Okuma lathe conversion.

- timewarp

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

03 Oct 2015 04:33 #63383

by timewarp

Okuma lathe conversion. was created by timewarp

Hi, Paul here on Vancouver Island. I recently bought an Okuma lnc8 that ended up having significant damage to the spindle drive and servo drive boards.

I have been exploring retrofitting the lathe with linuxcnc and will probably go ahead with the conversion. I am heading to a repair facility tomorrow in Vancouver to cost new/repaired boards.

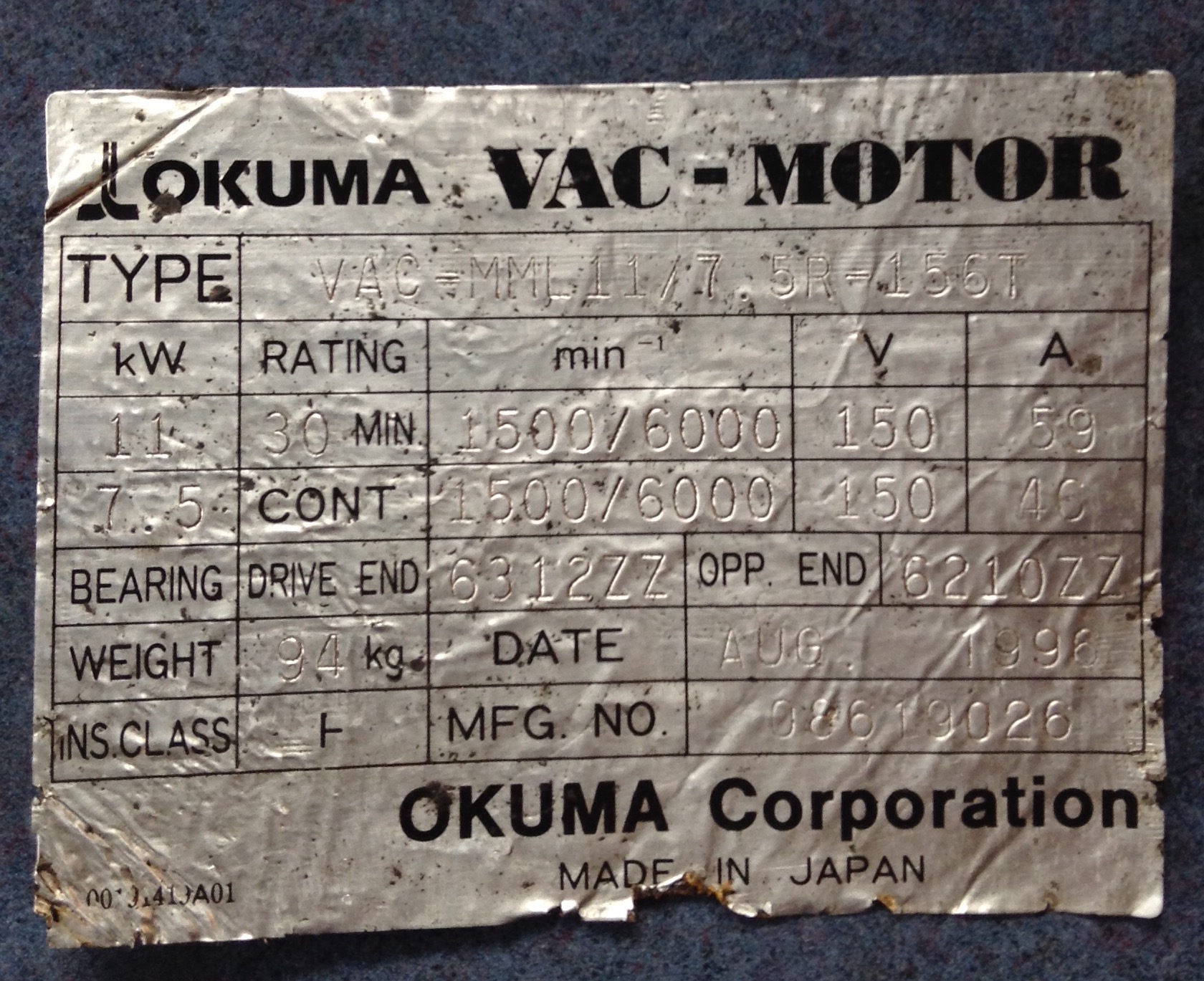

I am lucky to have a board member about an hour south who has looked at wiring diagrams with me and been really helpful. The spindle motor is some kind of AC Motor, I might be able to run it with a vfd. I will try and get more info tomorrow.

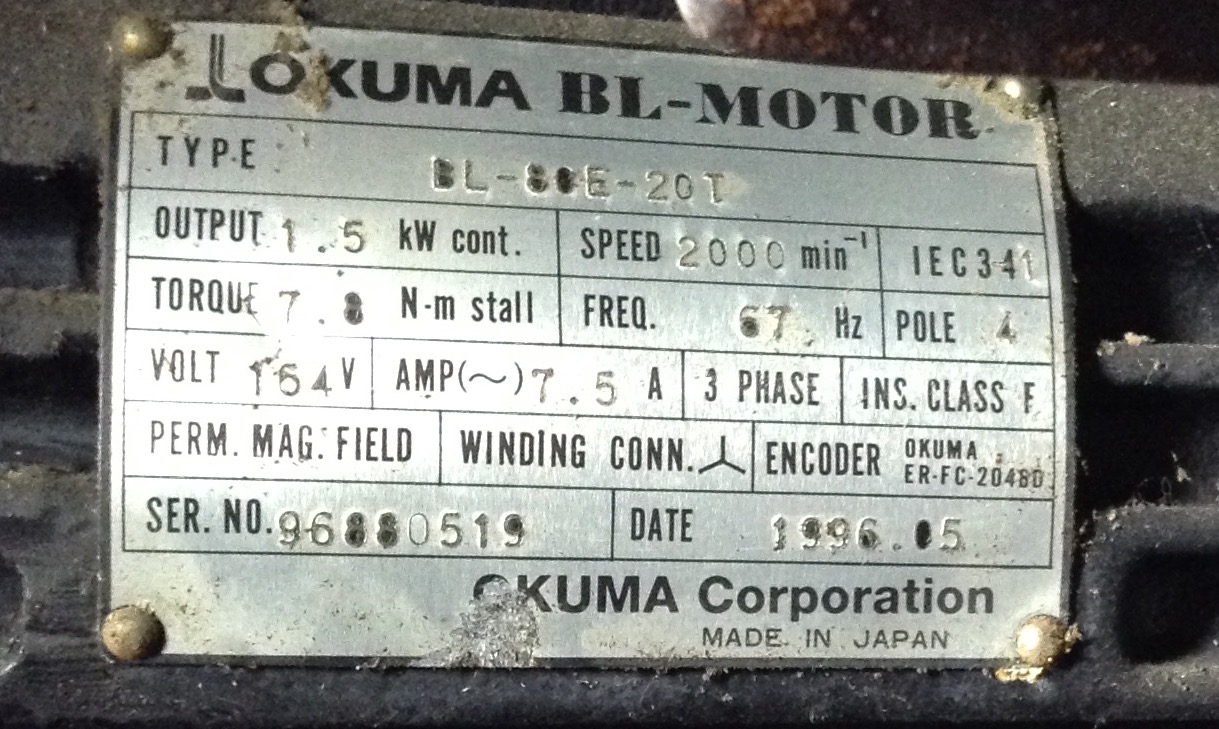

Servos seem to be proprietary to Okuma with a serial encoder. The servo drive may be repairable, but I am not sure (unlikely) that linuxcnc will talk to the drive. So I may be shopping for new servos and drives. Hopefully I might be able to sell some of the old components.

Honestly I am kind of sitting on the fence right now. It is tempting to just pay for new boards and get the machine running, but not cheap. Also I don't know the full extent of the problems. Plus the control does not have usb file transfer!

I am really new to linuxcnc so please do not hesitate to give advice.

Thanks, Paul

I have been exploring retrofitting the lathe with linuxcnc and will probably go ahead with the conversion. I am heading to a repair facility tomorrow in Vancouver to cost new/repaired boards.

I am lucky to have a board member about an hour south who has looked at wiring diagrams with me and been really helpful. The spindle motor is some kind of AC Motor, I might be able to run it with a vfd. I will try and get more info tomorrow.

Servos seem to be proprietary to Okuma with a serial encoder. The servo drive may be repairable, but I am not sure (unlikely) that linuxcnc will talk to the drive. So I may be shopping for new servos and drives. Hopefully I might be able to sell some of the old components.

Honestly I am kind of sitting on the fence right now. It is tempting to just pay for new boards and get the machine running, but not cheap. Also I don't know the full extent of the problems. Plus the control does not have usb file transfer!

I am really new to linuxcnc so please do not hesitate to give advice.

Thanks, Paul

Please Log in or Create an account to join the conversation.

- LearningLinuxCNC

-

- Offline

- Elite Member

-

Less

More

- Posts: 226

- Thank you received: 39

03 Oct 2015 19:25 #63390

by LearningLinuxCNC

Replied by LearningLinuxCNC on topic Okuma lathe conversion.

Paul,

Looks like it will be a good machine and a fun project.

I recently converted my mill from Fanuc controls to LinuxCNC. I had to deal with the same question as to replace the old boards with "new" old boards or retrofit. I chose to retrofit. It was a fun process. It does take a while, three months for me working on it in my spare time. If you have good wiring diagrams it will help a lot. I was fortunate to have most of the wiring diagrams for my machine.

Do you plan on keeping the existing servo amplifier/drives? If so you might find out how the encoders are connected to the existing control system. If they connect to the servo amp/drive then the drive may give simple quadrature signal back to the main control board. Otherwise there is a possibility that there is a converter for the serial encoder.

Anyway let us know what you decide and keep the tread going with the retrofit if/when you decide to go that route.

Jim

Looks like it will be a good machine and a fun project.

I recently converted my mill from Fanuc controls to LinuxCNC. I had to deal with the same question as to replace the old boards with "new" old boards or retrofit. I chose to retrofit. It was a fun process. It does take a while, three months for me working on it in my spare time. If you have good wiring diagrams it will help a lot. I was fortunate to have most of the wiring diagrams for my machine.

Do you plan on keeping the existing servo amplifier/drives? If so you might find out how the encoders are connected to the existing control system. If they connect to the servo amp/drive then the drive may give simple quadrature signal back to the main control board. Otherwise there is a possibility that there is a converter for the serial encoder.

Anyway let us know what you decide and keep the tread going with the retrofit if/when you decide to go that route.

Jim

Please Log in or Create an account to join the conversation.

- marcellanz01

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

06 Oct 2015 01:23 #63454

by marcellanz01

Replied by marcellanz01 on topic Okuma lathe conversion.

Hi Gents,

I have a OKUMA LB15 of 1985 still working with the original OSP 5000 controller.

Okuma makes wonderful machines, very heavy and dead reliable.

I converted myself a Maho MH700C (cnc) mill into linuxcnc because of the outdated programming methods in hardware and software as well.

The Okuma LB15 with the OSP 5000 LG controller is equipped with IGF (this is programming via drawing method like you do today in CAD/CAM software).

The Okuma controllers are very good designed in general and I am not convinced yet that the LCNC can compete with it.

But as soon as my controller hardware is giving up, I decided already to switch over to Lcnc.

But some practical problems will appear very quickly.

First Okuma uses absolute encoders instead of incremental. They work with Gray codes. So multiple lines are available in parallel for the counters.

No homing is necessary, only an offset parameter will be needed to program the zero of the axis.

Now, replacing the encoders is probably the best option. Good advice use 0.5um encoders.

Many Okumas are using FANUC drives and motors. They are also very good but they work with strange voltages. So a lot of transformers are used in the machine.

I have no glue what to do in case of a drive or motor failure.

In case somebody has suggestions, feel free...

Anyway I am convinced that retrofitting a Okuma is worth the money and the energy.

So I am eager how you will proceed and in case you have schematics of your machine available I would like to see them and compare them with the LB15.

It seems that your lathe is working with the OSP 100?

Kind regards,

Noach

I have a OKUMA LB15 of 1985 still working with the original OSP 5000 controller.

Okuma makes wonderful machines, very heavy and dead reliable.

I converted myself a Maho MH700C (cnc) mill into linuxcnc because of the outdated programming methods in hardware and software as well.

The Okuma LB15 with the OSP 5000 LG controller is equipped with IGF (this is programming via drawing method like you do today in CAD/CAM software).

The Okuma controllers are very good designed in general and I am not convinced yet that the LCNC can compete with it.

But as soon as my controller hardware is giving up, I decided already to switch over to Lcnc.

But some practical problems will appear very quickly.

First Okuma uses absolute encoders instead of incremental. They work with Gray codes. So multiple lines are available in parallel for the counters.

No homing is necessary, only an offset parameter will be needed to program the zero of the axis.

Now, replacing the encoders is probably the best option. Good advice use 0.5um encoders.

Many Okumas are using FANUC drives and motors. They are also very good but they work with strange voltages. So a lot of transformers are used in the machine.

I have no glue what to do in case of a drive or motor failure.

In case somebody has suggestions, feel free...

Anyway I am convinced that retrofitting a Okuma is worth the money and the energy.

So I am eager how you will proceed and in case you have schematics of your machine available I would like to see them and compare them with the LB15.

It seems that your lathe is working with the OSP 100?

Kind regards,

Noach

Please Log in or Create an account to join the conversation.

- timewarp

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

06 Oct 2015 02:11 #63457

by timewarp

Replied by timewarp on topic Okuma lathe conversion.

Noach,

I went to the Cnc repair facility on Saturday. I am sure he could repair or replace any okma problems you might have. He also has some good ideas to prevent catastrophic failure. It looks like i could replace some drives and hav a running machine in short order. I also don't have igf. I think if i could run the servos with linuxcnc it would be an easy decision. Cncrepair.ca

Paul

I went to the Cnc repair facility on Saturday. I am sure he could repair or replace any okma problems you might have. He also has some good ideas to prevent catastrophic failure. It looks like i could replace some drives and hav a running machine in short order. I also don't have igf. I think if i could run the servos with linuxcnc it would be an easy decision. Cncrepair.ca

Paul

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

06 Oct 2015 21:57 #63498

by andypugh

Mesa has firmware support for certain types of absolute encoders.

www.linuxcnc.org/docs/html/man/man9/hostmot2.9.html#Synchronous Serial Interface (SSI)

Replied by andypugh on topic Okuma lathe conversion.

First Okuma uses absolute encoders instead of incremental. They work with Gray codes. So multiple lines are available in parallel for the counters.

No homing is necessary, only an offset parameter will be needed to program the zero of the axis.

Now, replacing the encoders is probably the best option. Good advice use 0.5um encoders.

Mesa has firmware support for certain types of absolute encoders.

www.linuxcnc.org/docs/html/man/man9/hostmot2.9.html#Synchronous Serial Interface (SSI)

Please Log in or Create an account to join the conversation.

- timewarp

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

06 Oct 2015 23:51 #63508

by timewarp

Replied by timewarp on topic Okuma lathe conversion.

If I could figure out how to reuse the servos, either with the drives or with different drives that would my first choice. Is replacing the encoders an option?

2nd choice would be selling the drives and motors and finding suitable replacement servos that are easier to drive.

I do own a DSO, but really dont know how to use it to do anything useful.

2nd choice would be selling the drives and motors and finding suitable replacement servos that are easier to drive.

I do own a DSO, but really dont know how to use it to do anything useful.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

07 Oct 2015 05:31 #63521

by andypugh

The drives probably take a +/- 10V input, and handle the encoder internally. If they do, then you may be (almost) home and dry.

Replied by andypugh on topic Okuma lathe conversion.

If I could figure out how to reuse the servos, either with the drives or with different drives that would my first choice.

The drives probably take a +/- 10V input, and handle the encoder internally. If they do, then you may be (almost) home and dry.

Please Log in or Create an account to join the conversation.

- timewarp

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

07 Oct 2015 06:14 #63524

by timewarp

Replied by timewarp on topic Okuma lathe conversion.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

Less

More

- Posts: 19815

- Thank you received: 4614

07 Oct 2015 17:11 #63533

by andypugh

Replied by andypugh on topic Okuma lathe conversion.

It is starting to look not 100% trivial...

It looks like sin/cos encoders converted to a serial data format by the OSP700L board. That also seems to create 3 commutation signals (COMA1, COMB1, COMC1)

That diagram doesn't seem to show where the motion controller connects to the servo amplifier?

It looks like sin/cos encoders converted to a serial data format by the OSP700L board. That also seems to create 3 commutation signals (COMA1, COMB1, COMC1)

That diagram doesn't seem to show where the motion controller connects to the servo amplifier?

Please Log in or Create an account to join the conversation.

- timewarp

- Offline

- Junior Member

-

Less

More

- Posts: 21

- Thank you received: 1

08 Oct 2015 03:03 #63555

by timewarp

Replied by timewarp on topic Okuma lathe conversion.

I think I am going to look for new servos with usable encoders as the motors and drives probably have some value.

Is there a standard for servo motor mounts (Nema?) Bolt pattern looks to be about 150mm.

Are all Fanuc Red cap motors usable with the pico adapter?

Here is the Servo I have.

When looking for a new servo What is the most important to look for? Output,torque,rpm?

Just ordered some mesa cards - 5i25, 7i77, 7i69

Thanks again, Paul

Is there a standard for servo motor mounts (Nema?) Bolt pattern looks to be about 150mm.

Are all Fanuc Red cap motors usable with the pico adapter?

Here is the Servo I have.

When looking for a new servo What is the most important to look for? Output,torque,rpm?

Just ordered some mesa cards - 5i25, 7i77, 7i69

Thanks again, Paul

Please Log in or Create an account to join the conversation.

Time to create page: 0.202 seconds