Toyota embroidery machine - retrofit

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

04 Jun 2025 17:42 - 04 Jun 2025 17:43 #329705

by greg23_78

Replied by greg23_78 on topic Toyota embroidery machine - retrofit

thank you for your feedback.

indeed,

- it's a 0-5K ohm single turn potentiometer.

- on the 2 X and Y axes there are

- there is no limit switch.

-Since it's a single turn, I assume (not tried) that 1 turn = the distance the axis moves.

Thanks for the procedure, I was going to ask if it was possible to homing with a potentiometer.

Which reasoning do you think is best?

- when homing, the motor runs until the potentionemetre is read at 1 ohm, then it looks for the incremental encoder index?

- No homing, the encoder reads the potentiometer value directly?

I have a question about the needle motor control.

I have this electronic component, I suppose it's an encoder because of the markings next to the wires. A (Phase A) Z(Pulse) G(Ground) V(VCC) B ( Phase B )

Can you confirm this?

If yes, I suppose that I control the speed of the motor for embroidery and the position for changing the head (I have 5 heads).

However, I don't have a reference for this one. What test would allow me to know the number of pulses for this encoder?

indeed,

- it's a 0-5K ohm single turn potentiometer.

- on the 2 X and Y axes there are

- there is no limit switch.

-Since it's a single turn, I assume (not tried) that 1 turn = the distance the axis moves.

Thanks for the procedure, I was going to ask if it was possible to homing with a potentiometer.

Which reasoning do you think is best?

- when homing, the motor runs until the potentionemetre is read at 1 ohm, then it looks for the incremental encoder index?

- No homing, the encoder reads the potentiometer value directly?

I have a question about the needle motor control.

I have this electronic component, I suppose it's an encoder because of the markings next to the wires. A (Phase A) Z(Pulse) G(Ground) V(VCC) B ( Phase B )

Can you confirm this?

If yes, I suppose that I control the speed of the motor for embroidery and the position for changing the head (I have 5 heads).

However, I don't have a reference for this one. What test would allow me to know the number of pulses for this encoder?

Attachments:

Last edit: 04 Jun 2025 17:43 by greg23_78.

Please Log in or Create an account to join the conversation.

- juliankoenig87

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 55

05 Jun 2025 04:47 #329723

by juliankoenig87

Replied by juliankoenig87 on topic Toyota embroidery machine - retrofit

For homing I would meassure how much the resistor value changes for one motor revolution. After that one can think of solutions. That said. It would be a good step to identify the ratios of the axis.

For the needle encoder. Plug it to a mesa card (first test with bench power supply and oscilloscope) and turn 10 revolutions....

For the needle encoder. Plug it to a mesa card (first test with bench power supply and oscilloscope) and turn 10 revolutions....

Please Log in or Create an account to join the conversation.

- juliankoenig87

- Offline

- Premium Member

-

Less

More

- Posts: 119

- Thank you received: 55

05 Jun 2025 04:50 #329724

by juliankoenig87

Replied by juliankoenig87 on topic Toyota embroidery machine - retrofit

To be honest. I think I would ad a lever and a switch for homing (plus index). But it depends. Maybe you want to have it as original as possible?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21339

- Thank you received: 7281

05 Jun 2025 14:06 #329739

by tommylight

Replied by tommylight on topic Toyota embroidery machine - retrofit

Forget the pots, you can do without them, might need adding a home switch.

And also open the possibility of working with roll's of material, meaning not being limited to a certain length.

And also open the possibility of working with roll's of material, meaning not being limited to a certain length.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

06 Jun 2025 11:58 #329805

by andypugh

Replied by andypugh on topic Toyota embroidery machine - retrofit

If the original manufacturer thought that is was important enough not to require homing to go to the trouble of fitting potentimeters I would be inclined to follow their lead.

I don't think it's a difficult thing to integrate.

I don't think it's a difficult thing to integrate.

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

07 Jun 2025 22:07 #329902

by greg23_78

Replied by greg23_78 on topic Toyota embroidery machine - retrofit

i'm sorry i'm back so late, i was in the middle of cleaning the machine.

i think i'll keep the potentiometers, because i've never coded a homing with an encoder so this will allow me to improve, and if i never manage to, it's easy to dismantle so i could insert home switches.

i think i'll keep the potentiometers, because i've never coded a homing with an encoder so this will allow me to improve, and if i never manage to, it's easy to dismantle so i could insert home switches.

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

07 Jun 2025 22:08 #329903

by greg23_78

Replied by greg23_78 on topic Toyota embroidery machine - retrofit

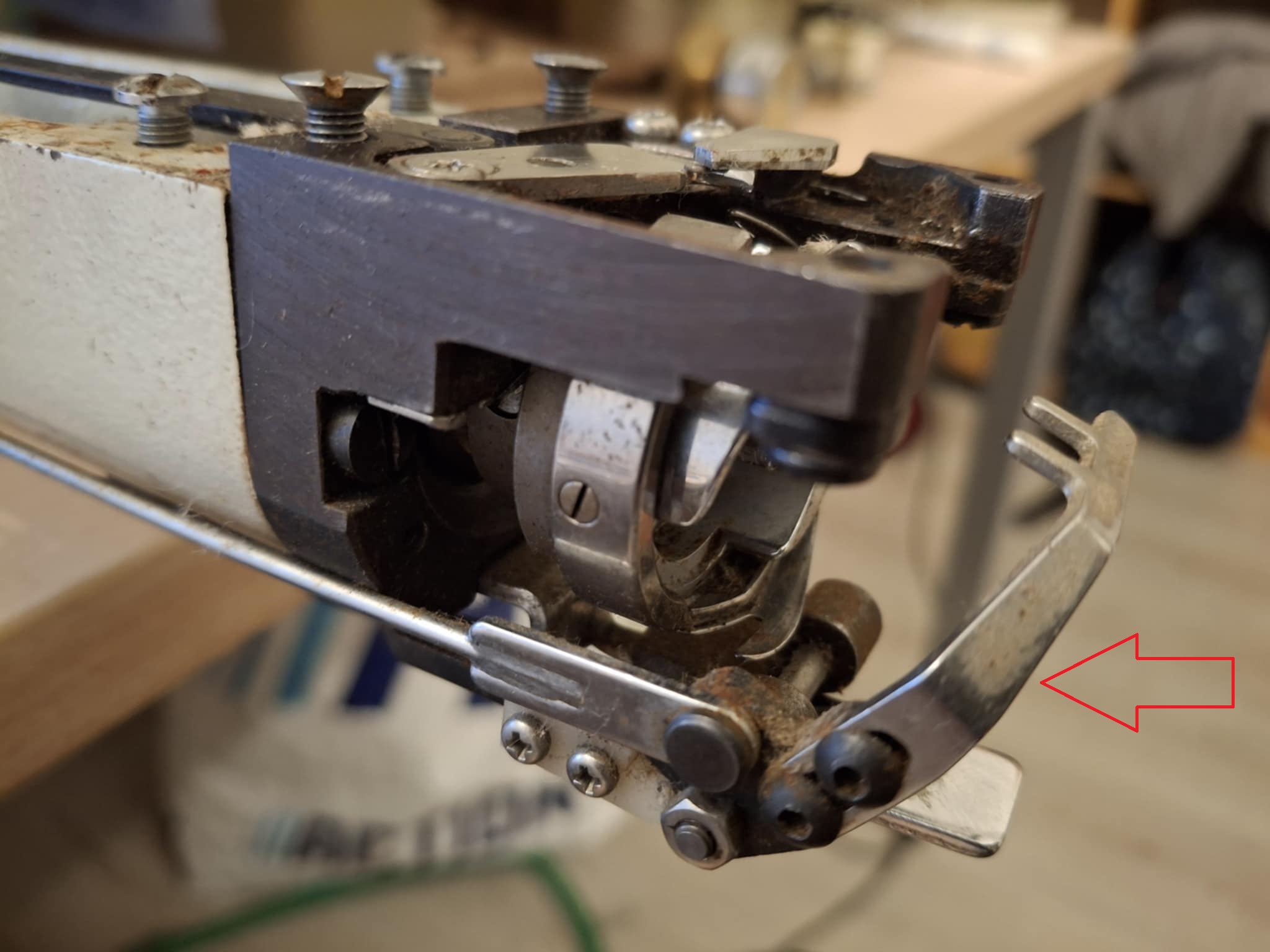

I'm trying to identify each component to find out how this embroidery machine works.

I have two rotary solenoids that operate elements in the bobbin.

I presume that this lever locks the bobbin. Is this correct?

For this component, I'm not sure. At first glance, I have the impression that it cuts the thread, but I have a rotary solenoid on the upper arm.

The way it works, when the rotary solenoid is active, it engages the system and the component moves back and forth when the needle is up and stays in the position shown in the photo when the needle goes down and up.

I have two rotary solenoids that operate elements in the bobbin.

I presume that this lever locks the bobbin. Is this correct?

For this component, I'm not sure. At first glance, I have the impression that it cuts the thread, but I have a rotary solenoid on the upper arm.

The way it works, when the rotary solenoid is active, it engages the system and the component moves back and forth when the needle is up and stays in the position shown in the photo when the needle goes down and up.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21339

- Thank you received: 7281

07 Jun 2025 22:43 #329905

by tommylight

I will try to get my mother to have a look at the pictures, she still uses those machines daily despite being 75 years old.

Replied by tommylight on topic Toyota embroidery machine - retrofit

Nice.i think i'll keep the potentiometers, because i've never coded a homing with an encoder so this will allow me to improve, and if i never manage to, it's easy to dismantle so i could insert home switches.

I will try to get my mother to have a look at the pictures, she still uses those machines daily despite being 75 years old.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21339

- Thank you received: 7281

08 Jun 2025 19:36 #329964

by tommylight

Replied by tommylight on topic Toyota embroidery machine - retrofit

Nope, she can not figure out what those do, strange as her machines have that part much, much more complicated.

Please Log in or Create an account to join the conversation.

- greg23_78

- Offline

- Premium Member

-

Less

More

- Posts: 142

- Thank you received: 7

08 Jun 2025 22:11 - 08 Jun 2025 22:11 #329977

by greg23_78

Replied by greg23_78 on topic Toyota embroidery machine - retrofit

Thank you for asking.

I've done a lot of research and I've just about found the solution, now I just have to imagine how it works in my head.

Below is the result of my research for those who are interested:

I found exploded diagrams of toyota embroiderers and therefore found their name.

Then it got easier!

Their names: thread catcher and ass'y picker (assembly picker).

ass'y picker :

thread catcher :

I've done a lot of research and I've just about found the solution, now I just have to imagine how it works in my head.

Below is the result of my research for those who are interested:

I found exploded diagrams of toyota embroiderers and therefore found their name.

Then it got easier!

Their names: thread catcher and ass'y picker (assembly picker).

ass'y picker :

thread catcher :

Last edit: 08 Jun 2025 22:11 by greg23_78.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.160 seconds