Toyota embroidery machine - retrofit

- greg23_78

- Offline

- Premium Member

-

- Posts: 142

- Thank you received: 7

I need your advice on an industrial embroidery machine.

I've managed to recover a Toyota ESP embroidery machine, but it's broken down to the level of the electronic board, I have the impression that it has lost all its parameters, there's a ‘-’ on the screen and then nothing.

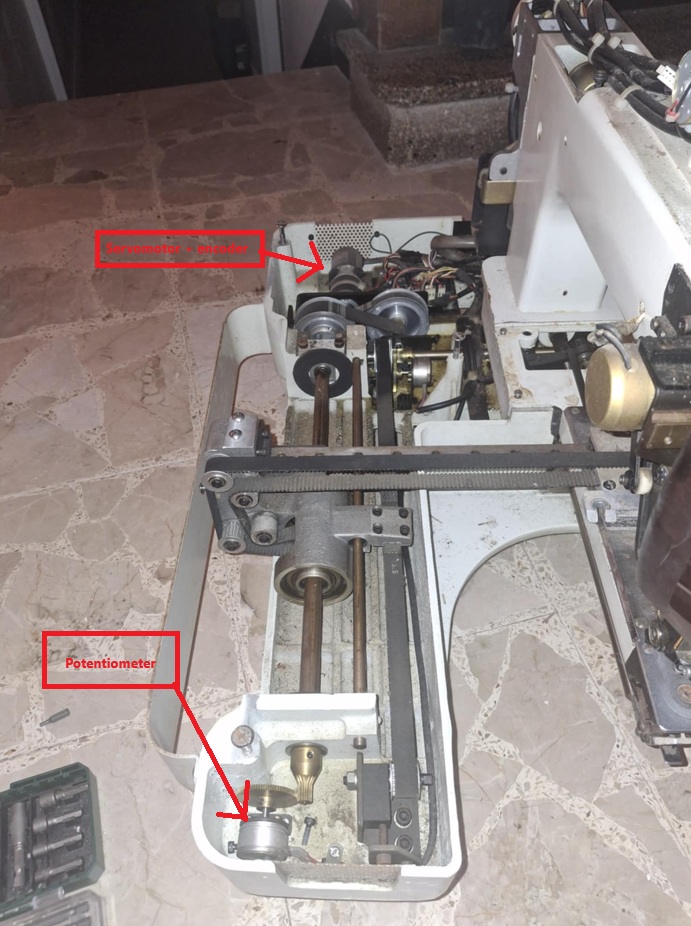

I'm going to retrofit it and drive it with linuxcnc.

Following the dismantling of the casings, I have a few questions:

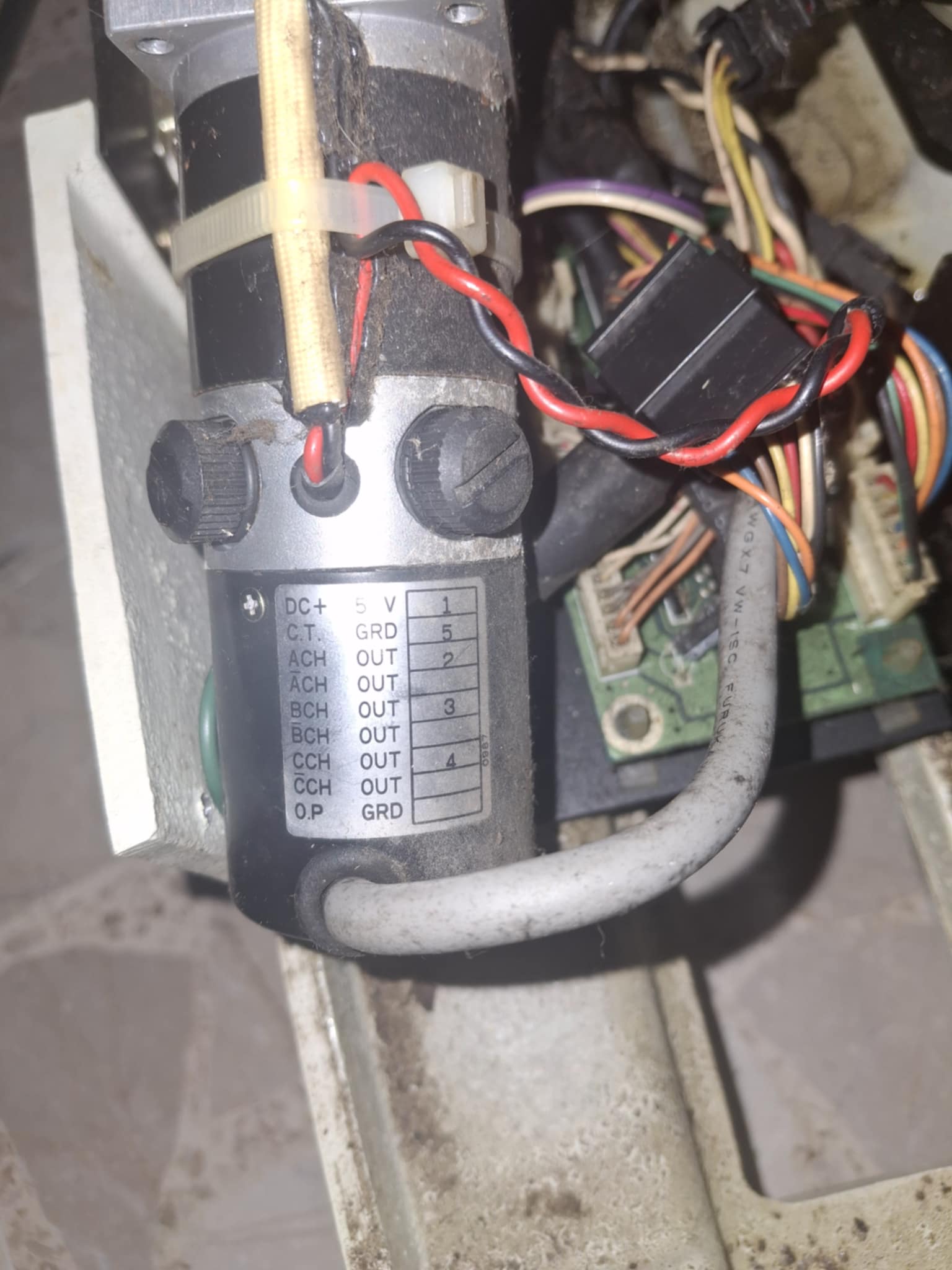

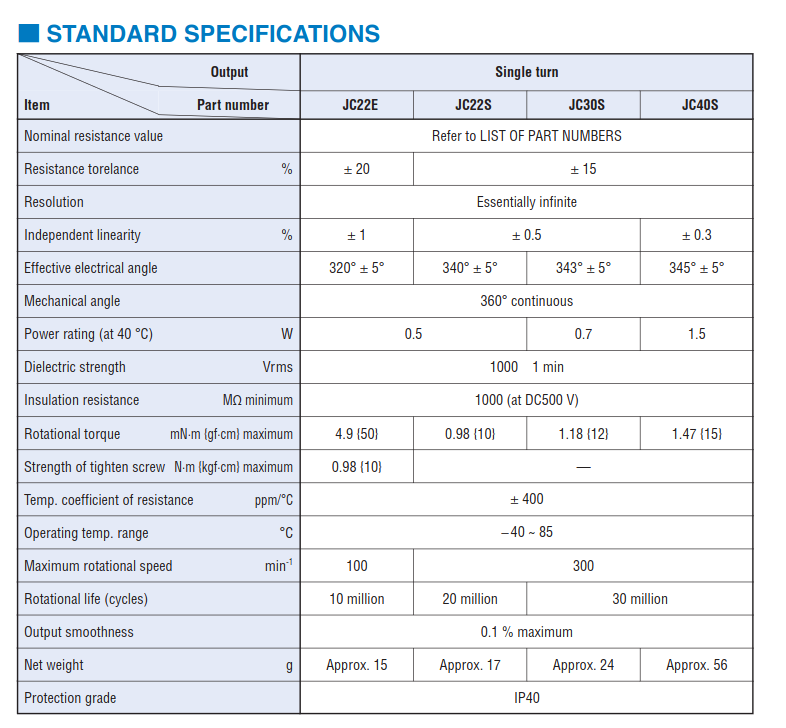

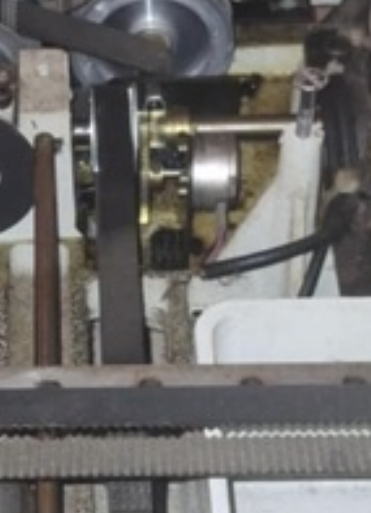

-1: I have a DC 30W servomotor with 500 pt encoder in single ended 5V. and at the end of my axis I have a Copal JC30S potentiometer. Does this potentiometer correspond to a tacho (speed control)?

-2 : On my motor, the maximum voltage is not indicated. To power my machine, I use a power supply that mixes 5V and 24V DC. I assume that its motors are powered by 24V DC, correct? Do you know of any DC driver references for this motor power with tacho (if the potentiometer has one)

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17722

- Thank you received: 5186

(probably meaning that the long shaft only turns a few times)

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21339

- Thank you received: 7281

+1I think the potentiometer is being used as an absolute position feedback device.

(probably meaning that the long shaft only turns a few times)

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

- Posts: 142

- Thank you received: 7

But what is the operating condition of this potentiometer?

- Is it precise enough for me to use it for position control and the encoder for speed control?

- it only allows the machine to be homed without moving to a homing switch (the embroidery machine doesn't have a home and limit switch).

- does it allow homing and limit switches? If so, would a potentiometer for travel limits be useful in addition to the soft limit, or is the soft limit enough?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 21339

- Thank you received: 7281

How many turns does it take to hit those stops, if any?

How many degrees can it turn, if it does less than 1 turn?

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17722

- Thank you received: 5186

(and since it's absolute no homing cycle would be needed at startup)

The encoder is possibly used for both position and velocity feedback

Is there another motion axis?

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4655

- Thank you received: 2078

Does the pot have hard stops?

How many turns does it take to hit those stops, if any?

How many degrees can it turn, if it does less than 1 turn?

www.alldatasheet.com/datasheet-pdf/view/862058/COPAL/JC30S.html

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4655

- Thank you received: 2078

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19802

- Thank you received: 4609

Then configure HOME_ABSOLUTE_ENCODER in the INI

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19802

- Thank you received: 4609

Please Log in or Create an account to join the conversation.