Bridgeport Torq-Cut TC4G Retrofit

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

01 Apr 2020 02:33 - 01 Apr 2020 02:36 #162325

by chopper79

Bridgeport Torq-Cut TC4G Retrofit was created by chopper79

Attachments:

Last edit: 01 Apr 2020 02:36 by chopper79.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

01 Apr 2020 21:36 #162382

by andypugh

Replied by andypugh on topic Bridgeport Torq-Cut TC4G Retrofit

You are having too much fun!

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

01 Apr 2020 22:20 #162389

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Thanks... I believe I will be having tons of fun doing these.

Unfortunately I need to finish getting the shop together and floors painted before I begin. Moved 10hrs from my old shop and starting over, but this gives me an opportunity to do the things I wish I would have the first time.

Unfortunately I need to finish getting the shop together and floors painted before I begin. Moved 10hrs from my old shop and starting over, but this gives me an opportunity to do the things I wish I would have the first time.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

18 Apr 2020 21:26 - 18 Apr 2020 21:32 #164518

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

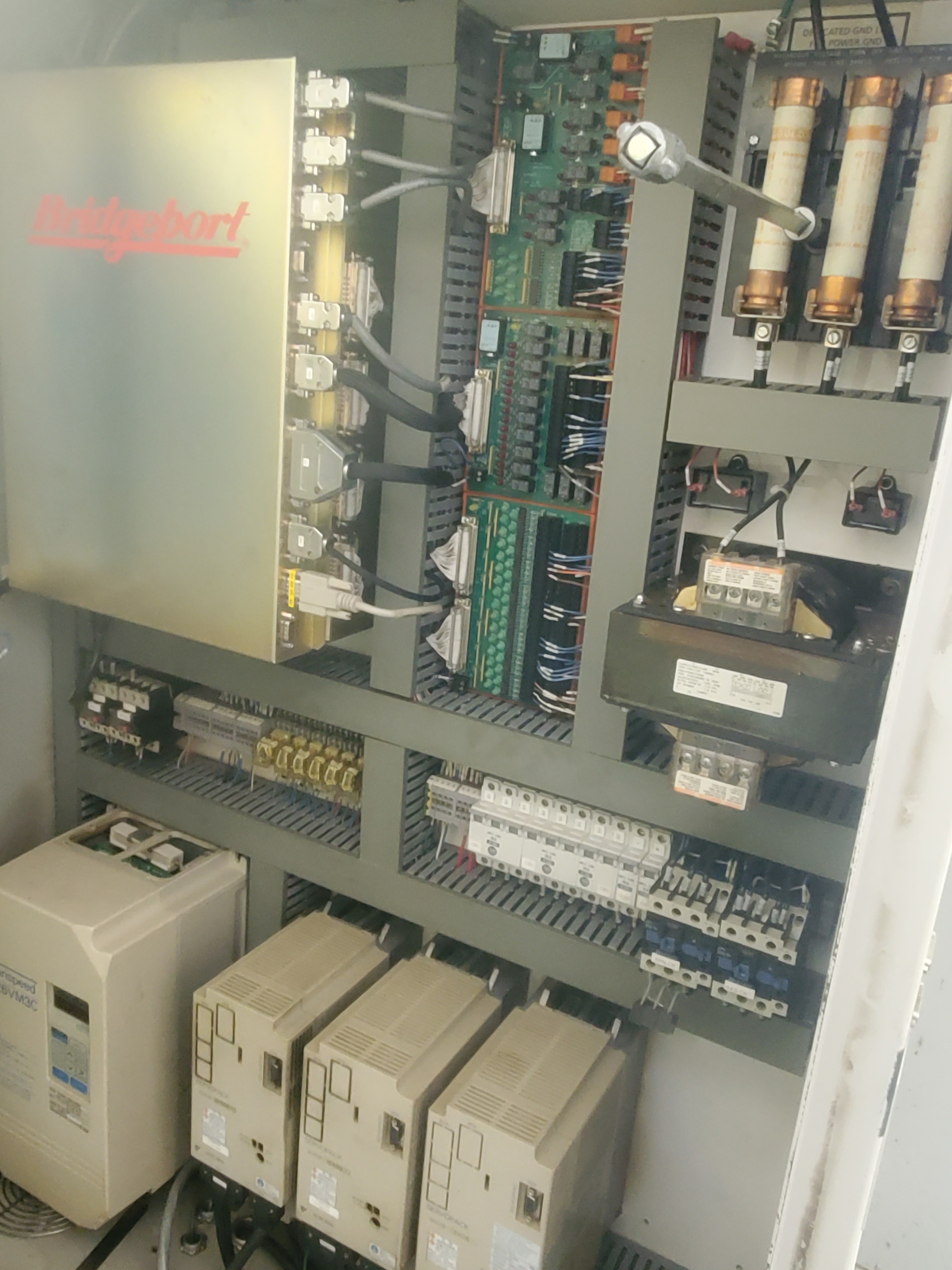

The fun has begun.

* Floors painted (Had my kids throw the paint sprinkle chips. They had a blast doing that)

* Ran power to machine (Ignore the temp wire connections. Will finish conduit once machine is on the floor)

* Tested all functions of machine

* Began disassembly and cleaning (Machine is filthy behind the scenes)

* Looking over mechanical components for issues (Found bad X axis thrust bearing. Appears rusted badly on the left side of X axis. Makes me think machine may not have been level and also do not see any drainage holes.)

* Floors painted (Had my kids throw the paint sprinkle chips. They had a blast doing that)

* Ran power to machine (Ignore the temp wire connections. Will finish conduit once machine is on the floor)

* Tested all functions of machine

* Began disassembly and cleaning (Machine is filthy behind the scenes)

* Looking over mechanical components for issues (Found bad X axis thrust bearing. Appears rusted badly on the left side of X axis. Makes me think machine may not have been level and also do not see any drainage holes.)

Last edit: 18 Apr 2020 21:32 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

18 Apr 2020 21:28 #164519

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

18 Apr 2020 21:31 - 18 Apr 2020 21:35 #164521

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Will update more as I make progress with the cleaning, painting, and assembly. Then comes LCNC goodness...

Last edit: 18 Apr 2020 21:35 by chopper79.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

18 Apr 2020 22:08 #164529

by andypugh

Replied by andypugh on topic Bridgeport Torq-Cut TC4G Retrofit

It looks lovely until you undress it, then horrors emerge.

But they look like good quality parts, at least. That probbaly means they will clean up.

But they look like good quality parts, at least. That probbaly means they will clean up.

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21316

- Thank you received: 7279

18 Apr 2020 23:08 #164537

by tommylight

Replied by tommylight on topic Bridgeport Torq-Cut TC4G Retrofit

Nice.

The fun has began !

The fun has began !

The following user(s) said Thank You: chopper79

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

19 Apr 2020 01:53 - 19 Apr 2020 01:55 #164564

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

Agree with both of you.

I ordered the replacement thrust bearing already. Part number below for anybody needing it.

Thrust bearing = INA ZKLF 2575 2RS

I ordered the replacement thrust bearing already. Part number below for anybody needing it.

Thrust bearing = INA ZKLF 2575 2RS

Last edit: 19 Apr 2020 01:55 by chopper79.

Please Log in or Create an account to join the conversation.

- chopper79

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 193

- Thank you received: 44

21 Apr 2020 01:40 - 21 Apr 2020 01:41 #164911

by chopper79

Replied by chopper79 on topic Bridgeport Torq-Cut TC4G Retrofit

While I was cleaning the mill I have been contemplating what computer I should use to run this thing. I keep coming back to using my RPI4 communicating with a 7i92.

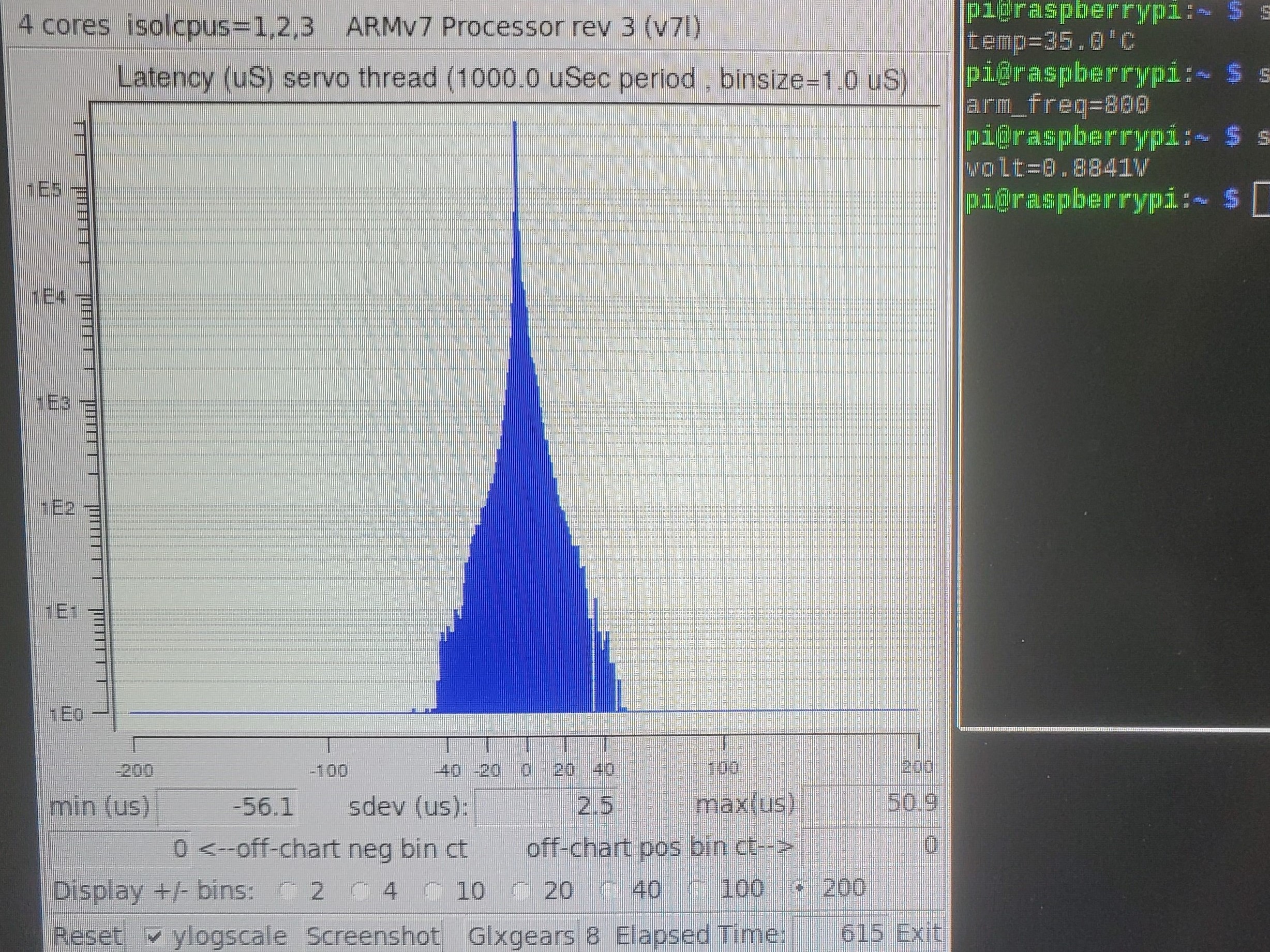

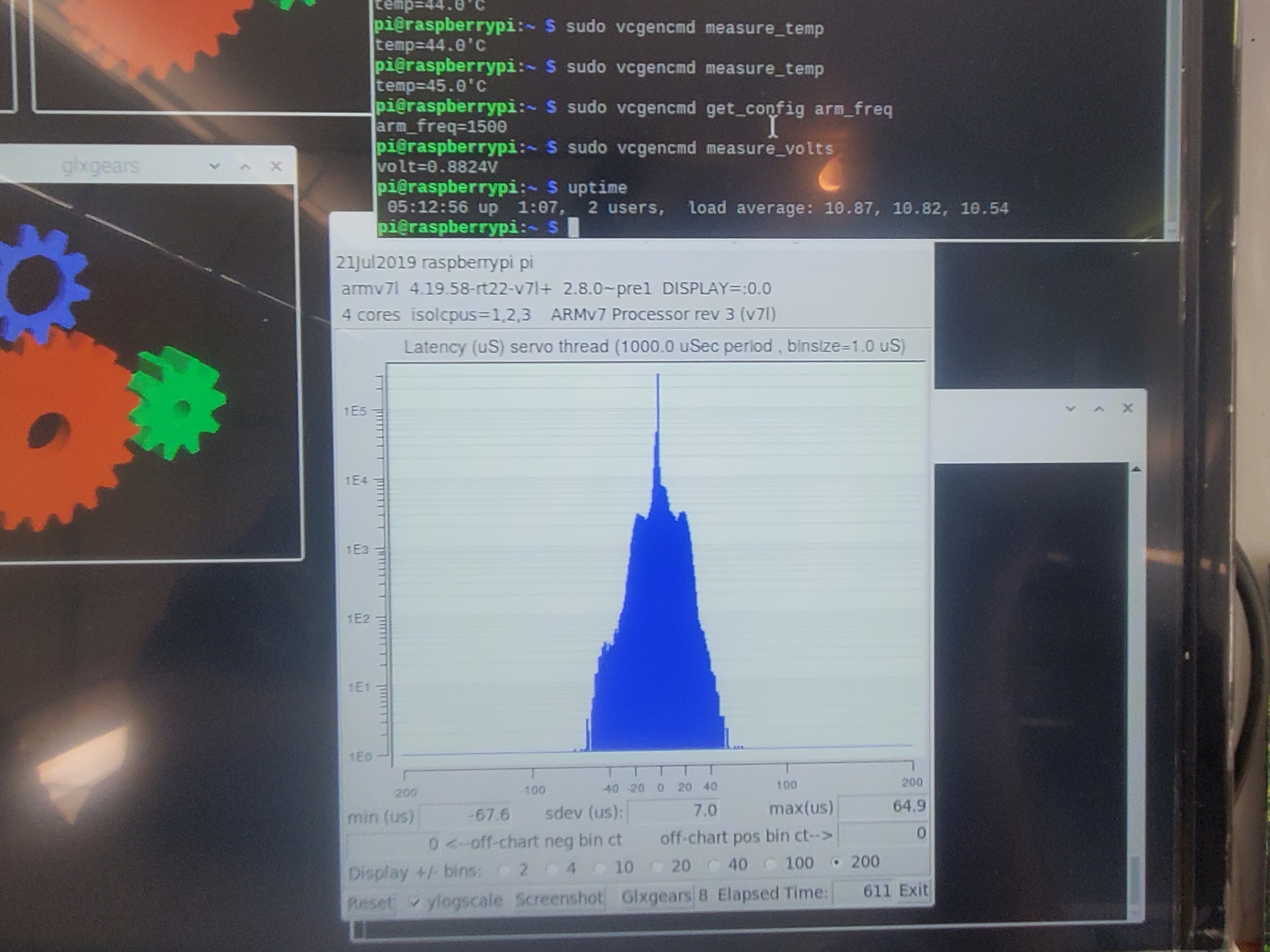

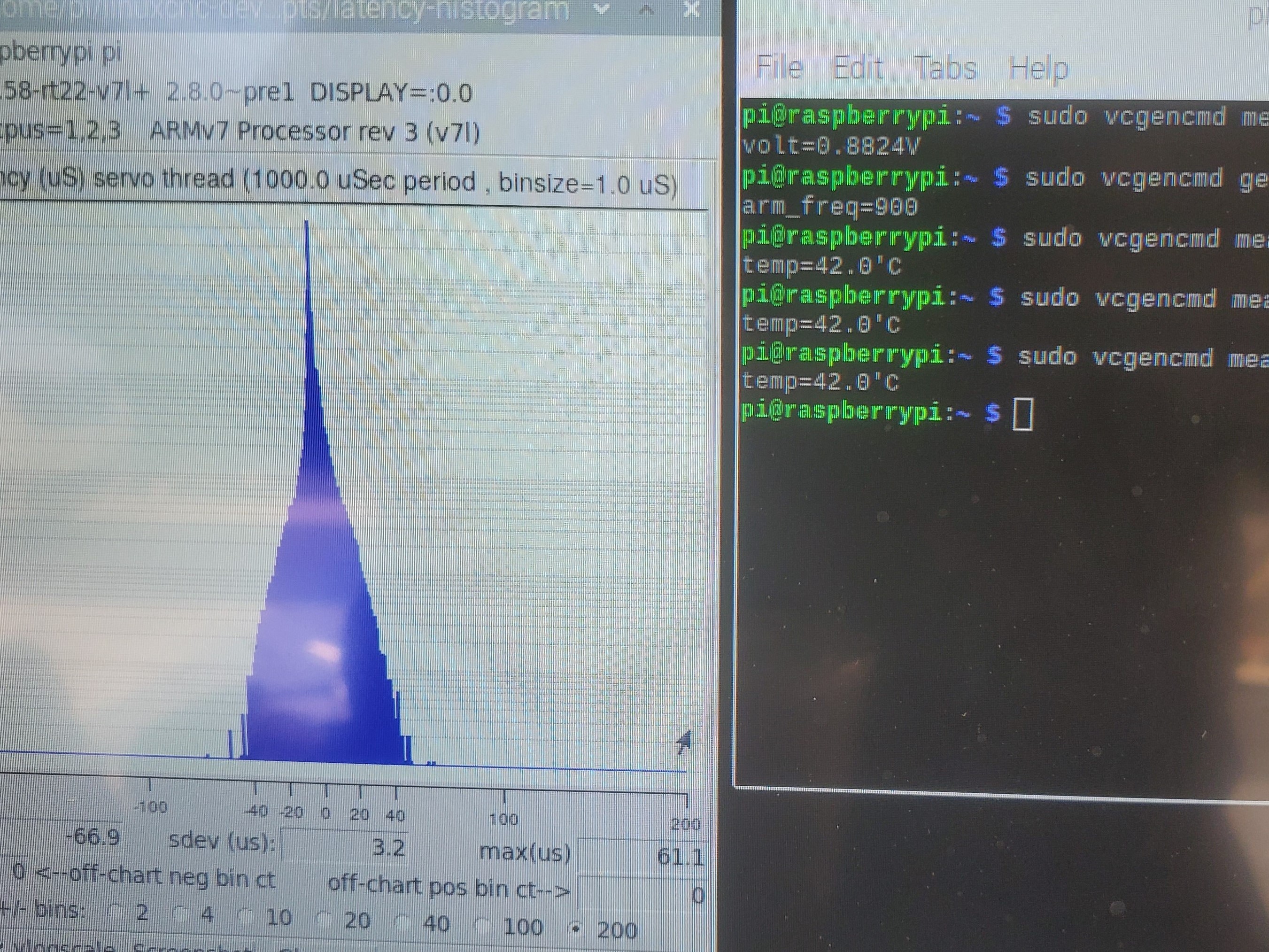

Here are my latency results over a 10 minute duration with 8 glxgears and moving files around. The 3 different views are from different arm frequencies. (800mhz, 900mhz, and 1500mhz)

Notice that the best numbers come from the 800mhz frequency.

What do y'all think about the results and why does the latency change with arm frequency? Any reason I should not run the mill from a RPI4?

Here are my latency results over a 10 minute duration with 8 glxgears and moving files around. The 3 different views are from different arm frequencies. (800mhz, 900mhz, and 1500mhz)

Notice that the best numbers come from the 800mhz frequency.

What do y'all think about the results and why does the latency change with arm frequency? Any reason I should not run the mill from a RPI4?

Last edit: 21 Apr 2020 01:41 by chopper79.

Please Log in or Create an account to join the conversation.

Time to create page: 0.586 seconds