Bridgeport Torq Cut 22 Retrofit

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

11 Nov 2019 03:45 #150080

by Michael

Bridgeport Torq Cut 22 Retrofit was created by Michael

I was able to purchase a used Torq Cut 22 for cheap. It has an unknown history and after some unsuccessful tinkering with the DX32 control I decided on a full retrofit. At the price I bought the machine at I am fine with the only original parts left after the retrofit being the 6000 lbs casting. I am starting this thread to test out some ideas and hardware/software questions that will come up. The old control is stripped out of the machine and most of the new components have been installed, wired and ready for testing. The only original parts I have kept are:

Spindle motor and drive (although I have a bad bearing in either the spindle or the motor)

All tool changer components (simple Geneva mechanism that can be controlled using relays)

This is what I am using or plan to use for the build:

DMM AC Servos X/Y 1.3kw and Z 1.8kw

ASRock J3455 with SATA SSD 120GB and generic Pico power supply, 17" monoprice touch screen

6i25 and 7i77 combo

I have everything ready to power up and start testing connections and function. Currently the J3455 is mounted in the control cabinet, open face (brace on the 6i25 bracket) but the wiring coming in and out of it looks rough. With this setup I have to run some USB extensions, HDMI, power and reset buttons all the way up to the console. I really wanted to have the motherboard in a case was not a reality with it in the cabinet. And I read that I should not run a DB25 the 15 feet it would take to reach from the console back to the cabinet.

I did see that I could go with PC mounted in the console and run ethernet back to a 7i92 in the cabinet.

Is there any advantage to use the 6i25 over a 7i92?

Is there a max run distance on the ethernet cable to the 7i92?

Will the 7i92M plug directly into the 7i77 or will it still need a cable?

I will be pushing the limits of I/O on the 7i77 and want to know if there are better options than a 7i70 or 7i84?

Thanks for taking a look and giving some feedback.

Spindle motor and drive (although I have a bad bearing in either the spindle or the motor)

All tool changer components (simple Geneva mechanism that can be controlled using relays)

This is what I am using or plan to use for the build:

DMM AC Servos X/Y 1.3kw and Z 1.8kw

ASRock J3455 with SATA SSD 120GB and generic Pico power supply, 17" monoprice touch screen

6i25 and 7i77 combo

I have everything ready to power up and start testing connections and function. Currently the J3455 is mounted in the control cabinet, open face (brace on the 6i25 bracket) but the wiring coming in and out of it looks rough. With this setup I have to run some USB extensions, HDMI, power and reset buttons all the way up to the console. I really wanted to have the motherboard in a case was not a reality with it in the cabinet. And I read that I should not run a DB25 the 15 feet it would take to reach from the console back to the cabinet.

I did see that I could go with PC mounted in the console and run ethernet back to a 7i92 in the cabinet.

Is there any advantage to use the 6i25 over a 7i92?

Is there a max run distance on the ethernet cable to the 7i92?

Will the 7i92M plug directly into the 7i77 or will it still need a cable?

I will be pushing the limits of I/O on the 7i77 and want to know if there are better options than a 7i70 or 7i84?

Thanks for taking a look and giving some feedback.

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

11 Nov 2019 06:30 #150085

by thefabricator03

Replied by thefabricator03 on topic Bridgeport Torq Cut 22 Retrofit

Any pictures of the beast?

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

11 Nov 2019 12:02 #150101

by pl7i92

Replied by pl7i92 on topic Bridgeport Torq Cut 22 Retrofit

you can use the 7i92m connects direct no cable needed

the motherboard woudt be best inside the consol so only CAT5 is to be run towards the 7i77

the motherboard woudt be best inside the consol so only CAT5 is to be run towards the 7i77

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

12 Nov 2019 05:40 #150171

by Michael

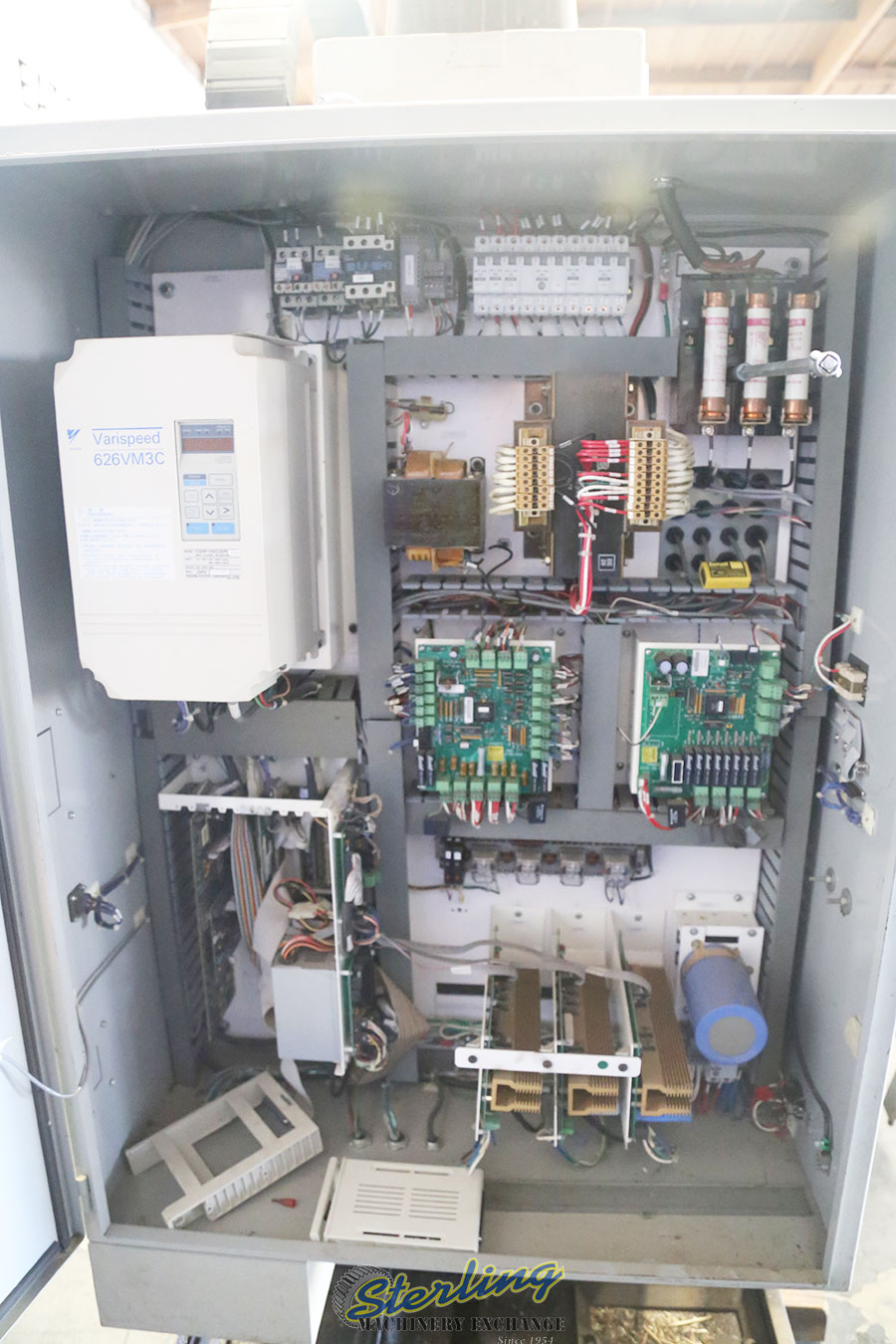

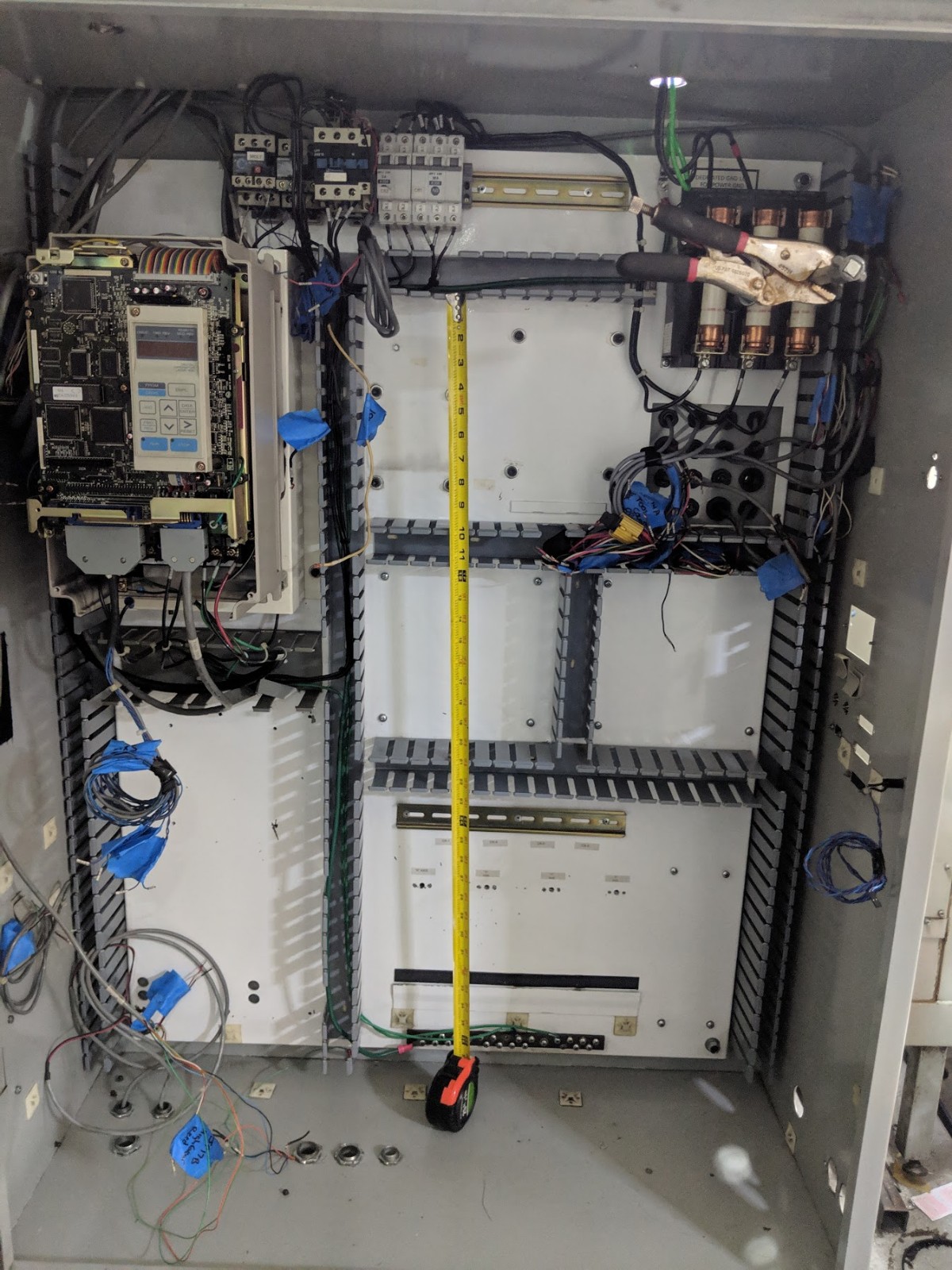

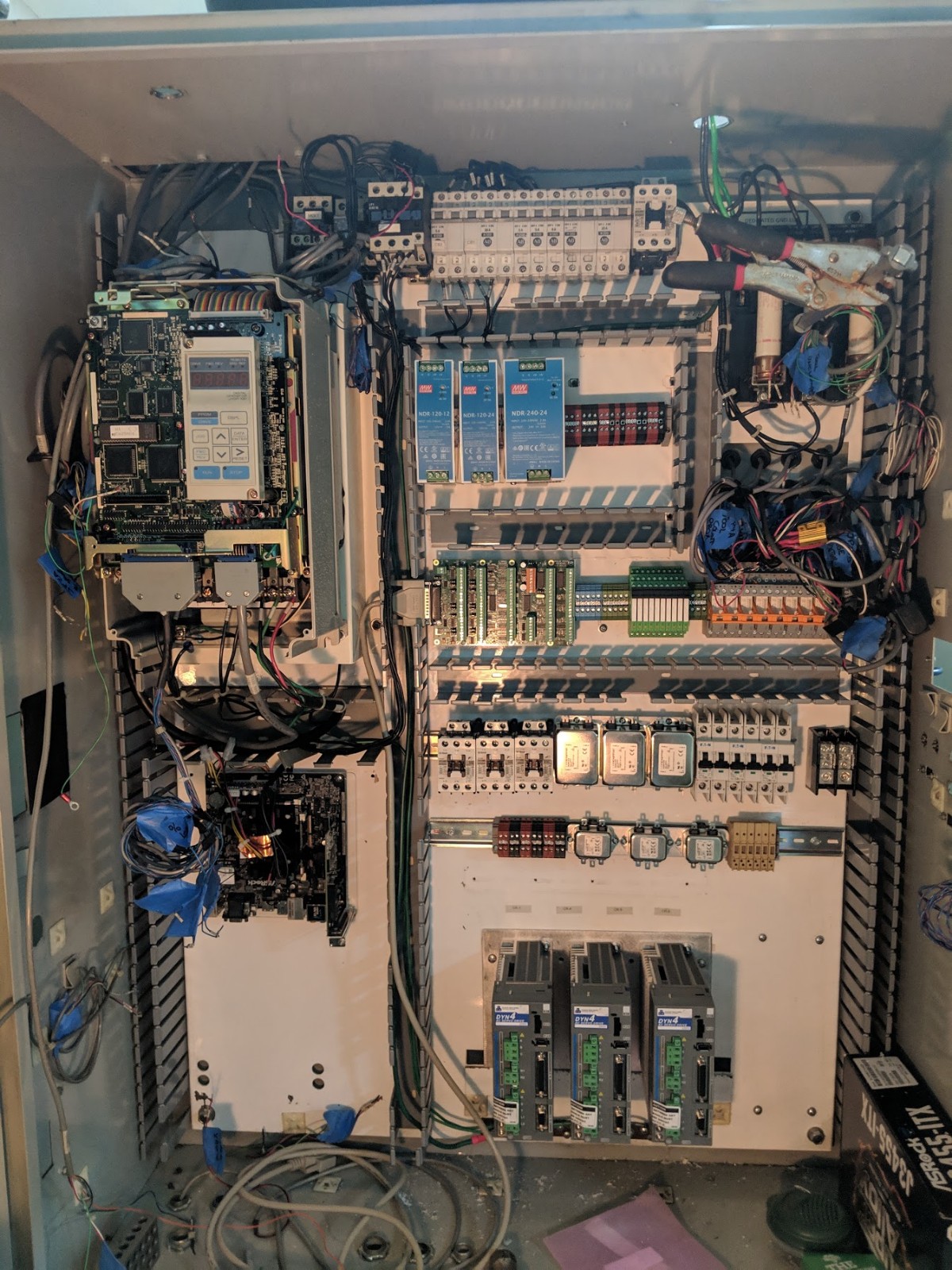

Sure do. Here it is in various stages of tear down and rebuild.

Replied by Michael on topic Bridgeport Torq Cut 22 Retrofit

Any pictures of the beast?

Sure do. Here it is in various stages of tear down and rebuild.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

12 Nov 2019 06:06 #150172

by thefabricator03

Replied by thefabricator03 on topic Bridgeport Torq Cut 22 Retrofit

Looks great,

I am on the look out for a similar condition machine here in Australia to retrofit and they are difficult to find.

I saw a bridgeport machine like yours sell for $25,000 AUD a couple of months ago.

I look on US ebay and there are plenty for sale for reasonable prices, makes me jealous of you yanks

I am on the look out for a similar condition machine here in Australia to retrofit and they are difficult to find.

I saw a bridgeport machine like yours sell for $25,000 AUD a couple of months ago.

I look on US ebay and there are plenty for sale for reasonable prices, makes me jealous of you yanks

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

12 Nov 2019 06:10 #150173

by Michael

Replied by Michael on topic Bridgeport Torq Cut 22 Retrofit

That is unfortunate. Right after I got this one I found someone who sold 3 Bridgeports, 2 TC22's and a TC30, mid 1990's models for I think $6500 total. I really wanted a TC30 but this deal was too good to pass up. There are a lot of used 3 axis machines for sale on the west coast of the US, maybe freight would be worth it if you can get the price right.

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

- thefabricator03

-

- Visitor

-

12 Nov 2019 06:16 #150174

by thefabricator03

Its funny you mention that as I have been looking at freight forwarders and seeing how much it will cost to import a used machine.

I would really like a late 90's model HAAS VF2 but most I have seen are in the 15-20,000 USD range. Converting to AUD = 22-30,000. + Freight and import fees.

Not exactly cheap but I guess thats what I get for living on a island at the bottom of the world.

Replied by thefabricator03 on topic Bridgeport Torq Cut 22 Retrofit

There are a lot of used 3 axis machines for sale on the west coast of the US, maybe freight would be worth it if you can get the price right.

Its funny you mention that as I have been looking at freight forwarders and seeing how much it will cost to import a used machine.

I would really like a late 90's model HAAS VF2 but most I have seen are in the 15-20,000 USD range. Converting to AUD = 22-30,000. + Freight and import fees.

Not exactly cheap but I guess thats what I get for living on a island at the bottom of the world.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

12 Nov 2019 14:14 - 12 Nov 2019 14:14 #150200

by andypugh

Depending on what you need to drive you might want to look at the 7i64. It switches 48V and 2.5A, so might save you some relays. Also each channel is completely isolated so you can switch / sense as many different voltages as you need.

Replied by andypugh on topic Bridgeport Torq Cut 22 Retrofit

No, they both work.Is there any advantage to use the 6i25 over a 7i92?

I will be pushing the limits of I/O on the 7i77 and want to know if there are better options than a 7i70 or 7i84?

Depending on what you need to drive you might want to look at the 7i64. It switches 48V and 2.5A, so might save you some relays. Also each channel is completely isolated so you can switch / sense as many different voltages as you need.

Last edit: 12 Nov 2019 14:14 by andypugh.

The following user(s) said Thank You: Michael

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

Less

More

- Posts: 335

- Thank you received: 59

13 Nov 2019 22:07 - 13 Nov 2019 22:08 #150329

by Michael

The 7i64 looks really nice. Wish I noticed in my original planning for the machine. I am already a couple hundred dollars into relays or I would. I would for sure do the 7i64 if it could also switch AC circuits at 120V as a lot of my tool changers components are AC. The switching flexibility is perfect for a bunch of the servo drive inputs/outputs.

So I am about to place an order. One 7i92M that will connect direct to the 7i77. One CAT5E cable for SSERIAL 4M RJ45 both ends, from the computer to the 7i92

Then I can run off 7i77 TB6 to a 7i84 with a CAT5E cable. Looking at the mesa price list though their two different cable options:

CAT5E cable for SSERIAL 1M one end TB6 for 7I76,7I78

or

CAT5E cable for SSERIAL 1M one end TB8 for 7I52,7I53,7I77

Wondering if there is a typo (price list attached) in there as the RS-422 on the 7i77 is off TB6. I may just make my own cable for this, sure I have a ton lying around.

I take it once connected the 7i84 can be programmed using pnconf at least to get started on some basics?

Replied by Michael on topic Bridgeport Torq Cut 22 Retrofit

Depending on what you need to drive you might want to look at the 7i64. It switches 48V and 2.5A, so might save you some relays. Also each channel is completely isolated so you can switch / sense as many different voltages as you need.

The 7i64 looks really nice. Wish I noticed in my original planning for the machine. I am already a couple hundred dollars into relays or I would. I would for sure do the 7i64 if it could also switch AC circuits at 120V as a lot of my tool changers components are AC. The switching flexibility is perfect for a bunch of the servo drive inputs/outputs.

So I am about to place an order. One 7i92M that will connect direct to the 7i77. One CAT5E cable for SSERIAL 4M RJ45 both ends, from the computer to the 7i92

Then I can run off 7i77 TB6 to a 7i84 with a CAT5E cable. Looking at the mesa price list though their two different cable options:

CAT5E cable for SSERIAL 1M one end TB6 for 7I76,7I78

or

CAT5E cable for SSERIAL 1M one end TB8 for 7I52,7I53,7I77

Wondering if there is a typo (price list attached) in there as the RS-422 on the 7i77 is off TB6. I may just make my own cable for this, sure I have a ton lying around.

I take it once connected the 7i84 can be programmed using pnconf at least to get started on some basics?

Last edit: 13 Nov 2019 22:08 by Michael.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

15 Nov 2019 13:40 #150422

by andypugh

No, it is DC 48V max. For 120V AC you would still need relays or SSRs

Replied by andypugh on topic Bridgeport Torq Cut 22 Retrofit

The 7i64 looks really nice. Wish I noticed in my original planning for the machine. I am already a couple hundred dollars into relays or I would. I would for sure do the 7i64 if it could also switch AC circuits at 120V as a lot of my tool changers components are AC.

No, it is DC 48V max. For 120V AC you would still need relays or SSRs

Please Log in or Create an account to join the conversation.

Time to create page: 0.384 seconds