looking for advice on retrofitting hydrolic mill

- steers

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

04 Jul 2025 18:16 #331256

by steers

looking for advice on retrofitting hydrolic mill was created by steers

hey all!im in the market for a decent mill that i want to retrofit with Mesa/linuxCnC. its a Knüth WF 5 NC, a hydrolic controlled mill with currently a Ljumo-PNC 63 controller. currently the mill isnt operational, but even with the full schematics we cant seem to figure out the current issue.i have done a retrofit before using mesa on a Vermano r170 which used some big servos, but i cant seem to find much info regarding retrofitting mesa hardware on a hydrolic controlled mill.is this even possible, and where can i find some more info on how to tackle this?best regards,steers

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17754

- Thank you received: 5191

04 Jul 2025 21:42 #331271

by PCW

Replied by PCW on topic looking for advice on retrofitting hydrolic mill

If you are retaining the hydraulics, the question would be how are the hydraulic valves

that control position controlled and what is the position feedback method.

that control position controlled and what is the position feedback method.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

04 Jul 2025 22:44 #331277

by tommylight

Replied by tommylight on topic looking for advice on retrofitting hydrolic mill

Something does not add up, google shows many of the same model machines with manual controls

www.google.com/search?q=knuth+wf5nc&num=...mgdii=EVvF2wH31GoAHM

So upload some pictures of the machine.

www.google.com/search?q=knuth+wf5nc&num=...mgdii=EVvF2wH31GoAHM

So upload some pictures of the machine.

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

04 Jul 2025 23:27 #331285

by jmelson

Replied by jmelson on topic looking for advice on retrofitting hydrolic mill

Are the axes moved by hydraulic motors or cylinders? Or, are there electric motors for the axes? Is it really an NC mill, or is that Ljumo just a digital readout?

Driving a machine with proportional hydraulic valves requires "dither" to be added to keep the valve freely floating.

Driving a machine with proportional hydraulic valves requires "dither" to be added to keep the valve freely floating.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- timo

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 50

05 Jul 2025 10:20 - 05 Jul 2025 10:33 #331310

by timo

Replied by timo on topic looking for advice on retrofitting hydrolic mill

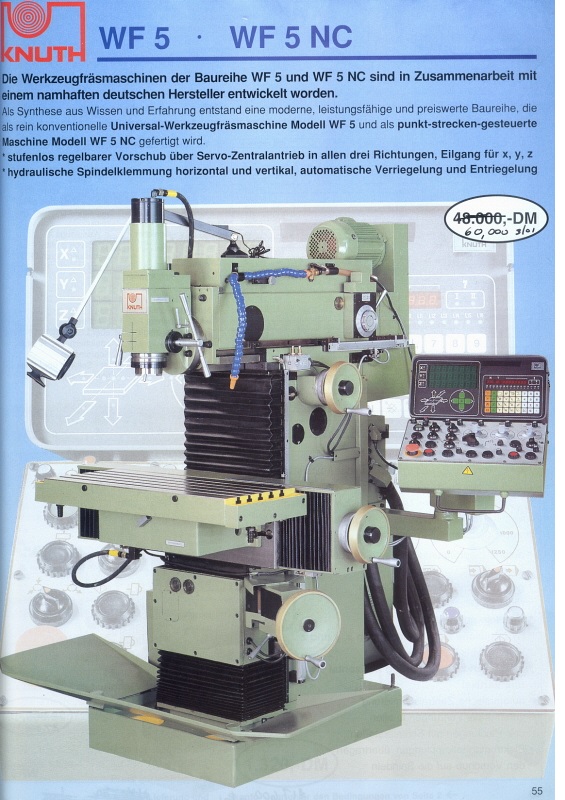

In one of the pictures in a sales catalogue it says There is a WF5 and a WF5NC, which seems to be a control to move.

The attached picture of the original post clearly says WF5 NC on the machine tag.

It says "punkt-strecken-gesteuert", I guess that means it can move one axis from a given position to another given position at a time?

p.s. that thing must be from the last century , older than computers.

, older than computers.

The attached picture of the original post clearly says WF5 NC on the machine tag.

It says "punkt-strecken-gesteuert", I guess that means it can move one axis from a given position to another given position at a time?

p.s. that thing must be from the last century

Attachments:

Last edit: 05 Jul 2025 10:33 by timo.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

05 Jul 2025 10:42 #331311

by tommylight

Replied by tommylight on topic looking for advice on retrofitting hydrolic mill

Servo Zentralantrieb in allen drei richtungen

means

central (single) servo drive for all 3 directions

So not hydraulic, but the tool lock is hydraulic, both for horizontal and vertical head.

In short, retrofitting to full CNC would require removing the central drive and gearbox and adding motors to each axis on the hand crank, most probably.

Also, normally, this type of machine uses trapezoidal screws and brass nuts, so have a lot of backlash, that can be fixed in software to a certain degree, but do not expect much precision.

means

central (single) servo drive for all 3 directions

So not hydraulic, but the tool lock is hydraulic, both for horizontal and vertical head.

In short, retrofitting to full CNC would require removing the central drive and gearbox and adding motors to each axis on the hand crank, most probably.

Also, normally, this type of machine uses trapezoidal screws and brass nuts, so have a lot of backlash, that can be fixed in software to a certain degree, but do not expect much precision.

Please Log in or Create an account to join the conversation.

- timo

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 50

05 Jul 2025 11:04 #331312

by timo

Replied by timo on topic looking for advice on retrofitting hydrolic mill

Means a similar retro fit like these ones?

forum.linuxcnc.org/12-milling/33035-retr...86-maho-400e?start=0

forum.linuxcnc.org/12-milling/33035-retr...86-maho-400e?start=0

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21379

- Thank you received: 7290

05 Jul 2025 11:42 #331313

by tommylight

Replied by tommylight on topic looking for advice on retrofitting hydrolic mill

Those Maho's are already CNC from the factory, meaning they have motors on each axis and have ballscrews, so very easy to retrofit.

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 520

- Thank you received: 126

05 Jul 2025 14:57 #331321

by jmelson

Replied by jmelson on topic looking for advice on retrofitting hydrolic mill

I had an old Bridgeport mill that had had heavy production use. After getting some level of proficiency with it, I was having BIG problems getting things to fit together. So, I'd make some device, and then in a different setup, make a cover with screw holes that were supposed to line up. They didn't! It turned out that the Acme (trapezoidal thread) screws were more worn in the center that at the ends.

This was enough so that there was a large positioning error when moving from one end of the screw toward the middle.

Tommy, so this machine has ONE servo motor and clutches to the various leadscrews? I've heard of such machines, but never seen one. That does kind of match the amount of electronics in the thing.

Jon

This was enough so that there was a large positioning error when moving from one end of the screw toward the middle.

Tommy, so this machine has ONE servo motor and clutches to the various leadscrews? I've heard of such machines, but never seen one. That does kind of match the amount of electronics in the thing.

Jon

Please Log in or Create an account to join the conversation.

- timo

- Offline

- Elite Member

-

Less

More

- Posts: 174

- Thank you received: 50

18 Jul 2025 11:36 #331974

by timo

Replied by timo on topic looking for advice on retrofitting hydrolic mill

As far as I understood not. I thing the TOT variant had a central motor which drove the axis via some sort of internals. (maybe I remember wrong).

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.121 seconds