Bridgeport Torq Cut 22 Retrofit

- Michael

- Offline

- Platinum Member

-

- Posts: 335

- Thank you received: 59

Pretty close to throwing in the towel on these servos. I could not find any posts where someone successfully set them in velocity mode. Almost all of the info out there for them is when used in position mode.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21364

- Thank you received: 7287

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

- Posts: 335

- Thank you received: 59

Yeah I had a look at that. I looked at JT's. Looked at dozens of other posts on her about the same thing. A lot of the info contradicts itself. Starting off adjusting P was about an 8 hour waste as I would get it to a point and then try and adjust FF1 off of zero only to cause a crash at the high P value. Also contradictory was the advice that if you know your axis speeds in IPS and use those for your scale then FF=1. So chased that around for awhile.

Spent about 16 hours chasing my tail following your guide. Every time I got the error close and and increase jog speed and dial it in a bit more. Thought I was making decent progress but would go back to a slower jog speed and the ferror would be horribly off so I would start again. All this with varying values of P since your guide says to start their and then move to FF1 but also back off P while you do that. Only to think I was close util I added P back in and it was no good. Didn't get this far until PCW told me I should be adjusting ferror at least half rapid speed. So I started testing at 292 IPM and seemed to find a decent spot that does scale backwards but my ferror line has a lot of over/under shoot.

I have also been back and forth with DMM about their drive tuning. Did the auto tune and as soon as I switched the control method to analog and speed the axis came crashing down. They were surprised at how low the settings auto tune suggested were and gave me some manual tuning info. Of the 5 settings they basically told me to adjust 2 of them main and speed gain. between 10 and 50 the (of 127) the axis will hold position without making horrible noises. but most of those settings cause a clicking or electronic ringing noise. I think I am currently t 40 for both of those settings. The integration gain "usually doesn't effect things". Both the max acceleration and torque filter have the nice feature of being off at max value of 127 (not mentioned anywhere in the manual for accel) so I spent a good amount of time doing that backwards. The end result is that torque filter should probably be left off and max accel is actually a smoothing feature and seems to do more to quite the noise of the motor at zero speed then anything else noticeable. The conclusion I got from DMM is that the issue is in Linux, or noise on the analog or.... who knows. Oh and at 292IPM I am getting an over voltage error so I am ordering a braking resistor to help. And also on a few random occasions the drives decided after an error that they were going to default back to some previous setting. WHich usually led to a crash after I cleared the error and tried to jog the axis.

So I am a bit frustrated because this ended up being a big time sink despite all the prep and reading I did before hand. Most of the DMM servo threads are actually in position mode. I didn't find anyone who was successful at analog speed control. In fact in the thread Tommy linked a good majority of the pages are questions discussing tuning a DMM servo in position mode.

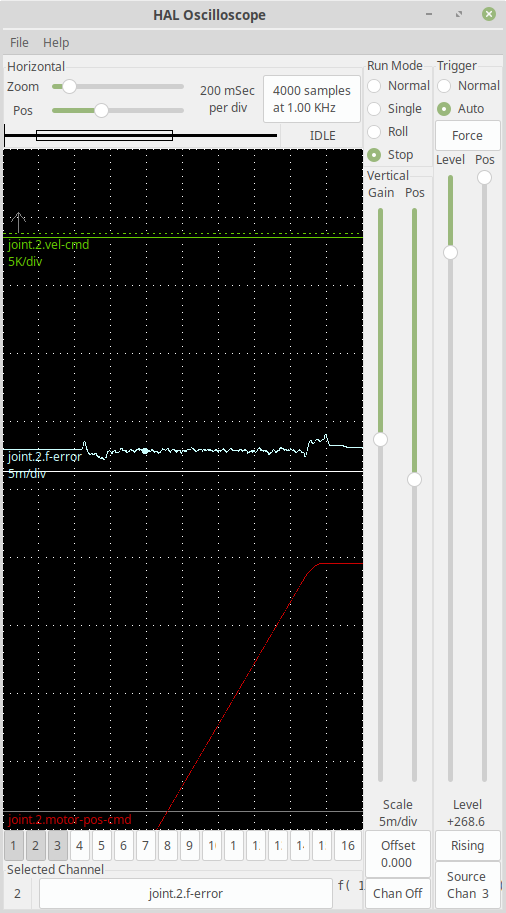

Here is where I am at now. I would love to know what the graduations on the ferror gain are? Currently been reading at 5m/div, no idea if this is good, just copied off the pictures I saw. I have a decent looking line with a bit of over/under at both ends. If I go up too much with FF2 then I actually move it to an undershoot at the beginning and over at the end. I am guessing there is a happy medium in there somewhere. The FF2 testing is being done at 135IPM to avoid the over voltage issue. Any thoughts?

P65 FF1= 1.0215 FF2= .0047 at 135IPM

P65 FF1= 1.0215 FF2= .0047 at 292IPM

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17730

- Thank you received: 5187

Also contradictory was the advice that if you know your axis speeds in IPS and use those for your scale then FF=1. So chased that around for awhile.

I have never given this advice, The math is that for a analog velocity mode servo,

if you set the output scale to the machine units per second at full scale output (10V)

FF1 ==1.000. If you need a value other than FF1=1.000, you have not set the output

scale according to the rule.

This is very basic to how velocity mode servos work, even before any feedback is

applied, the applied voltage should be what is required to move the axis at

LinuxCNCs requested velocity. This is what FF1 does.

The error in the plots is in machine units so with imperial units, the scale is .005"

per division.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

- Posts: 335

- Thank you received: 59

After reading through a number of similar threads were folks are stuck tuning servos I can to realize that none of them had FF1=1 as I am willing to bet that is near impossible to adjust your scale perfectly to make that happen.

It would be better to phrase that as "theoretically FF=1 when output is scaled in IPS at max velocity but other factors such as friction and actual output voltage variances will cause it to be different then velocity calculations." This requiring you to adjust it off 1. Every post I have read you make that statement. It's very matter of fact. Following tommy's post it's also states

"You can either calculate FF1 (10/velocity@10V) or scale the analog output

in velocity in which case FF1 = 1.0"

I haven't read everything on here but I found a lot of threads where people were stuck on the same subject. The same things were given to them as advice. The same links were provided, Andy, JT and tommy. But folks never seemed to make much progress or took their project another direction. I get that what you guys are saying makes sense to you and that tuning a servo should only take 5 minutes but the info isn't very clear and it just seems to be repeated.

I am very much appreciative but am trying to give some feedback as to how the things you say are being interpreted and used.

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

- Posts: 335

- Thank you received: 59

.

The error in the plots is in machine units so with imperial units, the scale is .005"

per division.

A division being the dots or each box on the scope?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17730

- Thank you received: 5187

in fact if you do the calculation, and are close to tuned with FF1 =1.000

you can just adjust OUTPUT_SCALE instead.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17730

- Thank you received: 5187

.

The error in the plots is in machine units so with imperial units, the scale is .005"

per division.

A division being the dots or each box on the scope?

A division is one square on the grid , (a dot is 1/10 of a division)

Please Log in or Create an account to join the conversation.

- Michael

- Offline

- Platinum Member

-

- Posts: 335

- Thank you received: 59

Any reason why when I try and jog in .0001" increments that a change of direction takes around 20 button pushes before the axis moves in the opposite direction. It's not backlash, movement of the encoder doesn't happen. Product of the axis not being dialed in all the way?

What speeds should FF2 be dialed in at?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17730

- Thank you received: 5187

Have you set it as high as possible?

Also make sure you dont have any filtering enabled in the drive

as that will prevent setting linuxCNCs P term as high as possible

so as to minimize following error.

The larger the velocity, the longer the accel/decell times so I

would use the highest velocity for tuning FF2 as the

pedestal will be more clearly separated from other

errors.

Please Log in or Create an account to join the conversation.