Do you really need a spring loaded pinion drive?

- emcPT

-

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 95

05 Sep 2016 07:36 #80042

by emcPT

Replied by emcPT on topic Do you really need a spring loaded pinion drive?

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

05 Sep 2016 11:01 #80048

by rodw

Very nice. My foray into CNC plasma comes from a zero base but I've moved from a ghetto home build to something of commercial quality (I hope). Eventually I think servo motors are on the horizon once I get a working system.

I'd really be interested any data on air flow for down draft plasma tables if some one can help.

Replied by rodw on topic Do you really need a spring loaded pinion drive?

If you need motivation:

forum.linuxcnc.org/forum/show-your-stuff...m-powermax-125#80041

Very nice. My foray into CNC plasma comes from a zero base but I've moved from a ghetto home build to something of commercial quality (I hope). Eventually I think servo motors are on the horizon once I get a working system.

I'd really be interested any data on air flow for down draft plasma tables if some one can help.

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

05 Sep 2016 13:17 #80053

by cncbasher

Replied by cncbasher on topic Do you really need a spring loaded pinion drive?

i use 3 low voltage 8" fans below the grid , into the end of the pan , this is enclosed to funnel down to one 6" flexiable pipe

which is then vented out , the fans work fine by drawing the dust down and out . they are not running fast , but enough to cause a negative flow out , i built it more for air mass movement than speed .

which is then vented out , the fans work fine by drawing the dust down and out . they are not running fast , but enough to cause a negative flow out , i built it more for air mass movement than speed .

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

07 Sep 2016 19:45 #80161

by andypugh

Surely grids get cut too? Why not float the workpiece on a pool of mercury?

I admit there are a few possible minor drawbacks, but I am sure that dealing with those isa mere detail.

Replied by andypugh on topic Do you really need a spring loaded pinion drive?

i use 3 low voltage 8" fans below the grid ,

Surely grids get cut too? Why not float the workpiece on a pool of mercury?

I admit there are a few possible minor drawbacks, but I am sure that dealing with those isa mere detail.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

18 Sep 2016 12:19 - 18 Sep 2016 12:20 #80559

by rodw

Replied by rodw on topic Do you really need a spring loaded pinion drive?

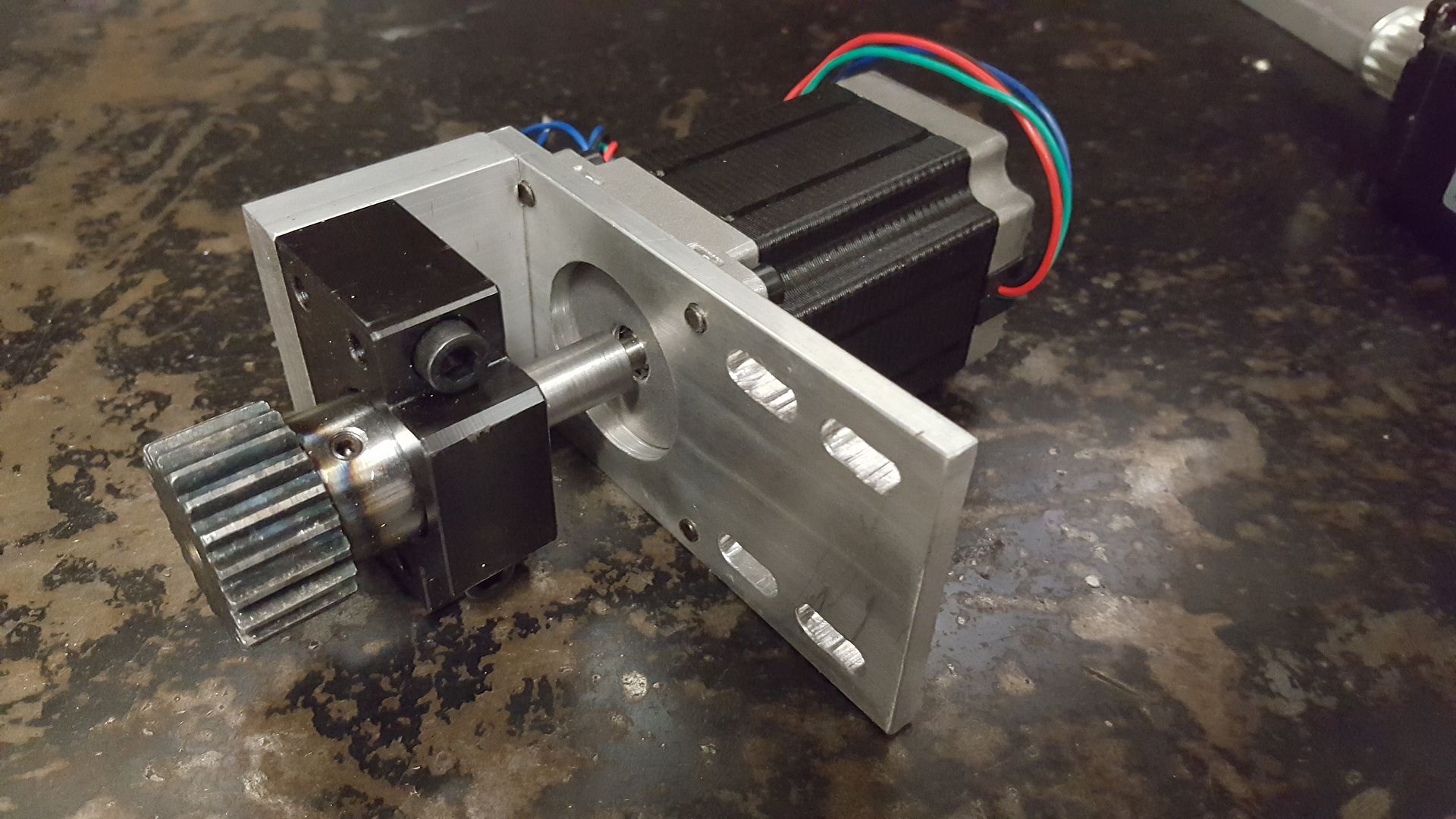

Its taken a while to find some time to get back onto this project but today, I got this far

There are some pretty tight clearances to get the stepper and bearing aligned along the shaft perfectly and I surprised myself. Everything turned out perfectly aligned with no binding at all. (After I noticed the centre bored hole for the stepper was out of position by 3mm on my first drawing).

There are some pretty tight clearances to get the stepper and bearing aligned along the shaft perfectly and I surprised myself. Everything turned out perfectly aligned with no binding at all. (After I noticed the centre bored hole for the stepper was out of position by 3mm on my first drawing).

Last edit: 18 Sep 2016 12:20 by rodw.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

18 Sep 2016 13:19 #80562

by tommylight

Replied by tommylight on topic Do you really need a spring loaded pinion drive?

Two problems with that setup:

The pinion is to big so you will have around 10cm of movement for one revolution of the motor

To much vibration at low speeds

Resulting in jerky movement and the end result.

Lowering the current to the motor will mitigate both problems to a certain extent, at the cost of speed and acceleration.

From experience, you need about 1-2.5cm of movement per motor turn, so use of reduction is necessary.

Move the motor to the side and slap 2 pulleys at 1:3 to 1:5 ratio, that will do nicely.

Do try it as is, later you do improvements.

The pinion is to big so you will have around 10cm of movement for one revolution of the motor

To much vibration at low speeds

Resulting in jerky movement and the end result.

Lowering the current to the motor will mitigate both problems to a certain extent, at the cost of speed and acceleration.

From experience, you need about 1-2.5cm of movement per motor turn, so use of reduction is necessary.

Move the motor to the side and slap 2 pulleys at 1:3 to 1:5 ratio, that will do nicely.

Do try it as is, later you do improvements.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- emcPT

-

- Offline

- Platinum Member

-

Less

More

- Posts: 424

- Thank you received: 95

18 Sep 2016 13:57 #80567

by emcPT

Replied by emcPT on topic Do you really need a spring loaded pinion drive?

Take tommylight information for serious. You will not have a good movement with that.

I might guess that a 1/5 to 1/10 reducer is suitable for your setup.

I might guess that a 1/5 to 1/10 reducer is suitable for your setup.

The following user(s) said Thank You: tommylight, rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

18 Sep 2016 20:59 #80583

by rodw

Replied by rodw on topic Do you really need a spring loaded pinion drive?

Thanks guys. I wondered about that. I will take it all on board but may wait until I get a working system so I can experiment.

The pinion is a 20 tooth 1.5 module gear so it is 30mm per revolution. Somewhere I had read that 25mm per revolution was the sweet spot and 30mm was as close as I could get to that when I went looking for a rack and pinion. Maybe a 2:1 reduction is where I should be looking then? That would give me 15mm per revolution.

Finally, what module gear rack is the best choice? I have not bought the X axis racks yet.

The pinion is a 20 tooth 1.5 module gear so it is 30mm per revolution. Somewhere I had read that 25mm per revolution was the sweet spot and 30mm was as close as I could get to that when I went looking for a rack and pinion. Maybe a 2:1 reduction is where I should be looking then? That would give me 15mm per revolution.

Finally, what module gear rack is the best choice? I have not bought the X axis racks yet.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

18 Sep 2016 21:06 #80584

by rodw

Replied by rodw on topic Do you really need a spring loaded pinion drive?

Ooops, I had never actually measured the travel, you guys made me go and do it. I was way wrong, Tommy was right! It measures out at about 90mm travel! Back to the drawing board!

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

18 Sep 2016 21:09 #80585

by andypugh

20 x 1.5 x pi per rev, I think.

You might as well build it and make it work anyway, seeing stuff actually move is a real encouragement.

Replied by andypugh on topic Do you really need a spring loaded pinion drive?

Ooops, I had never actually measured the travel, you guys made me go and do it. I was way wrong, Tommy was right! It measures out at about 90mm travel! Back to the drawing board!

20 x 1.5 x pi per rev, I think.

You might as well build it and make it work anyway, seeing stuff actually move is a real encouragement.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.315 seconds