Servo wiring and operation - Help needed wiring diagram

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

14 Nov 2019 14:57 #150366

by jools

Servo wiring and operation - Help needed wiring diagram was created by jools

Hi All

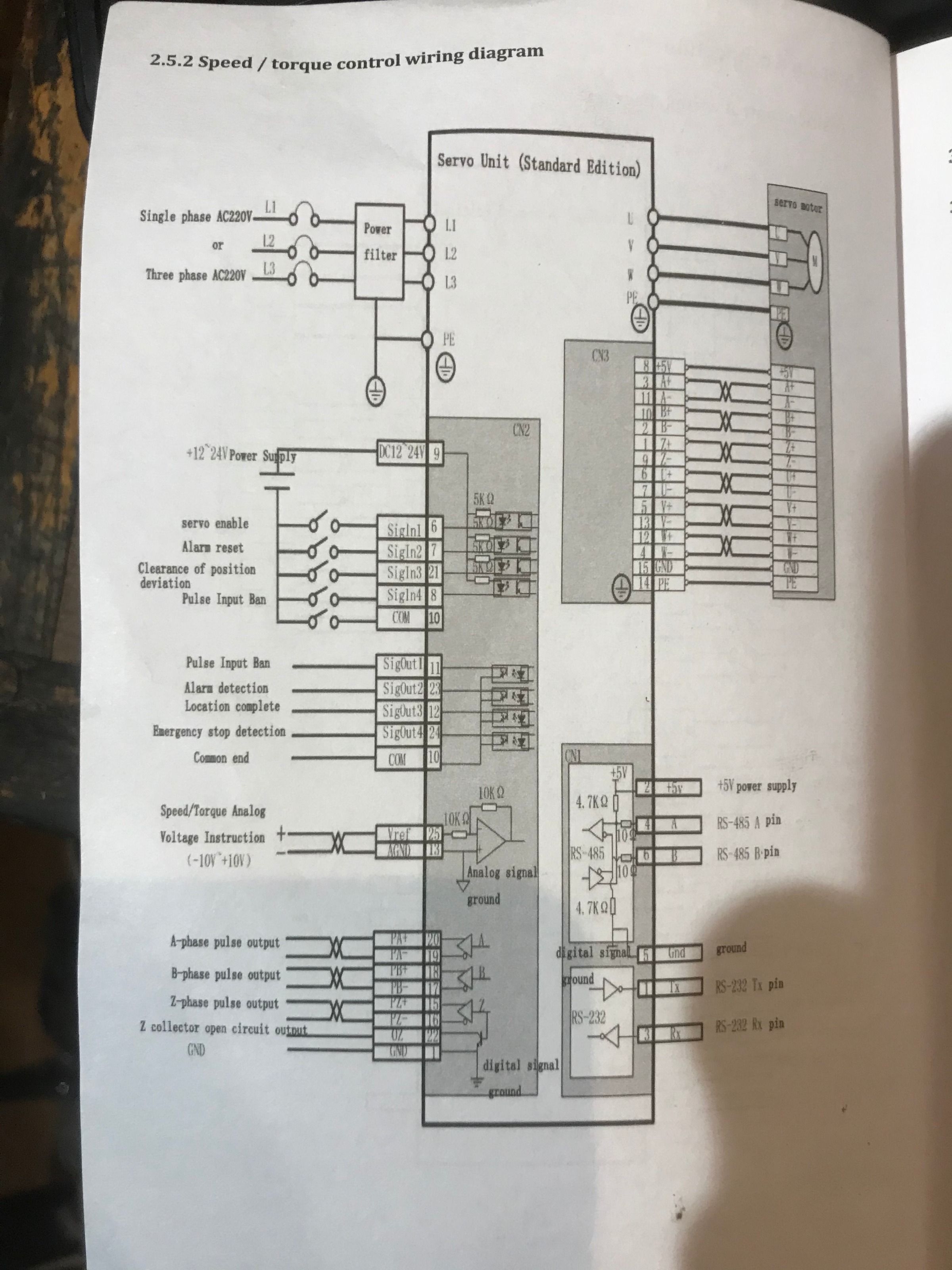

I'm wiring my servo for the spindle motor and would like some help as the manual is overwhelming and the wiring diagram confuses me and my basic knowledge.

The diagram is below to refer to.

Questions.

- Middle left CN2 panel: There are 5 switches/inputs shown; Servo enable, Alarm reset, clearance of deviation and pulse input ban.

1st) Can these just be push-button manual switches. So for Servo-Enable could I have a No-Volt-Relay, for Alarm-Clear and Clear-Deviation just a moment switch? These to be wired through a 24v dc power supply.

2nd) What is pulse input ban and do I need it?

In the Sigout there are 5 outputs: Pulse-Input_ban, Alarm-Detection, Location-Complete, Emergency-Stop-Detection and Common-End.

1st) Do I need Pulse input ban?

2nd) Alarm-detection. Should I wire common end to the common input ground on the Mesa 7i96 and the Alarm-Detection output to the input +ve on the Mesa?

3rd) Do I need location complete? I can't see a use for this at all!

4th) Emergency stop detection - My emergency stop just shuts down mains power, do I need this?

Speed Torque Analogue Voltage Instruction

I have enabled the PWM output on the MESA. PCW says get an digital to analogue converter so I will do.

1st) Will the converter only output +ve voltage?

2nd) If so should I use an output pin on the Mesa to drive some sort of polarity inverter or relay that switches pins so the spindle will drive in reverse?

Encoder

I read my encoder via differential signals with two wires so get the top part of this diagram.

1st) What is OZ and do I need to connect it to the Mesa? If so where on the Mesa?

2nd) GND - What if anything should I connect this too?

Thanks guys for all your help, you're all amazing

Jools

I'm wiring my servo for the spindle motor and would like some help as the manual is overwhelming and the wiring diagram confuses me and my basic knowledge.

The diagram is below to refer to.

Questions.

- Middle left CN2 panel: There are 5 switches/inputs shown; Servo enable, Alarm reset, clearance of deviation and pulse input ban.

1st) Can these just be push-button manual switches. So for Servo-Enable could I have a No-Volt-Relay, for Alarm-Clear and Clear-Deviation just a moment switch? These to be wired through a 24v dc power supply.

2nd) What is pulse input ban and do I need it?

In the Sigout there are 5 outputs: Pulse-Input_ban, Alarm-Detection, Location-Complete, Emergency-Stop-Detection and Common-End.

1st) Do I need Pulse input ban?

2nd) Alarm-detection. Should I wire common end to the common input ground on the Mesa 7i96 and the Alarm-Detection output to the input +ve on the Mesa?

3rd) Do I need location complete? I can't see a use for this at all!

4th) Emergency stop detection - My emergency stop just shuts down mains power, do I need this?

Speed Torque Analogue Voltage Instruction

I have enabled the PWM output on the MESA. PCW says get an digital to analogue converter so I will do.

1st) Will the converter only output +ve voltage?

2nd) If so should I use an output pin on the Mesa to drive some sort of polarity inverter or relay that switches pins so the spindle will drive in reverse?

Encoder

I read my encoder via differential signals with two wires so get the top part of this diagram.

1st) What is OZ and do I need to connect it to the Mesa? If so where on the Mesa?

2nd) GND - What if anything should I connect this too?

Thanks guys for all your help, you're all amazing

Jools

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

14 Nov 2019 15:09 #150368

by tommylight

Replied by tommylight on topic Servo wiring and operation - Help needed wiring diagram

Attachments:

The following user(s) said Thank You: jools

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

14 Nov 2019 15:59 #150371

by jools

Replied by jools on topic Servo wiring and operation - Help needed wiring diagram

Thanks Tommy; saviour as always.

Can I reverse the PWM signal to make the spindle reverse? Essentially use some switch to swap the wires?

Can I reverse the PWM signal to make the spindle reverse? Essentially use some switch to swap the wires?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21240

- Thank you received: 7251

14 Nov 2019 16:27 #150374

by tommylight

It can be done as you say, but switching has to be done while the drive is disabled.

Replied by tommylight on topic Servo wiring and operation - Help needed wiring diagram

To what are you wiring it?Can I reverse the PWM signal to make the spindle reverse? Essentially use some switch to swap the wires?

It can be done as you say, but switching has to be done while the drive is disabled.

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

14 Nov 2019 16:38 #150376

by jools

As I am aware, though often get things muddled, the pwm output on the 7i96 is a 5v digital output; so can go from 0volts to 5volts using duty cycle. I have a pwm to analogue converter so think that I can then get an analogue signal in the range of 0 volts to +10 volts. This will drive the spindle in only one direction and I'm hoping for my machine to tap so need the spindle to reverse to withdraw the tap. The manual of the servo says that, again I'm using my knowledge that may be wrong, 0-10v+ drives the spindle one way and 0- -10v reverses it.

I was thinking of using one of the outputs on the 7i96 to drive a relay or 'gizmo' of some sort that had the PWM signal running through it, that would switch the polarity of the PWM signal so it essentially spins in reverse.

Jools

Replied by jools on topic Servo wiring and operation - Help needed wiring diagram

To what are you wiring it?Can I reverse the PWM signal to make the spindle reverse? Essentially use some switch to swap the wires?

It can be done as you say, but switching has to be done while the drive is disabled.

As I am aware, though often get things muddled, the pwm output on the 7i96 is a 5v digital output; so can go from 0volts to 5volts using duty cycle. I have a pwm to analogue converter so think that I can then get an analogue signal in the range of 0 volts to +10 volts. This will drive the spindle in only one direction and I'm hoping for my machine to tap so need the spindle to reverse to withdraw the tap. The manual of the servo says that, again I'm using my knowledge that may be wrong, 0-10v+ drives the spindle one way and 0- -10v reverses it.

I was thinking of using one of the outputs on the 7i96 to drive a relay or 'gizmo' of some sort that had the PWM signal running through it, that would switch the polarity of the PWM signal so it essentially spins in reverse.

Jools

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

14 Nov 2019 17:49 #150381

by Todd Zuercher

Replied by Todd Zuercher on topic Servo wiring and operation - Help needed wiring diagram

It might just be simpler to configure your servo drive to use a step/dir signal.

PS. You know you don't have to have a servo on the spindle to rigid tap with Linuxcnc. (I hope you didn't go out and buy one thinking you did.) In Linuxcnc rigid tapping is done by the axis following the movement of the spindle, not the spindle following the axis.

PS. You know you don't have to have a servo on the spindle to rigid tap with Linuxcnc. (I hope you didn't go out and buy one thinking you did.) In Linuxcnc rigid tapping is done by the axis following the movement of the spindle, not the spindle following the axis.

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

14 Nov 2019 18:53 #150382

by jools

Replied by jools on topic Servo wiring and operation - Help needed wiring diagram

No the servo met the needs I had best.

I’ll look into the step sir option, might be simpler as you say.

I’ll look into the step sir option, might be simpler as you say.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

19 Nov 2019 12:45 #150636

by andypugh

Replied by andypugh on topic Servo wiring and operation - Help needed wiring diagram

Does the manual mention configuring the SigOut pins to be encoder pulse repeaters? It is useful to be able to output spindle position to LinuxCNC.

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 15

19 Nov 2019 13:44 #150642

by jools

I think that does that from the a b z differential outputs. I'm going to hook them up to the encoder inputs on the 7i96 anyway and see if I get a reading.

As an aside Andy I'm really struggling to get my PWM output working is there any chance you can have a look at this thread forum.linuxcnc.org/21-axis/37828-pwm-not-working-7i96#150612

and see if you can spot any errors in the HAL or ini that I've attached there.

Cheers

Jools

Replied by jools on topic Servo wiring and operation - Help needed wiring diagram

Does the manual mention configuring the SigOut pins to be encoder pulse repeaters? It is useful to be able to output spindle position to LinuxCNC.

I think that does that from the a b z differential outputs. I'm going to hook them up to the encoder inputs on the 7i96 anyway and see if I get a reading.

As an aside Andy I'm really struggling to get my PWM output working is there any chance you can have a look at this thread forum.linuxcnc.org/21-axis/37828-pwm-not-working-7i96#150612

and see if you can spot any errors in the HAL or ini that I've attached there.

Cheers

Jools

Please Log in or Create an account to join the conversation.

Time to create page: 0.230 seconds