV); when it is active the signal is +24V althouth there is noise on it (+/-5V at 20kHz)

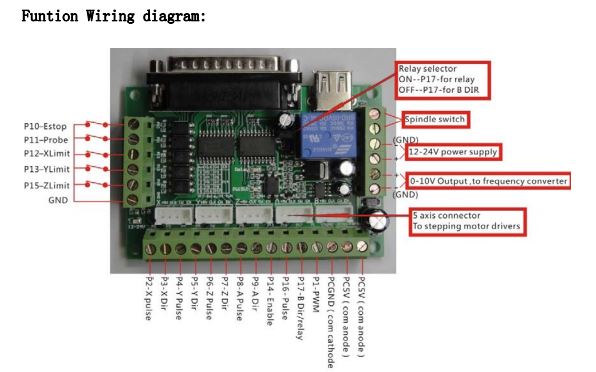

What inputs are you using on the 5ABOB?

I would verify the signal levels at the DB25 connector of the BOB

Also AFAIK you must have the 7I92T set for pullups on the I/O to work with the

5ABOB isolated inputs.

Please Log in or Create an account to join the conversation.

- gothia

-

- Visitor

-

1/4: inputs in the 5abob

Inputs for en end and emergency stops in the 5aBob are the ones previously wired in the machine currently in production:

- X end stop - > P10 (input voltage in the 5abob: 0v when activated, 24v when not activated)

- Y end stop - > P11 (input voltage in the 5abob: 0v when activated, 24v when not activated)

- Z end stop - > P12 (input voltage in the 5abob: 0v when activated, 24v when not activated)

- Emergency Stop -> P14 ( input voltage in the 5abob: 9 v when the button is not pressed, 0v when pressed)

2/4: Output voltage after the 5abob

Voltage is 4.85V in the output DB25 connector of all the End Stops and Emergency Stop related pins when activated / unpressed.

This voltage was tested in the wire output DB25 connector having the pull up jumpers down (jumper w1 and w2 down Pull down to 0V)

3/3: Might interferences / noise be interrupting the comunication with hal show window???

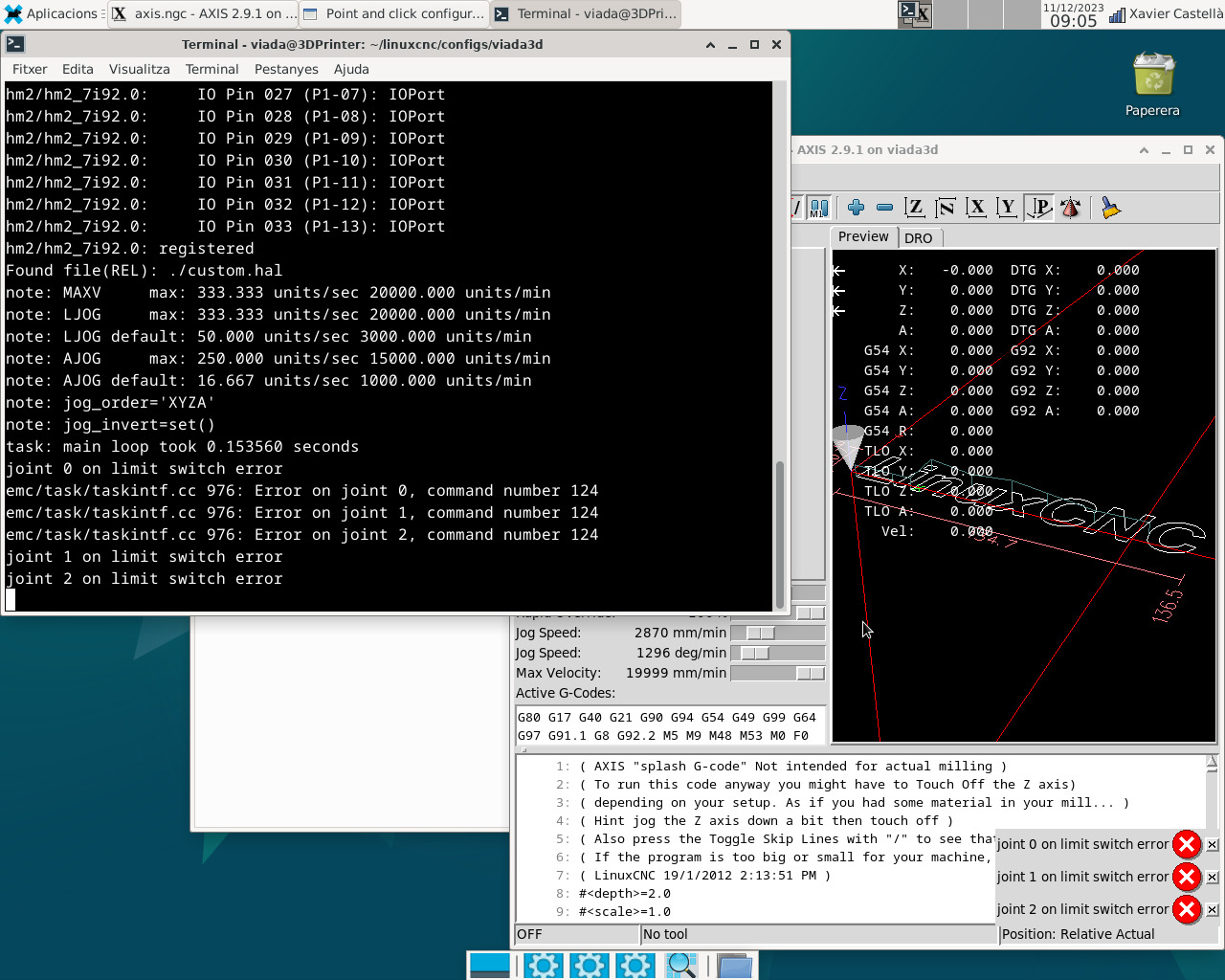

All axis steppers moves but end stops have no sensitivity!! :_(

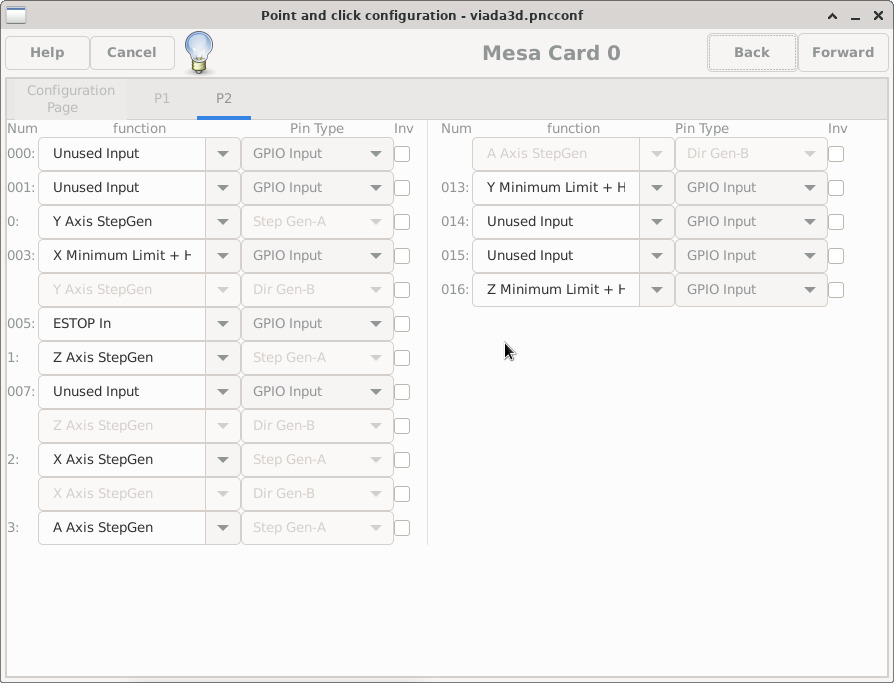

As for the PncConf wizard the best aproximation set up i was able to have was the one below:

Now no error messages appear but i can not assing the right end stop to each axis.

All other options regarding the end stops switches show an error related to a joint:

emc/task/taskintf.cc 976: Error on joit [0/1/2], command number 124

Joint on limit switch error

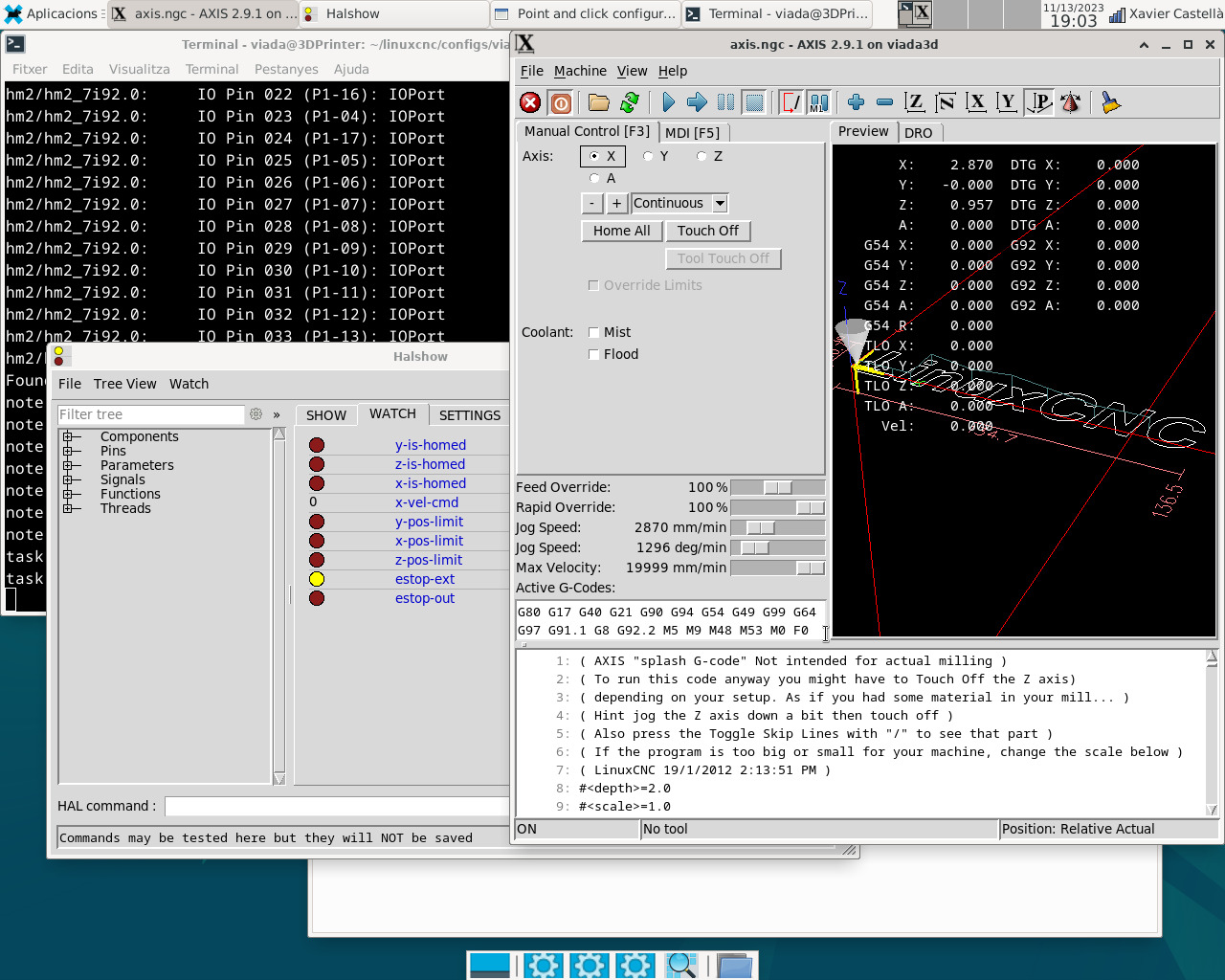

On the other hand the main issue is i have no feed back of any end stop signals using the Hal Show window (the window showing yellow circles when a signal is received by linuxcnc and redish circles when it is not received ot it is off)

4/4: Emergency button shows status change in the hal show window, but it is really random

The only yellow circle that changes its status color is one for the emergency stop (pin 14).

But I must press and relase the red emergency button 10 times or more to let the yellow circle appear or turn to redish again.

It is really a random process: not always 10 times sometimes is less sometimes is more.

I connected the mesa card 7i92 to the frame ground using the top left mounting hole (near the Ethernet jack) as said in the manual, but this kind of interferences remain...

My main goal at that moment is getting the right status of the end and emergency signals in the hal show window (yellow and red circles window)...

Do you have any idea about what may interfere the signals??

Am i going the wrong way?

As always, thanks in advance for all the assistance you can bring me.

Best regards

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17503

- Thank you received: 5116

enabled on the 7I92T to interface to the BOB. This is because the input optocouplers

connect their bare phototransistor outputs to the DB25 connector pins with no buffer or pullups.

Please Log in or Create an account to join the conversation.

- gothia

-

- Visitor

-

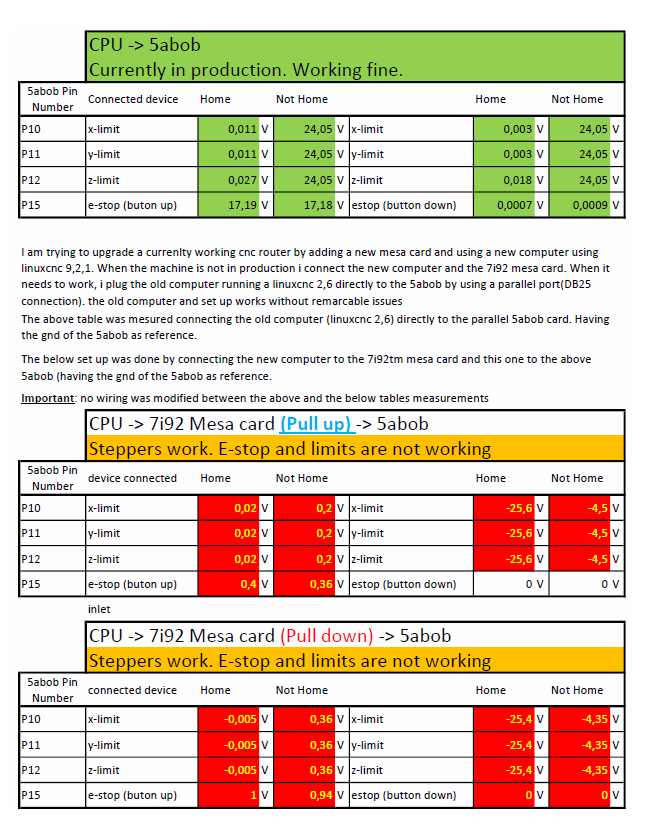

i finally measured all the limits and the endstop voltage in the 5abob pins/terminals having 3 stages:

Always keeping the same wiring and having the CNC router connected to the 5abob and then;

a) to the old computer linuxcnc 2.6 with a parallel cable (DB25)

(everything works fine this way and the the limits and e-stop voltage looks reasonable.)

b) to the mesa card 7i92 (having the jumpers W1 and W2 up/pull up) and then to a new computer(linuxcnc 2.9.1)

(only the steppers work fine)

c) to the mesa card 7i92 (having the jumpers W1 and W2 down/pull down ) and then to a new computer (linuxcnc 2.9.1)

(only the steppers work fine)

There you have the voltage:

As you can see when not using the mesa 7i92 end stops and emergency stop voltage look reasonable.

but on the other hand, when adding the mesa card, the Voltages look quite crazy.

Questions:

Might this situation be fixed by reseting the card and uploading the firmware for the 5abob again?

Does it looks like a problem due to a wrong jumper set up in the mesa card ( Pull-up jumpers ) or a wrong pncconf option selection?

As always thanks in advance!!

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17503

- Thank you received: 5116

Probably the 24V supply got is ground connection via the parallel

port on the PC. You must make sure the 24V common connects to the

BOB common.

(The 7I92 can have no effect on the 24V side of the BOB inputs

so this has to be a power supply connection issue)

Please Log in or Create an account to join the conversation.

- gothia

-

- Visitor

-

As you said, the common cathode pin on the 5abob, the one next to the Pin 1 (Vcc [+5v] ) is appearently not working...

I found 2 working solutions that let the emergency stop work:

a) Using the power supply gnd Pin ( the one next to the +24v pin/connector)

b) Using the Gnd pin/connector ( next to the Pin 15 ) used in our case for EMI protection.

In adition the end limits were also set up without troubles!!

Anyway i think i am going to replace this 5abob for a new mesa breakout board so I am going to turn cnc router into a 3d machine using a A axis to control a pellet extruder...

Let's see what daughter boards are available in the mesa website...

Once more thank you all for your assistance!

Attachments:

Please Log in or Create an account to join the conversation.

- gothia

-

- Visitor

-

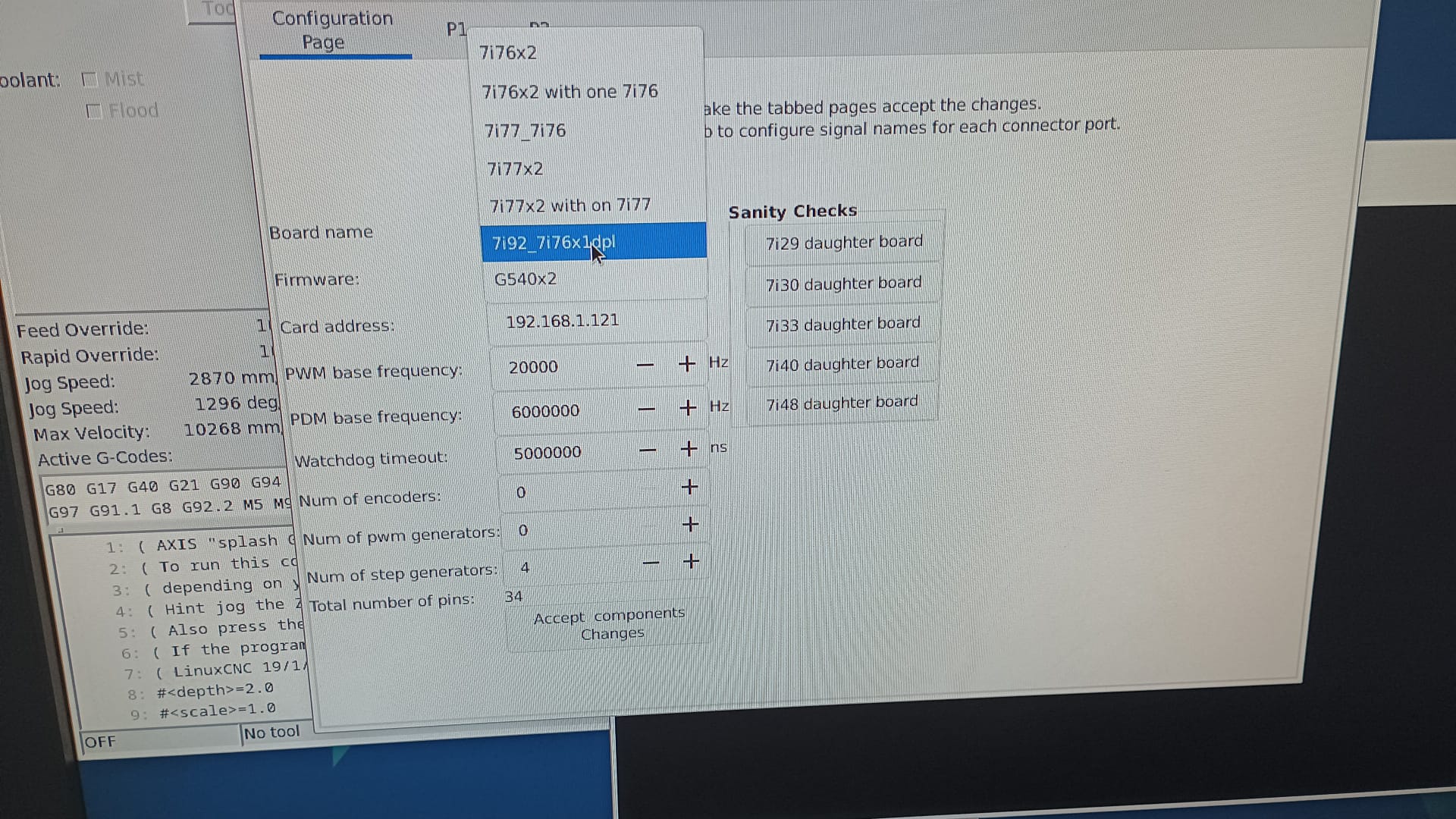

I wish i could improve an old 5aBOB for a mesa 7i76 daugther board by mesa during the comming Xmas holidays.

Shall i ask you if the 7i76 daughter board is the most reasonable option for a 7i92t controller board?

I am working on 4axis machine based upon steppers although i might replace them for servos in a few months.

Do you have any expecience having 7i92 + 7i76??

Would you recomend me any other combination?

Thanks and best regards.

Attachments:

Please Log in or Create an account to join the conversation.