DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

- ROB-CNC

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

02 Apr 2015 02:42 - 17 Mar 2016 18:38 #57407

by ROB-CNC

DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10 was created by ROB-CNC

Hello all,

I've been building a heavy, rigid 5x10ft CNC mill/router which is almost completed just need to finish up the electrical panel and a couple other minor things (I will post pictures and perhaps some videos when the machine is completed and it is running).

I am planning to use (already purchased) DMM Technology Dyn4 servo drives and servo motors (all 1.3kW) for XYZ (A axis will be added later on). I will be interfacing to the Mesa 5i25 + 7i77 "plug n go kit". I really like the build quality of both the DMM servos and Mesa hardware...It's very professional hardware and I feel like this combination with LinuxCNC will make a nice CNC control.

DMM DYN4

DMM DYN4 Manual

I have wired the Dyn4 JP4 encoder outs to the 7i77 board, it was all pretty straight forward.

The trouble I am having is understanding certain pin-outs from the Dyn4 JP4 i/o and wiring them to the 7i77 board.

Are the ENA+, ENA-, AIN+, AIN- the only pins required to run the drives with the 7i77?

I would like to take advantage of other features of the Dyn4 (Current monitoring, Position error monitoring, Absolute encoder home etc..) is it as simple as using up some inputs on the 7i77 board?

I have made a pin-out chart for the Dyn4 and 7i77. Please see the attachment and advise me on the correct pins.

I have built a few machines but they were all controlled by industrial controllers or Mach3 (which I dislike for various reasons...easy to work with though). Although I am new to LinuxCNC I can already see how customizable it is and very open to most hardware. I plan to use LinuxCNC on all future machine builds.

Thanks guys, all and any information is greatly appreciated!

Rob

I've been building a heavy, rigid 5x10ft CNC mill/router which is almost completed just need to finish up the electrical panel and a couple other minor things (I will post pictures and perhaps some videos when the machine is completed and it is running).

I am planning to use (already purchased) DMM Technology Dyn4 servo drives and servo motors (all 1.3kW) for XYZ (A axis will be added later on). I will be interfacing to the Mesa 5i25 + 7i77 "plug n go kit". I really like the build quality of both the DMM servos and Mesa hardware...It's very professional hardware and I feel like this combination with LinuxCNC will make a nice CNC control.

DMM DYN4

DMM DYN4 Manual

I have wired the Dyn4 JP4 encoder outs to the 7i77 board, it was all pretty straight forward.

The trouble I am having is understanding certain pin-outs from the Dyn4 JP4 i/o and wiring them to the 7i77 board.

Are the ENA+, ENA-, AIN+, AIN- the only pins required to run the drives with the 7i77?

I would like to take advantage of other features of the Dyn4 (Current monitoring, Position error monitoring, Absolute encoder home etc..) is it as simple as using up some inputs on the 7i77 board?

I have made a pin-out chart for the Dyn4 and 7i77. Please see the attachment and advise me on the correct pins.

I have built a few machines but they were all controlled by industrial controllers or Mach3 (which I dislike for various reasons...easy to work with though). Although I am new to LinuxCNC I can already see how customizable it is and very open to most hardware. I plan to use LinuxCNC on all future machine builds.

Thanks guys, all and any information is greatly appreciated!

Rob

Last edit: 17 Mar 2016 18:38 by ROB-CNC.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

02 Apr 2015 03:51 #57409

by Todd Zuercher

Replied by Todd Zuercher on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

I think you would connect your +voltage source from the drive to the ENA+ on the 7i77, then connect the 7i77 ENA- to the ENA input on the drive. It's best to just think of the Enable output on the 7i77 as just a switch. (One where the polarity matters though!)

The enables, the analog connection, and what ever position feed back your using should be all the 7i77 needs.

The enables, the analog connection, and what ever position feed back your using should be all the 7i77 needs.

The following user(s) said Thank You: ROB-CNC

Please Log in or Create an account to join the conversation.

- ROB-CNC

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

02 Apr 2015 05:08 - 17 Mar 2016 18:41 #57411

by ROB-CNC

Replied by ROB-CNC on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

Hi Todd,

Well that really clears it up. I may have been over thinking it, it now makes perfect sense.

I will finish wiring up the 7i77 with only the basic necessary signals to test axis movement. I would like to eventually integrate some of the Dyn4 extra features after I get the machine running.

Also, the way I have the encoders wired now are Dyn4 JP5 encoder out, I feel this is the way it was meant to be wired. Is it better to run the encoder straight to the 7i77 then split back to the drive?

Any advantages , disadvantages , or not even possible?

Sorry if my questions are very basic or have been answered many times before. I just want to make sure I am doing it right.

Much Thanks!

Well that really clears it up. I may have been over thinking it, it now makes perfect sense.

I will finish wiring up the 7i77 with only the basic necessary signals to test axis movement. I would like to eventually integrate some of the Dyn4 extra features after I get the machine running.

Also, the way I have the encoders wired now are Dyn4 JP5 encoder out, I feel this is the way it was meant to be wired. Is it better to run the encoder straight to the 7i77 then split back to the drive?

Any advantages , disadvantages , or not even possible?

Sorry if my questions are very basic or have been answered many times before. I just want to make sure I am doing it right.

Much Thanks!

Last edit: 17 Mar 2016 18:41 by ROB-CNC.

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 22

02 Apr 2015 08:20 #57413

by alan_3301

Replied by alan_3301 on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

the encoders communicate through a serial line to the drives, no easy way to connect them directly to LinuxCNC.

Doesn't matter though, it's not necessary or recommended.

The encoders go straight to the dyn4, and the JP5 encoder output connection on the drive goes to linuxcnc.

This can be scaled as necessary using pulse_num as described in section 4.5 of the docs.

The dyn4 docs look better than the dyn3, I was banging my head for a long time due to missing info, and misprints.

They are a good value though.

Doesn't matter though, it's not necessary or recommended.

The encoders go straight to the dyn4, and the JP5 encoder output connection on the drive goes to linuxcnc.

This can be scaled as necessary using pulse_num as described in section 4.5 of the docs.

The dyn4 docs look better than the dyn3, I was banging my head for a long time due to missing info, and misprints.

They are a good value though.

The following user(s) said Thank You: ROB-CNC

Please Log in or Create an account to join the conversation.

- ROB-CNC

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

03 Apr 2015 01:24 - 17 Mar 2016 18:31 #57448

by ROB-CNC

Replied by ROB-CNC on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

Thanks Alan.

I'm reading the Dyn4 manual over and over and I am finally beginning to understand most stuff in there.

The Dyn4 so far seem to be rock solid servo's. I've used Yaskawa sigma 5 servos on other machines and I feel the dyn4 will prove themselves to be a good replacement.

So you have Dyn3 servos on your machine? If so, how do you like them? Smooth motion, reliable? easy to work with?

I'm reading the Dyn4 manual over and over and I am finally beginning to understand most stuff in there.

The Dyn4 so far seem to be rock solid servo's. I've used Yaskawa sigma 5 servos on other machines and I feel the dyn4 will prove themselves to be a good replacement.

So you have Dyn3 servos on your machine? If so, how do you like them? Smooth motion, reliable? easy to work with?

Last edit: 17 Mar 2016 18:31 by ROB-CNC.

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 22

03 Apr 2015 01:30 #57449

by alan_3301

Replied by alan_3301 on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

I am building a lathe using delta servos for X and Z, with a dyn3 running spindle servo motor.

The deltas took all of 10 minutes to setup.

The DMM I am still working on, haven't had it running yet.

The dyn3 doesnt have error or current monitoring that I know of, there I/O on the drive is literally bare minimum.

The dyn4 looks a lot more like an industrial drive, as far as I/O and features.

The deltas took all of 10 minutes to setup.

The DMM I am still working on, haven't had it running yet.

The dyn3 doesnt have error or current monitoring that I know of, there I/O on the drive is literally bare minimum.

The dyn4 looks a lot more like an industrial drive, as far as I/O and features.

Please Log in or Create an account to join the conversation.

- ROB-CNC

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

23 May 2015 06:19 - 17 Mar 2016 18:25 #58943

by ROB-CNC

Replied by ROB-CNC on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

Hey guys,

I have been quite busy with the day job and have only had a few hours to work on the machine. Progress is slow but good. I have more time to work on it for the remainder of the month as work has slowed down .

The servos are responding to the analog signal from the 7i77 and they seem to run quite nicely. The electrical panel is about 90% finished and coming along nicely. Finished the e-stop circuit, it is controlled with a Pilz Pnoz X9P safety relay as well as Linuxcnc.

A problem that I am having and can't seem to figure out what it is I am doing wrong is that all drives seem to be constantly enabled and I can run the servos even when there is no enable signal present (enable wire removed from 7i77).

I have wired the enable just as the Dyn4 manual suggests and also the way it is described in the 7i77 manual.

The drive Enable is Active high so I wired it as the 7i77 manual suggest, ENAN+to main 24vdc, ENAN- to drive ENABLE input.

I know that the 7i77 enable out is working as it should because when linuxcnc is not running the measured voltage to ENAN- is 13.3V and when enable signal is sent from Pncconfig or Linuxcnc it measures 24V.

Any suggestions?

I have been quite busy with the day job and have only had a few hours to work on the machine. Progress is slow but good. I have more time to work on it for the remainder of the month as work has slowed down .

The servos are responding to the analog signal from the 7i77 and they seem to run quite nicely. The electrical panel is about 90% finished and coming along nicely. Finished the e-stop circuit, it is controlled with a Pilz Pnoz X9P safety relay as well as Linuxcnc.

A problem that I am having and can't seem to figure out what it is I am doing wrong is that all drives seem to be constantly enabled and I can run the servos even when there is no enable signal present (enable wire removed from 7i77).

I have wired the enable just as the Dyn4 manual suggests and also the way it is described in the 7i77 manual.

The drive Enable is Active high so I wired it as the 7i77 manual suggest, ENAN+to main 24vdc, ENAN- to drive ENABLE input.

I know that the 7i77 enable out is working as it should because when linuxcnc is not running the measured voltage to ENAN- is 13.3V and when enable signal is sent from Pncconfig or Linuxcnc it measures 24V.

Any suggestions?

Last edit: 17 Mar 2016 18:25 by ROB-CNC.

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 22

23 May 2015 07:59 #58944

by alan_3301

Replied by alan_3301 on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

For some reason they thought it was a good idea to default to enabled.

I was very frustrated with the dyn3 that I was trying to configure and ended up taking it off, I'm shopping for a delta to replace it right now.

Anyways...

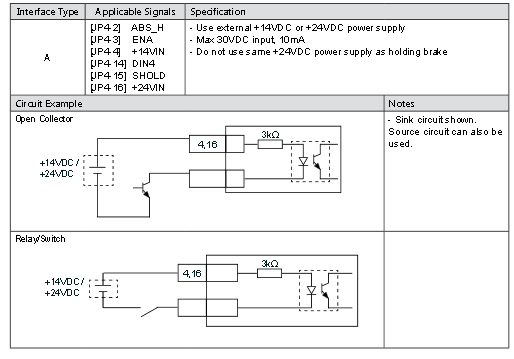

In the dyn4 manual it looks like you need to wire field power 24v to jp4 pin 16 (+24VIN)

then field ground would be supplied to JP4 pin 3 to enable. (or would that be a disable input????)

it shows this as a sinking input circuit.

it says a sourcing input circuit may be used, but of course no example. It may be obvious for electrical engineers, but I want something showing me exactly how NOT to fry the input.

I would try wiring field ground to ENAN+, with field power wired to jp4 pin 16.

If you need it, they have ok email support lately. I usually get a response within a day.

I was very frustrated with the dyn3 that I was trying to configure and ended up taking it off, I'm shopping for a delta to replace it right now.

Anyways...

In the dyn4 manual it looks like you need to wire field power 24v to jp4 pin 16 (+24VIN)

then field ground would be supplied to JP4 pin 3 to enable. (or would that be a disable input????)

it shows this as a sinking input circuit.

it says a sourcing input circuit may be used, but of course no example. It may be obvious for electrical engineers, but I want something showing me exactly how NOT to fry the input.

I would try wiring field ground to ENAN+, with field power wired to jp4 pin 16.

If you need it, they have ok email support lately. I usually get a response within a day.

The following user(s) said Thank You: ROB-CNC

Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

Less

More

- Posts: 136

- Thank you received: 22

23 May 2015 08:12 #58945

by alan_3301

Replied by alan_3301 on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

I guess I wasn't completely clear. scratch my last suggestion.

What makes sense to me is:

Field ground to 7i77 ENAN-

7i77 ENAN+ to DYN4 JP4 pin 3 (enable input)

Field power to DYN4 JP4 pin 16 (EXT +24V IN)

What makes sense to me is:

Field ground to 7i77 ENAN-

7i77 ENAN+ to DYN4 JP4 pin 3 (enable input)

Field power to DYN4 JP4 pin 16 (EXT +24V IN)

The following user(s) said Thank You: ROB-CNC

Please Log in or Create an account to join the conversation.

- ROB-CNC

- Offline

- New Member

-

Less

More

- Posts: 19

- Thank you received: 0

23 May 2015 08:41 - 17 Mar 2016 18:20 #58946

by ROB-CNC

Replied by ROB-CNC on topic DMM DYN 4 servos + Mesa 5i25 & 7i77 XYZ+A Cnc 5x10

Hi Alan,

I definitely understand your frustration with getting the dyn3 to run, It has been somewhat a struggle for me too in order to get the dyn4 servos to spin. With the Yaskawa's I had previously they were easy to configure... the dyn4 manuals are lacking info and are really hard to understand... really unclear at times.

I will go ahead and wire the drive up the way you suggest and report back... Thanks.

I definitely understand your frustration with getting the dyn3 to run, It has been somewhat a struggle for me too in order to get the dyn4 servos to spin. With the Yaskawa's I had previously they were easy to configure... the dyn4 manuals are lacking info and are really hard to understand... really unclear at times.

I will go ahead and wire the drive up the way you suggest and report back... Thanks.

Last edit: 17 Mar 2016 18:20 by ROB-CNC.

Please Log in or Create an account to join the conversation.

Time to create page: 0.215 seconds