Wayyy in over my head AXYZ CNC Router retrofit

- Muibubbles

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

27 Oct 2017 16:16 #100888

by Muibubbles

Wayyy in over my head AXYZ CNC Router retrofit was created by Muibubbles

Hey all, a few months back I purchased a second hand AZYX CNC Router that was in semi working condition. I was wishing for the best that it would be a quick fix but I've ended up digging into it rebuilding and replacing various parts.This is my 3rd CNC (2x4 CNCrouterparts & 5x10 Arclight plasma) so I am familiar with the mechanics, not so much the tech and software side. Coming from Mach3 and ready to run machines, Linuxcnc has proved to be out of my league so far

Here's My set up:

Axyz 5014 Table

Dal spindle carriage (2 Z Motors)

HSD ES919

AZYX ELTE TMPE5 14/2

(2) Emerson Commander SE Inverter

Mesa 5i25

Mesa 7i76

Vexta PK299-F4.5A Stepper Motors

Keling 8060 Drives

Rack and Pinion XY

Ball screw Z

For the ease of things I just want to get the table running with the one HSD ES919 spindle.

Currently I am stuck on setting up the motors. Since I'm using the MESA boards, do I have to use PNCconfig only? or am I suppose to use stepconfig as well?

Currently I'm waiting for a reply back from Automationtechincs for

Step Length/Time

Step Space

Direction Setup

Direction Hold

Steps on :(Falling or Rising edge?)

Now my x y and z motor have movement (well they bind) but there is connection so now I'm struggling on tuning in the right specs..

my motors have a 18tooth pulley which drives the transmission/Barrel with a 60t pulley and on the opposite end there is a 24t gear that goes the the rack (I think its 7tpi but I am struggling figuring out how to precisely measure this)

So would these settings be correct under Step Motor Scale?

Pulley Teeth 18:60

Microstep multiplication factor 5 (I have the dip switches on the drive set to 1/5)

leadscrew tpi 7

motor steps per revolution 200 (my motors are 1.8*)

Here's My set up:

Axyz 5014 Table

Dal spindle carriage (2 Z Motors)

HSD ES919

AZYX ELTE TMPE5 14/2

(2) Emerson Commander SE Inverter

Mesa 5i25

Mesa 7i76

Vexta PK299-F4.5A Stepper Motors

Keling 8060 Drives

Rack and Pinion XY

Ball screw Z

For the ease of things I just want to get the table running with the one HSD ES919 spindle.

Currently I am stuck on setting up the motors. Since I'm using the MESA boards, do I have to use PNCconfig only? or am I suppose to use stepconfig as well?

Currently I'm waiting for a reply back from Automationtechincs for

Step Length/Time

Step Space

Direction Setup

Direction Hold

Steps on :(Falling or Rising edge?)

Now my x y and z motor have movement (well they bind) but there is connection so now I'm struggling on tuning in the right specs..

my motors have a 18tooth pulley which drives the transmission/Barrel with a 60t pulley and on the opposite end there is a 24t gear that goes the the rack (I think its 7tpi but I am struggling figuring out how to precisely measure this)

So would these settings be correct under Step Motor Scale?

Pulley Teeth 18:60

Microstep multiplication factor 5 (I have the dip switches on the drive set to 1/5)

leadscrew tpi 7

motor steps per revolution 200 (my motors are 1.8*)

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

27 Oct 2017 18:13 #100892

by Todd Zuercher

Replied by Todd Zuercher on topic Wayyy in over my head AXYZ CNC Router retrofit

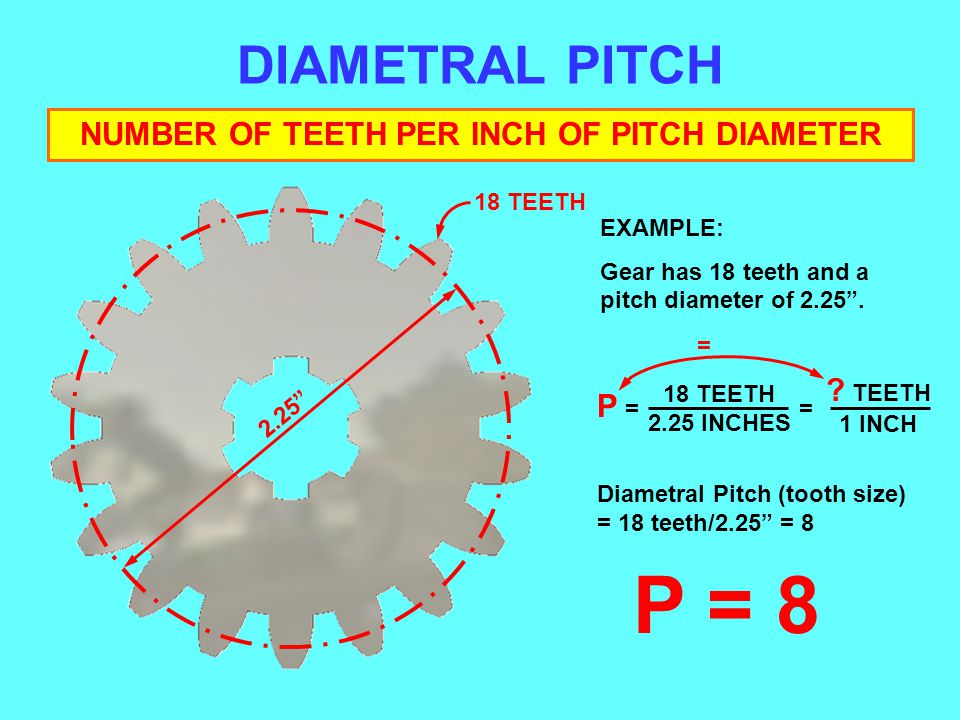

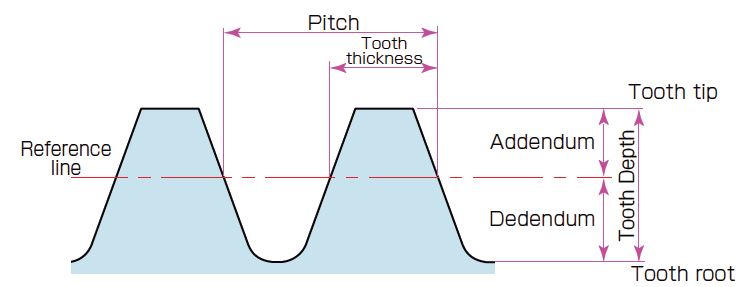

To calculate the number you should put in for the Leadscrew Pitch. You will need to know (or figure out) the diametrical pitch of your pinion gear, That would be the distance it the pinion will move the machine divided by pi. Actually all you need is that distance.

So anyway what you enter in the Leadscrew Pitch is the number of turns (or more likely fraction of a turn) the pinion must turn to move the machine 1 unit (inch or mm). And that would be 1/the pinions diametrical pitch*pi

Assuming your 24t pinion gear is a 20dp (and this might be a big assumption), it would have a 1.2" pitch diameter, and would travel 3.7691 inches per rev. and you would put in 0.265258 in for the Leadscrew pitch.

So anyway what you enter in the Leadscrew Pitch is the number of turns (or more likely fraction of a turn) the pinion must turn to move the machine 1 unit (inch or mm). And that would be 1/the pinions diametrical pitch*pi

Assuming your 24t pinion gear is a 20dp (and this might be a big assumption), it would have a 1.2" pitch diameter, and would travel 3.7691 inches per rev. and you would put in 0.265258 in for the Leadscrew pitch.

The following user(s) said Thank You: Muibubbles

Please Log in or Create an account to join the conversation.

- Muibubbles

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

27 Oct 2017 19:27 - 27 Oct 2017 19:28 #100895

by Muibubbles

Replied by Muibubbles on topic Wayyy in over my head AXYZ CNC Router retrofit

Thanks for the reply Todd.

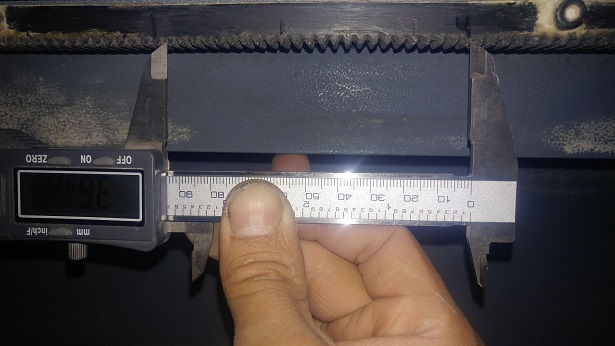

To measure the diametrical pitch I found this image:

Now to find the true diametrical pitch I would have to measure at the angle of the tooth (which I cannot see) So what would be my allowed tolerance?

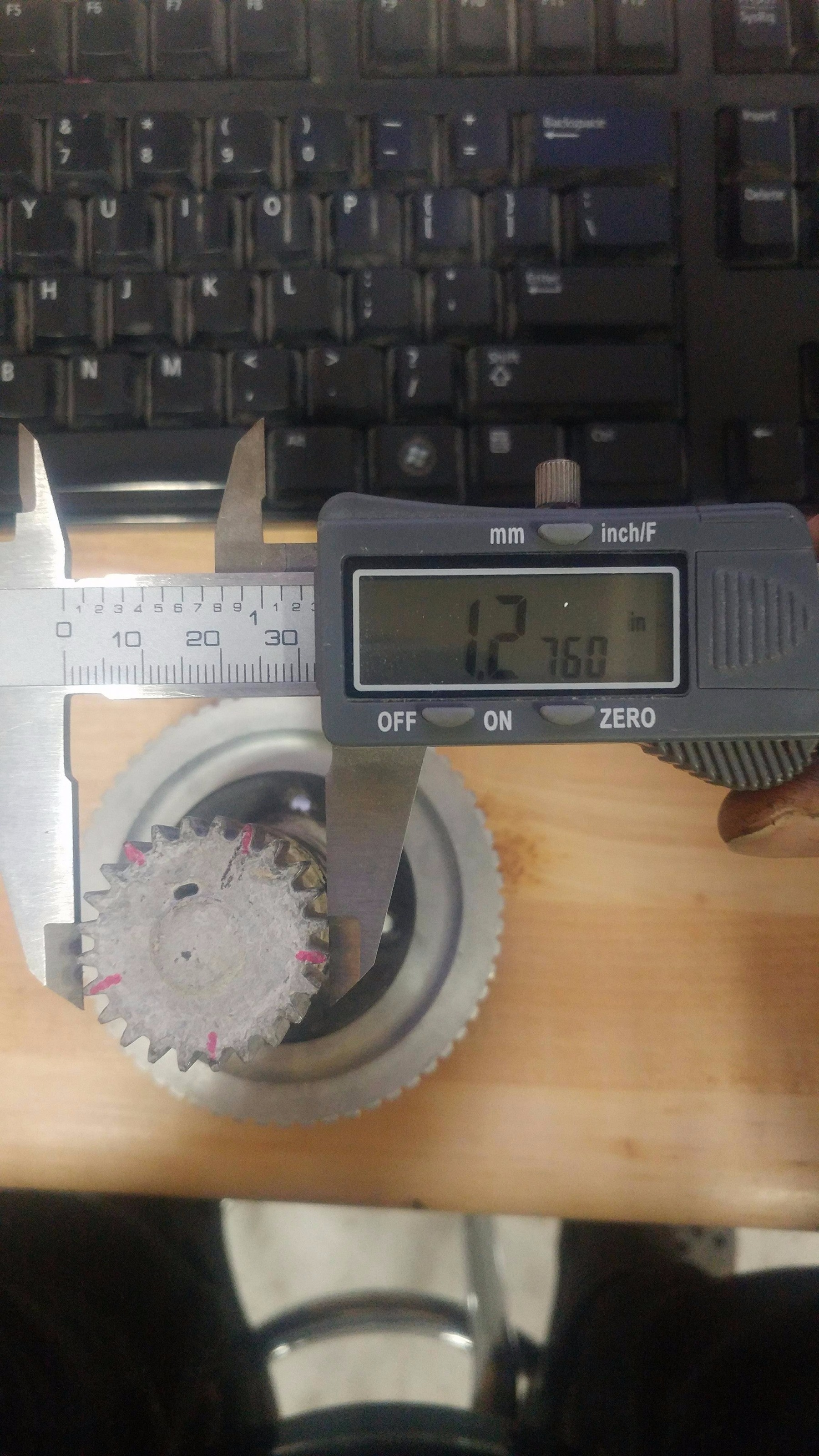

I measured the diameter (outside of the teeth) and got 1.2760"

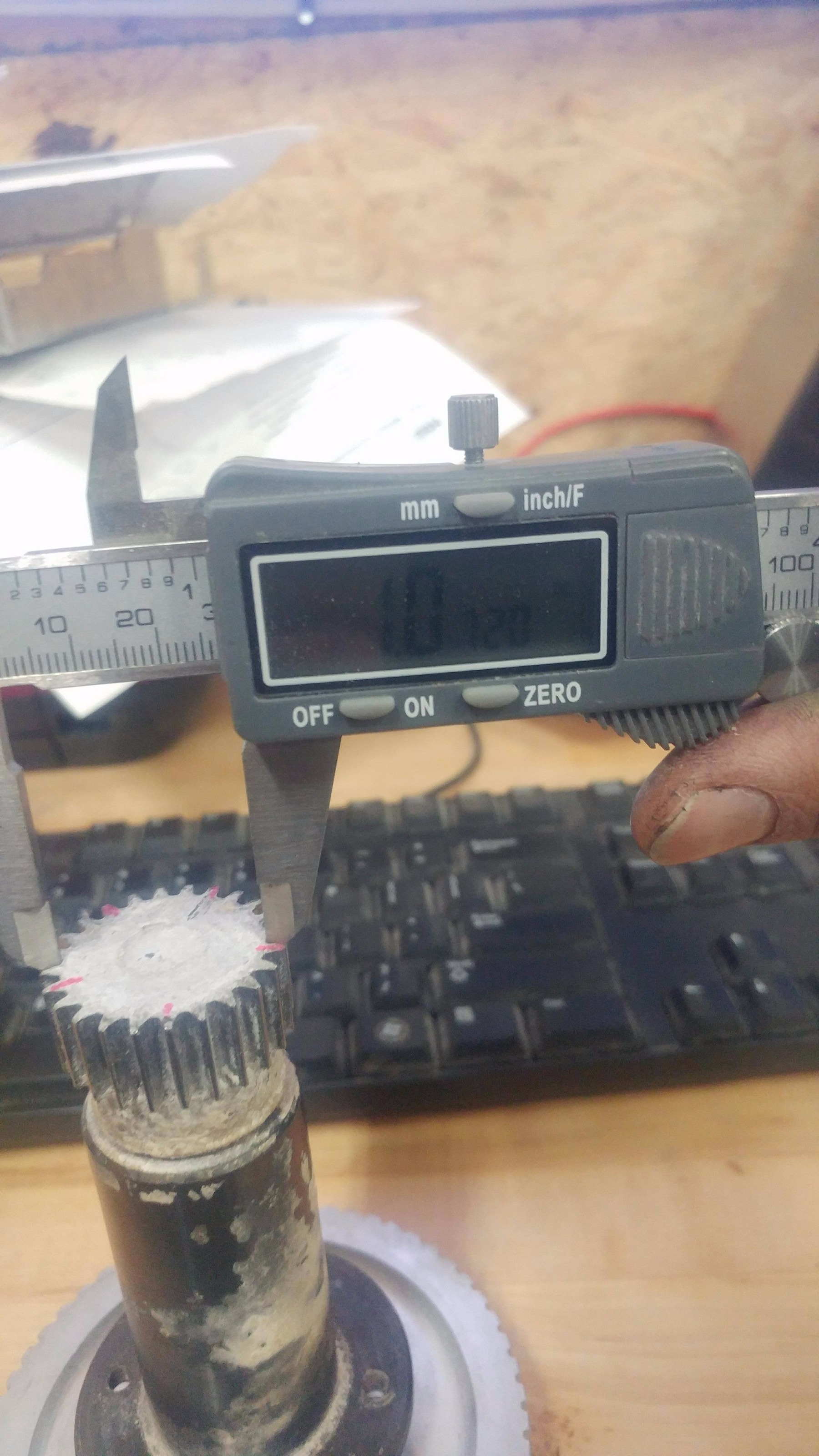

Then I measured the diameter of the base circle? and got 1.0120"

Could this be assumed the diametrical pitch is 1.2 as you suggested? Again, what would the tolerance be for this? Is 1.2 enough or should it be as accurate as 1.2x/1.2xx?

"Assuming your 24t pinion gear is a 20dp (and this might be a big assumption), it would have a 1.2" pitch diameter"

What does "20dp" refer to in this statement?

To measure the diametrical pitch I found this image:

Now to find the true diametrical pitch I would have to measure at the angle of the tooth (which I cannot see) So what would be my allowed tolerance?

I measured the diameter (outside of the teeth) and got 1.2760"

Then I measured the diameter of the base circle? and got 1.0120"

Could this be assumed the diametrical pitch is 1.2 as you suggested? Again, what would the tolerance be for this? Is 1.2 enough or should it be as accurate as 1.2x/1.2xx?

"Assuming your 24t pinion gear is a 20dp (and this might be a big assumption), it would have a 1.2" pitch diameter"

What does "20dp" refer to in this statement?

Last edit: 27 Oct 2017 19:28 by Muibubbles.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

27 Oct 2017 20:12 #100896

by Todd Zuercher

Replied by Todd Zuercher on topic Wayyy in over my head AXYZ CNC Router retrofit

It seems kind of close. Looking up the specs for 20dp 24tooth gear shows an outside diameter of 1.3". If you turned the pinion so the caliper measured from tooth to tooth instead of bridging between two pairs of teeth, it may be very close to that.

Another test would be to measure the length of 24 teeth on your rack, then divide that number by pi and see how close that comes to 1.2.

Another test would be to measure the length of 24 teeth on your rack, then divide that number by pi and see how close that comes to 1.2.

Please Log in or Create an account to join the conversation.

- Muibubbles

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

30 Oct 2017 17:33 - 30 Oct 2017 17:36 #101024

by Muibubbles

Replied by Muibubbles on topic Wayyy in over my head AXYZ CNC Router retrofit

So if I measured correctly, (which is quiet difficult to guess where the exact reference line is) I yield 3.6935/pi =1.1756

I re-measured the pinion making sure it was from the tip of the tooth-to-tooth. I'm reading 1.2855, is it safe to say I can round this to 1.3?

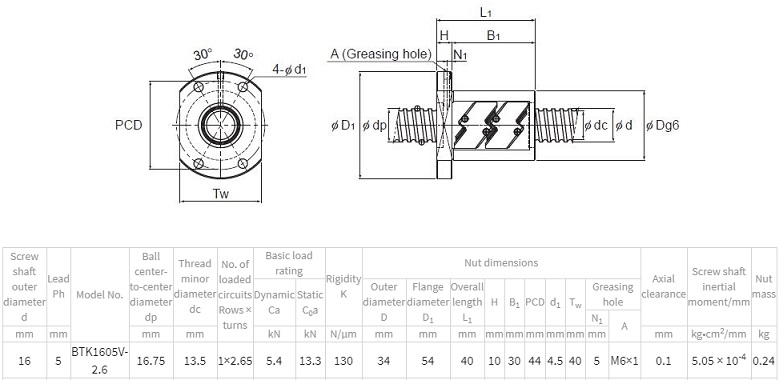

Also how would I figure out the lead screw pitch?

I am using a THK BTK 1605A AX-8E20

Is "Lead ph" Lead pitch? (What does the ph stand for?) If so, it states 5mm so is that 5:1mm?

Thanks again for your help, this is pretty confusing as there are so many abbreviations and terminology that I'm struggling with.

I re-measured the pinion making sure it was from the tip of the tooth-to-tooth. I'm reading 1.2855, is it safe to say I can round this to 1.3?

Also how would I figure out the lead screw pitch?

I am using a THK BTK 1605A AX-8E20

Is "Lead ph" Lead pitch? (What does the ph stand for?) If so, it states 5mm so is that 5:1mm?

Thanks again for your help, this is pretty confusing as there are so many abbreviations and terminology that I'm struggling with.

Last edit: 30 Oct 2017 17:36 by Muibubbles.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

30 Oct 2017 20:21 #101026

by Todd Zuercher

Replied by Todd Zuercher on topic Wayyy in over my head AXYZ CNC Router retrofit

1605 is a common ballscrew size, (16mm screw with a 5mm pitch) The nut will move 5mm with one turn, so if you are setting your machine up in inches you would enter 5.08 revs/inch. (25.4mm/inch / 5mm) If you are setting up the machine in mm then just enter 5. (Stepconfig uses a different calculation for inches and mm, inches uses turns/inch and mm uses mm/turn, just to keep things nice and confusing.)

The measurement of 1.28...inches might be close enough to 1.3 to count especially if the pinion is a bit worn. 20DP seems to be the closest standard gear size for a 24tooth gear with about that OD.

Hopefully someone will correct me if I'm wrong.

The measurement of 1.28...inches might be close enough to 1.3 to count especially if the pinion is a bit worn. 20DP seems to be the closest standard gear size for a 24tooth gear with about that OD.

Hopefully someone will correct me if I'm wrong.

The following user(s) said Thank You: Muibubbles

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11718

- Thank you received: 3966

30 Oct 2017 20:28 - 30 Oct 2017 20:36 #101028

by rodw

Replied by rodw on topic Wayyy in over my head AXYZ CNC Router retrofit

Check your results on the pinion on this calculator.

www.gearconcern.com.au/gear-size-calculator/

EDIT: It looks like your rack and pinion is a metric Module 1.25 gear set from the above. So the circumference is 24 * 1.25mm * pi

= 94.2477796076938 mm

= 3.71054250423991 inches (divide x 25.4)

www.gearconcern.com.au/gear-size-calculator/

EDIT: It looks like your rack and pinion is a metric Module 1.25 gear set from the above. So the circumference is 24 * 1.25mm * pi

= 94.2477796076938 mm

= 3.71054250423991 inches (divide x 25.4)

Last edit: 30 Oct 2017 20:36 by rodw.

The following user(s) said Thank You: Muibubbles

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

30 Oct 2017 20:50 #101030

by Todd Zuercher

Replied by Todd Zuercher on topic Wayyy in over my head AXYZ CNC Router retrofit

You could always remove all doubt and call the machine manufacturer and ask them for the rack and pinion spec.

(for some reason I was thinking 1.25mod was an uncommon size, but a Google search showed up several.)

Are there any identifying numbers stamped anywhere on the pinion? (probably under that layer of caked on crud)

(for some reason I was thinking 1.25mod was an uncommon size, but a Google search showed up several.)

Are there any identifying numbers stamped anywhere on the pinion? (probably under that layer of caked on crud)

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11718

- Thank you received: 3966

30 Oct 2017 21:07 - 30 Oct 2017 21:08 #101031

by rodw

Replied by rodw on topic Wayyy in over my head AXYZ CNC Router retrofit

So following along, at 1100 steps per rev (200 * 5)

and 18:60 reduction drive.(3.333333 : 1) lets see,

To turn the pinion 1 revolution, you need 3333.333333 steps (1000 x 3.33333)

So to determine your steps per inch its

3333.33333 / 3.71054250423991

= 898.341225358

This is the value you need to use for the

SCALE or STEP_SCALE in your ini file (edit same by hand)

and 18:60 reduction drive.(3.333333 : 1) lets see,

To turn the pinion 1 revolution, you need 3333.333333 steps (1000 x 3.33333)

So to determine your steps per inch its

3333.33333 / 3.71054250423991

= 898.341225358

This is the value you need to use for the

SCALE or STEP_SCALE in your ini file (edit same by hand)

Last edit: 30 Oct 2017 21:08 by rodw.

The following user(s) said Thank You: Muibubbles

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11718

- Thank you received: 3966

30 Oct 2017 21:18 #101032

by rodw

module 1.25 is a very common gear size in the metric world (97% of the world's population). 94mm is remarkably familiar to me as I've used a mod 1.25 rack on my machine.

The calculator on my supplier's site is good. I think it gave me module 1.256 and DP of 20.226 so its clearly metric. The pinion looked worn to me. I'd run with mod 1.25 for now. You know its a metric machine by the 1605 ball screw used.

I know I did a fair few tests with a 1.0m steel long ruler fine tuning one axis and the other was spot on perfect. If it was out by 0.1%, I'd change the scale by 0.1%

Replied by rodw on topic Wayyy in over my head AXYZ CNC Router retrofit

You could always remove all doubt and call the machine manufacturer and ask them for the rack and pinion spec.

(for some reason I was thinking 1.25mod was an uncommon size, but a Google search showed up several.)

Are there any identifying numbers stamped anywhere on the pinion? (probably under that layer of caked on crud)

module 1.25 is a very common gear size in the metric world (97% of the world's population). 94mm is remarkably familiar to me as I've used a mod 1.25 rack on my machine.

The calculator on my supplier's site is good. I think it gave me module 1.256 and DP of 20.226 so its clearly metric. The pinion looked worn to me. I'd run with mod 1.25 for now. You know its a metric machine by the 1605 ball screw used.

I know I did a fair few tests with a 1.0m steel long ruler fine tuning one axis and the other was spot on perfect. If it was out by 0.1%, I'd change the scale by 0.1%

Please Log in or Create an account to join the conversation.

Time to create page: 0.563 seconds