Recommendation for Max ripple voltage for DC servo drives?

- Dbsharp

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 2

10 Feb 2021 14:47 #198281

by Dbsharp

Replied by Dbsharp on topic Recommendation for Max ripple voltage for DC servo drives?

So one thought I keep having is how simple it would be for me to just put some brand new dmm servos in here.

Are the old gn6 hiak really worth the trouble? Will I ever get "great" results considering the feedback is on the screw and not motor? I would assume I would have to compromise a bit on tuning for performance to account for the compliance in the drive belt arrangement.... then again I'm a newbie to servo tuning.

Are the old gn6 hiak really worth the trouble? Will I ever get "great" results considering the feedback is on the screw and not motor? I would assume I would have to compromise a bit on tuning for performance to account for the compliance in the drive belt arrangement.... then again I'm a newbie to servo tuning.

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1052

- Thank you received: 183

11 Feb 2021 11:00 #198382

by Mike_Eitel

Replied by Mike_Eitel on topic Recommendation for Max ripple voltage for DC servo drives?

A simple but not riskless way to find out:

Take a rectifier, connect big c and feed that into your drives. You can scope voltage on the external. Not super precise but a good guess

Mike

Take a rectifier, connect big c and feed that into your drives. You can scope voltage on the external. Not super precise but a good guess

Mike

Please Log in or Create an account to join the conversation.

- Dbsharp

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 2

14 Feb 2021 02:45 - 14 Feb 2021 02:49 #198774

by Dbsharp

Replied by Dbsharp on topic Recommendation for Max ripple voltage for DC servo drives?

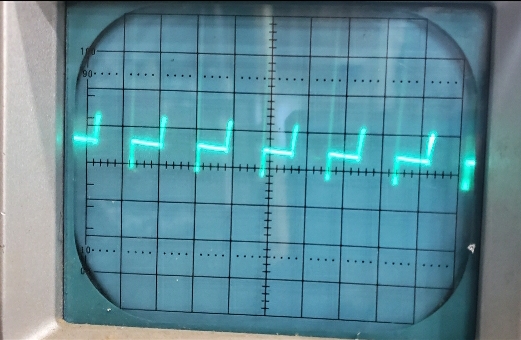

So I got my scope working and discovered a very strange output from the servo amplifier.

I can see some very slight osolations in input signal that seem like they could have a frequency similar to that seen in the velocity from the resolver. I would assume this can be the pid loop? I see similar osolations at a greater amplitude in the drive output.

I find it very odd that half of the signal "disappears" and can only assume a very high voltage during this period. I also get this when the drive is at rest....

Dc 90v supply actually had a very low ripple voltage as it turns out.

This photo is of the servo at reast with the drive powered up.

I can see some very slight osolations in input signal that seem like they could have a frequency similar to that seen in the velocity from the resolver. I would assume this can be the pid loop? I see similar osolations at a greater amplitude in the drive output.

I find it very odd that half of the signal "disappears" and can only assume a very high voltage during this period. I also get this when the drive is at rest....

Dc 90v supply actually had a very low ripple voltage as it turns out.

This photo is of the servo at reast with the drive powered up.

Attachments:

Last edit: 14 Feb 2021 02:49 by Dbsharp.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

14 Feb 2021 09:40 #198784

by andypugh

Replied by andypugh on topic Recommendation for Max ripple voltage for DC servo drives?

I would expect to see PWM, but you seem to be seeing a 1kHz variable amplitude square wave.

But, I have never scoped a servo drive output, so don't know what you would see in practice.

Was that output in the video with a motor connected, turning and reversing?

But, I have never scoped a servo drive output, so don't know what you would see in practice.

Was that output in the video with a motor connected, turning and reversing?

Please Log in or Create an account to join the conversation.

- Dbsharp

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 2

14 Feb 2021 13:22 #198805

by Dbsharp

Replied by Dbsharp on topic Recommendation for Max ripple voltage for DC servo drives?

Yes 20 ipm and it reverses direction a few times. I think ill hook a double aa battery to the drive input next to see if I still get the osolations in output.

In this test I can see osolations in both but the osolations in the drive output seem to be more severe (leading me to believe this could be the source of issues.)

Both x and y do this kind of signal.

In this test I can see osolations in both but the osolations in the drive output seem to be more severe (leading me to believe this could be the source of issues.)

Both x and y do this kind of signal.

Please Log in or Create an account to join the conversation.

- scotth

- Offline

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

14 Feb 2021 19:27 #198829

by scotth

Replied by scotth on topic Recommendation for Max ripple voltage for DC servo drives?

The old Hiak driver were pretty solid. Can you use a battery box to slowly run the slide in an open loop and see if you still have the problem?

Please Log in or Create an account to join the conversation.

- Dbsharp

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 2

17 Feb 2021 21:25 #199182

by Dbsharp

Replied by Dbsharp on topic Recommendation for Max ripple voltage for DC servo drives?

Thanks for all the suggestions, I verified wiring of resolver last night.

I also scoped out the resolver signals and they look exactly as I expected.

I removed the drive belt to the motor and turned the ballscrew by hand and I am still getting this very choppy velocity feedback. At this point I think I have more or less proven the issue is in the resolver interface or my setup of Linux cnc.

Plan is to redo this setup from scratch, very little actually works well here (even the instal of Linux seems to have weird bugs). I will start clean with 2.8 on a new hard drive (so I can switch back if needed)... and ssd > hdd

I also scoped out the resolver signals and they look exactly as I expected.

I removed the drive belt to the motor and turned the ballscrew by hand and I am still getting this very choppy velocity feedback. At this point I think I have more or less proven the issue is in the resolver interface or my setup of Linux cnc.

Plan is to redo this setup from scratch, very little actually works well here (even the instal of Linux seems to have weird bugs). I will start clean with 2.8 on a new hard drive (so I can switch back if needed)... and ssd > hdd

Please Log in or Create an account to join the conversation.

- Dbsharp

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 2

29 Jan 2023 22:51 #263192

by Dbsharp

Replied by Dbsharp on topic Recommendation for Max ripple voltage for DC servo drives?

In case anyone ever is searching for answers to a similar problem, I found the issue on this. The resolvers on my hardinge are not 1:2 or 1:1. They are "syncro resolver control transformer" with 2:1 ratio. It says 2 pahse in 12v and 1 phase out 6v on the resolver. I was getting 1.6v back from the resolvers using the half voltage ouptut.

So I made a voltage divider circuit to cut the 1v reference signal from the 7i49 down to .5v, and now the resolver signals are right at 1 v and it's working great. I checked motion with a couple different .0001" indicators and it's on the money, no more nonlinear issues.

So I made a voltage divider circuit to cut the 1v reference signal from the 7i49 down to .5v, and now the resolver signals are right at 1 v and it's working great. I checked motion with a couple different .0001" indicators and it's on the money, no more nonlinear issues.

Please Log in or Create an account to join the conversation.

Time to create page: 0.105 seconds