cnc Bosch cc100m retrofit

- lois

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 0

25 Sep 2019 21:02 - 25 Sep 2019 21:03 #146182

by lois

cnc Bosch cc100m retrofit was created by lois

Hi there.

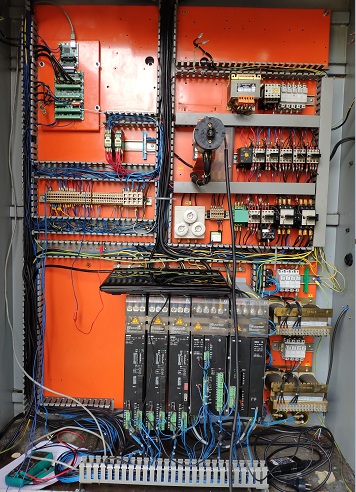

I’m retrofitting old (1994) cnc machine . It came disassembled. I found in this forum one electrical schematic and fits ok in what I have. Decided to move on and use MESA drivers (7i92+7i77).

At the moment a can move xyz axis and spindle (all analog +-10v) and only by the pncconfig wizard. I din't touch, too much, hal and ini files.

The problem i have is in the spindle control. The spindle has one encoder that goes direct to SPM module, so, how to get spindle feedback to 7i77? can i strip the cable and use A-A B-B and R-R to 7i77 and maintain the cable connected to SPM (maybe 5v power issues here)?

Can't figure out how the original cnc control could manage trheading comands, etc. Is the analog +-10v capable to handle with precision the spindle control without feedback?

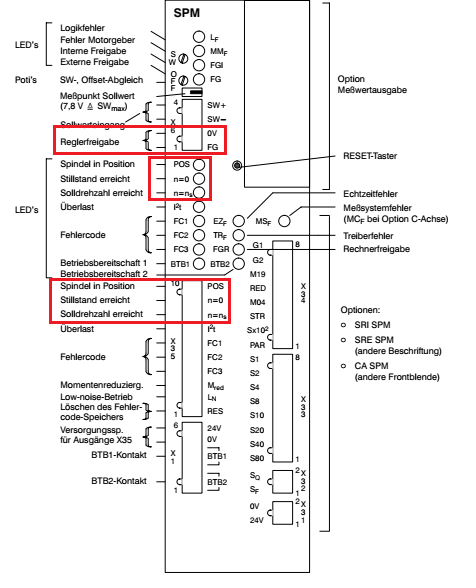

The SPM module had connected other lines:

- enable, FG ( I assume 24v from 7i77)

- spindle in position POS (assuming 24v to 7i77), after M19 reference signal

- spindle stop, n=0 (assuming 24v to 7i77)

- M19 (assuming 24v from 7i77 to stop in reference position)

If i have spindle feedback encoder to the 7i77 don't need the avobe comands n=0 and POS? Linux cnc can handle with all this issues?

Now is time to get hands on hal and ini files, but no experience on this. First time on linux.

Tomorrow more pics about the project.

I’m retrofitting old (1994) cnc machine . It came disassembled. I found in this forum one electrical schematic and fits ok in what I have. Decided to move on and use MESA drivers (7i92+7i77).

At the moment a can move xyz axis and spindle (all analog +-10v) and only by the pncconfig wizard. I din't touch, too much, hal and ini files.

The problem i have is in the spindle control. The spindle has one encoder that goes direct to SPM module, so, how to get spindle feedback to 7i77? can i strip the cable and use A-A B-B and R-R to 7i77 and maintain the cable connected to SPM (maybe 5v power issues here)?

Can't figure out how the original cnc control could manage trheading comands, etc. Is the analog +-10v capable to handle with precision the spindle control without feedback?

The SPM module had connected other lines:

- enable, FG ( I assume 24v from 7i77)

- spindle in position POS (assuming 24v to 7i77), after M19 reference signal

- spindle stop, n=0 (assuming 24v to 7i77)

- M19 (assuming 24v from 7i77 to stop in reference position)

If i have spindle feedback encoder to the 7i77 don't need the avobe comands n=0 and POS? Linux cnc can handle with all this issues?

Now is time to get hands on hal and ini files, but no experience on this. First time on linux.

Tomorrow more pics about the project.

Attachments:

Last edit: 25 Sep 2019 21:03 by lois.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

26 Sep 2019 07:07 #146220

by pl7i92

Replied by pl7i92 on topic cnc Bosch cc100m retrofit

hi welcome

all German so i guess i try !

die SPM braucht diese Signale als freigabe von der Controll software

das heist deine Remap M6 sollte diese signale zur SPM geben

ist da ein Wechselarm angeschlossen oder nur ein ATC

schau dir mal das an

forum.linuxcnc.org/20-g-code/33837-m19-spindle-orient

die SPM bekommt dan noch diese anforderung mit

Spindle in position

Spindle off

all German so i guess i try !

die SPM braucht diese Signale als freigabe von der Controll software

das heist deine Remap M6 sollte diese signale zur SPM geben

ist da ein Wechselarm angeschlossen oder nur ein ATC

schau dir mal das an

forum.linuxcnc.org/20-g-code/33837-m19-spindle-orient

die SPM bekommt dan noch diese anforderung mit

Spindle in position

Spindle off

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21230

- Thank you received: 7249

26 Sep 2019 08:26 #146233

by tommylight

Replied by tommylight on topic cnc Bosch cc100m retrofit

OP is from Portugal.

Freigabe = enable

But i do not see any analogue reference input there ?

Freigabe = enable

But i do not see any analogue reference input there ?

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

26 Sep 2019 14:28 #146269

by pl7i92

Replied by pl7i92 on topic cnc Bosch cc100m retrofit

@tom ist just the ATC logic SPM module not the Servo controller the M19 is the enable

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21230

- Thank you received: 7249

27 Sep 2019 00:50 #146306

by tommylight

Danke shon.

Djakuju bardzo.

Replied by tommylight on topic cnc Bosch cc100m retrofit

Ok, i see that now, thank you.@tom ist just the ATC logic SPM module not the Servo controller the M19 is the enable

Danke shon.

Djakuju bardzo.

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

27 Sep 2019 04:40 #146328

by Henk

Replied by Henk on topic cnc Bosch cc100m retrofit

Hi.

SW+ and SW- is the analog input for speed reference. +- 10v.

My deckel FP4nc use the same

Regards

Henk

SW+ and SW- is the analog input for speed reference. +- 10v.

My deckel FP4nc use the same

Regards

Henk

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

27 Sep 2019 07:11 #146344

by pl7i92

Replied by pl7i92 on topic cnc Bosch cc100m retrofit

its now a quite time as he dident sned more Images i guess he solved the problem on its own

Please Log in or Create an account to join the conversation.

- lois

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 0

27 Sep 2019 08:59 #146352

by lois

Replied by lois on topic cnc Bosch cc100m retrofit

I’m around the wires…

When the SPM is enabled, 24v on FG, the spindle starts drifting/vibrating. There is a tiny screw to adjust the rotation, when enabled with no voltage (sw+ sw-). Maybe some MESA voltage offset to adjust this behavior.

If I connect 24v to M19 terminal, led n=0 turns on and led POS turns on also, spindle rotates always to the same angular position and holds with torque, so this is the reference to ATC (later…). If disconnect 24v on M19 the spindle, slowly, continues slowly drifting.

So at the moment I need wiring 2 outputs and 2 inputs from 7i77 (enable, M19, n=0 and POS).

The main issue here (i think) is about the spindle angular/position feedback to 7i77. The spindle encoder (1000 lines TTL) is connected to the SPM. Doesn’t work not connected. Tapping cycle with no kind of feedback?? Or, the +-voltage from 7i77 must be so precise, so fine tuning that assures the correct rpm?

I’ve also measured the voltage on n=ns terminal (it wasn’t used). When the spindle is on high rpm the voltage is low and low rpm the voltage is high. Don’t know if could be used to confirm rpm.

So at the moment my doubts are about the spindle feedback and I’m looking to something kinda terminal/window to see and test the inputs and outputs on 7i77. There is some app to install and see this?

I haven't started messing with the ini and hal files yet

When the SPM is enabled, 24v on FG, the spindle starts drifting/vibrating. There is a tiny screw to adjust the rotation, when enabled with no voltage (sw+ sw-). Maybe some MESA voltage offset to adjust this behavior.

If I connect 24v to M19 terminal, led n=0 turns on and led POS turns on also, spindle rotates always to the same angular position and holds with torque, so this is the reference to ATC (later…). If disconnect 24v on M19 the spindle, slowly, continues slowly drifting.

So at the moment I need wiring 2 outputs and 2 inputs from 7i77 (enable, M19, n=0 and POS).

The main issue here (i think) is about the spindle angular/position feedback to 7i77. The spindle encoder (1000 lines TTL) is connected to the SPM. Doesn’t work not connected. Tapping cycle with no kind of feedback?? Or, the +-voltage from 7i77 must be so precise, so fine tuning that assures the correct rpm?

I’ve also measured the voltage on n=ns terminal (it wasn’t used). When the spindle is on high rpm the voltage is low and low rpm the voltage is high. Don’t know if could be used to confirm rpm.

So at the moment my doubts are about the spindle feedback and I’m looking to something kinda terminal/window to see and test the inputs and outputs on 7i77. There is some app to install and see this?

I haven't started messing with the ini and hal files yet

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

27 Sep 2019 13:17 #146378

by bevins

Replied by bevins on topic cnc Bosch cc100m retrofit

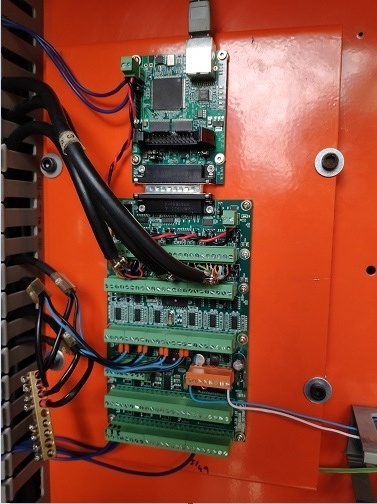

You have standoffs behind those mesa boards?

Please Log in or Create an account to join the conversation.

- lois

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 0

27 Sep 2019 22:46 #146438

by lois

Replied by lois on topic cnc Bosch cc100m retrofit

Just simple nylon spacers

Please Log in or Create an account to join the conversation.

Time to create page: 0.708 seconds