- Hardware & Machines

- Driver Boards

- Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

- GeckoWorks

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 8

12 Jul 2024 03:43 #304960

by GeckoWorks

Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide) was created by GeckoWorks

Hi all,

Looong time lurker but finally signed up and first post here.

Quick background, I've wanted a CNC mill/router for years and was intending to have a custom granite frame made and put on good, used hardware but a cast iron 3040 (cm) Chinese machine came up and I jumped on that. It came with a standalone, Chinese controller that I know I will have to ditch as I want a nicer GUI and also, it can't do probing. Finally, I am over my 'Linux is too hard for me' phase, so here I am:)

Apologies if my lingo is off or I am missing some electronical know how, but I will do my best.

Anyways, from reading a bunch of posts, I am leaning towards a 7i96s board but I am not sure of whether I need a daughterboard and if so, which one? E.g. I am not sure I can attach an MPG to the 7i96s? I recall someone mentioning that perhaps one of the step/dir banks could be used for it?

Would it be ok if I do description of the machine below and maybe one of you can judge which daughterboard I'd need, if any?

4 Axis/ 4 Servos

Three axis, one servo on each but I see a rotary in my future, so let's call it four.

I can set the Delta servos up to enable as soon as they boot (I hope that's not bad practice) so that saves a pin, each. But I would need to read, at least, the Z pulse for homing. Also, not sure what else is common without going overboard, maybe an alarm and alarm reset?

Spindle

I guess I will be running 0-10V to the VFD. (The VFD is also a Delta)

Limit Switches

The router will have Delta servos on it (came with steppers, but I have the servos already). It has cheap proximity limit switches on both ends of each axis and I intend to home the machine via the Z pulse of the servo.

Mist Coolant

The machine will run mist only, no flood. Would be great to have this hooked up to the board.

ATC

No ATC, none planned, either.

Pendent/MPG

I have a cheap one with the encoder wheel and two knobs (axis and increments) that I would like to use. But I could also get the wireless WHB04B-4 down the road. I guess that works with a USB dongle - so maybe it doesn't take up any IOs on the board...?

Tool Setter and Probe

I'd like to have a tool setter on the table and then also a probe.

I would love to just be able to give you a total of IO counts, but I am actually not sure how many the servos will eat up and honestly, I am sometimes still confused about what needs analog vs. dig signals.

Anyhow, sorry for the long write up. If you made it this far, I am basically asking whether the 7i96s can run an MPG and if it has enough IOs or if I need a daughterboard and if so, which one would be a good one?

Looong time lurker but finally signed up and first post here.

Quick background, I've wanted a CNC mill/router for years and was intending to have a custom granite frame made and put on good, used hardware but a cast iron 3040 (cm) Chinese machine came up and I jumped on that. It came with a standalone, Chinese controller that I know I will have to ditch as I want a nicer GUI and also, it can't do probing. Finally, I am over my 'Linux is too hard for me' phase, so here I am:)

Apologies if my lingo is off or I am missing some electronical know how, but I will do my best.

Anyways, from reading a bunch of posts, I am leaning towards a 7i96s board but I am not sure of whether I need a daughterboard and if so, which one? E.g. I am not sure I can attach an MPG to the 7i96s? I recall someone mentioning that perhaps one of the step/dir banks could be used for it?

Would it be ok if I do description of the machine below and maybe one of you can judge which daughterboard I'd need, if any?

4 Axis/ 4 Servos

Three axis, one servo on each but I see a rotary in my future, so let's call it four.

I can set the Delta servos up to enable as soon as they boot (I hope that's not bad practice) so that saves a pin, each. But I would need to read, at least, the Z pulse for homing. Also, not sure what else is common without going overboard, maybe an alarm and alarm reset?

Spindle

I guess I will be running 0-10V to the VFD. (The VFD is also a Delta)

Limit Switches

The router will have Delta servos on it (came with steppers, but I have the servos already). It has cheap proximity limit switches on both ends of each axis and I intend to home the machine via the Z pulse of the servo.

Mist Coolant

The machine will run mist only, no flood. Would be great to have this hooked up to the board.

ATC

No ATC, none planned, either.

Pendent/MPG

I have a cheap one with the encoder wheel and two knobs (axis and increments) that I would like to use. But I could also get the wireless WHB04B-4 down the road. I guess that works with a USB dongle - so maybe it doesn't take up any IOs on the board...?

Tool Setter and Probe

I'd like to have a tool setter on the table and then also a probe.

I would love to just be able to give you a total of IO counts, but I am actually not sure how many the servos will eat up and honestly, I am sometimes still confused about what needs analog vs. dig signals.

Anyhow, sorry for the long write up. If you made it this far, I am basically asking whether the 7i96s can run an MPG and if it has enough IOs or if I need a daughterboard and if so, which one would be a good one?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17484

- Thank you received: 5108

12 Jul 2024 03:56 #304961

by PCW

Replied by PCW on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

A 7I96S would do as it has the 0-10V VFD output and 5 step/dir axis

and support MPG encoders. You might run out of inputs however.

What signal levels are the Z (Index) outputs?

Another possibility is a 7I95T but its likely overkill

and support MPG encoders. You might run out of inputs however.

What signal levels are the Z (Index) outputs?

Another possibility is a 7I95T but its likely overkill

The following user(s) said Thank You: GeckoWorks

Please Log in or Create an account to join the conversation.

- GeckoWorks

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 8

12 Jul 2024 04:37 #304964

by GeckoWorks

Replied by GeckoWorks on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

Hi PCW,

Thanks for the speedy reply, I will need to dive into the manual for the Delta B2 servos to answer you but about to run some errands, so will update with that info once I get it.

(No shade on Spumco's great work, but his compiled list here said '0' for the MPG for the 7i96s hence why I got confused;))

Thanks for the speedy reply, I will need to dive into the manual for the Delta B2 servos to answer you but about to run some errands, so will update with that info once I get it.

(No shade on Spumco's great work, but his compiled list here said '0' for the MPG for the 7i96s hence why I got confused;))

Please Log in or Create an account to join the conversation.

- GeckoWorks

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 8

12 Jul 2024 06:10 #304969

by GeckoWorks

Replied by GeckoWorks on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

So, as for the question about signal levels for the B2 servos' Z pulse, I am honestly a bit daft when it comes to eletronics and don't even yet have a grasp on when a signal is digital vs. analog...

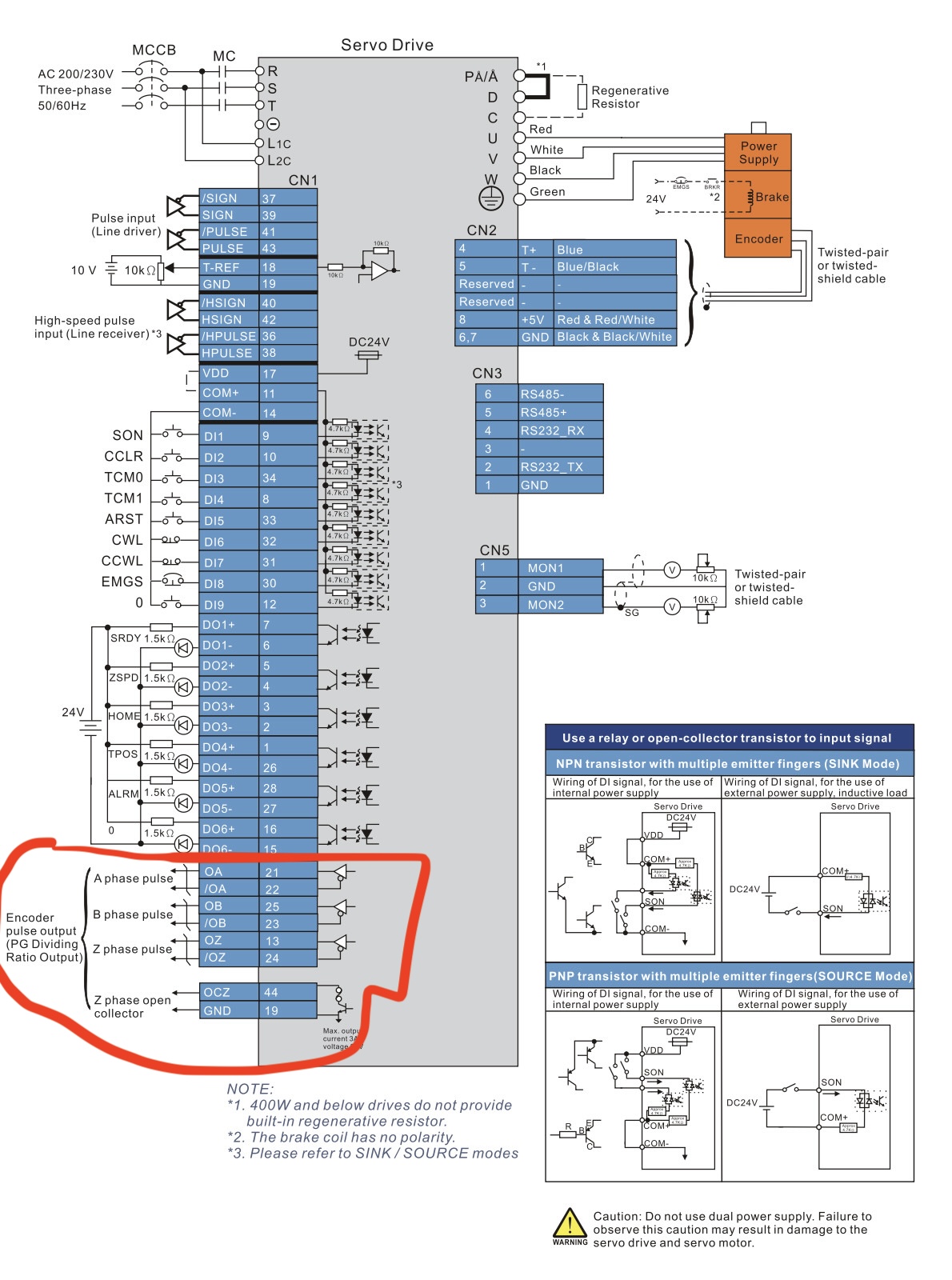

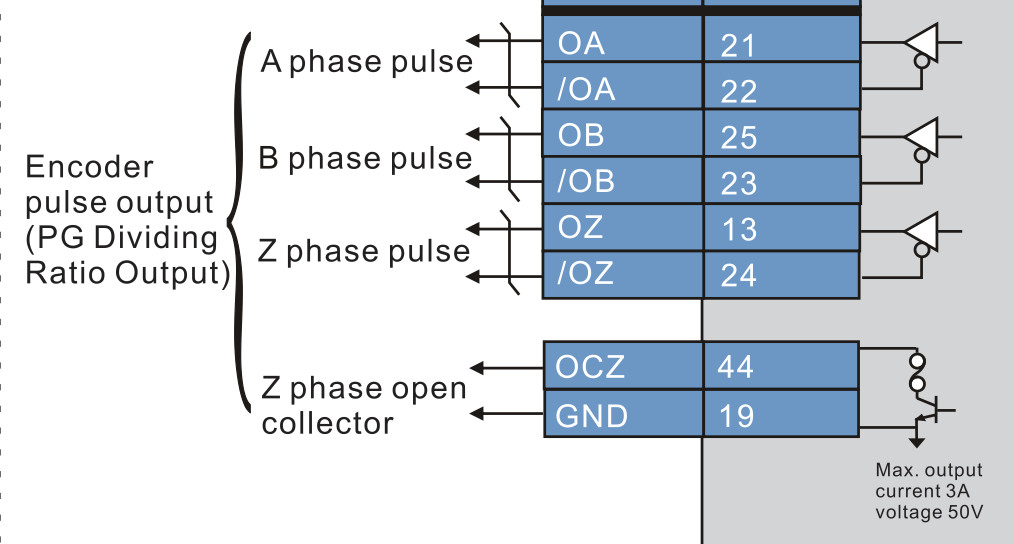

I can only find a mentioning of: " Z-phase Differential Signal". Not sure if that's what you're after. And then some screenshots from the manual:

I can only find a mentioning of: " Z-phase Differential Signal". Not sure if that's what you're after. And then some screenshots from the manual:

Attachments:

Please Log in or Create an account to join the conversation.

- Cant do this anymore bye all

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1200

- Thank you received: 425

12 Jul 2024 10:38 #304974

by Cant do this anymore bye all

Replied by Cant do this anymore bye all on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

Simplifying things.

DIgital has 2 distinct states either 1 or 0 , using 5 volt logic as example:

5v = Logic 1

0v = Logic 0

A simple on off switch would give you these 2 values.

Anlaogue on the other hand... would have an infinite amount of voltages between 0v & 5v, ie any voltage between 0v & 5v.

A rheostat or potentiometer will give these voltages.

Turning a knob on a rheostat gives you an analogue signal. eg like a old school light dimmer, the like will go from dim to bright

Flicking a switch on & off gives you a digital signal. eg a light switch, will turn the light on or off.

DIgital has 2 distinct states either 1 or 0 , using 5 volt logic as example:

5v = Logic 1

0v = Logic 0

A simple on off switch would give you these 2 values.

Anlaogue on the other hand... would have an infinite amount of voltages between 0v & 5v, ie any voltage between 0v & 5v.

A rheostat or potentiometer will give these voltages.

Turning a knob on a rheostat gives you an analogue signal. eg like a old school light dimmer, the like will go from dim to bright

Flicking a switch on & off gives you a digital signal. eg a light switch, will turn the light on or off.

The following user(s) said Thank You: GeckoWorks

Please Log in or Create an account to join the conversation.

- GeckoWorks

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 8

12 Jul 2024 12:19 #304986

by GeckoWorks

Now, a question to properly cement my ignorance. Let's say I have a Dig signal coming into the MESA, like a probe or tool setter - how many pins will it take up? Is it two pins? Is one of them ground and if so, can the ground just go "anywhere"? Would it be the same for analog?

I am trying to get my head around how to actually count how many IOs I will be using in total and how many pins it will take up...

Replied by GeckoWorks on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

That was a great explanation, thanks:)Simplifying things.

DIgital has 2 distinct states either 1 or 0 , using 5 volt logic as example:

5v = Logic 1

0v = Logic 0

A simple on off switch would give you these 2 values.

Anlaogue on the other hand... would have an infinite amount of voltages between 0v & 5v, ie any voltage between 0v & 5v.

A rheostat or potentiometer will give these voltages.

Turning a knob on a rheostat gives you an analogue signal. eg like a old school light dimmer, the like will go from dim to bright

Flicking a switch on & off gives you a digital signal. eg a light switch, will turn the light on or off.

Now, a question to properly cement my ignorance. Let's say I have a Dig signal coming into the MESA, like a probe or tool setter - how many pins will it take up? Is it two pins? Is one of them ground and if so, can the ground just go "anywhere"? Would it be the same for analog?

I am trying to get my head around how to actually count how many IOs I will be using in total and how many pins it will take up...

Please Log in or Create an account to join the conversation.

- Cant do this anymore bye all

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1200

- Thank you received: 425

12 Jul 2024 13:02 #304991

by Cant do this anymore bye all

Replied by Cant do this anymore bye all on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

Don't worry about GND or Power when counting inputs. Just the actual input itself.

Please Log in or Create an account to join the conversation.

- GeckoWorks

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 8

13 Jul 2024 04:20 - 13 Jul 2024 06:52 #305048

by GeckoWorks

Hi again,

So, I attached some screenshots from the Delta servo manual a few posts above but don't know if they answer your question about the Z pulse signal levels.

Also, I tried to do an updated IO list below. Kinda worst case scenario for now, though. But given the list, which daughter card would you recommend?

Out

In

Again, this is my first CNC, so I am not sure what’s prudent nor practical. Maybe it’s ok to run all limit switches in series and maybe the servo enables, alarms and resets, too? Also, no hard buttons at all on that list and I may have forgotten something. But it sure starts looking like some more IOs would be nice.

Replied by GeckoWorks on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

A 7I96S would do as it has the 0-10V VFD output and 5 step/dir axis

and support MPG encoders. You might run out of inputs however.

What signal levels are the Z (Index) outputs?

Another possibility is a 7I95T but its likely overkill

Hi again,

So, I attached some screenshots from the Delta servo manual a few posts above but don't know if they answer your question about the Z pulse signal levels.

Also, I tried to do an updated IO list below. Kinda worst case scenario for now, though. But given the list, which daughter card would you recommend?

Out

- 4 axis, step/dir

- 1 spindle via VFD

For mist coolant (fancy setup with a peristaltic pump): - 1 enable for the peristaltic pump (stepper with its own driver board with a range of speed settings)

- 1 solenoid for air (I could run them on the same pin, I guess but it would be nice to also have the option of only running air)

In

- 1 4-axis MPG with axis select and increment knobs

- 1 tool setter

- 1 probe

- 6 limit switches.I don’t know if these should be connected in series and what the impact would be, except for saving on pins. But I could also feed limit switches to the servo drivers and not the Mesa.

- 1 “home switch” for rotary homing together with Z pulse

- 4 Z pulse from the servo drives for homing (rotary axis at some point in the future)

- 3-4 Servo Enables (I can also program the servos to enable by default as the drives power on)

- 3-4 Servo Alarms (not sure it’s needed)

- 3-4 Servo Alarm Resets (not sure it’s needed)

- 3-4 Servo COMs (not sure it’s needed)

- 3-4 E-stop to servo drives (Not really needed but may be nice to have the drives stop the servos?)

Again, this is my first CNC, so I am not sure what’s prudent nor practical. Maybe it’s ok to run all limit switches in series and maybe the servo enables, alarms and resets, too? Also, no hard buttons at all on that list and I may have forgotten something. But it sure starts looking like some more IOs would be nice.

Last edit: 13 Jul 2024 06:52 by GeckoWorks.

Please Log in or Create an account to join the conversation.

- Dave2024

-

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 10

13 Jul 2024 16:56 #305093

by Dave2024

Replied by Dave2024 on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

Ok I think you've got a differential encoder. Differential encoders will use 6 wires but you can also configure them to only use 3 if you wanted being single ended. The wires will be A+, A-, B+, B-, Z+, and Z-. Sometimes the encoders Z will be called Index or I. So it would instead of Z+ and Z- its I+ and I-. There both the same I and Z. If you get the Mesa 7i96s theres a jumper called W3 that you can change the boards encoder input from single ended(3-wire) to differential(6-wire). They come out of the box already set in differential so you wont have to move it. Differential is what you want anyways its more accurate. Also sometimes this differential and single ended terminology is called biphase encoding. Theres like four different kind of encoding signal/protocols its all really complex and is difficult to understand sorrySo, as for the question about signal levels for the B2 servos' Z pulse, I am honestly a bit daft when it comes to eletronics and don't even yet have a grasp on when a signal is digital vs. analog...

I can only find a mentioning of: " Z-phase Differential Signal". Not sure if that's what you're after. And then some screenshots from the manual:

The following user(s) said Thank You: GeckoWorks

Please Log in or Create an account to join the conversation.

- GeckoWorks

- Offline

- Senior Member

-

Less

More

- Posts: 55

- Thank you received: 8

13 Jul 2024 18:04 #305099

by GeckoWorks

So, perhaps to get homing to the Z-index pulse working, I just need two wires, maybe 1 In pin only, maybe 2. But since I think I will be needing an extra board with more Ins anyways, perhaps this is less important now. And the part about actually making this work can come later - it will take a while to get the boards here anyways.

I've been digging a bit deeper in the manual and if I really needed to save on pins or somehow wanted to move some tasks out of Lcnc then I could actually have the servo drives do the homing themselves. The limit switches would then also go to the drives and I guess just one dig out and one in to basically tell the drive to start the homing routine and then an in to receive a signal that it was completed.

But I think I want to keep as much as I can in Lcnc so just waiting for PWC to confirm which daughterboard he thinks is the right one (or anyone else with the overview). I am just dreading the whole sourcing/sinking question right now as it may impact which daughterboard I'd need...

Replied by GeckoWorks on topic Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

Thanks for giving it a go:).

So, as for the question about signal levels for the B2 servos' Z pulse, I am honestly a bit daft when it comes to eletronics and don't even yet have a grasp on when a signal is digital vs. analog...

I can only find a mentioning of: " Z-phase Differential Signal". Not sure if that's what you're after. And then some screenshots from the manual:

Ok I think you've got a differential encoder. Differential encoders will use 6 wires but you can also configure them to only use 3 if you wanted being single ended. The wires will be A+, A-, B+, B-, Z+, and Z-. Sometimes the encoders Z will be called Index or I. So it would instead of Z+ and Z- its I+ and I-. There both the same I and Z. If you get the Mesa 7i96s theres a jumper called W3 that you can change the boards encoder input from single ended(3-wire) to differential(6-wire). They come out of the box already set in differential so you wont have to move it. Differential is what you want anyways its more accurate. Also sometimes this differential and single ended terminology is called biphase encoding. Theres like four different kind of encoding signal/protocols its all really complex and is difficult to understand sorry

So, perhaps to get homing to the Z-index pulse working, I just need two wires, maybe 1 In pin only, maybe 2. But since I think I will be needing an extra board with more Ins anyways, perhaps this is less important now. And the part about actually making this work can come later - it will take a while to get the boards here anyways.

I've been digging a bit deeper in the manual and if I really needed to save on pins or somehow wanted to move some tasks out of Lcnc then I could actually have the servo drives do the homing themselves. The limit switches would then also go to the drives and I guess just one dig out and one in to basically tell the drive to start the homing routine and then an in to receive a signal that it was completed.

But I think I want to keep as much as I can in Lcnc so just waiting for PWC to confirm which daughterboard he thinks is the right one (or anyone else with the overview). I am just dreading the whole sourcing/sinking question right now as it may impact which daughterboard I'd need...

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

- Hardware & Machines

- Driver Boards

- Sorry, Another 'Which Mesa?' Post. (Yes, I read Spumco's magnificient guide)

Time to create page: 0.245 seconds