Feed speed clarification please...

- Sterling

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 120

- Thank you received: 1

The router I've attached is the Bosch PR10E "Colt" Palm router. It's a 1HP motor, with a fixed spindle that turns at 35,000 RPM.

Is there a calculator /reference sheet handy to determine what the feed rate I ought to be using based on the type of wood/router bit?

I had thought it would be a simple reference chart, but nay. However, after multiple searches, I did find something that made sense to me =

An excerpt from THIS page is below =

Calculate the test FEED by:

multiplying the diameter of the bit (D) by 0.02 to determine the CHIP LOAD (2% chip load)

multiply the CHIP LOAD by the number of flutes (F) on the cutter you are testing to determine the TOTAL CHIP LOAD

multiply the TOTAL CHIP LOAD by the SPEED (RPM) to calculate the FEED

in other words, FEED = D X 0.02 X F X SPEED

For example, a good test FEED for a 1/4" dia. 2-flute cutter with a SPEED of 12,500 RPM would be:

0.250 in. X 0.02 X 2 (flutes) X 12,500 RPM = 125 Inches Per Minute (IPM)

If the above is correct; then using my router at 35,000 RPM, the feed rate I'd be putting down in my preamble would be F350.

Is that so?

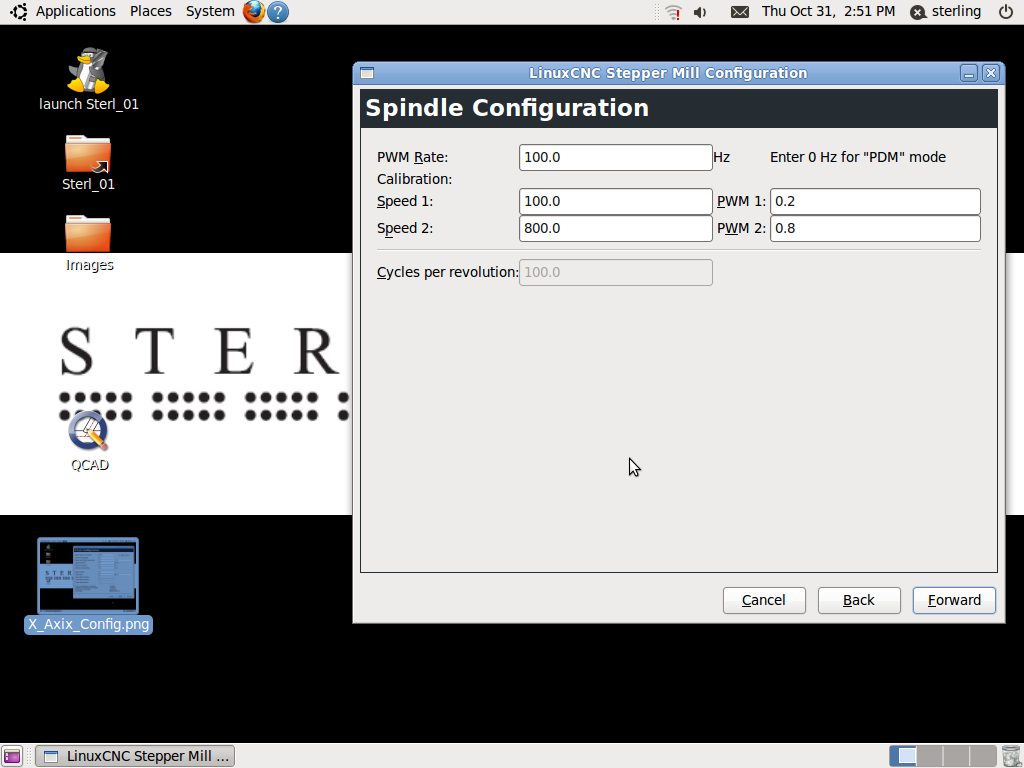

My stepper motors are three Xylotex 8s-3 units. I've pasted a screen shot of my Spindle Config screen =

So, based on this, will they go that fast? Is that what the 800 is for? Max speed? (Note; someone else set up the config, not me!)

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 6999

- Thank you received: 1176

There are two main things to consider when milling, SFM (Surface Feet per Minute) which is how fast the outer surface of the cutter or material in the case of a lathe is moving and chip load which is how much of a bite each toot takes for each cut. You don't say how many teeth your cutter has but less teeth means a slower feed rate.

For example from my feed speed spreadsheet

Tool Dia 0.25

Tooths 2

FPT 0.005

RPM 35000

IPM 350

SFM 2291JT

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 6999

- Thank you received: 1176

Please Log in or Create an account to join the conversation.

- Sterling

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 120

- Thank you received: 1

I'm using a 'double flute' bit (so that's "two teeth", right?)

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 6999

- Thank you received: 1176

If you use the switch on the router then no spindle related stuff is used by LinuxCNC.

I wonder if you can use a VFD on a router to slow it down?

What diameter is your cutter?

JT

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 23459

- Thank you received: 4990

I wonder if you can use a VFD on a router to slow it down?

Not normally, they tend to be "Universal" motors, basically a field-coil brush motor. They are basically DC motors (and the motors will run on DC, but the internal speed controller won't when they have one (and they generally do, nowadays)

If you wanted to have a CNC speed-controlled spindle then one of the Chinese spindle + VFD packages is probably the way to go.

This kind of thing (random example, top of the search in eBay, no recommendation should be inferred)

www.ebay.com/itm/1-5KW-AIR-COOLE-SPINDLE...ER-VFD-/250788776889

Please Log in or Create an account to join the conversation.

- Sterling

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 120

- Thank you received: 1

I usually use 1/8" & 1/4" bits (.125" & .25" respectivly)

Please Log in or Create an account to join the conversation.

- Sterling

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 120

- Thank you received: 1

I'll experemint with this today & hope I don't break anything important...

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

- Posts: 27

- Thank you received: 155

www.rockler.com/router-speed-control?utm...74xboCFUyd4AodzlwAiw

Rick G

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 6999

- Thank you received: 1176

A quote from Onsrud

Chipload is simply defined as the thickness of a chip which is formed during the machining of a material. Chipload is critical because if the chip is the proper size, the chip will carry away the heat promoting long tool life. If the chip is too small, the heat is transferred to the cutting tool causing prematurely dulling. Too high of a chipload will cause an unsatisfactory edge finish, or part movement.

Using the calculator from this page

At 35000 rpm with a 1/4" cutter your SFM is about 2300 and from the Onsrud link for hardwood their cutter have a 0.002" to 0.008" chip load. To get that much chip load at 35000 RPM your feed rate is 140 - 560 IPM.

A quote from a google search

I think most people would be surprised to learn that you can actually cut at much lower speeds than are typically used. With the 7518 in my router table, I typically keep it at 16,000 rpm for work with 1/2” bits, and even slower with larger bits. With smaller bits, you may need to spin a bit faster.

I’ve been running big CNC routers for over 10 years, and rpm and feedrate are calculated using a recommended chipload, which is the amount of material (size of chip) each tooth or flute removes. Unfortunately, most carbide tipped bit manufacturers won’t give you a chipload, but instead a max rpm, which is more for safety than cut quality.

The biggest enemy with carbide router bits is heat. Heat is what causes carbide tools to dull. The cooler you keep them while cutting, the longer they will last. You keep tools cool by increasing the chip load; taking the biggest bite per tooth that you can. There are two ways to do this. Increase the rate the your feeding material into the bit (or pushing the router through material), or lowering the rpm.

There is a trade off, though. As chip load increases, cut quality can suffer. If that happens, then increase the rpm until you get an acceptable quality of cut. If you use any higher rpm’s than that, you’re just decreasing the tool life.

As for burn marks, that’s typically a sign of a dull bit, or to many rpm’s. When the bit is spinning too fast, it takes very small cuts, and does more “rubbing” the wood than cutting it. This creates tremendous friction, which quickly caused dulling. Which leads to a vicious cycle of more burning. If you’re getting burning, try lowering the rpm, or pushing the bit through faster. If it still burns, you may need a sharper bit. Some woods, like maple, and especially cherry, are very prone to burning. Be sure to use very sharp bits with these woods for best results.

Bottom line, if you have a variable speed router, try using lower rpm’s. You may be surprised that your cuts are the same quality, your bits may last longer, and you also get the added benefit of much less noise.

JT

Please Log in or Create an account to join the conversation.