Inaccurate circles/squares ...thoughts ?

- dlipford370

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

11 Jun 2015 05:04 - 11 Jun 2015 05:20 #59686

by dlipford370

Inaccurate circles/squares ...thoughts ? was created by dlipford370

Hello,

I use my sherline for customer work. I used to use a manual sieg x2, and I was able to produce squares/rectangles that were almost perfect by just counting units on my hand wheel, now with the sherline, I figured I would be able to get perfect shapes, but it looks like the mill is going to far, or not far enough etc. This isn't too much to expect right?

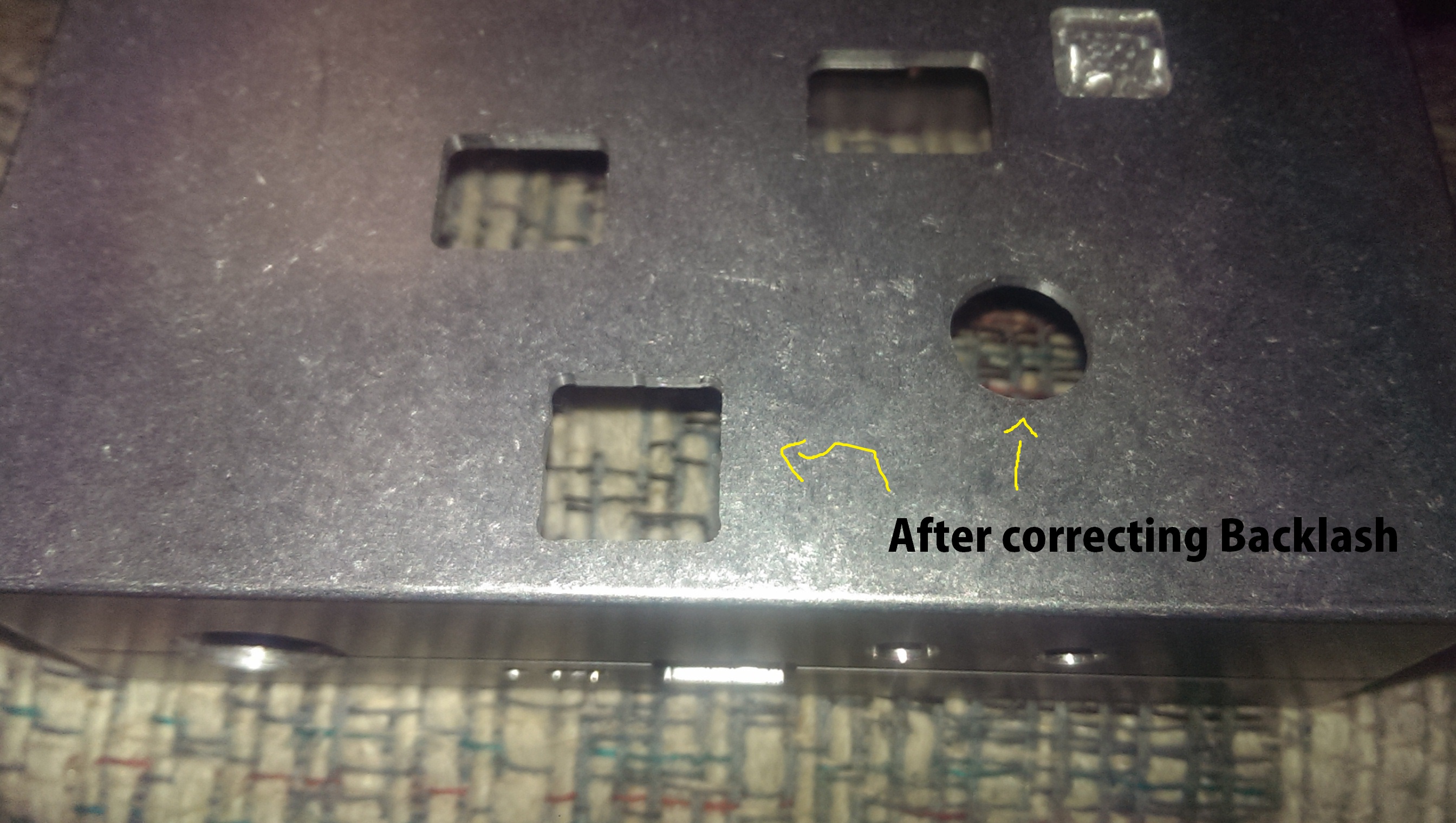

I used a interapid switzerland dial gauge (accurate to .0005") to measure backlash. And I entered everything in to the .ini while also adding 1.5 - 2x the acceleration or whichever unit I needed to change. I had to go back into the .ini a couple times, but now when I got +.01 mm 10 times on any axis, and then go -.01mm 10 times back I end up in the exact spot I started. Completely eliminating backlash, at least within the system. My largest backlash adjustment was .2 mm the smallest being around .03mm. Seems like a lot, could that be the problem, making up that much backlash?

It looks like my circles look a lot better. When I say a circle, I mean I'm taking a approx. 1mm endmill and having the machine cutout a (the most common is 7/16th") circle. My rectangles/squares just look like garbage still. It's just ridiculous in my mind. How much better I could get on the Siegx2 manual mill just using the hand dials.

Do you know what else there is to adjust to do a better job?

Just an added note, please see my attached latency test. This is the most latency I can get, which is pretty darn low latency, right?

I use my sherline for customer work. I used to use a manual sieg x2, and I was able to produce squares/rectangles that were almost perfect by just counting units on my hand wheel, now with the sherline, I figured I would be able to get perfect shapes, but it looks like the mill is going to far, or not far enough etc. This isn't too much to expect right?

I used a interapid switzerland dial gauge (accurate to .0005") to measure backlash. And I entered everything in to the .ini while also adding 1.5 - 2x the acceleration or whichever unit I needed to change. I had to go back into the .ini a couple times, but now when I got +.01 mm 10 times on any axis, and then go -.01mm 10 times back I end up in the exact spot I started. Completely eliminating backlash, at least within the system. My largest backlash adjustment was .2 mm the smallest being around .03mm. Seems like a lot, could that be the problem, making up that much backlash?

It looks like my circles look a lot better. When I say a circle, I mean I'm taking a approx. 1mm endmill and having the machine cutout a (the most common is 7/16th") circle. My rectangles/squares just look like garbage still. It's just ridiculous in my mind. How much better I could get on the Siegx2 manual mill just using the hand dials.

Do you know what else there is to adjust to do a better job?

Just an added note, please see my attached latency test. This is the most latency I can get, which is pretty darn low latency, right?

Last edit: 11 Jun 2015 05:20 by dlipford370.

Please Log in or Create an account to join the conversation.

- dlipford370

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

11 Jun 2015 05:09 #59687

by dlipford370

Replied by dlipford370 on topic Inaccurate circles/squares ...thoughts ?

Here's a couple links to some other engraving work my mill has done. I'm not sure how it produces such accurate looking engravings, yet the squares, circles look so off.

imgur.com/MTw22YF

imgur.com/UdQRnu5

imgur.com/TmO3ycK

imgur.com/JmRRifO

imgur.com/MTw22YF

imgur.com/UdQRnu5

imgur.com/TmO3ycK

imgur.com/JmRRifO

Please Log in or Create an account to join the conversation.

- dlipford370

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

11 Jun 2015 05:19 #59688

by dlipford370

Replied by dlipford370 on topic Inaccurate circles/squares ...thoughts ?

Here is my Config file.

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 758

11 Jun 2015 15:16 #59692

by ArcEye

Replied by ArcEye on topic Inaccurate circles/squares ...thoughts ?

Hi

The controller software is only as good as the machine.

What you saw as backlash was probably flex and general slackness

As far as I am concerned Sherline are an expensive desktop toy, only suitable for cutting soft materials slowly.

Some of their designs defy logic as far as rigidity is concerned.

For instance this at $1300 plus for the CNC version, for which you could buy a used industrial machine

There are so many flimsy flex points, I would be surprised if it cut anything harder than plastic well.

Your Seig was heavy cast iron with proper cast iron beds, column etc.

Sherline have a following in the US, next to none here and none at all with me I'm afraid

regards

The controller software is only as good as the machine.

What you saw as backlash was probably flex and general slackness

As far as I am concerned Sherline are an expensive desktop toy, only suitable for cutting soft materials slowly.

Some of their designs defy logic as far as rigidity is concerned.

For instance this at $1300 plus for the CNC version, for which you could buy a used industrial machine

There are so many flimsy flex points, I would be surprised if it cut anything harder than plastic well.

Your Seig was heavy cast iron with proper cast iron beds, column etc.

Sherline have a following in the US, next to none here and none at all with me I'm afraid

regards

Please Log in or Create an account to join the conversation.

- dlipford370

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

11 Jun 2015 16:49 #59694

by dlipford370

Replied by dlipford370 on topic Inaccurate circles/squares ...thoughts ?

Well geeze, wasn't expecting an answer like that. Anyone else have any thoughts ? Any other sherline owners want to shed some light?

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

11 Jun 2015 17:34 - 11 Jun 2015 17:36 #59699

by BigJohnT

Replied by BigJohnT on topic Inaccurate circles/squares ...thoughts ?

I don't own any hobby mills but I did play with a friends Sherline lathe once but could not get it to cut aluminum so I gave up.

Here is a photo of a Sieg X2 and it is 10 times the machine the Sherline is as far as mass.

If your Sherline looks like the photo ArcEye posted then IMHO your expecting far too much from it.

Software will not fix machine problems.

1. Backlash and CNC don't work well together. If you have backlash you will see that in your finished product. While backlash compensation does exist it is not the answer to a sloppy machine.

2. Weak flimsy machines can flex as cutting loads are applied. This also will show up in the finished product.

3. The lead screws on the Sherline look like normal all thread and that is not very accurate. Have you mapped the screw out to see how far off it might be. LinuxCNC does have mapping compensation .

I have seen some videos from a guy in South America that has modified his Sherline to the point he can make some nice things on it.

JT

Here is a photo of a Sieg X2 and it is 10 times the machine the Sherline is as far as mass.

If your Sherline looks like the photo ArcEye posted then IMHO your expecting far too much from it.

Software will not fix machine problems.

1. Backlash and CNC don't work well together. If you have backlash you will see that in your finished product. While backlash compensation does exist it is not the answer to a sloppy machine.

2. Weak flimsy machines can flex as cutting loads are applied. This also will show up in the finished product.

3. The lead screws on the Sherline look like normal all thread and that is not very accurate. Have you mapped the screw out to see how far off it might be. LinuxCNC does have mapping compensation .

I have seen some videos from a guy in South America that has modified his Sherline to the point he can make some nice things on it.

JT

Last edit: 11 Jun 2015 17:36 by BigJohnT.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

11 Jun 2015 18:01 #59700

by BigJohnT

Replied by BigJohnT on topic Inaccurate circles/squares ...thoughts ?

Just looking at your ini file and your scale seem fine enough at 0.00125mm per step. My BridgePort conversion mill is only 0.003175mm per encoder count ( its actually inch but I converted it ). However your acceleration seems way out of proportion to your max velocity. What I've usually seen is max acceleration is 10-20 times max velocity. Your max velocity seems appropriate for this machine at 14mm a second.

JT

JT

Please Log in or Create an account to join the conversation.

- dlipford370

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

11 Jun 2015 18:39 #59701

by dlipford370

Replied by dlipford370 on topic Inaccurate circles/squares ...thoughts ?

Would you mind elaborating on mapping compensation ? I clicked the link you put in, but I don't see anything about it. I think I'm going to try and mount the mill to my table better, and see if that makes a difference.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

11 Jun 2015 18:44 #59702

by BigJohnT

Replied by BigJohnT on topic Inaccurate circles/squares ...thoughts ?

Look at the COMP_FILE and COMP_FILE_TYPE in the ini AXIS section.

JT

JT

Please Log in or Create an account to join the conversation.

- dlipford370

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 0

11 Jun 2015 18:55 #59703

by dlipford370

Replied by dlipford370 on topic Inaccurate circles/squares ...thoughts ?

Ok, I see it now. I'll have to look into that more, because I don't know what it means to map the screw out. I do notice that it says if you specify a comp_file, backlash is ignored.

Thank you for pointing that out to me.

Thank you for pointing that out to me.

Please Log in or Create an account to join the conversation.

Time to create page: 0.129 seconds