Electrically preloaded Dual motor drive for R&P

- raadu

- Offline

- New Member

-

- Posts: 3

- Thank you received: 0

i'm researching building a 4' x 8' cnc router for a woodshop.

I was wondering if LinuxCNC has the capability to drive 2 stepper motors per side of X axis ( 2 pinions per rack for reduced backlash, electrically preloaded ).

That would be 4 motors for the X axis.

Motor A would drive in one direction while motor B would have less torque (dragging) to keep the pinion engaged.

When switching direction, the motors would switch also to B driving and A preloading.

Thanks,

Radu

Please Log in or Create an account to join the conversation.

- andypugh

-

- Online

- Moderator

-

- Posts: 23399

- Thank you received: 4971

I was wondering if LinuxCNC has the capability to drive 2 stepper motors per side of X axis ( 2 pinions per rack for reduced backlash, electrically preloaded ).

It isn't something built-in, and I am not sure that it would work all that well.

If I was building a big machine I think I would try copying the Bell-Everman "Servobelt" arrangement. Or I might try double helical rack-and-pinion displaced sideways to take up backlash.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 5020

- Thank you received: 1464

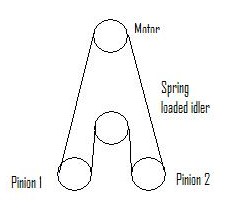

Maybe something a little like this.

When you tension the belt with the motor pulley it would remove the backlash and apply opposing force to the two pinions. The idler just takes up any slack. The motor tensioning might need to be dynamic if your amount of backlash varies too much across your range of motion.

Please Log in or Create an account to join the conversation.

- guyprotection

- Offline

- New Member

-

- Posts: 1

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- andypugh

-

- Online

- Moderator

-

- Posts: 23399

- Thank you received: 4971

I think it would be done by asymmetric PID controllers, with the asymmetry switching depending on direction of motion.

The problem is likely to be that the direction that the cutting force acts is not necessarily the direction in which the axis is moving. This is the problem with software backlash comensation, and the dual-motor arrangement is likely to suffer the same problem.

With servo control you might be able to have a small bias current to take up the slack, then a slow I-term in a PID controller to adapt to the encoder-counts offset between the pinions. Any change in counts-offset could be seen as a "backlash rattle" and counteracted.

I can't see a workable way to do it open-loop with stepper motors, though.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 5020

- Thank you received: 1464

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 5020

- Thank you received: 1464

Please Log in or Create an account to join the conversation.

- raadu

- Offline

- New Member

-

- Posts: 3

- Thank you received: 0

I'm trying to stay away from belts for now...

What if the steppers were set up like a unipolar stepper, with motor A stepping in one direction and motor B stepping in the other. This still dosn't help with the case when cutting forces are pulling you.

This sounds interesting!

What i would like to do is use inexpensive planetary assemblies (e.g. from power tools ) which, most likely are not high precision.

If the motors take turns to drive and the teeth of the R&P are pre-engaged for the direction change, wouldn't this be the same as one motor driving both ways with a high precision R&P?

If the motors are strong enough would the cutting force still be an issue?

Thanks again,

Radu

Please Log in or Create an account to join the conversation.

- andypugh

-

- Online

- Moderator

-

- Posts: 23399

- Thank you received: 4971

Why? Belts are excellent.I'm trying to stay away from belts for now.

If the motors take turns to drive and the teeth of the R&P are pre-engaged for the direction change, wouldn't this be the same as one motor driving both ways with a high precision R&P?

The issue here is that the cutting force direction and the axis movement direction are not the same thing, and each can reverse without the other reversing. The controller only knows the motion direction.

This is why our suggestions all tend to come back to closed-loop systems where the motor encoders can be used to deduce cutting force direction.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 5020

- Thank you received: 1464

Please Log in or Create an account to join the conversation.