7i77 encoder split to amp and servo

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

02 May 2024 18:04 #299580

by OT-CNC

7i77 encoder split to amp and servo was created by OT-CNC

Hi,

I have an encoder on a servo motor that is being read in single ended at the servo drive (A, B, velocity feedback) and want to use all the channels on the mesa 7i77 side (A, /A, B, /B, Z, /Z). The 7i77 is sourcing the +5v going to the encoder and +5v is not connected at the drive. Is it okay to do so or should the 7i77 also be reading in single ended? In other words, is it okay to mix open ended with differential?

For testing, if the connector has all the wiring in place, can I just move the 3 jumpers to go into single ended mode on the 7i77 or do I need to disconnect the /A, /B, /Z wires?

TIA

I have an encoder on a servo motor that is being read in single ended at the servo drive (A, B, velocity feedback) and want to use all the channels on the mesa 7i77 side (A, /A, B, /B, Z, /Z). The 7i77 is sourcing the +5v going to the encoder and +5v is not connected at the drive. Is it okay to do so or should the 7i77 also be reading in single ended? In other words, is it okay to mix open ended with differential?

For testing, if the connector has all the wiring in place, can I just move the 3 jumpers to go into single ended mode on the 7i77 or do I need to disconnect the /A, /B, /Z wires?

TIA

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17546

- Thank you received: 5128

02 May 2024 18:30 #299585

by PCW

Replied by PCW on topic 7i77 encoder split to amp and servo

The thing I would worry about is that you would lower the single ended swing

considerably because of the differential mode termination.

considerably because of the differential mode termination.

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

02 May 2024 18:45 - 02 May 2024 18:48 #299587

by OT-CNC

Replied by OT-CNC on topic 7i77 encoder split to amp and servo

Thanks for the response PCW. I will try single ended as tuning has been very difficult.

Do I need to pull the inverse wires or can I leave them in place and just switch the jumpers?

Do I need to pull the inverse wires or can I leave them in place and just switch the jumpers?

Last edit: 02 May 2024 18:48 by OT-CNC. Reason: added jumper question

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

17 May 2024 19:41 - 17 May 2024 19:45 #300859

by OT-CNC

Replied by OT-CNC on topic 7i77 encoder split to amp and servo

Besides noise issue on my other post, I'm trying to see if encoder is working correctly. Initial encoder counter mode 0 resulted in rough running motor. I switched to mode 1 and is smoother. A and B channel look to have closer to 90 quadrature shift than in mode 0 which had the rising edges almost in line. Is that possible? If incremental encoder outputs step/dir, (mode 1) wouldn't the direction channel be flat?

Tuning questions. I'm running the analog drive in velocity hall feedback and not reading in the encoder to the drive. Drive was configured internally to match best motor response.

Hall velocity mode in drive and pid tuning in linuxcnc does not follow regular encoder velocity tuning with I. It seems to like high P term. Why?

Not really grasping the difference between velocity tuning and torque/current tuning as linuxcnc still reads in a velocity from the encoder regardless of how the drive is set up.

Last, in hal scope, f-error plot should follow vel-commanded. Correct? Mine is mirrored. Can I flip the channel view somehow or is something misconfigured?

Tuning questions. I'm running the analog drive in velocity hall feedback and not reading in the encoder to the drive. Drive was configured internally to match best motor response.

Hall velocity mode in drive and pid tuning in linuxcnc does not follow regular encoder velocity tuning with I. It seems to like high P term. Why?

Not really grasping the difference between velocity tuning and torque/current tuning as linuxcnc still reads in a velocity from the encoder regardless of how the drive is set up.

Last, in hal scope, f-error plot should follow vel-commanded. Correct? Mine is mirrored. Can I flip the channel view somehow or is something misconfigured?

Last edit: 17 May 2024 19:45 by OT-CNC. Reason: clarification

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17546

- Thank you received: 5128

17 May 2024 20:08 #300862

by PCW

Replied by PCW on topic 7i77 encoder split to amp and servo

The hostmot2 encoder can accept step/dir or quadrature

I would expect quadrature to be more standard. Step/dir

output may have a constant value on the direction pin but

it's not necessary as it's only important that the direction pin

be in the correct state on the rising edge of the "A" input

A true velocity mode drive need encoder feedback to the drive.

Without this feedback you need higher D and P terms in a single

control loop.

The following error direction relative to velocity is dependent on the FF1 term

Though if you have a pure torque mode drive you normally do not need any FF1

I would expect quadrature to be more standard. Step/dir

output may have a constant value on the direction pin but

it's not necessary as it's only important that the direction pin

be in the correct state on the rising edge of the "A" input

A true velocity mode drive need encoder feedback to the drive.

Without this feedback you need higher D and P terms in a single

control loop.

The following error direction relative to velocity is dependent on the FF1 term

Though if you have a pure torque mode drive you normally do not need any FF1

The following user(s) said Thank You: OT-CNC

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

17 May 2024 20:14 - 17 May 2024 20:16 #300863

by blazini36

Replied by blazini36 on topic 7i77 encoder split to amp and servo

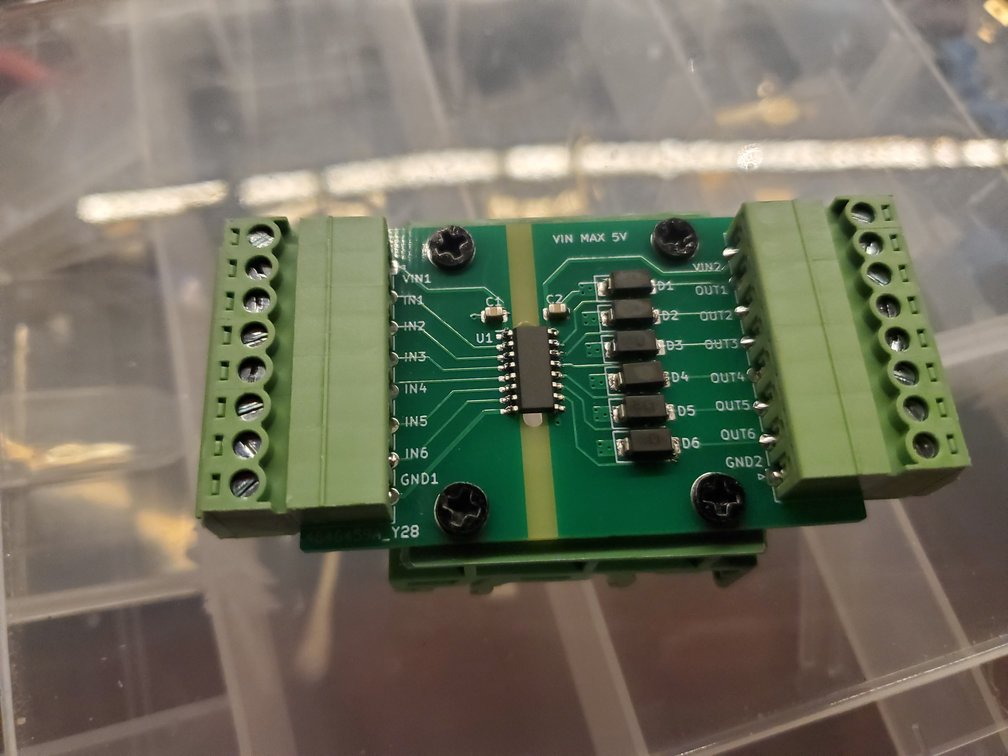

Wouldn't it be wise to use something like the Encoder Y for this? I assume Mesa still sells it, I've had one for years and never got to use it.

IIRC it has a buffer/redriver......might help with some of those other issues.

IIRC it has a buffer/redriver......might help with some of those other issues.

Last edit: 17 May 2024 20:16 by blazini36.

Please Log in or Create an account to join the conversation.

- OT-CNC

- Offline

- Platinum Member

-

Less

More

- Posts: 615

- Thank you received: 75

18 May 2024 18:06 #300927

by OT-CNC

Replied by OT-CNC on topic 7i77 encoder split to amp and servo

blazini36,

Thanks for pointing out the Encoder Y! Of course Mesa makes a solution for everything!

PCW, will the encoder y board offer isolation? Not sharing the grounds? Could I read in differential from the encoder and split(Y) to drive single ended without lowering the voltage swing? Sorry, I could not find the product doc on your site. Do you have a link?

I need to further scope the encoder as the A and B channels look flaky on halscope. I have an inconsistent pulse width both in mode1 and 0.

I also enabled quad-error-enable true but it didn't trigger. I assume in 2.8 version, axis gui would display a warning? Or does the error checking need further hal connection?

Thanks for pointing out the Encoder Y! Of course Mesa makes a solution for everything!

PCW, will the encoder y board offer isolation? Not sharing the grounds? Could I read in differential from the encoder and split(Y) to drive single ended without lowering the voltage swing? Sorry, I could not find the product doc on your site. Do you have a link?

I need to further scope the encoder as the A and B channels look flaky on halscope. I have an inconsistent pulse width both in mode1 and 0.

I also enabled quad-error-enable true but it didn't trigger. I assume in 2.8 version, axis gui would display a warning? Or does the error checking need further hal connection?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17546

- Thank you received: 5128

18 May 2024 19:29 #300931

by PCW

Replied by PCW on topic 7i77 encoder split to amp and servo

The EncY is not isolated by will function as a re-driver

to lower loads from termination. We have considered an

isolated version but have not made it yet.

You have to monitor the encoder error bit youself

and it requires using 2.9 or later as there were errors

in handling errors in multiple channels before that.

to lower loads from termination. We have considered an

isolated version but have not made it yet.

You have to monitor the encoder error bit youself

and it requires using 2.9 or later as there were errors

in handling errors in multiple channels before that.

The following user(s) said Thank You: OT-CNC

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

18 May 2024 23:47 #300942

by blazini36

If you actually need isolation on the encoder you might try looking for a magnetic or "digital" isolator. I think they'd be fast enough to handle differential inputs directly, pd is <8ns. I whipped up a few in case I ever needed them, don't think I've bothered to test them for that. I use the same family of isolator for a bunch of serial stuff since they work as simple 3v-5v level shifters as well.

Replied by blazini36 on topic 7i77 encoder split to amp and servo

I don't fully understand your setup but i've never considered sharing a single encoder between 2 devices as a particularly good idea, it's probably espescially bad if one is single ended as the load on the inverting and non-inverting outputs will be different besides however it affects RS422 termination.blazini36,

Thanks for pointing out the Encoder Y! Of course Mesa makes a solution for everything!

PCW, will the encoder y board offer isolation? Not sharing the grounds? Could I read in differential from the encoder and split(Y) to drive single ended without lowering the voltage swing? Sorry, I could not find the product doc on your site. Do you have a link?

I need to further scope the encoder as the A and B channels look flaky on halscope. I have an inconsistent pulse width both in mode1 and 0.

I also enabled quad-error-enable true but it didn't trigger. I assume in 2.8 version, axis gui would display a warning? Or does the error checking need further hal connection?

If you actually need isolation on the encoder you might try looking for a magnetic or "digital" isolator. I think they'd be fast enough to handle differential inputs directly, pd is <8ns. I whipped up a few in case I ever needed them, don't think I've bothered to test them for that. I use the same family of isolator for a bunch of serial stuff since they work as simple 3v-5v level shifters as well.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21126

- Thank you received: 7217

19 May 2024 00:19 #300947

by tommylight

Replied by tommylight on topic 7i77 encoder split to amp and servo

I am using split encoders on a plasma machine, with no isolation and no add on boards, but that implies having both sides at the same potential, failure to have them at the same potential will end up badly.

Do not take this as advice to do so, just as a "can be done" thing.

forum.linuxcnc.org/show-your-stuff/47357...ines?start=10#257711

Do not take this as advice to do so, just as a "can be done" thing.

forum.linuxcnc.org/show-your-stuff/47357...ines?start=10#257711

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.095 seconds