Pressbrake CNC Control Setup Questions

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Compile / install it with

sudo halcompile --install press.compOnce installed

man pressIt takes a number of position commands on HAL pins from a GUI, and outputs a target position and velocity.

These should be the inputs to either a limit3 or simple_tp HAL component (I am not sure which will work best) to control velocity, accel and limits. Then the output of that would go to your PID.

The press component also needs to see the position feedback. Provision might have to be made for homing if your scales are not absolute.

I have assumed a three-position foot pedal with up, down and neither outputs.

Starting at the top, pressing the down switch will request a down feed. Releasing the down will set the velocity to zero.

Actuating the up switch will start a retract. releasing the up switch on a retract will stop the motion.

When the press reaches the start height the speed will be changed.

At the finish height motion will stop. Releasing the pedal _without_ actuating the up switch, then re-actuating the down switch will set a target press.0.tweak-down lower. This can be repeated indefinitely.

component press "A component to control a press-brake";

pin in float brake-pos-fb "Position feedback of the press";

pin in float top_position = 0 "Position to return to";

pin in float return_speed = 1 "Speed to return to top at";

pin in float bend_start = 0 "Point of contact with work";

pin in float start_speed = 1 "Speed to move down to initial contact";

pin in float bend_finish = 0 "Position to complete bend";

pin in float bend_speed = 1 "Speed to move at during bend";

pin in float tweak-down = 0 "Extra bend increment";

pin in float pos-tolerance = 0.05 "How close to target to be to stop";

pin out float brake-pos-cmd "Brake position command to motion";

pin out float brake-vel-cmd "Speed command to motion";

pin in float backstop-pos = 100 "Required backstop position";

pin in float backstop-fb = 100 "Backstop position feedback";

pin out float backstop-pos-cmd "Position command out to backstop";

pin in bit up "Command to move up from pedal";

pin in bit down "Command to move down from pedal";

pin in bit abort "Abort current operation and stop all motion";

pin in bit interlock = 1 "Input signal from interlocks to allow cycle";

function _;

license "GPL";

author "andypugh"

;;

#include "rtapi_math.h"

FUNCTION(_){

static int state = 0;

static double target;

switch (state) {

case 0: // at the top, awaiting commands

if (interlock != 1){ // interlock

return; // do nothing. Needs further consideration

}

if (fabs(backstop_pos_cmd - backstop_fb) > 4 * pos_tolerance){ // new backstop position

state = 10;

break;

}

if (down){

target = bend_start;

state = 5;

return;

}

break;

case 5: // moving down to work

brake_pos_cmd = target;

brake_vel_cmd = start_speed;

if (up){ // aborted motion

target = top_position;

state = 8;

return;

}

if (! down){ // pause the downfeed

brake_vel_cmd = 0;

}

if (fabs(brake_pos_fb - target) < pos_tolerance){ // in position

target = bend_finish;

state = 6;

}

break;

case 6: // bending

brake_pos_cmd = target;

brake_vel_cmd = bend_speed;

if (up){ // aborted motion

target = top_position;

state = 8;

return;

}

if (! down){ // pedal released

if (fabs(brake_pos_fb - target) < pos_tolerance){ // in position, consider tweaking

state = 7;

} else { // not in position, just stop

brake_vel_cmd = 0;

}

}

break;

case 7: // at bottom of stroke, waiting for a tweak

if (up){ // return to top

target = top_position;

state = 8;

return;

}

if (down) { // give it a tweak

target += tweak_down;

state = 6;

}

break;

case 8: // return to top

brake_pos_cmd = target;

brake_vel_cmd = return_speed;

// What to do if the down switch is pressed on the retract?

if (! up) { // pedal un-released

brake_vel_cmd = 0;

}

if (fabs(brake_pos_fb - target) < pos_tolerance){ // retracted

state = 0;

}

break;

case 10: // Backstop positioning

backstop_pos_cmd = backstop_pos;

if (fabs(backstop_fb - backstop_pos_cmd) < pos_tolerance){ // retracted

state = 0;

}

break;

default:

rtapi_print_msg(RTAPI_MSG_ERR, "Unsupported state reached in state machine");

}

}Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 31

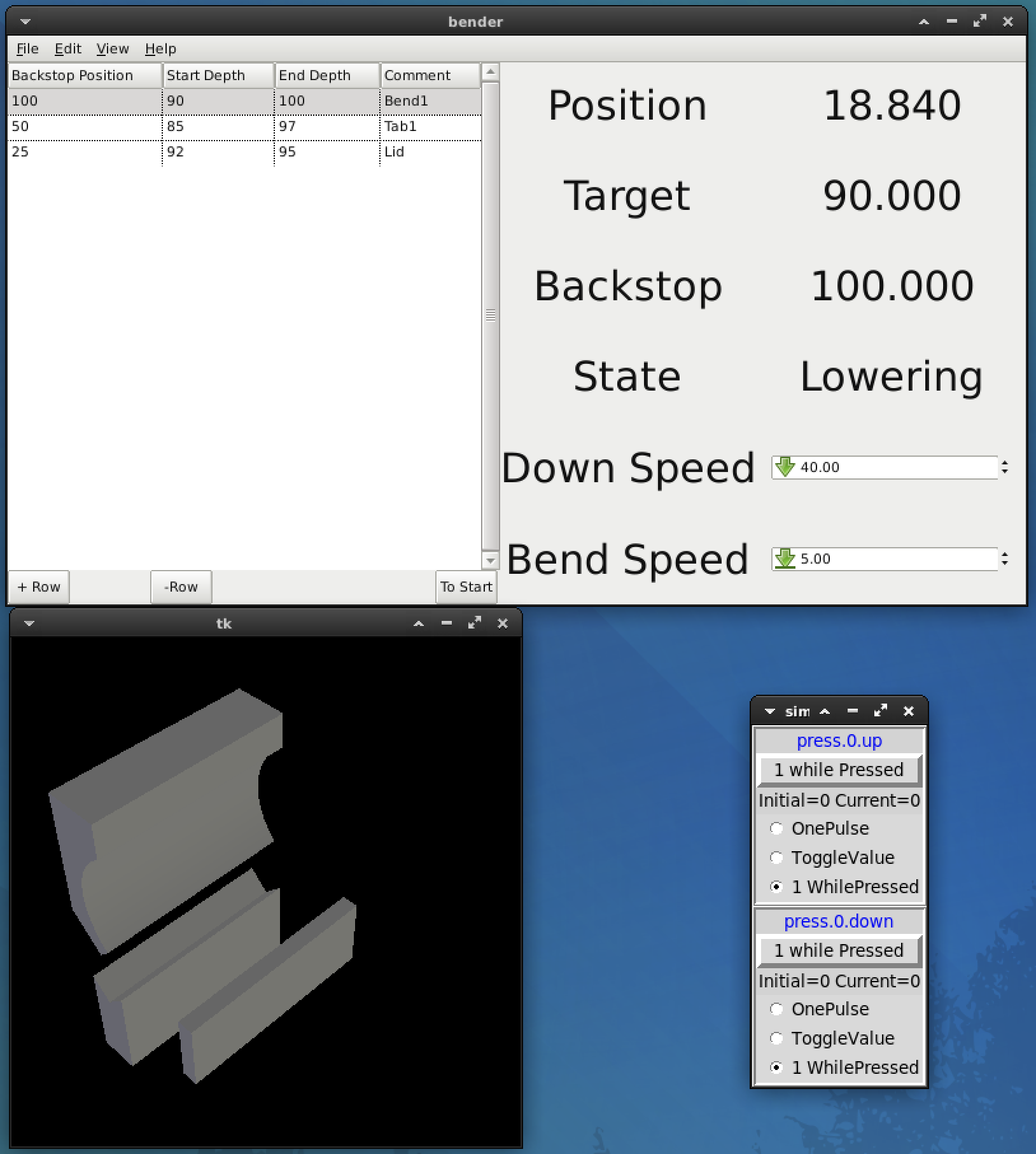

Yes, the UI works, and yes it is only partially set up. I had an electrician, friend helped me retrofit the tubing bender and we got it working and never took the time to refine it. He did the glade gui so I will still need to learn the process myself.andypugh wrote:

Does that UI work? It looks like it is only partially set up, but perhaps I am missing things.

Thanks for the press.comp, looks good. I'm hoping to work at the project today and see if I can make any progress.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

It's prpbably best to define your "wish list" early in the process, and maybe sketch out some GUI designs as you would like them, rather than how you know how to make them in Glade.

Should the bar go down to depth and stay there, or auto-retract a little once at-depth?

Pause at depth?

The state machine should probably have some timeouts and/or overload "escapes"

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Unzip the archive somewhere on your HD. Probably linuxcnc/configs/Bender

You will need to install the press.comp

cd ~/linuxcnc/configs/Bender

sudo halcompile --install press.compchmod x pressguichmod x bender./benderThings that I gave up on for the moment

1) File save / open etc.

It's mainly intended as a basic skeleton for your real machine.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

But I left it in so that it is easy to open a halmeter and watch things / explore the HAL pins, etc.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

I have also re-arranged the UI layout.

Re-download the ZIP file for the new version. There are also changes to the press.comp, that will need to be re-installed.

Still no file save / load though. But I am looking at it.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

(re-uploaded the zip file)

I will stop now, awaiting feedback from someone who has at least used a press brake.

What would be useful? "dublicate bend" button?

Once you are going up, you can't go down again. Is that OK?

Please play with the simulator and see how it feels.

I think that there is plenty of scope for cosmetic improvement too.

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 31

Now my next step is to get it to work with my machine. I've been trying to get the press.comp to work in axis gui, but just can't get it going. Might be with my encoder, pwm, pid settings. I'll attach my hal file. I had the ram jogging before with keyboard y jog.

How do I merge my settings with your program?

Do I use an ini file?

Where do I keep the pid settings?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Now my next step is to get it to work with my machine. I've been trying to get the press.comp to work in axis gui, but just can't get it going.

Basically the output of the simple_tps in my config would need to go to the input of the pids in your config.

You can do away with the INI, or pass it to the HAL file in the bash script with a -i option.

linuxcnc.org/docs/2.8/html/man/man1/halcmd.1.html

If you prefer to not use the INI then you can put the PID gains in the HAL:

setp pid.0.Pgain 100setp pid.0.Pgain [JOINT_0]PGAINYou should remove the loadrt MOTMOD and loadrt KINS lines, and remove anything with "motion" in the name from the HAL.

Do you need homing? There isn't any homing in my config, it rather depends on an absolute encoder as things stand.

There is also nothing controlling machine on/off state or e-stop etc at the moment.

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 114

- Thank you received: 31

Yes, I will need machine on/offAs far as homing goes, now yet I was manuel homing with ram cylinder at top of stroke. Should I be adding a homing switch or is it possible to home off of encoder index?My encoder is an incremental linear encoder.andypugh wrote: Do you need homing? There isn't any homing in my config, it rather depends on an absolute encoder as things stand.There is also nothing controlling machine on/off state or e-stop etc at the moment.

Please Log in or Create an account to join the conversation.