DIY CNC Camgrinder

- marsheng

-

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

07 Jul 2020 21:24 - 07 Jul 2020 21:26 #173920

by marsheng

Replied by marsheng on topic DIY CNC Camgrinder

schmidtmotorworks said: The data is 6 decimal, I doubt the measurements are 6 unless in a controlled temperature environment with exceptionally accurate tools. .

I have a different approach to the Performance Trends unit. I let my shaft run through 10 + revolutions then average the data. This gives good results. Even still I can massage the data to make sure it is clean. That is why I'm looking at point to point on my grinder as that is what the original data is. My end result is to measure the valve movement and not that cam. That is what I want to be correct. Changing valve length, seat height etc all affect motion when you have rockers.

I have a different approach to the Performance Trends unit. I let my shaft run through 10 + revolutions then average the data. This gives good results. Even still I can massage the data to make sure it is clean. That is why I'm looking at point to point on my grinder as that is what the original data is. My end result is to measure the valve movement and not that cam. That is what I want to be correct. Changing valve length, seat height etc all affect motion when you have rockers.

Last edit: 07 Jul 2020 21:26 by marsheng.

Please Log in or Create an account to join the conversation.

- schmidtmotorworks

- Offline

- Premium Member

-

Less

More

- Posts: 107

- Thank you received: 6

07 Jul 2020 22:38 #173933

by schmidtmotorworks

Replied by schmidtmotorworks on topic DIY CNC Camgrinder

The duplicate measurement method will get you by, but if you round to less than 0.0001" the acceleration curve will not be smooth as much of the acceleration values are in that range. The G-code (in inches) needs to be 5 places past decimal.

On a master at 0.0001" and 0.1 degree steps, the faceting is noticeable and needs to be polished out. The grinder even sounds smoother when you do.

On a master at 0.0001" and 0.1 degree steps, the faceting is noticeable and needs to be polished out. The grinder even sounds smoother when you do.

Please Log in or Create an account to join the conversation.

- marsheng

-

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

12 Jul 2020 10:33 #174377

by marsheng

Replied by marsheng on topic DIY CNC Camgrinder

This got me thinking

schmidtmotorworks said On a master at 0.0001" and 0.1 degree steps, the faceting is noticeable and needs to be polished out.

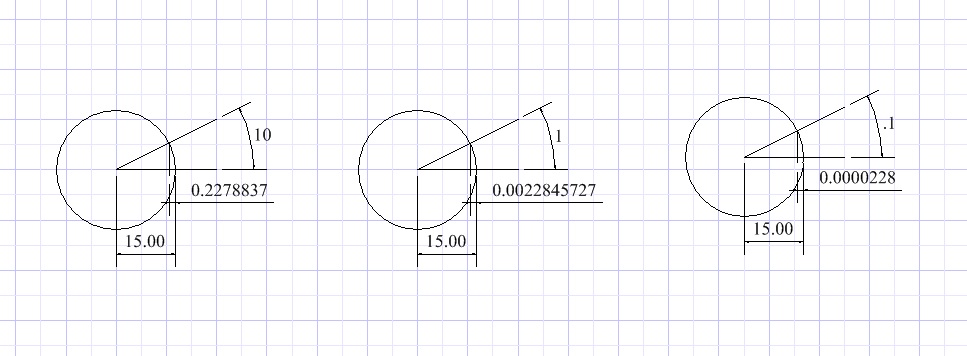

I did a CAD test. I used a 30 mm circle and wanted to see how accurate a step I may need. The cam is not a circle but if I put in a 'safety' factor of 2 or 3 for the ramp, I should be in the ball park. So if you traverse a circle in 0.1 deg increments, how much does the X axis have to move.

At 0.1 deg increments, the X axis has to move 0.000028 mm on a 30 mm circle.

Even at 1 deg movements, it is only 0.0023 mm Say the cam has a really steep lobe and it is 5 times that rate, its still only 0..01 mm.

Where am I going wrong ? It looks like 1 mm steps will be more than accurate enough.

schmidtmotorworks said On a master at 0.0001" and 0.1 degree steps, the faceting is noticeable and needs to be polished out.

I did a CAD test. I used a 30 mm circle and wanted to see how accurate a step I may need. The cam is not a circle but if I put in a 'safety' factor of 2 or 3 for the ramp, I should be in the ball park. So if you traverse a circle in 0.1 deg increments, how much does the X axis have to move.

At 0.1 deg increments, the X axis has to move 0.000028 mm on a 30 mm circle.

Even at 1 deg movements, it is only 0.0023 mm Say the cam has a really steep lobe and it is 5 times that rate, its still only 0..01 mm.

Where am I going wrong ? It looks like 1 mm steps will be more than accurate enough.

Please Log in or Create an account to join the conversation.

- schmidtmotorworks

- Offline

- Premium Member

-

Less

More

- Posts: 107

- Thank you received: 6

12 Jul 2020 17:06 #174406

by schmidtmotorworks

Replied by schmidtmotorworks on topic DIY CNC Camgrinder

After you machine it, run a hard bench stone on the surface, the peaks will show.

It doesn't take much to remove them.

If you put the points closer together the peaks diminish.

The commercial cam grinders have smoothing routines to enable them to use 1 degree increments.

It doesn't take much to remove them.

If you put the points closer together the peaks diminish.

The commercial cam grinders have smoothing routines to enable them to use 1 degree increments.

Please Log in or Create an account to join the conversation.

Time to create page: 0.104 seconds