Radius to end of arc differs from radius to start

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

04 Mar 2017 22:47 #89010

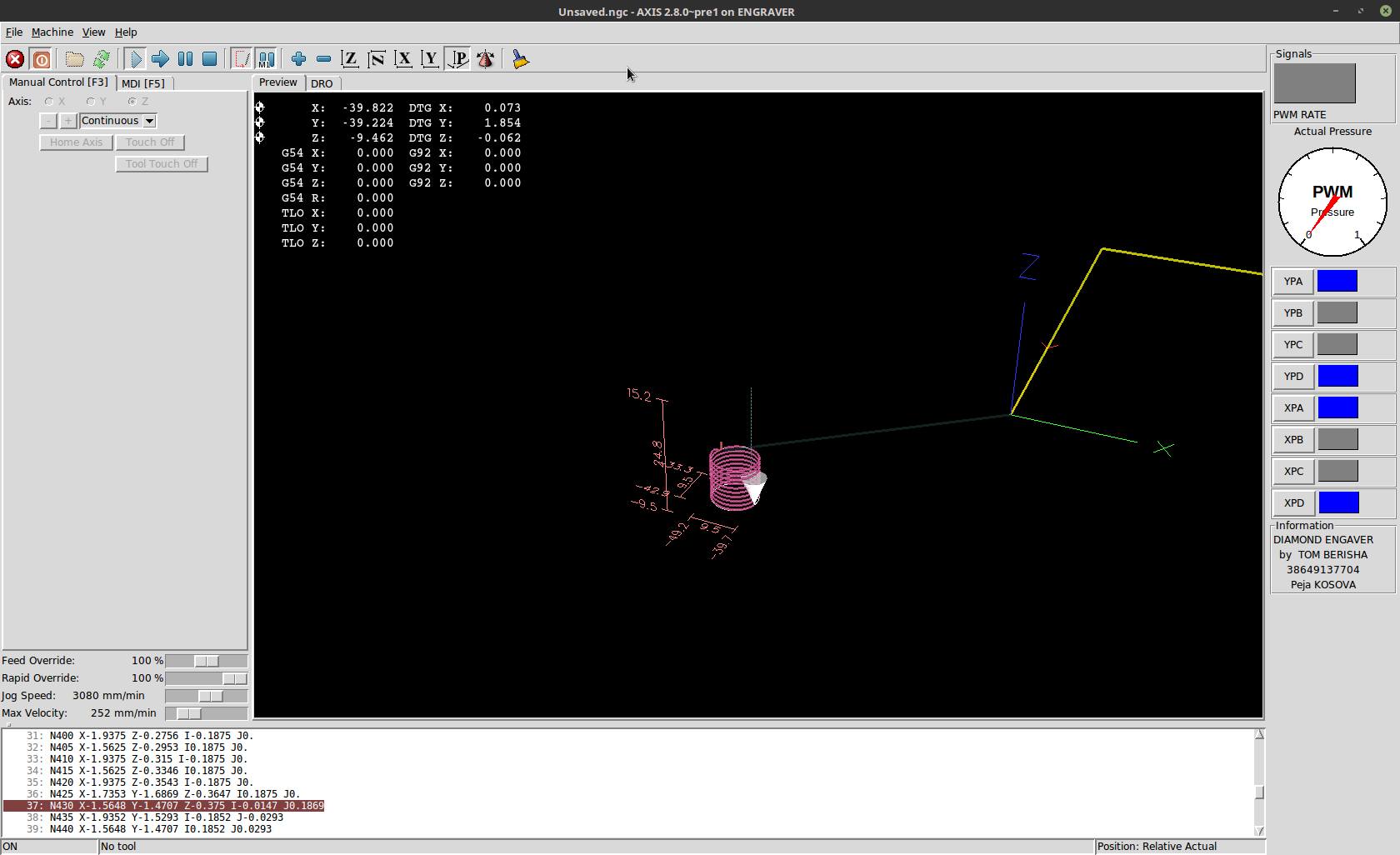

by Jake

Radius to end of arc differs from radius to start was created by Jake

I am having a bit of a challenge with this piece of code. It is a boring cycle with a 1/4" EM I have read through some of the other threads that have had a similar issue. My CAM Fusion360 was set on 4 decimal places, I did stretch it out to 5 and it is still giving me the same error. Anybody familiar enough with Fusion360 cam to know how to work through this?

Thanks!

Thanks!

(BORE1)

N260 M9

N265 M1

N270 T2 M6

N275 T5

N280 S8000 M3

N285 G54

N290 M7

N300 G0 X-1.875 Y-1.475

N305 G43 Z0.6 H2

N310 G0 Z0.08

N315 G1 Z0.025 F30.

N320 G18 G3 X-1.9 Z0. I-0.025 K0.

N325 G1 X-1.9125

N330 G17 G3 X-1.9375 Y-1.5 I0. J-0.025 <------Its blowing up here.

N335 X-1.5625 Z-0.0197 I0.1875 J0.

N340 X-1.9375 Z-0.0394 I-0.1875 J0.

N345 X-1.5625 Z-0.0591 I0.1875 J0.

N350 X-1.9375 Z-0.0787 I-0.1875 J0.

N355 X-1.5625 Z-0.0984 I0.1875 J0.

N360 X-1.9375 Z-0.1181 I-0.1875 J0.

N365 X-1.5625 Z-0.1378 I0.1875 J0.

N370 X-1.9375 Z-0.1575 I-0.1875 J0.

N375 X-1.5625 Z-0.1772 I0.1875 J0.

N380 X-1.9375 Z-0.1969 I-0.1875 J0.

N385 X-1.5625 Z-0.2165 I0.1875 J0.

N390 X-1.9375 Z-0.2362 I-0.1875 J0.

N395 X-1.5625 Z-0.2559 I0.1875 J0.

N400 X-1.9375 Z-0.2756 I-0.1875 J0.

N405 X-1.5625 Z-0.2953 I0.1875 J0.

N410 X-1.9375 Z-0.315 I-0.1875 J0.

N415 X-1.5625 Z-0.3346 I0.1875 J0.

N420 X-1.9375 Z-0.3543 I-0.1875 J0.

N425 X-1.7353 Y-1.6869 Z-0.3647 I0.1875 J0.

N430 X-1.5648 Y-1.4707 Z-0.375 I-0.0147 J0.1869

N435 X-1.9352 Y-1.5293 I-0.1852 J-0.0293

N440 X-1.5648 Y-1.4707 I0.1852 J0.0293

N445 X-1.5934 Y-1.4499 I-0.0247 J-0.0039

N450 G1 X-1.6058 Y-1.4518

N455 X-1.6096 Y-1.4525 Z-0.3747

N460 X-1.6134 Y-1.4531 Z-0.3738

N465 X-1.617 Y-1.4536 Z-0.3723

N470 X-1.6203 Y-1.4541 Z-0.3702

N475 X-1.6232 Y-1.4546 Z-0.3677

N480 X-1.6257 Y-1.455 Z-0.3647

N485 X-1.6278 Y-1.4553 Z-0.3613

N490 X-1.6292 Y-1.4556 Z-0.3577

N495 X-1.6301 Y-1.4557 Z-0.3539

N500 X-1.6304 Y-1.4558 Z-0.35

N505 G0 Z0.6

N515 M5

N520 G53 Z0.Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21342

- Thank you received: 7283

04 Mar 2017 23:54 #89012

by tommylight

Replied by tommylight on topic Radius to end of arc differs from radius to start

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

05 Mar 2017 01:14 #89014

by Jake

Replied by Jake on topic Radius to end of arc differs from radius to start

Thanks Tommy!

Its a 1/4 endmill, 9.5mm = .0.374 + 0.25 should put me right there. A guy on the Fusion forum said move my tolerance to 0.0001 and it made it happy, Ill go try it in a little bit.

The "Z0.???"

Are you talking about line N315? Yeah I could add some top clearance in, I left it since the 25/64" hole is already drilled so I can rapid right to the top of the piece.

Its a 1/4 endmill, 9.5mm = .0.374 + 0.25 should put me right there. A guy on the Fusion forum said move my tolerance to 0.0001 and it made it happy, Ill go try it in a little bit.

The "Z0.???"

Are you talking about line N315? Yeah I could add some top clearance in, I left it since the 25/64" hole is already drilled so I can rapid right to the top of the piece.

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

05 Mar 2017 02:50 #89017

by Jake

Replied by Jake on topic Radius to end of arc differs from radius to start

I had my tool table screwed up. When I was setting my Z offsets on the tools I didnt have the correct axis selected it looks like. As the T2 and T5 offsets were in the Y. It runs on the SIM. We will see if it will run tommorrow. thanks again for the help.

Please Log in or Create an account to join the conversation.

- turbo

-

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 0

26 Mar 2017 17:13 #90302

by turbo

Replied by turbo on topic Radius to end of arc differs from radius to start

I'm having the same problem, but on my lathe. When you say that changing the tolerance to .0001 fixed it do you mean the fusion post options screen? I did that and it didn't change anything.

Please Log in or Create an account to join the conversation.

- turbo

-

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 0

26 Mar 2017 17:17 #90303

by turbo

Replied by turbo on topic Radius to end of arc differs from radius to start

Please Log in or Create an account to join the conversation.

- turbo

-

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 0

26 Mar 2017 17:22 #90304

by turbo

Replied by turbo on topic Radius to end of arc differs from radius to start

Can I override the error? I just want it to run the code that I feed it.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

27 Mar 2017 10:43 #90345

by andypugh

Replied by andypugh on topic Radius to end of arc differs from radius to start

On a lathe it might be a problem with radius/diameter mode or absolute/relative hole centres.

If you over-ride the error, what do you expect LinuxCNC to do? It can't work out from the input data what the arc radius is.

What is the exact error message, the starting-point of the arc and the G-code line that errors?

If you over-ride the error, what do you expect LinuxCNC to do? It can't work out from the input data what the arc radius is.

What is the exact error message, the starting-point of the arc and the G-code line that errors?

Please Log in or Create an account to join the conversation.

- Jake

- Offline

- Elite Member

-

Less

More

- Posts: 282

- Thank you received: 10

27 Mar 2017 14:27 - 27 Mar 2017 15:08 #90373

by Jake

Replied by Jake on topic Radius to end of arc differs from radius to start

I changed the tolerance in Fusion in the model not in the post processor. It was under preferences I believe, ill look tonight

Make sure your tool offsets are correct also. I have screwed up by having the wrong axis selected when touching off a tool which placed the offset in the wrong axis in the tool table.

Also if your cutter is too large for the radius it will give you that error also.

Make sure your tool offsets are correct also. I have screwed up by having the wrong axis selected when touching off a tool which placed the offset in the wrong axis in the tool table.

Also if your cutter is too large for the radius it will give you that error also.

Last edit: 27 Mar 2017 15:08 by Jake.

Please Log in or Create an account to join the conversation.

- turbo

-

- Offline

- Senior Member

-

Less

More

- Posts: 75

- Thank you received: 0

27 Mar 2017 23:36 - 27 Mar 2017 23:41 #90405

by turbo

Replied by turbo on topic Radius to end of arc differs from radius to start

In the tool table am I correct doubling my tool tip radius and putting that in the diameter column? So for my OD profiling tool I have .08 in the diameter column since the tool tip radius is .04mm.

I think I got past this problem yesterday by reducing the tolerance and turning on smoothing in the profiling op. Once I got past that I realized that the g76 format from the tormach post was totally wrong anyway.

I think I got past this problem yesterday by reducing the tolerance and turning on smoothing in the profiling op. Once I got past that I realized that the g76 format from the tormach post was totally wrong anyway.

Last edit: 27 Mar 2017 23:41 by turbo.

Please Log in or Create an account to join the conversation.

Time to create page: 0.134 seconds