Pressbrake CNC Control Setup Questions

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

06 Jun 2021 22:48 #211372

by andypugh

Replied by andypugh on topic Pressbrake CNC Control Setup Questions

So, what is the current status?

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 113

- Thank you received: 29

07 Jun 2021 20:03 #211438

by EW_CNC

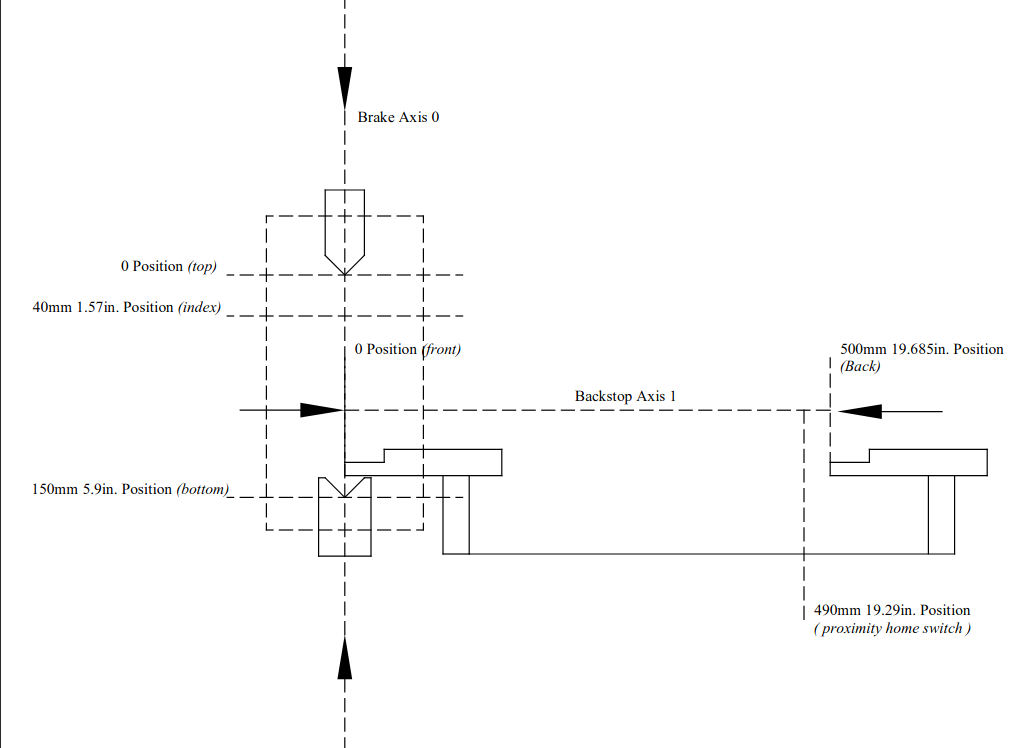

I have the brake ram working down=positive with the homing switch at the 0 negative end of travel.

The backstop has its homing switch at the back=positive of the axis travel, opposite direction of the ram.

The backstop has an index pulse approx. every 20mm.

I tried inverting the home switch input, which lets it search in the right direction, but it does not continue long enough to find an index after tripping the home switch.

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

I'm back to working on the backstop homing. No success yet.So, what is the current status?

I have the brake ram working down=positive with the homing switch at the 0 negative end of travel.

The backstop has its homing switch at the back=positive of the axis travel, opposite direction of the ram.

The backstop has an index pulse approx. every 20mm.

I tried inverting the home switch input, which lets it search in the right direction, but it does not continue long enough to find an index after tripping the home switch.

net home1 press.axis.1.home-switch hm2_7i97.0.inmux.00.input-15-notAttachments:

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 113

- Thank you received: 29

08 Jun 2021 00:21 #211466

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

I have a few questions about the setup.

EW

- Are the pressgui.ini min. and max. axis limits supposed to be functional yet?

- Would it be easy to add a pin to indicate if the axis is homed?

- What is the procedure to add another glade treeview column for the second backstop axis, do changes need to be made to the pressgui python file?

EW

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

10 Jun 2021 14:00 #211701

by andypugh

Replied by andypugh on topic Pressbrake CNC Control Setup Questions

I will try to get to the other points later, when I have the files in front of me.

But...

When you say "approximately every 20mm" do you mean that it is one of the scales with index marks at 20.00, 40.01, 60.03, 80.06 (or similar scheme) so that absolute position can be calculated from any two indices?

There was some discussion about a HAL component to handle such systems elsewhere on the forum.

But...

The backstop has an index pulse approx. every 20mm.

When you say "approximately every 20mm" do you mean that it is one of the scales with index marks at 20.00, 40.01, 60.03, 80.06 (or similar scheme) so that absolute position can be calculated from any two indices?

There was some discussion about a HAL component to handle such systems elsewhere on the forum.

The following user(s) said Thank You: EW_CNC

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 113

- Thank you received: 29

10 Jun 2021 19:13 #211722

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

Unfortunately the backstop axis do not have linear encoders.

They are controlled by programmable Moog servo drives.

The motors give resolver feedback directly to the servo drives, then the servo drives output a simulated differential encoder signal.

So my encoder feedback to the 7i97 is coming from the servo drive. I would say it resembles a rotary encoder.

I don't exactly understand, does the resolver have a zero position that is passed on as the simulated index pulse?

They are controlled by programmable Moog servo drives.

The motors give resolver feedback directly to the servo drives, then the servo drives output a simulated differential encoder signal.

So my encoder feedback to the 7i97 is coming from the servo drive. I would say it resembles a rotary encoder.

I don't exactly understand, does the resolver have a zero position that is passed on as the simulated index pulse?

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 113

- Thank you received: 29

12 Jun 2021 14:04 #211869

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

I now have the bending sequence going through it's whole cycle.

Ram down, bend, return, and adjust both backstop axis. Then proceed to the next bend. Works Good!

The backstop axis still need homing.

Ram down, bend, return, and adjust both backstop axis. Then proceed to the next bend. Works Good!

The backstop axis still need homing.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

14 Jun 2021 22:44 #212066

by andypugh

Yes, resolvers are absolute devices, and the drive will choose one position to call "zero" and can output a Z pulse at that point.

The HAL component was written on the assumption that the axes were the same with regards feedback. I assumed a sing mid-point index, but looking at the code it can be made to work with repeated indices.

Note how it does not pay any attention to index as long as the axis home-switch it active, so you need to set up some sort of target for the home switch that remains active until just after the last index. (this might be easier with a short target an an inverted input in HAL)

The the machine will run one way until home-switch goes false, then reverse direction and home to the index. You just need to ensure that this ends up always being the same index.

Replied by andypugh on topic Pressbrake CNC Control Setup Questions

I don't exactly understand, does the resolver have a zero position that is passed on as the simulated index pulse?

Yes, resolvers are absolute devices, and the drive will choose one position to call "zero" and can output a Z pulse at that point.

The HAL component was written on the assumption that the axes were the same with regards feedback. I assumed a sing mid-point index, but looking at the code it can be made to work with repeated indices.

switch home_state{

case 0:

if (axis_home_switch(axis)) {

axis_pos_cmd_out(axis) = axis_home_offset(axis) * 2;

axis_vel_cmd(axis) = axis_home_search_velocity(axis);

home_state = 1;

} else {

axis_index_enable(axis) = 1;

axis_pos_cmd_out(axis) = -1 * axis_home_offset(axis);

axis_vel_cmd(axis) = axis_home_search_velocity(axis);

home_state = 2;

}

break;

case 1: // searching down

if (! axis_home_switch(axis)){

home_state = 0;

}

break;

case 2: // searching up

if (! axis_index_enable(axis)){

offset(axis) = axis_pos_fb_in(axis) + axis_home_offset(axis);

home_state = 0;

state = 0;

}

break;

}Note how it does not pay any attention to index as long as the axis home-switch it active, so you need to set up some sort of target for the home switch that remains active until just after the last index. (this might be easier with a short target an an inverted input in HAL)

The the machine will run one way until home-switch goes false, then reverse direction and home to the index. You just need to ensure that this ends up always being the same index.

The following user(s) said Thank You: EW_CNC

Please Log in or Create an account to join the conversation.

- Diederik

-

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 2

25 Jun 2021 10:12 - 25 Jun 2021 12:51 #212891

by Diederik

Replied by Diederik on topic Pressbrake CNC Control Setup Questions

(OK...) I have been trying to read some more, therefore rather Edit my post... I am now planning to set my configuration up to be the same as yours.

First now, I am going to run a simulation on my laptop, to play around with it a bit, then learn what to do to best modify my configuration on the machine.

Thanks for the people who is involved here. I will provide feedback soon...

(here with my previous questions, and explanation of my machine's current configuration... (this is my first press brake, so I'm learning as I'm going here)

| | |

~ ~ ~

I'm interested in this. Does anyone have a simulation configuration on this yet? I started with a press brake about a year ago. It's a Amada APX300. It has 6-axis back-stops, and 3 Hydraulic cylinders with proportional hydraulic valves.

I have the back-stops left hand side as X,Y,Z, X-right = positive, Y-away from the ram = positive, and Z-Up= positive.

I have the back-stops right- hand side as U,V,W, U-right = positive, V-away from the ram = positive, and W-Up= positive.

My initial plan was to simplify it by making the Y and V joints, a Tandem Y-Axis. And at a later stage, when I have more knowledge of sheet metal bending, then I can separate the joints again, in order to bend cones / tapers.

So for now, I have the Ram as a A-axis, and then the dies come closer / closing the ram, then the A-axis move in negative direction, and when it opens, then it moves in positive direction. I know ideally A,B and C-axis should be rotating on a machine, but I made my Ram a linear A-axis. If there's specific rules that you should stick to in bending, for cam processing, I would like to know those rules, but these rules is just my own ideas, and I have just about no knowledge on sheet metal work. I only know Lathes and milling machines really. (turning centers, and machining centers.)

So I am very interested in this project, as it is something that I started, but put on hold, as I didn't know a lot of information. And now my mind is in a place again, where I want to learn more.

Please share if anyone has simulation configurations, or videos, or any information really, I would appreciate it.

Question: Is there a rule/ logic reason why linuxcnc is not ideal for a press brake? And is that something in development? I'm not much of a developer, and don't know much about programming, but is that something that the linuxcnc developers will include as a standard configuration within linuxcnc in the future? I know currently there's machining centers(like mills and routers) and there's turning centers(like lathes) and cutters (like plasmac/ plasma cutters, lasers, and waterjets) which works well. But many people currently is telling me that linuxcnc should not be used for press brakes. But I do think for developers to add in bending machines as a standard feature within linuxcnc, would be great. Because at this stage I think what I started, is not great, and people who saw my machine so far, thinks it's not great, and I should have rather spent money on a Delem control or something?

So configurations that would be great to add to linuxcnc (I think) would be : Bending machines and robotic arms (with rotating joints & standard kinematics, where the machine builder only need to fill in parameters, for joint-joint lengths, and options for 3,4,5,6 or 7 Axes robotic arms), with sample configurations? I know this is a lot of work, but I wish I had the knowledge how to get involved... and had the time... But maybe someone is already busy with this? We've built some robotic arms, and Prof. Rudy helped us with the kinematics, and 5-axis machining centers, etc., but I was like re-inventing the wheel almost... and I would not be able to do it without Prof. Rudy du Preez' help... My mind/Brain has a cut-off switch... when it hears math's / Algebra / Complicated-Programming...

First now, I am going to run a simulation on my laptop, to play around with it a bit, then learn what to do to best modify my configuration on the machine.

Thanks for the people who is involved here. I will provide feedback soon...

(here with my previous questions, and explanation of my machine's current configuration... (this is my first press brake, so I'm learning as I'm going here)

| | |

~ ~ ~

I'm interested in this. Does anyone have a simulation configuration on this yet? I started with a press brake about a year ago. It's a Amada APX300. It has 6-axis back-stops, and 3 Hydraulic cylinders with proportional hydraulic valves.

I have the back-stops left hand side as X,Y,Z, X-right = positive, Y-away from the ram = positive, and Z-Up= positive.

I have the back-stops right- hand side as U,V,W, U-right = positive, V-away from the ram = positive, and W-Up= positive.

My initial plan was to simplify it by making the Y and V joints, a Tandem Y-Axis. And at a later stage, when I have more knowledge of sheet metal bending, then I can separate the joints again, in order to bend cones / tapers.

So for now, I have the Ram as a A-axis, and then the dies come closer / closing the ram, then the A-axis move in negative direction, and when it opens, then it moves in positive direction. I know ideally A,B and C-axis should be rotating on a machine, but I made my Ram a linear A-axis. If there's specific rules that you should stick to in bending, for cam processing, I would like to know those rules, but these rules is just my own ideas, and I have just about no knowledge on sheet metal work. I only know Lathes and milling machines really. (turning centers, and machining centers.)

So I am very interested in this project, as it is something that I started, but put on hold, as I didn't know a lot of information. And now my mind is in a place again, where I want to learn more.

Please share if anyone has simulation configurations, or videos, or any information really, I would appreciate it.

Question: Is there a rule/ logic reason why linuxcnc is not ideal for a press brake? And is that something in development? I'm not much of a developer, and don't know much about programming, but is that something that the linuxcnc developers will include as a standard configuration within linuxcnc in the future? I know currently there's machining centers(like mills and routers) and there's turning centers(like lathes) and cutters (like plasmac/ plasma cutters, lasers, and waterjets) which works well. But many people currently is telling me that linuxcnc should not be used for press brakes. But I do think for developers to add in bending machines as a standard feature within linuxcnc, would be great. Because at this stage I think what I started, is not great, and people who saw my machine so far, thinks it's not great, and I should have rather spent money on a Delem control or something?

So configurations that would be great to add to linuxcnc (I think) would be : Bending machines and robotic arms (with rotating joints & standard kinematics, where the machine builder only need to fill in parameters, for joint-joint lengths, and options for 3,4,5,6 or 7 Axes robotic arms), with sample configurations? I know this is a lot of work, but I wish I had the knowledge how to get involved... and had the time... But maybe someone is already busy with this? We've built some robotic arms, and Prof. Rudy helped us with the kinematics, and 5-axis machining centers, etc., but I was like re-inventing the wheel almost... and I would not be able to do it without Prof. Rudy du Preez' help... My mind/Brain has a cut-off switch... when it hears math's / Algebra / Complicated-Programming...

Last edit: 25 Jun 2021 12:51 by Diederik.

The following user(s) said Thank You: EW_CNC

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19752

- Thank you received: 4584

28 Jun 2021 13:13 - 28 Jun 2021 13:14 #213133

by andypugh

Yes, in fact that is all that I have.

See attached, that's my development folder. Unzip it into "configs", halcompile --install the ,comp file, and it should just run.

Note that you don't start it from the LinuxCNC config picker, it is started with the ./bender command.

Replied by andypugh on topic Pressbrake CNC Control Setup Questions

I'm interested in this. Does anyone have a simulation configuration on this yet?

Yes, in fact that is all that I have.

See attached, that's my development folder. Unzip it into "configs", halcompile --install the ,comp file, and it should just run.

Note that you don't start it from the LinuxCNC config picker, it is started with the ./bender command.

Last edit: 28 Jun 2021 13:14 by andypugh.

The following user(s) said Thank You: Diederik

Please Log in or Create an account to join the conversation.

- EW_CNC

-

Topic Author

Topic Author

- Offline

- Premium Member

-

Less

More

- Posts: 113

- Thank you received: 29

28 Jun 2021 18:12 - 28 Jun 2021 18:34 #213163

by EW_CNC

Replied by EW_CNC on topic Pressbrake CNC Control Setup Questions

Andy, I'm still struggling to get the homing working right.

The ram axis with hydraulic homes ok, but it makes a fast move when it homes on the index. Is it applying the offset?

With the other axis it makes that move very rapid, seemingly without velocity control.

I attached a halscope of it homing the the ram axis.

Had you taken notice that earlier I had changed the press.comp to subtract instead of adding the offset? press.comp change

Would this be causing other issues for me?

I attached my .hal file

Thanks, EW

The ram axis with hydraulic homes ok, but it makes a fast move when it homes on the index. Is it applying the offset?

With the other axis it makes that move very rapid, seemingly without velocity control.

I attached a halscope of it homing the the ram axis.

If you notice on the halscope, that it is applying the offset on index with the home switch active. (edit, the halscope is actually showing the reverse direction. so it is working like it should, but has that fast correction move.)Note how it does not pay any attention to index as long as the axis home-switch it active, so you need to set up some sort of target for the home switch that remains active until just after the last index. (this might be easier with a short target an an inverted input in HAL)

The the machine will run one way until home-switch goes false, then reverse direction and home to the index. You just need to ensure that this ends up always being the same index.

Had you taken notice that earlier I had changed the press.comp to subtract instead of adding the offset? press.comp change

Would this be causing other issues for me?

I attached my .hal file

Thanks, EW

Last edit: 28 Jun 2021 18:34 by EW_CNC. Reason: edit comment

Please Log in or Create an account to join the conversation.

Time to create page: 0.108 seconds