First test cut

- Sven

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 2

08 Jun 2015 08:43 - 08 Jun 2015 08:49 #59614

by Sven

First test cut was created by Sven

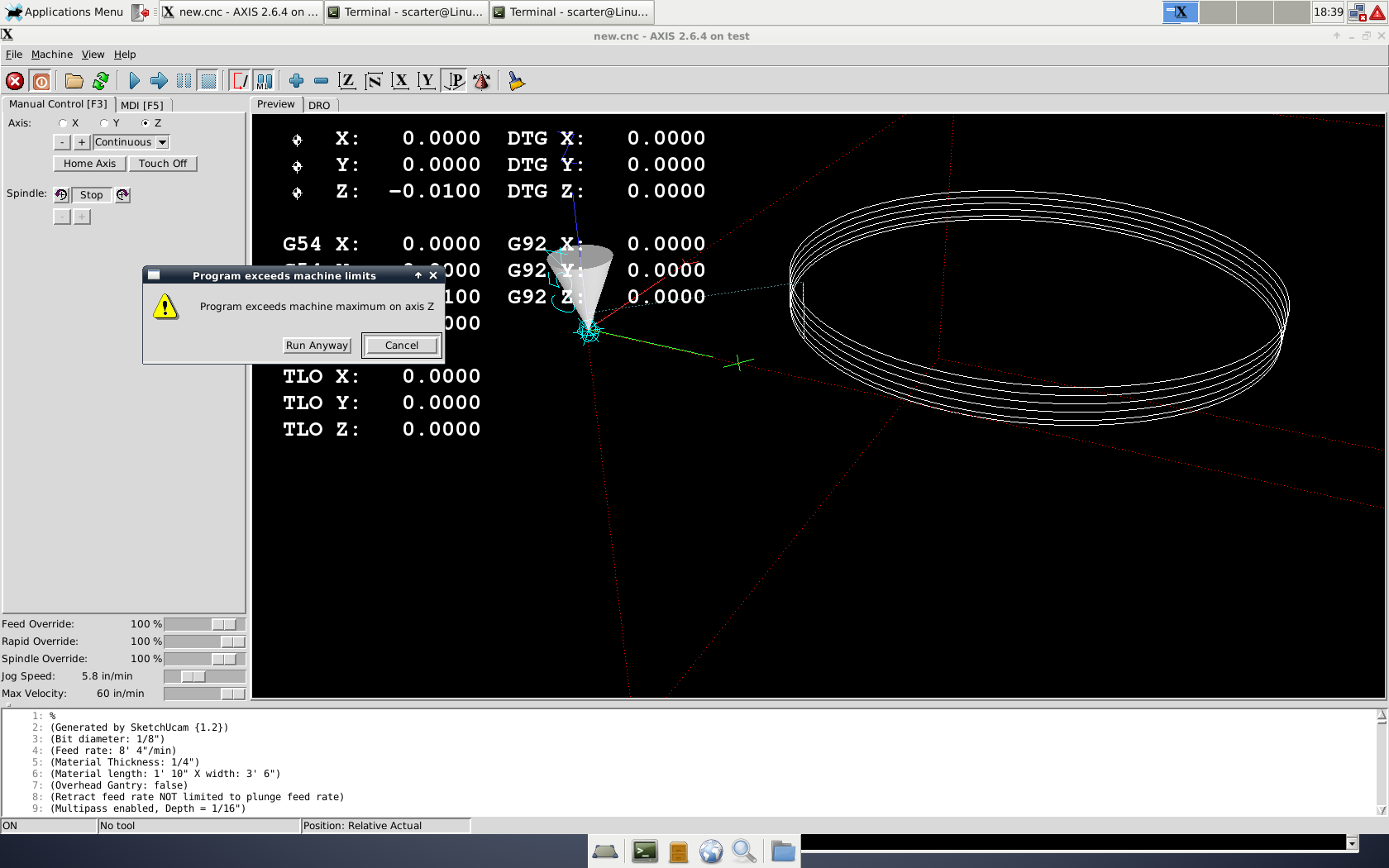

I am trying my first test cut on a 3 axis CNC router machine I just finished building. I am getting an error message shown in the attached screenshot. I assume the error is about the initial move from home. It moves up, across then down and plunges to start the first cut pass. I think the initial move from home is outside what LinuxCNC thinks is the working size of my machine. I am struggling to get started trying to get past this. Any help would be awesome.

I also don't know where LinuxCNC came about those limits, how to set them correctly. On machines I've used previously, one just zero'd the axis and kicked it off and the machine didn't impose restrictions, I suppose assuming the operator knew what they were doing.

Also, what I find strange is the cut is shown at the top of the X axis range, where I would expect it to be at the bottom, which I would view as the top of my spoilt board.

It's conceptual problems I'm having, I think ...

-Steve

I also don't know where LinuxCNC came about those limits, how to set them correctly. On machines I've used previously, one just zero'd the axis and kicked it off and the machine didn't impose restrictions, I suppose assuming the operator knew what they were doing.

Also, what I find strange is the cut is shown at the top of the X axis range, where I would expect it to be at the bottom, which I would view as the top of my spoilt board.

It's conceptual problems I'm having, I think ...

-Steve

Last edit: 08 Jun 2015 08:49 by Sven. Reason: add

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7947

- Thank you received: 2160

08 Jun 2015 10:50 #59617

by cmorley

Replied by cmorley on topic First test cut

Linuxcnc has the machine limits defined in the INI file.

After being homed (so it knows where its at ) it will use soft (software) limits so it should never hit the ends of the axes.

When you touchoff tools you are setting the user coordinate system, but linuxcnc still keeps track of where it is relative to those soft limits.

If your program asks linuxcnc to move outside the soft limits - it will refuse to run the program.

The screen plot shows the movement as if the tool moves.

I'm not sure how you built the config for the machine but if the screen and the machine don't jive then it was probably misconfigured.

It looks to me that your program is at the top of the Z axis limit and you need to move down and touch off.

The red lines define the limits graphically.

hard to say much more without more info.

Chris M

After being homed (so it knows where its at ) it will use soft (software) limits so it should never hit the ends of the axes.

When you touchoff tools you are setting the user coordinate system, but linuxcnc still keeps track of where it is relative to those soft limits.

If your program asks linuxcnc to move outside the soft limits - it will refuse to run the program.

The screen plot shows the movement as if the tool moves.

I'm not sure how you built the config for the machine but if the screen and the machine don't jive then it was probably misconfigured.

It looks to me that your program is at the top of the Z axis limit and you need to move down and touch off.

The red lines define the limits graphically.

hard to say much more without more info.

Chris M

The following user(s) said Thank You: Sven

Please Log in or Create an account to join the conversation.

- Sven

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 2

08 Jun 2015 13:52 #59618

by Sven

Replied by Sven on topic First test cut

Thanks Chris, that was the perfect information I needed to put me on the right path. The run worked, albeit simulated (it got late). Next I'll work on configuring the machine limits in LinuxCNC to match my actual machine.

-Steve

-Steve

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23383

- Thank you received: 4968

09 Jun 2015 00:01 #59631

by andypugh

What you have might be fine.

You just need to jog the Z axis down to where the material is (inside the red box in the preview) and say "_This_ is where my Z = 0 point is"

You do that with the "Touch Off" Button. Typically you might literally touch the tool to the top of the material and se Z to zero at that point.

Replied by andypugh on topic First test cut

Next I'll work on configuring the machine limits in LinuxCNC to match my actual machine.

What you have might be fine.

You just need to jog the Z axis down to where the material is (inside the red box in the preview) and say "_This_ is where my Z = 0 point is"

You do that with the "Touch Off" Button. Typically you might literally touch the tool to the top of the material and se Z to zero at that point.

The following user(s) said Thank You: Sven

Please Log in or Create an account to join the conversation.

- Sven

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 13

- Thank you received: 2

09 Jun 2015 00:24 #59634

by Sven

Thank you. That is what I did to get it to work as I expected.

-Steve

Replied by Sven on topic First test cut

Next I'll work on configuring the machine limits in LinuxCNC to match my actual machine.

What you have might be fine.

You just need to jog the Z axis down to where the material is (inside the red box in the preview) and say "_This_ is where my Z = 0 point is"

You do that with the "Touch Off" Button. Typically you might literally touch the tool to the top of the material and se Z to zero at that point.

Thank you. That is what I did to get it to work as I expected.

-Steve

Please Log in or Create an account to join the conversation.

Time to create page: 0.062 seconds