Pete's Cincinatti Arrow 500 Retrofit...

- PetefromTn

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 0

07 Nov 2012 08:23 #26326

by PetefromTn

Replied by PetefromTn on topic Cincinatti Arrow 500 retrofit questions.....

Okay guys,

I have been thinking about this one for a little while now and I have pretty much decided I will be doing this retrofit with LinuxCNC. I intend to use the mesa cards for it and I am looking for opinions about which ones to go with. The fellow in GB who did another Cincinatti Arrow 500 Used the 5I20 7I33 and 7I37 TA setup but I am hearing a lot of folks recommend the 5I25, 7I77 setup. I definitely want the screw down terminals on the IO board and at this point I am looking seriously at the Teco servo drives and motors from machmotion. Initially this will be just getting the basic three axis machine functioning but following that I will want to get the toolchanger working as well. I hope to be able to rely on you LinuxCNC genius' here to help me trudge thru this adventure. Thanks for any input in advance guys...peace

Pete

I have been thinking about this one for a little while now and I have pretty much decided I will be doing this retrofit with LinuxCNC. I intend to use the mesa cards for it and I am looking for opinions about which ones to go with. The fellow in GB who did another Cincinatti Arrow 500 Used the 5I20 7I33 and 7I37 TA setup but I am hearing a lot of folks recommend the 5I25, 7I77 setup. I definitely want the screw down terminals on the IO board and at this point I am looking seriously at the Teco servo drives and motors from machmotion. Initially this will be just getting the basic three axis machine functioning but following that I will want to get the toolchanger working as well. I hope to be able to rely on you LinuxCNC genius' here to help me trudge thru this adventure. Thanks for any input in advance guys...peace

Pete

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1177

07 Nov 2012 08:37 #26327

by BigJohnT

Replied by BigJohnT on topic Cincinatti Arrow 500 retrofit questions.....

The 5i20 7i33 7i37 does have a small advantage over the 5i25 7i77 but I'm not sure it is something that makes a difference. The 5i25 is new and is neater to wire up between the 5i25 and the 7i77 using the parallel port cable. I used the 5i20 on my CHNC but the 5i25 was not out yet. I used the 5i25 on my BP conversion just a short while back. In any case both the 5i25 and 5i20 daughter cards have screw terminals (specify TA on the 7i33 and 7i37).

The big difference that I can see is the 5i20 had a PID and the 5i25 you use the LinuxCNC PID loop IIRC.

John

The big difference that I can see is the 5i20 had a PID and the 5i25 you use the LinuxCNC PID loop IIRC.

John

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23550

- Thank you received: 5018

07 Nov 2012 20:20 #26333

by andypugh

Replied by andypugh on topic Cincinatti Arrow 500 retrofit questions.....

Those look like they will work (+/-10V command for velocity or torque). A bit more expensive than the dmm-tech equivalent, though, so I wonder what swung you that way?at this point I am looking seriously at the Teco servo drives and motors from machmotion

Please Log in or Create an account to join the conversation.

- JR1050

-

- Offline

- Platinum Member

-

Less

More

- Posts: 450

- Thank you received: 33

07 Nov 2012 23:05 #26342

by JR1050

Replied by JR1050 on topic Cincinatti Arrow 500 retrofit questions.....

Im a little late to this .....Anyway,tearing EVERTHING out and starting from scratch is gonna ensure one thing,a disassembled dead machine,been there done that. Im gonna assume you have Seiemens Ac drives and motors(kellomorgan?),if you keep blowing a drive,you have a motor problem or cable problem.Siemens motors are robust

the drives suck. Make sure the cables are not rubbed raw and if you are still having problems,replace the caps in the DC link(in the drive,6sc 6100?). Seimens ac drives use tachs for velocity control.Cinci used both tachs and resolvers.

$2500 is pretty cheap to repair a spindle drive.....if you are still having problems,I suggest a Hitachi WJ 200 vfd ,I recently repaced the induction motor and Mitsu drive on a Fadal with a Fanuc PM motor and a wj200 and it worked real well. Advanced Motion controls makes all kinds of drives,they are resonably priced and work well,you should be able to find a drive to work with your motors. Again,if you keep blowing up a drive,check the motor and cableing. And,again, caps in the drive...they take a lot of wear and tear.Metallic dust is the enemy of all electronics....

You might want to lose the resolvers,not because they dont work,because if you want a MPG and spindle feed back,you will need an encoder interface,which on a 5i20 will eat up another connector,which you need for i/o,in addition,if you want a rotab,you will also need another axis and most rotabs use encoders.

Feeding Seimens to keep the Acramatic running is painful, the Acramatic has some features Emc doesnt, I would really think thru tearing everything out and starting from scratch. Buy the mesa gear,get some cheap motors and drives off ebay(small stuff),maybe a couple of opto boards and experiment.

It will take a considerable effort to get your Arrow up to the level of any new machine,not impossible,but plan on spending some time and effort. I would be very wary of anything Chineese,I like the food,but servos and drives are asking for problems....

the drives suck. Make sure the cables are not rubbed raw and if you are still having problems,replace the caps in the DC link(in the drive,6sc 6100?). Seimens ac drives use tachs for velocity control.Cinci used both tachs and resolvers.

$2500 is pretty cheap to repair a spindle drive.....if you are still having problems,I suggest a Hitachi WJ 200 vfd ,I recently repaced the induction motor and Mitsu drive on a Fadal with a Fanuc PM motor and a wj200 and it worked real well. Advanced Motion controls makes all kinds of drives,they are resonably priced and work well,you should be able to find a drive to work with your motors. Again,if you keep blowing up a drive,check the motor and cableing. And,again, caps in the drive...they take a lot of wear and tear.Metallic dust is the enemy of all electronics....

You might want to lose the resolvers,not because they dont work,because if you want a MPG and spindle feed back,you will need an encoder interface,which on a 5i20 will eat up another connector,which you need for i/o,in addition,if you want a rotab,you will also need another axis and most rotabs use encoders.

Feeding Seimens to keep the Acramatic running is painful, the Acramatic has some features Emc doesnt, I would really think thru tearing everything out and starting from scratch. Buy the mesa gear,get some cheap motors and drives off ebay(small stuff),maybe a couple of opto boards and experiment.

It will take a considerable effort to get your Arrow up to the level of any new machine,not impossible,but plan on spending some time and effort. I would be very wary of anything Chineese,I like the food,but servos and drives are asking for problems....

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23550

- Thank you received: 5018

08 Nov 2012 08:26 #26354

by andypugh

I agree with this sentiment. You don't want your first retrofit to be something you really care about. It is going to be a learning experience and that is best approached without the wreckage of a money-maki9ng machine looming over you.

Consider a smaller project as an introduction. Do you have any need for a plasma table, for example?

Replied by andypugh on topic Cincinatti Arrow 500 retrofit questions.....

tearing EVERTHING out and starting from scratch is gonna ensure one thing,a disassembled dead machine

…

Buy the mesa gear,get some cheap motors and drives off ebay(small stuff),maybe a couple of opto boards and experiment. .

I agree with this sentiment. You don't want your first retrofit to be something you really care about. It is going to be a learning experience and that is best approached without the wreckage of a money-maki9ng machine looming over you.

Consider a smaller project as an introduction. Do you have any need for a plasma table, for example?

Please Log in or Create an account to join the conversation.

- PetefromTn

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 0

08 Nov 2012 09:23 #26357

by PetefromTn

Replied by PetefromTn on topic Cincinatti Arrow 500 retrofit questions.....

Thanks for the advice guys. Understand this machine is not the siemens Acramatic, it is the Emerson Control techniques FNC control. The motors are all resolver based and it is QUITE expensive to repair everything from my point of view. I have already done another retrofit on a small bedmill using Mach3 but this is another animal completely. I will be removing all three axis motors and drives and the spindle drive. I will be using EMC/linuxCNC to control the system using mesa cards and the only thing remaining of the original control will be the spindle motor. I intend to use a 10HP single phase vfd to run it. This has all already been done by another fellow so I will not be breaking any new ground but the toolchanger will of course be a challenge. The analog motors and drives will be a new experience but it seems that there is software included to tune the drives. I will be removing all the unused parts this weekend and then I will order the first of the three axis motors and drives and the mesa cards upon your recommendations for what I intend to do here. Thanks and peace

Pete

Pete

Please Log in or Create an account to join the conversation.

- PetefromTn

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 0

11 Mar 2013 20:28 #31220

by PetefromTn

Replied by PetefromTn on topic Cincinatti Arrow 500 retrofit questions.....

Okay guys,

I have been slowly working towards this project acquiring everything I need to make it happen. Despite the advice to the contrary I decided to basically gut the entire electronics cabinet and start over with new known working components. Until now I have been chronicling this build over on the CNCzone Cincinatti forum. Honestly I have enjoyed it over there for some time but ever since I moved to the VMC and that Cincinatti forum it seemed like it has slowed down considerably. That and all of the extraordinarily annoying advertisements and forum problems has made it quite frustrating to post over there. I am seriously considering posting all of my progress and questions here predominately because you guys know the system I am using better than most of those guys over there altho I know many of you post there too occasionally.

Anyways, I have gone with the Teco motors and drivers from Machmotion and so far I am very happy with that choice. The stuff I received is very high quality and their support has been good as well. I went with their TSTC-30 drives and 1kw motors for the axis drives and the Z has their integrated brake assembly since my machine has no counterweight. For the spindle after much deliberation I went with a hitachi WJ 200 model which seems to be a VERY nice unit made in japan. It has quite a lot of interesting features and even has encoder feedback. I also purchased a very tiny fractional HP VFD also a Hitachi to run the three phase coolant pump. Its a cute little thing that will sit on the bottom wall of the enclosure and be switched on and off with a 24v signal from the mesa card.

I am going to start posting my progress here so here is an update on the goings on. Thus far I have already removed everything from the electronics cabinet with the exception of the main disconnect, the various relays which some of them I will be re-using, and the 24v power supply as well as I left the original cables that were for the fourth axis prewire setup. I will be re-using the existing spindle motor and the toolchanger motor as well as the rest of the toolchanger system which is basically entirely pneumatic solenoids that are switched with 110vac. All of the original limits and home switches will also be reused as will the coolant pump. None of the original control parts will be reused including the entire pendant assembly.

So far I have installed the three new Teco drives into the cabinet, I have fabricated a nice pendant plate to mount the new LCD monitor into. I am re-using the old E-stop button as well as the original Cincinatti MPG wheel. I have already installed these into the pendant panel and have started to wire all of this stuff up. I am using an intel atom motherboard that is maxed out in Ram and I am using a small Solid state hard drive. My initial thoughts were to install the computer inside the electronics enclosure but that has since changed and I recently removed it from the steel box I had it in and installed it in the pendant housing which was quite large since it housed a CRT monitor before. So far I have hooked up the 120vac power to the pendant and got the computer and monitor to power up and my friend Connor has installed LinuxCNC to the computer for me. I am using the very capable 5i25/7i77 mesanet combo. I initially purchased it not knowing that they sell it with two cable options a six footer and a ten footer. I received the six footer and then found out they sold a ten foot cable for it. I just purchased that new ten foot cable as well as their din rail mounting kit for the 7i77 card. This will allow me to keep the computer up front away from the noise of the drives while still allowing me to locate the 7i77 interface daughter card where it makes the easiest wiring sense. So far after reading a bit thru the mesanet literature on the boards I am very pleased with my selections. It sounds like these boards should run the entire machine with relative ease.

The progress thus far has been chronicled pretty thoroughly on the CNCZONE thread here: www.cnczone.com/forums/cincinnati_cnc/15...w_500_adventure.html

I will answer any questions regarding what has been done so far in that thread but it is all there altho it is probably a lot to read. I will simply move forward here and post the progress as it comes. To be honest I am probably a bit long winded and sometimes talk about things that do not pertain directly to the build so you'll have to bear with me but I am sincerely hoping that with the help of all of you knowledgeable folks that I can get this machine running reliably. This machine is the culmination of a dream for me, I have wanted a full blown toolchanger equipped VMC in my shop for a LONG time now and so far this is turning out to be everything I had hoped for. Honestly it was quite frustrating initially as I struggled to make the original control work reliably but that was just not meant to be so now I am onto the retrofit adventure here an please understand that this machine WILL be used to make me money if I have anything to say about it. I have lots of ideas I want to explore with it and I have been approached recently by several folks who want parts made so with any luck this will turn out to be a happy prosperous story and the start of my CNC shop capabilities.

My goal is to wind up with a machine that works exactly like the original machine did or better. My other goal is to make this retrofit as simple and plug and play as humanly possible. I have made several decisions that lean towards this plug and play mentality. For instance I went with the Teco motors and drives and purchased them complete with premade milspec connectors on the cables that allow me to just plug in the power and encoder cables to all three motors. The Mesa cards are all screw down terminals of course and the rest of the setup I have made purchases that will allow the LEAST amount of soldering and wire splicing etc. The motors are all bolt on and the motor couplers are just clamp on type dual disk units so adapting motors to screws is a bolt on affair. This leaves me only to do the actual wiring of everything and integrate the existing limits/homes/ and toolchanger control into the system.

Initially my plan is to just get the basic machine working. IE all three axis drives, the limits and homes and estop circuit, and the spindle motor without feedback. Once that is operational I can then start using the machine to make parts if I need to while I work on the toolchanger and spindle alignment feedback etc.

Anyways I hope this is the right place for a build thread here as I am going to start posting that way. Here are some pictures of the machine progress thus far. I look forward sincerely to all of your input and ideas and help because I am quite sure I will need it. Peace

I have been slowly working towards this project acquiring everything I need to make it happen. Despite the advice to the contrary I decided to basically gut the entire electronics cabinet and start over with new known working components. Until now I have been chronicling this build over on the CNCzone Cincinatti forum. Honestly I have enjoyed it over there for some time but ever since I moved to the VMC and that Cincinatti forum it seemed like it has slowed down considerably. That and all of the extraordinarily annoying advertisements and forum problems has made it quite frustrating to post over there. I am seriously considering posting all of my progress and questions here predominately because you guys know the system I am using better than most of those guys over there altho I know many of you post there too occasionally.

Anyways, I have gone with the Teco motors and drivers from Machmotion and so far I am very happy with that choice. The stuff I received is very high quality and their support has been good as well. I went with their TSTC-30 drives and 1kw motors for the axis drives and the Z has their integrated brake assembly since my machine has no counterweight. For the spindle after much deliberation I went with a hitachi WJ 200 model which seems to be a VERY nice unit made in japan. It has quite a lot of interesting features and even has encoder feedback. I also purchased a very tiny fractional HP VFD also a Hitachi to run the three phase coolant pump. Its a cute little thing that will sit on the bottom wall of the enclosure and be switched on and off with a 24v signal from the mesa card.

I am going to start posting my progress here so here is an update on the goings on. Thus far I have already removed everything from the electronics cabinet with the exception of the main disconnect, the various relays which some of them I will be re-using, and the 24v power supply as well as I left the original cables that were for the fourth axis prewire setup. I will be re-using the existing spindle motor and the toolchanger motor as well as the rest of the toolchanger system which is basically entirely pneumatic solenoids that are switched with 110vac. All of the original limits and home switches will also be reused as will the coolant pump. None of the original control parts will be reused including the entire pendant assembly.

So far I have installed the three new Teco drives into the cabinet, I have fabricated a nice pendant plate to mount the new LCD monitor into. I am re-using the old E-stop button as well as the original Cincinatti MPG wheel. I have already installed these into the pendant panel and have started to wire all of this stuff up. I am using an intel atom motherboard that is maxed out in Ram and I am using a small Solid state hard drive. My initial thoughts were to install the computer inside the electronics enclosure but that has since changed and I recently removed it from the steel box I had it in and installed it in the pendant housing which was quite large since it housed a CRT monitor before. So far I have hooked up the 120vac power to the pendant and got the computer and monitor to power up and my friend Connor has installed LinuxCNC to the computer for me. I am using the very capable 5i25/7i77 mesanet combo. I initially purchased it not knowing that they sell it with two cable options a six footer and a ten footer. I received the six footer and then found out they sold a ten foot cable for it. I just purchased that new ten foot cable as well as their din rail mounting kit for the 7i77 card. This will allow me to keep the computer up front away from the noise of the drives while still allowing me to locate the 7i77 interface daughter card where it makes the easiest wiring sense. So far after reading a bit thru the mesanet literature on the boards I am very pleased with my selections. It sounds like these boards should run the entire machine with relative ease.

The progress thus far has been chronicled pretty thoroughly on the CNCZONE thread here: www.cnczone.com/forums/cincinnati_cnc/15...w_500_adventure.html

I will answer any questions regarding what has been done so far in that thread but it is all there altho it is probably a lot to read. I will simply move forward here and post the progress as it comes. To be honest I am probably a bit long winded and sometimes talk about things that do not pertain directly to the build so you'll have to bear with me but I am sincerely hoping that with the help of all of you knowledgeable folks that I can get this machine running reliably. This machine is the culmination of a dream for me, I have wanted a full blown toolchanger equipped VMC in my shop for a LONG time now and so far this is turning out to be everything I had hoped for. Honestly it was quite frustrating initially as I struggled to make the original control work reliably but that was just not meant to be so now I am onto the retrofit adventure here an please understand that this machine WILL be used to make me money if I have anything to say about it. I have lots of ideas I want to explore with it and I have been approached recently by several folks who want parts made so with any luck this will turn out to be a happy prosperous story and the start of my CNC shop capabilities.

My goal is to wind up with a machine that works exactly like the original machine did or better. My other goal is to make this retrofit as simple and plug and play as humanly possible. I have made several decisions that lean towards this plug and play mentality. For instance I went with the Teco motors and drives and purchased them complete with premade milspec connectors on the cables that allow me to just plug in the power and encoder cables to all three motors. The Mesa cards are all screw down terminals of course and the rest of the setup I have made purchases that will allow the LEAST amount of soldering and wire splicing etc. The motors are all bolt on and the motor couplers are just clamp on type dual disk units so adapting motors to screws is a bolt on affair. This leaves me only to do the actual wiring of everything and integrate the existing limits/homes/ and toolchanger control into the system.

Initially my plan is to just get the basic machine working. IE all three axis drives, the limits and homes and estop circuit, and the spindle motor without feedback. Once that is operational I can then start using the machine to make parts if I need to while I work on the toolchanger and spindle alignment feedback etc.

Anyways I hope this is the right place for a build thread here as I am going to start posting that way. Here are some pictures of the machine progress thus far. I look forward sincerely to all of your input and ideas and help because I am quite sure I will need it. Peace

Please Log in or Create an account to join the conversation.

- PetefromTn

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 0

11 Mar 2013 20:33 - 11 Mar 2013 20:41 #31221

by PetefromTn

Replied by PetefromTn on topic Cincinatti Arrow 500 retrofit questions.....

Last edit: 11 Mar 2013 20:41 by PetefromTn.

Please Log in or Create an account to join the conversation.

- PetefromTn

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 0

11 Mar 2013 20:49 #31223

by PetefromTn

Replied by PetefromTn on topic Cincinatti Arrow 500 retrofit questions.....

Okay that worked, lets try some more....

That last picture is when I first got it home and powered up. Unfortunately it was very problematic electrically.

Here I am showing the teco motors and hitachi drives I bought for the machine.

Here I have the three drives installed into the electronics cabinet and you can see it is pretty empty now.

Here is my pendant panel pretty naked so far LOL

That last picture is when I first got it home and powered up. Unfortunately it was very problematic electrically.

Here I am showing the teco motors and hitachi drives I bought for the machine.

Here I have the three drives installed into the electronics cabinet and you can see it is pretty empty now.

Here is my pendant panel pretty naked so far LOL

Please Log in or Create an account to join the conversation.

- PetefromTn

- Offline

- Senior Member

-

Less

More

- Posts: 58

- Thank you received: 0

11 Mar 2013 20:52 #31224

by PetefromTn

Replied by PetefromTn on topic Cincinatti Arrow 500 retrofit questions.....

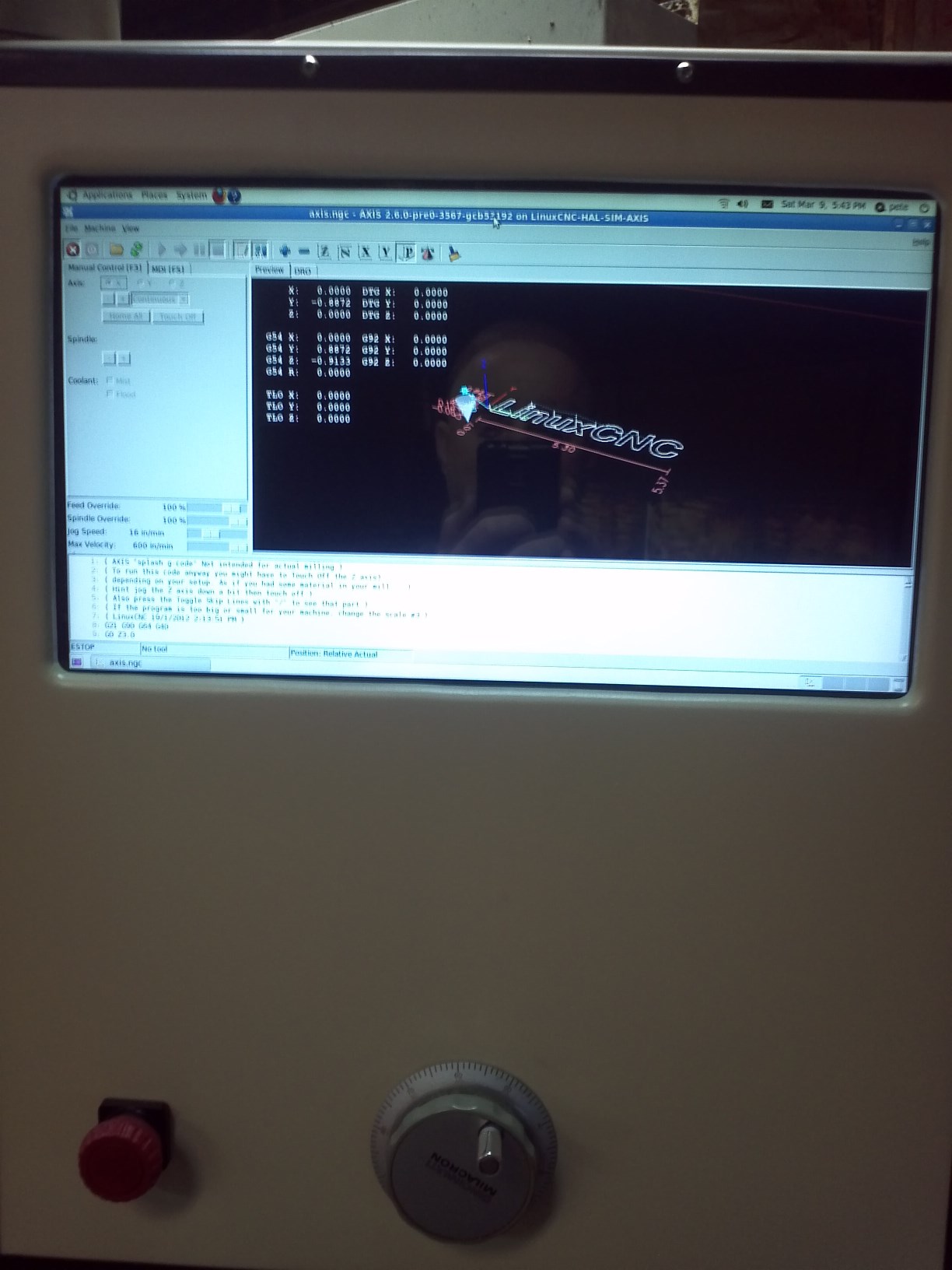

Some more pictures....

Here is the first mockup of the computer installed into the pendant enclosure.

Here it is finalized and wired up....

Here is the new monitor installed behind some lexan sealed inside the pendant panel

Here is the pendant with the computer finally booted up with linuxCNC...

Thats all I've got so far with the pictures more to come as I progress here....thanks guys. peace

Pete

Here is the first mockup of the computer installed into the pendant enclosure.

Here it is finalized and wired up....

Here is the new monitor installed behind some lexan sealed inside the pendant panel

Here is the pendant with the computer finally booted up with linuxCNC...

Thats all I've got so far with the pictures more to come as I progress here....thanks guys. peace

Pete

Please Log in or Create an account to join the conversation.

Time to create page: 0.348 seconds