Luxmill CNC retrofit project

- Oehli

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

29 May 2020 18:38 #169339

by Oehli

Replied by Oehli on topic Luxmill CNC retrofit project

Befor adding the spindle synchronization and orientation part it was quite a simple "standard" hal file (spindle part). I attached the old one.

I'll have a look in the manuel. But would be great to get in run in the configuration it currently is...

PCW you are my hope

I'll have a look in the manuel. But would be great to get in run in the configuration it currently is...

PCW you are my hope

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17569

- Thank you received: 5140

30 May 2020 01:28 - 30 May 2020 03:49 #169374

by PCW

Replied by PCW on topic Luxmill CNC retrofit project

The orient component is not trivial to setup

In addition to the orient component you will need an additional PID component for

position control and a mux component for selecting which PID component

(the normal spindle speed PID or the spindle position PID) drives the spindle

velocity setting pin.

You might get a response from someone who has already done this if

you started a new thread titled something like:

"How do I setup spindle orientation"

In addition to the orient component you will need an additional PID component for

position control and a mux component for selecting which PID component

(the normal spindle speed PID or the spindle position PID) drives the spindle

velocity setting pin.

You might get a response from someone who has already done this if

you started a new thread titled something like:

"How do I setup spindle orientation"

Last edit: 30 May 2020 03:49 by PCW.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4624

- Thank you received: 2046

30 May 2020 06:25 #169386

by Aciera

Replied by Aciera on topic Luxmill CNC retrofit project

Have you seen this?

Attachments:

Please Log in or Create an account to join the conversation.

- Oehli

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

30 May 2020 13:48 #169421

by Oehli

Replied by Oehli on topic Luxmill CNC retrofit project

Thank you.

@Aciera: I do already know this PDF but my configuration is different.

Can anybody say something to my second problem:

I already mentioned I added a 2000ppr quadrature encoder to the high speed encoder input (10MHz) of my 7i76e in differential (RS-422) mode with A/A-, B/B-, Z/Z-. I have a stable but not equal (see 1) encoder velocity signal (hm2_7i76e.0.encoder.08.velocity-rpm) up to 5000 rpm. If I go further (max rpm is 6000) I loos the signal completely.

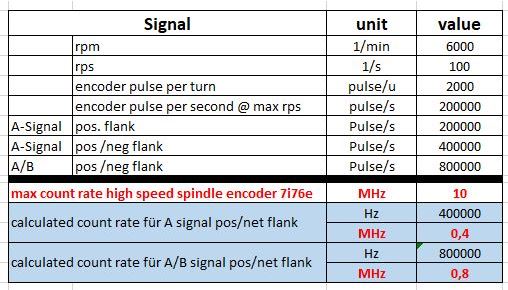

According to my Calculation the max count rate of my encoder at max spindle rpm is much lower than the possible 10MHz:

Is my calculation wrong or do I have to modify something?

@Aciera: I do already know this PDF but my configuration is different.

Can anybody say something to my second problem:

I already mentioned I added a 2000ppr quadrature encoder to the high speed encoder input (10MHz) of my 7i76e in differential (RS-422) mode with A/A-, B/B-, Z/Z-. I have a stable but not equal (see 1) encoder velocity signal (hm2_7i76e.0.encoder.08.velocity-rpm) up to 5000 rpm. If I go further (max rpm is 6000) I loos the signal completely.

According to my Calculation the max count rate of my encoder at max spindle rpm is much lower than the possible 10MHz:

Is my calculation wrong or do I have to modify something?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17569

- Thank you received: 5140

30 May 2020 14:16 - 30 May 2020 14:17 #169423

by PCW

Replied by PCW on topic Luxmill CNC retrofit project

Can you post your current hal/ini files?

The RPM may be different than requested if the scaling is not correct

either in the analog out (in LinuxCNC) analog in ( in your drive ).

The PID loop should correct for these errors if they are minor

but only if the tuning and setup is correct.

The maximum count rate of the encoder depends on how the encoder

input filtering is setup. This filtering is setup with 2 parameters:

1. The global encoder sample rate (this applies to all encoders)

2. The per channel filter bit

The A,B and Index inputs are sampled at the global encoder sample rate

and go through a digital filter for impulse noise rejection. The time constant

of the digital filter can be set to 3 sample periods or 15 sample periods on a per

channel basis via the filter bit. If you have only the one encoder,

I would change the sample frequency, if you have multiple encoders,

I would turn off the filter bit on the spindle encoder channel.

The RPM may be different than requested if the scaling is not correct

either in the analog out (in LinuxCNC) analog in ( in your drive ).

The PID loop should correct for these errors if they are minor

but only if the tuning and setup is correct.

The maximum count rate of the encoder depends on how the encoder

input filtering is setup. This filtering is setup with 2 parameters:

1. The global encoder sample rate (this applies to all encoders)

2. The per channel filter bit

The A,B and Index inputs are sampled at the global encoder sample rate

and go through a digital filter for impulse noise rejection. The time constant

of the digital filter can be set to 3 sample periods or 15 sample periods on a per

channel basis via the filter bit. If you have only the one encoder,

I would change the sample frequency, if you have multiple encoders,

I would turn off the filter bit on the spindle encoder channel.

Last edit: 30 May 2020 14:17 by PCW.

The following user(s) said Thank You: Oehli

Please Log in or Create an account to join the conversation.

- Oehli

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

17 Dec 2022 18:50 - 17 Dec 2022 18:51 #259754

by Oehli

Replied by Oehli on topic Luxmill CNC retrofit project

Hey,

for nearly two years the LinuxCNC configuration and the machine worked fine. Today I found an issue i couldn't really explain - perhaps you can help.

On the top end of my Z axis is a reference switch - this switch is also my home and reference position for ATC. In short distance further up is my soft-limit of the machine (+0.01mm).

Today I jogged the Z-axis up on to this soft limit and wanted to shut down LinuxCNC and the machine. In this point I got the failure " joint must be unhomed, jogged into limits, rehomed" and " Exceeded positive soft limit (0.01) on joint 2". After few tests I found out, that I can overtravel the soft limits in two axis (X and Z). Both axis have a closed loop system with linear scales. The Y-axis, without closed loop, always stops exactly at the soft limit position.

I think this point is related to the closed loop control and the PID. Is this a normal behavior?

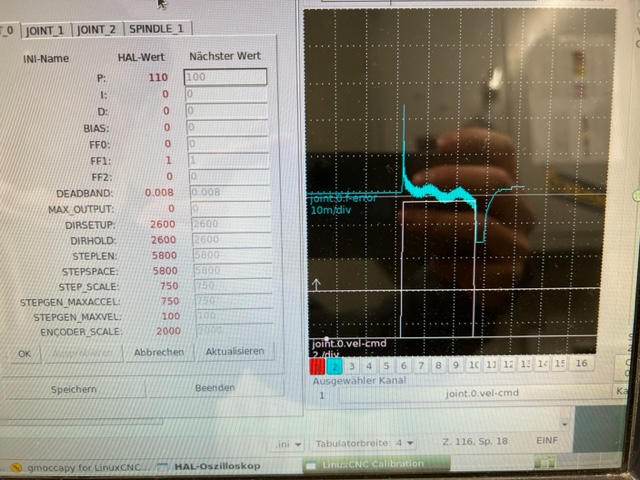

I also check the PID configuration of the axis via Hal-Scope and Halshow and couldn't get a better configuration (lower following error).

Is the peak at the beginning and at the end of the movement normal (acceleration / deceleration)?

Oehli

for nearly two years the LinuxCNC configuration and the machine worked fine. Today I found an issue i couldn't really explain - perhaps you can help.

On the top end of my Z axis is a reference switch - this switch is also my home and reference position for ATC. In short distance further up is my soft-limit of the machine (+0.01mm).

Today I jogged the Z-axis up on to this soft limit and wanted to shut down LinuxCNC and the machine. In this point I got the failure " joint must be unhomed, jogged into limits, rehomed" and " Exceeded positive soft limit (0.01) on joint 2". After few tests I found out, that I can overtravel the soft limits in two axis (X and Z). Both axis have a closed loop system with linear scales. The Y-axis, without closed loop, always stops exactly at the soft limit position.

I think this point is related to the closed loop control and the PID. Is this a normal behavior?

I also check the PID configuration of the axis via Hal-Scope and Halshow and couldn't get a better configuration (lower following error).

Is the peak at the beginning and at the end of the movement normal (acceleration / deceleration)?

Oehli

Attachments:

Last edit: 17 Dec 2022 18:51 by Oehli.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21145

- Thank you received: 7221

17 Dec 2022 19:22 #259762

by tommylight

Replied by tommylight on topic Luxmill CNC retrofit project

You should really remove those 0.01 for all axis/joints and set them to something more reasonable like 0 or -1 if it can travel there.

Assuming mm.

Assuming mm.

Please Log in or Create an account to join the conversation.

- Oehli

- Offline

- Junior Member

-

Less

More

- Posts: 20

- Thank you received: 2

17 Dec 2022 20:56 - 17 Dec 2022 20:57 #259766

by Oehli

Replied by Oehli on topic Luxmill CNC retrofit project

I already tried this by setting the MAX_LIMIT (axis/joints) = 0.01 to 0.1 but this resulted in the same behavior at the new MAX_LIMIT value.

MAX_LIMIT (axis/joints) = 0.01 --> Overtravel to approx. 0.015

MAX_LIMIT (axis/joints) = 0.1 --> Overtravel to approx. 0.105

Or do I understand that wrong?

I didn’t try 0 or 1….

MAX_LIMIT (axis/joints) = 0.01 --> Overtravel to approx. 0.015

MAX_LIMIT (axis/joints) = 0.1 --> Overtravel to approx. 0.105

Or do I understand that wrong?

I didn’t try 0 or 1….

Last edit: 17 Dec 2022 20:57 by Oehli.

Please Log in or Create an account to join the conversation.

Time to create page: 0.155 seconds