CHNC4 retrofit on the way.

- triumph406

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

27 Nov 2014 00:07 #53458

by triumph406

Replied by triumph406 on topic CHNC4 retrofit on the way.

My point was more that it isn't a _lot_ too weak.

This video shows it taking reasonable cuts on a moderately large piece of steel at a very low spindle speed:

Point taken, judging by your video, a 5hp motor and VFD would be more than adequate.

Please Log in or Create an account to join the conversation.

- Alloy Craft

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 1

27 Nov 2014 10:12 #53473

by Alloy Craft

Replied by Alloy Craft on topic CHNC4 retrofit on the way.

Your first order of business on this conversion is to check the servo amps to see if they work. If the axis work I would use them as is. There is no real good reason to upgrade to a newer amp unless yours are bad. especially the spindle drive as putting in a new motor and drive will require a lot of fab and wiring work. Also the torque developed by dc servo motors can be very good, the 5 hp dc servo motor on my CHNC is rated for 242 in lbs stall. A similar sized ac motor will generally generate less torque, especially at low spindle speeds. If you want to go over 200 ipm you would most likely need to do both servos and amps. On my CHNC retrofit I initially used the hi-aks and although they did work, they were slow. I eventually switched the drives and motors with 1kw ac servos.

Please Log in or Create an account to join the conversation.

- triumph406

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

27 Nov 2014 15:19 - 30 Nov 2014 04:36 #53474

by triumph406

If I get time I'm going to see if the Hi-aks are any good this week end.

Removing the large dc motor and pulling the plate out to mofiy for an AC would be a lot of work I agree.

As I don't genarally take on production work, I don't care about the 200ipm feedrate, the purported .0001 accuracy of a HNC/CHNC is the attraction.

According to identical items on ebay, the drive is an Inland Motor Drive System HPA03-158100-611-5306B35 and the motor is a Inland Motor TTBH-5306-425-8

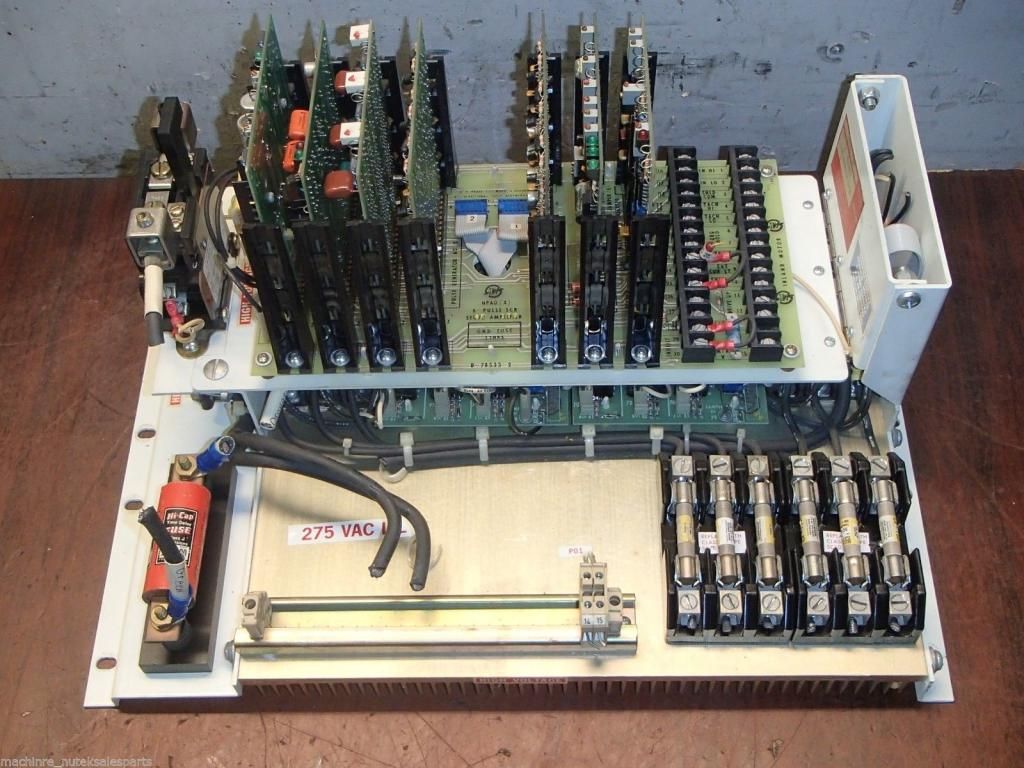

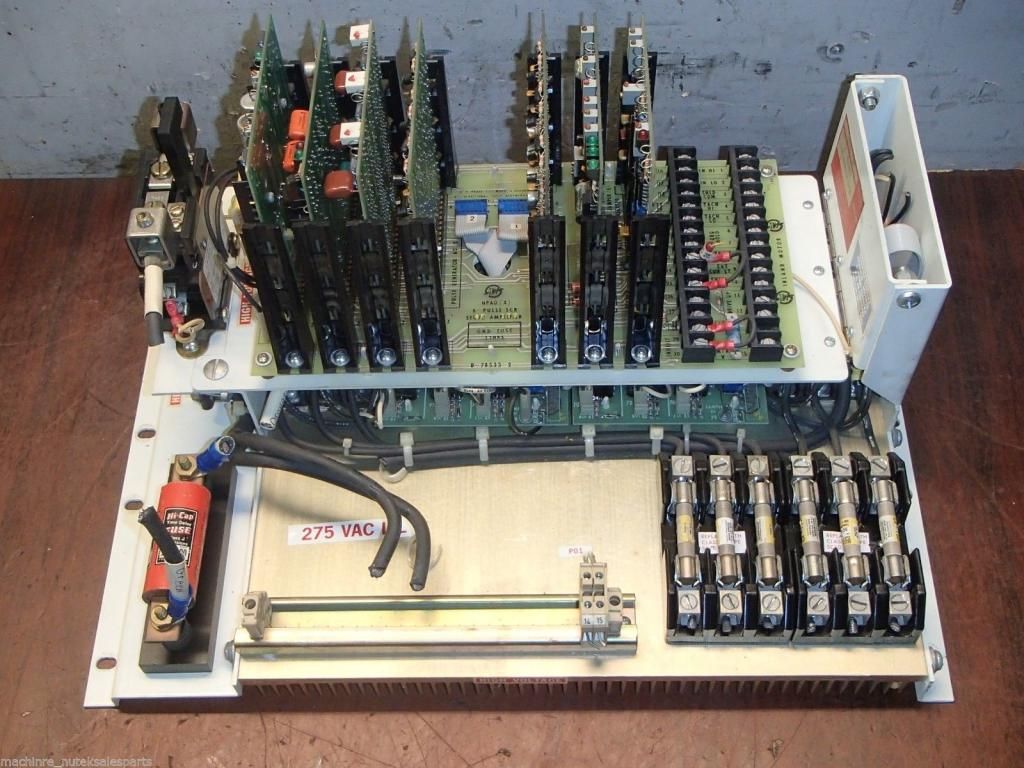

this is a picture of the servo drive (it's identical to the one in my CHNC4)

This is a picture of an identical, motor, the picture doesn't convey how big the motor is

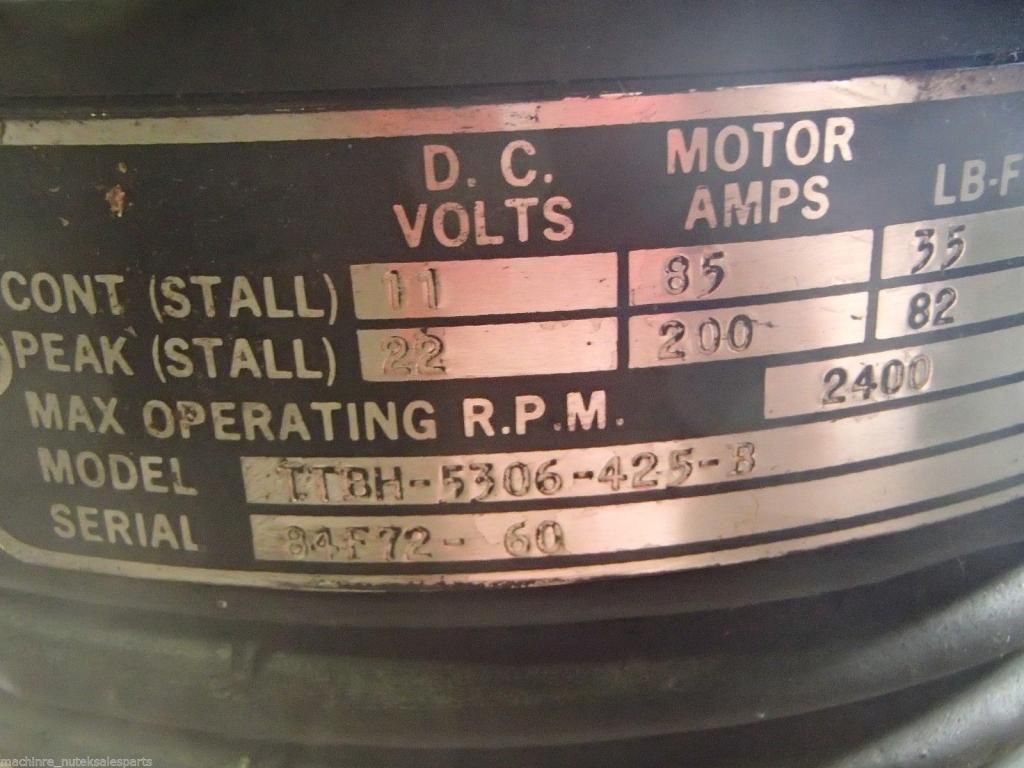

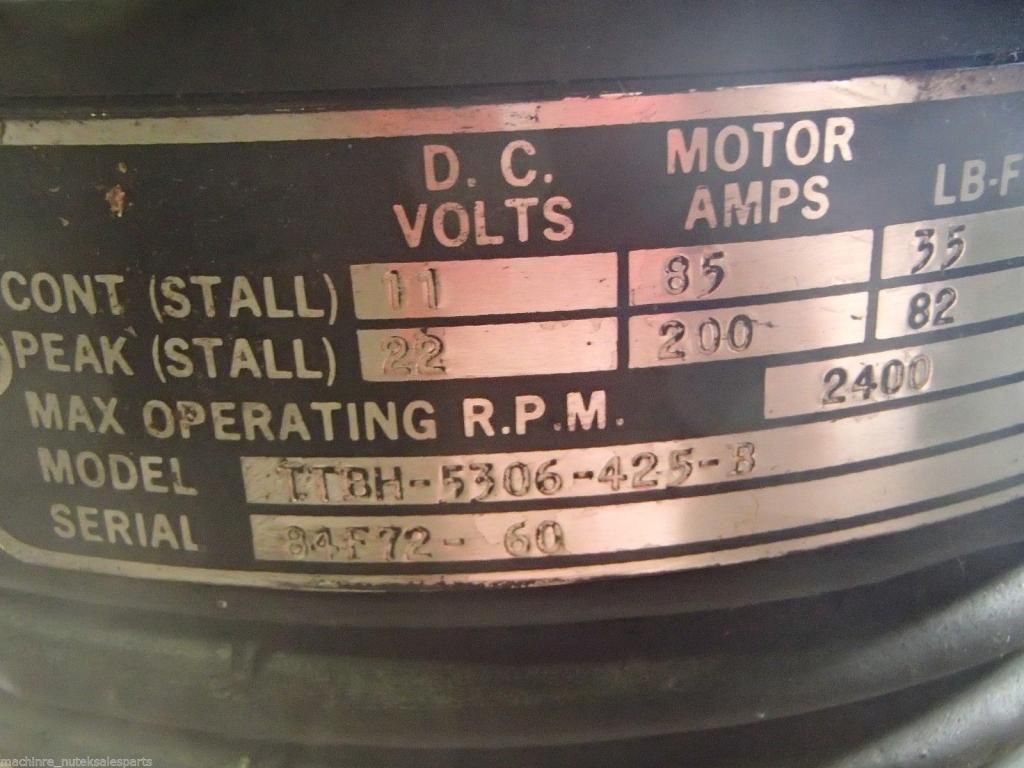

The motor spec plate

Replied by triumph406 on topic CHNC4 retrofit on the way.

Your first order of business on this conversion is to check the servo amps to see if they work. If the axis work I would use them as is. There is no real good reason to upgrade to a newer amp unless yours are bad. especially the spindle drive as putting in a new motor and drive will require a lot of fab and wiring work. Also the torque developed by dc servo motors can be very good, the 5 hp dc servo motor on my CHNC is rated for 242 in lbs stall. A similar sized ac motor will generally generate less torque, especially at low spindle speeds. If you want to go over 200 ipm you would most likely need to do both servos and amps. On my CHNC retrofit I initially used the hi-aks and although they did work, they were slow. I eventually switched the drives and motors with 1kw ac servos.

If I get time I'm going to see if the Hi-aks are any good this week end.

Removing the large dc motor and pulling the plate out to mofiy for an AC would be a lot of work I agree.

As I don't genarally take on production work, I don't care about the 200ipm feedrate, the purported .0001 accuracy of a HNC/CHNC is the attraction.

According to identical items on ebay, the drive is an Inland Motor Drive System HPA03-158100-611-5306B35 and the motor is a Inland Motor TTBH-5306-425-8

this is a picture of the servo drive (it's identical to the one in my CHNC4)

This is a picture of an identical, motor, the picture doesn't convey how big the motor is

The motor spec plate

Last edit: 30 Nov 2014 04:36 by triumph406.

Please Log in or Create an account to join the conversation.

- Alloy Craft

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 1

09 Dec 2014 11:00 #53840

by Alloy Craft

Replied by Alloy Craft on topic CHNC4 retrofit on the way.

It looks like my spindle drive is different than yours. Mine is a Ge hi-ak. My spindle motor is different as well. Do you have any documentation on that spindle drive?

Please Log in or Create an account to join the conversation.

- triumph406

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

10 Dec 2014 02:14 #53852

by triumph406

Is your spindle motor the Porter motor?

All the documentation I have is for the wrong control, I think who ever sold the CHNC4 to the people who I bought the machine from must have had a few CHNC's, as the threw in lots of documentation, lots of duplicates, I'm still trying to figure out what I have.

I have Hi-Ak servo boards for the X and Z, and documentation for a previuous iteration of Hi-Ak (I think)

If you tell me what the control is I could see if I have anything.

I've just recieved some manuals for the Inland motor HPA3 servo drive, I hope to test the drive this weekend. I was warned the caps may need replacing though. If I keep the drive I might pull the boards and replace all the caps.

Replied by triumph406 on topic CHNC4 retrofit on the way.

It looks like my spindle drive is different than yours. Mine is a Ge hi-ak. My spindle motor is different as well. Do you have any documentation on that spindle drive?

Is your spindle motor the Porter motor?

All the documentation I have is for the wrong control, I think who ever sold the CHNC4 to the people who I bought the machine from must have had a few CHNC's, as the threw in lots of documentation, lots of duplicates, I'm still trying to figure out what I have.

I have Hi-Ak servo boards for the X and Z, and documentation for a previuous iteration of Hi-Ak (I think)

If you tell me what the control is I could see if I have anything.

I've just recieved some manuals for the Inland motor HPA3 servo drive, I hope to test the drive this weekend. I was warned the caps may need replacing though. If I keep the drive I might pull the boards and replace all the caps.

Please Log in or Create an account to join the conversation.

Time to create page: 0.119 seconds