Bridgeport Torq-Cut TC4G Retrofit

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

12 Nov 2022 18:33 - 12 Nov 2022 18:36 #256519

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

The project is not dead, just delayed.

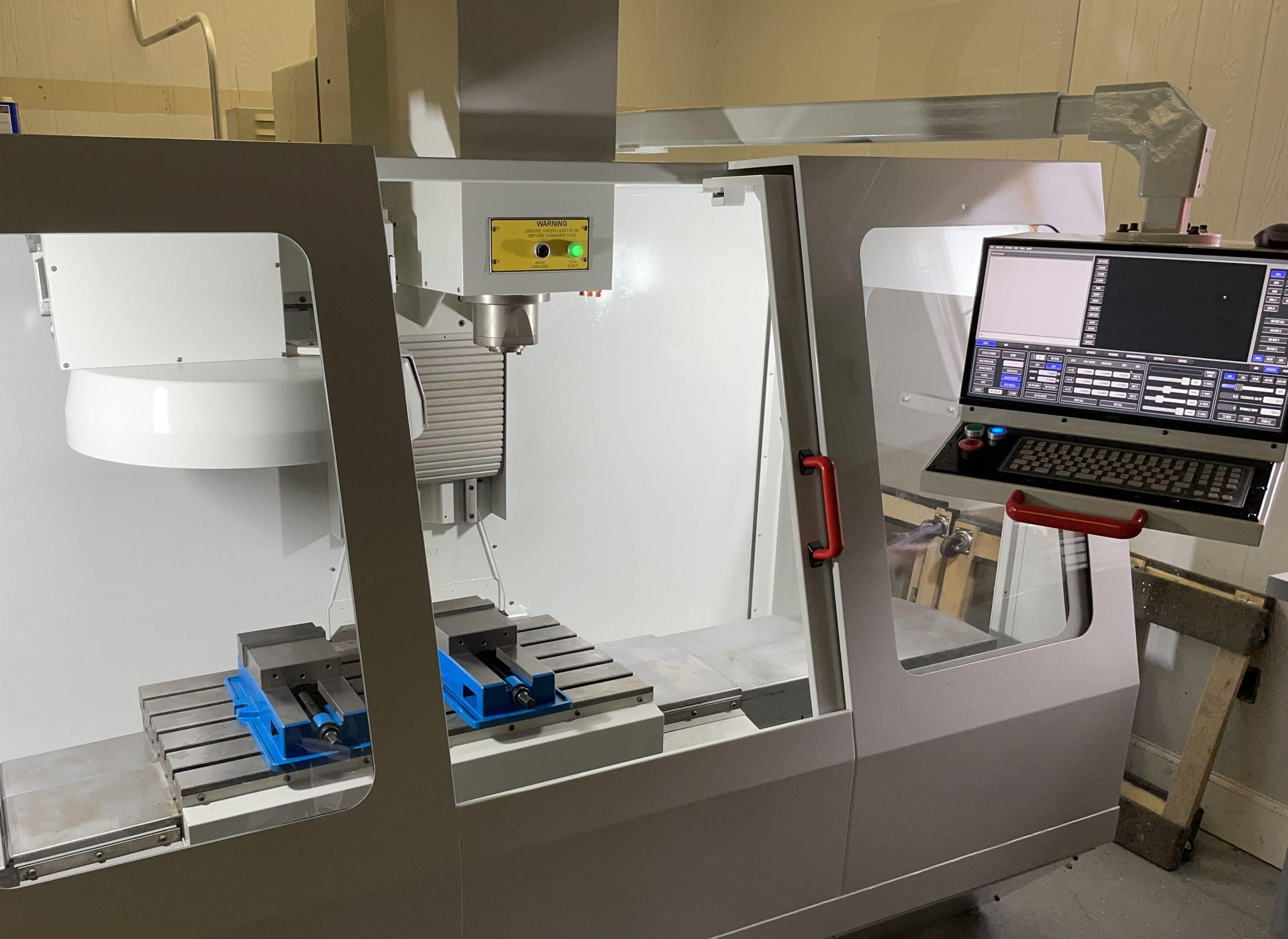

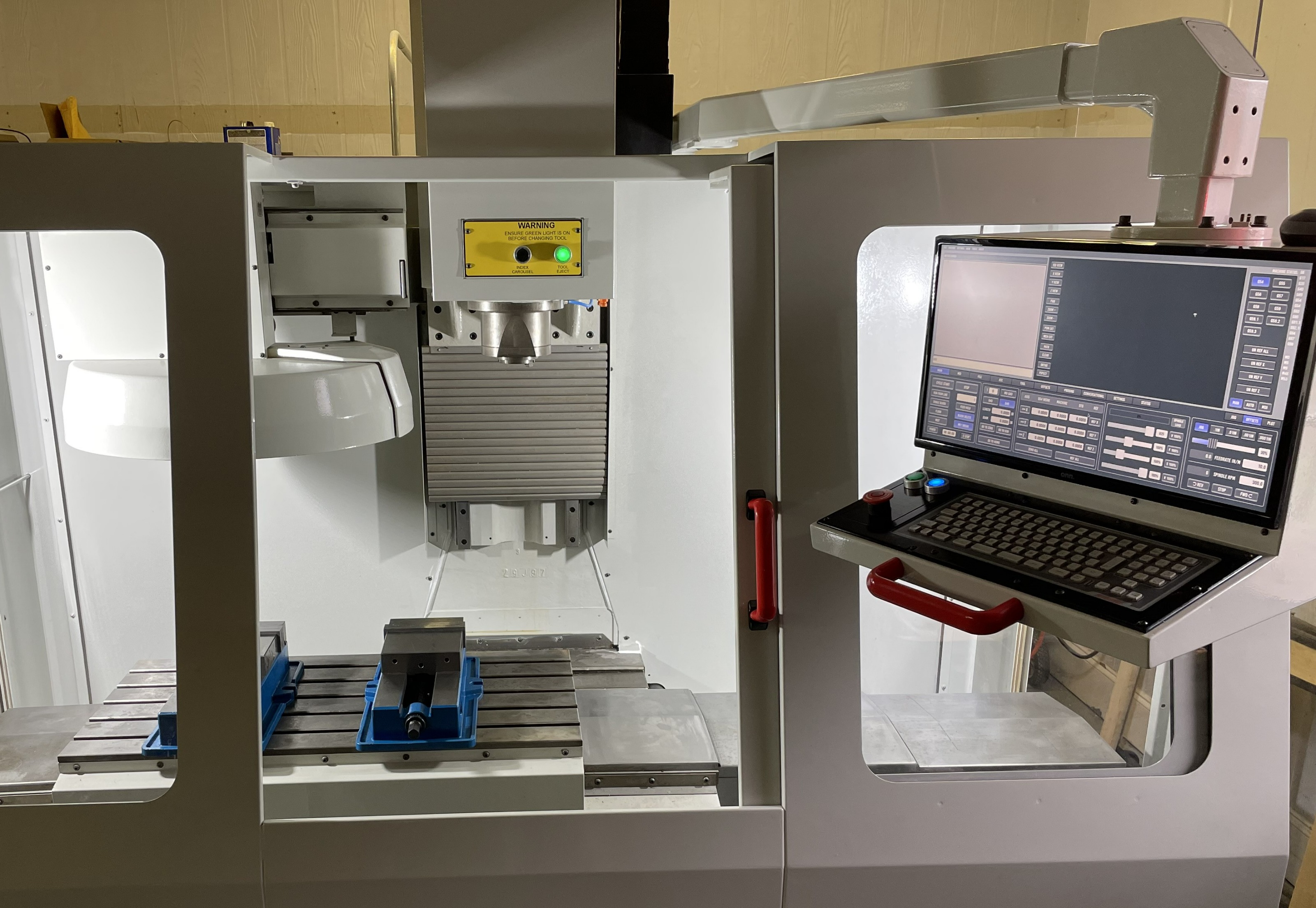

Got some free time to finish up the mill enclosure, control panel, and lighting. Also put all new seals on the way covers and replaced the lexan windows. Working on configuring probe basic as well. I still have my original working config but wanted to try this for a while now. Anyway sorry for the lack of updates, but when life calls you have to answer.

Got some free time to finish up the mill enclosure, control panel, and lighting. Also put all new seals on the way covers and replaced the lexan windows. Working on configuring probe basic as well. I still have my original working config but wanted to try this for a while now. Anyway sorry for the lack of updates, but when life calls you have to answer.

Attachments:

Last edit: 12 Nov 2022 18:36 by chopper79.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- arsenix

-

- Offline

- New Member

-

Less

More

- Posts: 15

- Thank you received: 1

19 Sep 2023 00:31 #281124

by arsenix

Replied by arsenix on topic Bridgeport Torq-Cut TC4G Retrofit

Looks awesome! I have a TC22 still on the stock control that I restored to well running (not restored to nearly the beauty of yours!). I thoroughly enjoy it. I have done a few LinuxCNC conversions so maybe someday I will dig into that. I don't know much about the differences for the TCxG machines vs the TC22. Not a lot of info online for these!

You mentioned a ways back that the spindle bearings were good to 11k and that you planned to configure it for 10k? Did this end up working out? My machine has the two speed "High Torque" spindle that only goes to 6500. Would love some additional RPM out of it as I'm usually machining aluminum and with modern tooling even on steel I'm usually in the lower range of the higher gear. Do these have the identical spindle to the TC22?

You mentioned you changed the seals on the way cover... I assume you mean the rear Y axis? Where did you get the seals? I need to do these on mine. Removing and cleaning out under this area is something I haven't done yet.

This is IMHO a great garage machine. Very small footprint and very capable. I just finished interfacing a 4th axis to mine.

You mentioned a ways back that the spindle bearings were good to 11k and that you planned to configure it for 10k? Did this end up working out? My machine has the two speed "High Torque" spindle that only goes to 6500. Would love some additional RPM out of it as I'm usually machining aluminum and with modern tooling even on steel I'm usually in the lower range of the higher gear. Do these have the identical spindle to the TC22?

You mentioned you changed the seals on the way cover... I assume you mean the rear Y axis? Where did you get the seals? I need to do these on mine. Removing and cleaning out under this area is something I haven't done yet.

This is IMHO a great garage machine. Very small footprint and very capable. I just finished interfacing a 4th axis to mine.

Please Log in or Create an account to join the conversation.

Time to create page: 0.167 seconds