Shizuoka AN-S Retrofit Advice Needed

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

09 Oct 2015 03:01 #63587

by Dale Lusby

Shizuoka AN-S Retrofit Advice Needed was created by Dale Lusby

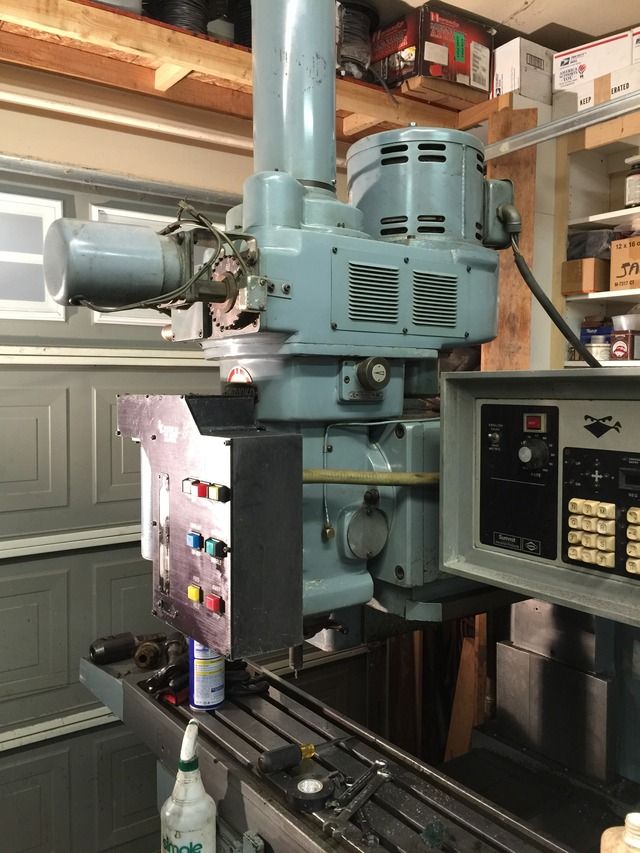

I recently acquired a Shizuoka AN-S milling machine with the intent on converting to LinuxCNC. It has stepper motors, Bandit controller as well as tool change and variable speed change. I hooked it up to see what all is working and currently I have Y axis function while Z and X perform the jitterbug dance as their boards aren't working correctly. I did take the driver from the Y axis and connected it to the other two axis to verify the motors are working. I also programmed some code to check the motor and tool changer. The main spindle motor works good and the tool changer functions with regards to removal and reinstallation of the tool but currently there is an issue with the carousel not rotating.

So that said I am looking at purchasing some drivers, breakout board and setting it up with a dedicated computer. I looked at the Geckodrives and they have a limit of 7 amps while the motor tag says 9.2 amps. I did see a tag inside the Bandit that was attached to the driver that says it is set to 5.5 amps/phase max currently. So will the geckodrive work? If not what would be another alternative as the max amps for any Gecko is 7.

My plan currently is to start to purchase the components and bit by bit get this machine up and running. I was very pleasantly surprised to see the mechanical aspects of the machine are in great condition. Ways look nearly new as if ground and the spindle sounds good. I know others have done similar machines so hoping to cut through a lot of the learning curve by using experience gained before me. Also as a side I have been scouring the internet and reading every post I can find on the subject matter but even still I've never done this so there is a lot of newbie'ness here.

Pictures soon to follow

Dale

So that said I am looking at purchasing some drivers, breakout board and setting it up with a dedicated computer. I looked at the Geckodrives and they have a limit of 7 amps while the motor tag says 9.2 amps. I did see a tag inside the Bandit that was attached to the driver that says it is set to 5.5 amps/phase max currently. So will the geckodrive work? If not what would be another alternative as the max amps for any Gecko is 7.

My plan currently is to start to purchase the components and bit by bit get this machine up and running. I was very pleasantly surprised to see the mechanical aspects of the machine are in great condition. Ways look nearly new as if ground and the spindle sounds good. I know others have done similar machines so hoping to cut through a lot of the learning curve by using experience gained before me. Also as a side I have been scouring the internet and reading every post I can find on the subject matter but even still I've never done this so there is a lot of newbie'ness here.

Pictures soon to follow

Dale

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

09 Oct 2015 03:13 #63588

by Dale Lusby

Replied by Dale Lusby on topic Shizuoka AN-S Retrofit Advice Needed

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

09 Oct 2015 03:16 #63589

by Dale Lusby

Replied by Dale Lusby on topic Shizuoka AN-S Retrofit Advice Needed

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

09 Oct 2015 03:17 - 09 Oct 2015 03:23 #63590

by Dale Lusby

Replied by Dale Lusby on topic Shizuoka AN-S Retrofit Advice Needed

I have had the machine for a week and mostly have been cleaning it up and trying to see what condition it's in. I was happy to see some of it working. As soon as I figure out if the gecko's will work and if not which I should go with I'll be getting them ordered. Also if anyone knows if the power supply that's in the machine will work that would save a little. Thanks ahead for any help you can provide. I'll do my best to document this so others can resource back to it. I'll see about getting some videos onto YouTube so you can see what it currently can do.

Dale

Dale

Last edit: 09 Oct 2015 03:23 by Dale Lusby.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

09 Oct 2015 06:15 #63593

by BigJohnT

Replied by BigJohnT on topic Shizuoka AN-S Retrofit Advice Needed

If you're talking about Gecko G203v drives they take 80v. What voltage is the OEM power supply? I would use Mesa 5i25 7i76 combo.

JT

JT

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

09 Oct 2015 08:14 #63595

by Dale Lusby

Replied by Dale Lusby on topic Shizuoka AN-S Retrofit Advice Needed

I'll take a look at the power supply as I'm not sure what the output voltage is. As to the Mesa I'm going to have to look further into them. Does the combo of the two items mentioned (5i25 and 7i76) cover the driver and breakout or would it require drivers in addition to the two? Also is it capable of handling the amperage of the motors? I think I have the idea correctly that the driver needs to be rated to handle the load of the motors but I could be showing some of my ignorance on the topic.

Please Log in or Create an account to join the conversation.

- Stephen

- Offline

- New Member

-

Less

More

- Posts: 1

- Thank you received: 0

13 Jan 2016 07:41 #68287

by Stephen

Replied by Stephen on topic Shizuoka AN-S Retrofit Advice Needed

Hello from Australia Dale. You have a basically excellent machine. I purchased mine new back in Feb. 1982, but manual tool change with Bristol Erikson spindle nose nut and NMTB 40 taper. and manual speed change. Mine had servo motors. I added this machine to complement my retrofitted Bridgeport which I set up with X & Y stepper motors only. Regrettably both the Bandits have gone to God, and spares not locate-able. So am seriously thinking about building up the needed bits and restoring both to running, and learning about EMC2 and Mach3 and 4. I have also been giving thought to seeing if it is practical to get rid of the spindle speed control, and fit maybe another motor and a VFD that will give me a higher spindle speed and convenience. The spindle is ready for overhaul and new bearings after 24 years of running at mainly max revs on light duty parts. I really wish that the Bandits were still running. They were a fantastic control and so easy to program and use. I am thinking of fitting new steppers of around 1200 oz in with micro-stepping drivers and also incorporating encoders or linear scales to the machine. I have had a separate Anilam DRO on the Bridgeport and it is amazing how you could just run for many hours and not lose a step. I have just joined this site, having seen your story. Have a long time interest in the electronics and what you can do with good low cost bits and pieces. Am semi retiring, but still like to play with my well equipped shop. Providing your machine has not been neglected or lacked slide-way lubrication it should be fine. The ball-screws on my machine were not fitted with an oil line, so I regularly lubed them. They are as good as the first day.

I have always considered that they need to be able to do maybe 8000 RPM, as well as keeping those useful low range speeds. Regards Stephen

I have always considered that they need to be able to do maybe 8000 RPM, as well as keeping those useful low range speeds. Regards Stephen

Please Log in or Create an account to join the conversation.

- JR1050

-

- Offline

- Elite Member

-

Less

More

- Posts: 284

- Thank you received: 31

03 Feb 2016 04:30 #69486

by JR1050

Replied by JR1050 on topic Shizuoka AN-S Retrofit Advice Needed

Stephen, Inhave a friend who has four new in the box Bandit controls, they are in Florida, USA . She would let them go pretty cheap. If you are interested , pm me and I'll put you two in touch with each other.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

07 Feb 2016 00:24 #69722

by BigJohnT

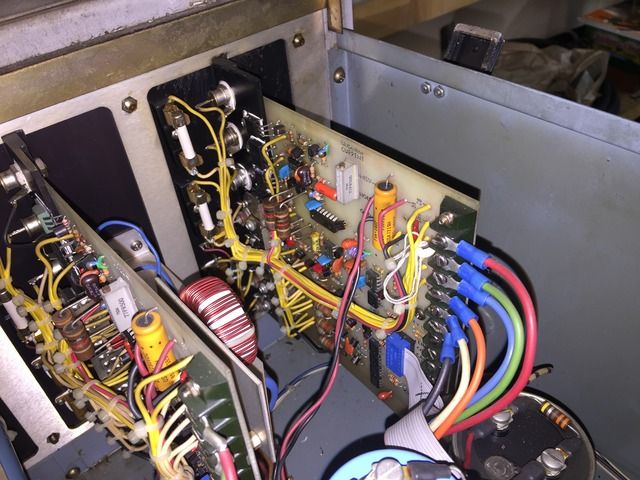

The 7i76 has 5 Axis of step & dir and 32 sinking inputs and 16 sourcing outputs so it pretty much covers most applications. I'm assuming you have steppers but looking again it looks like you have DC servos? It looks like you might have a bridge rectifier DC power supply you might measure the voltage that it puts out to start.

JT

Replied by BigJohnT on topic Shizuoka AN-S Retrofit Advice Needed

I'll take a look at the power supply as I'm not sure what the output voltage is. As to the Mesa I'm going to have to look further into them. Does the combo of the two items mentioned (5i25 and 7i76) cover the driver and breakout or would it require drivers in addition to the two? Also is it capable of handling the amperage of the motors? I think I have the idea correctly that the driver needs to be rated to handle the load of the motors but I could be showing some of my ignorance on the topic.

The 7i76 has 5 Axis of step & dir and 32 sinking inputs and 16 sourcing outputs so it pretty much covers most applications. I'm assuming you have steppers but looking again it looks like you have DC servos? It looks like you might have a bridge rectifier DC power supply you might measure the voltage that it puts out to start.

JT

Please Log in or Create an account to join the conversation.

- Dale Lusby

- Offline

- Senior Member

-

Less

More

- Posts: 50

- Thank you received: 2

14 Feb 2016 21:10 #70128

by Dale Lusby

Replied by Dale Lusby on topic Shizuoka AN-S Retrofit Advice Needed

It's crazy how time flies. I figured I should post an update to my machine. I do have stepper motors and went with the Geckodrive 201x drivers and for my breakout board I used the Sainsmart 5 axis it appears they designed for Mach3. Originally I used the stepper motors that came with the machine however I have upgraded to newer ones. I also went through the ball screws and adjusted to remove all the lash out of them. Now I'm down to about .0005" of lash so the machine is quite accurate. Overall it was a pretty simple retrofit since I gutted the old controller and just used the power supply. Currently I'm using the tool changer manually since I haven't figured out how to get it to work and quite frankly it's not too much trouble at this point to change the tools. Instead of investing the time and energy into the tool changer I will likely just be getting another larger machine. I do have another retrofit in the works on the lathe side which I'll be posting about soon. I've also recently built a 4th axis for this machine but as well I will start a new thread to show what and how I went about making it.

Please Log in or Create an account to join the conversation.

Time to create page: 0.090 seconds