Possible bug or other issue

- yoshimitsuspeed

- Offline

- Premium Member

-

- Posts: 95

- Thank you received: 0

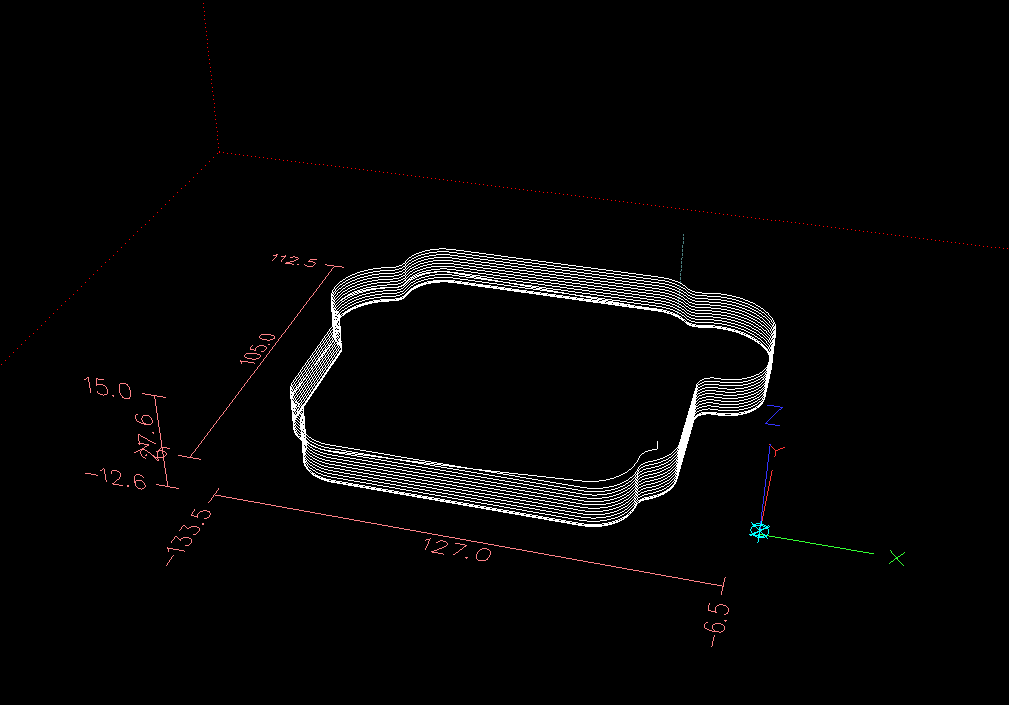

I was machining this part with a bullnose cutter doing a 3D pocket. I also did the outside profile to see how it did with the bullnose but it was struggling so I went into CAM and selected a 7mm flat mill that I have used before.

I post processed the toolpath and went back to my machine and it said that the new program exceeded my y travel. I came back in and looked everything over, ran a simulation and posted it again. This time I could see the toolpath in the viewer starting maybe 100mm or so further -y than it should have. Sometimes when I open it in linuxcnc it seems to show that line, other times it doesn't.

I restarted and rehomed linuxcnc and it still did it. Restarted the CNC computer and then linuxcnc and it still did it. Restarted fusion360 and it still did it.

I have scanned through the code and I don't see anything that suggests that it should start where it is.

So first question is does anyone have any ideas or input?

Second question is whether anyone else is seeing the same issue on their linuxcnc?

The issue is right at the beginning of the code.

(PROFILE2)

(T13 D=7. CR=0. - ZMIN=-12.6 - FLAT END MILL)

N10 G90 G94 G17 G91.1

N15 G21

N20 G53 G0 Z0.

(2D CONTOUR1)

N25 M9

N30 T13 M6

N35 S8000 M3

N40 G54

N45 M8

N55 G0 X-27.759 Y22.695

N60 G43 Z15. H13

N65 G0 Z5.

N70 G1 Z2.7 F800.

N75 X-27.766 Y22.693 Z2.648 F333.33N65-70 drops down outside the machines travel and then N75 is a long line on the visual display going from 100mm away from the part over to the part.

%

(PROFILE2)

(T13 D=7. CR=0. - ZMIN=-12.6 - FLAT END MILL)

N10 G90 G94 G17 G91.1

N15 G21

N20 G53 G0 Z0.

(2D CONTOUR1)

N25 M9

N30 T13 M6

N35 S8000 M3

N40 G54

N45 M8

N55 G0 X-27.759 Y22.695

N60 G43 Z15. H13

N65 G0 Z5.

N70 G1 Z2.7 F800.

N75 X-27.766 Y22.693 Z2.648 F333.33

N80 X-27.785 Y22.688 Z2.6

N85 X-27.816 Y22.679 Z2.559

N90 X-27.855 Y22.667 Z2.527

N95 X-27.902 Y22.654 Z2.507

N100 X-27.951 Y22.639 Z2.5

N105 X-28.144 Y22.584 F800.

N110 G3 X-28.206 Y22.553 I0.056 J-0.192

N115 G2 X-29.24 Y21.88 Z2.414 I-6.794 J9.303 F1000.

N120 G3 X-31.471 Y18.28 Z2.105 I2.24 J-3.88

N125 G2 X-42.969 Y7.48 Z0.89 I-11.497 J0.72

N130 G1 X-70. Z-1.

N135 X-107.

N140 G2 X-118.497 Y18.28 I0. J11.52

N145 G3 X-120.737 Y21.885 I-4.472 J-0.28

N150 G2 X-126.52 Y31.874 I5.737 J9.99

N155 G1 Y65.347

N160 G3 X-128.014 Y68.687 I-4.48 J0.

N165 G2 X-121.72 Y96.831 I11.013 J12.313

N170 G3 X-118.52 Y101.089 I-1.28 J4.294

N175 G2 X-107. Y112.52 I11.52 J-0.09

N180 G1 X-43.

N185 G2 X-34.014 Y108.209 I0. J-11.52

N190 G3 X-29.192 Y106.733 I3.495 J2.803

N195 G2 X-6.48 Y90. I5.192 J-16.733

N200 G1 Y74.5

N205 G2 X-18. Y62.98 I-11.52 J0.

N210 G1 X-19.

N215 G3 X-23.48 Y58.5 I0. J-4.48

N220 G1 Y31.856

N225 G2 X-29.24 Y21.88 I-11.52 J0.

N230 G3 X-31.471 Y18.28 I2.24 J-3.88

N235 G2 X-42.969 Y7.48 I-11.497 J0.72

N240 G1 X-70.

N245 X-90.425 Z-2.

N250 X-107.

N255 G2 X-118.497 Y18.28 I0. J11.52

N260 G3 X-120.737 Y21.885 I-4.472 J-0.28

N265 G2 X-126.52 Y31.874 I5.737 J9.99

N270 G1 Y65.347

N275 G3 X-128.014 Y68.687 I-4.48 J0.

N280 G2 X-121.72 Y96.831 I11.013 J12.313

N285 G3 X-118.52 Y101.089 I-1.28 J4.294

N290 G2 X-107. Y112.52 I11.52 J-0.09

N295 G1 X-43.

N300 G2 X-34.014 Y108.209 I0. J-11.52

N305 G3 X-29.192 Y106.733 I3.495 J2.803

N310 G2 X-6.48 Y90. I5.192 J-16.733

N315 G1 Y74.5

N320 G2 X-18. Y62.98 I-11.52 J0.

N325 G1 X-19.

N330 G3 X-23.48 Y58.5 I0. J-4.48

N335 G1 Y31.856

N340 G2 X-29.24 Y21.88 I-11.52 J0.

N345 G3 X-31.471 Y18.28 I2.24 J-3.88

N350 G2 X-42.969 Y7.48 I-11.497 J0.72

N355 G1 X-90.425

N360 X-107. Z-2.811

N365 G2 X-110.779 Y8.118 Z-3. I0. J11.52

N370 X-118.497 Y18.28 I3.78 J10.882

N375 G3 X-120.737 Y21.885 I-4.472 J-0.28

N380 G2 X-126.52 Y31.874 I5.737 J9.99

N385 G1 Y65.347

N390 G3 X-128.014 Y68.687 I-4.48 J0.

N395 G2 X-121.72 Y96.831 I11.013 J12.313

N400 G3 X-118.52 Y101.089 I-1.28 J4.294

N405 G2 X-107. Y112.52 I11.52 J-0.09

N410 G1 X-43.

N415 G2 X-34.014 Y108.209 I0. J-11.52

N420 G3 X-29.192 Y106.733 I3.495 J2.803

N425 G2 X-6.48 Y90. I5.192 J-16.733

N430 G1 Y74.5

N435 G2 X-18. Y62.98 I-11.52 J0.

N440 G1 X-19.

N445 G3 X-23.48 Y58.5 I0. J-4.48

N450 G1 Y31.856

N455 G2 X-29.24 Y21.88 I-11.52 J0.

N460 G3 X-31.471 Y18.28 I2.24 J-3.88

N465 G2 X-42.969 Y7.48 I-11.497 J0.72

N470 G1 X-107.

N475 G2 X-110.779 Y8.118 I0. J11.52

N480 X-118.497 Y18.28 Z-3.662 I3.78 J10.882

N485 G3 X-120.737 Y21.885 Z-3.879 I-4.472 J-0.28

N490 G2 X-122.739 Y23.341 Z-4. I5.737 J9.99

N495 X-126.52 Y31.874 I7.739 J8.534

N500 G1 Y65.347

N505 G3 X-128.014 Y68.687 I-4.48 J0.

N510 G2 X-121.72 Y96.831 I11.013 J12.313

N515 G3 X-118.52 Y101.089 I-1.28 J4.294

N520 G2 X-107. Y112.52 I11.52 J-0.09

N525 G1 X-43.

N530 G2 X-34.014 Y108.209 I0. J-11.52

N535 G3 X-29.192 Y106.733 I3.495 J2.803

N540 G2 X-6.48 Y90. I5.192 J-16.733

N545 G1 Y74.5

N550 G2 X-18. Y62.98 I-11.52 J0.

N555 G1 X-19.

N560 G3 X-23.48 Y58.5 I0. J-4.48

N565 G1 Y31.856

N570 G2 X-29.24 Y21.88 I-11.52 J0.

N575 G3 X-31.471 Y18.28 I2.24 J-3.88

N580 G2 X-42.969 Y7.48 I-11.497 J0.72

N585 G1 X-107.

N590 G2 X-118.497 Y18.28 I0. J11.52

N595 G3 X-120.737 Y21.885 I-4.472 J-0.28

N600 G2 X-122.739 Y23.341 I5.737 J9.99

N605 X-126.52 Y31.874 Z-4.47 I7.739 J8.534

N610 G1 Y42.69 Z-5.

N615 Y65.347

N620 G3 X-128.014 Y68.687 I-4.48 J0.

N625 G2 X-121.72 Y96.831 I11.013 J12.313

N630 G3 X-118.52 Y101.089 I-1.28 J4.294

N635 G2 X-107. Y112.52 I11.52 J-0.09

N640 G1 X-43.

N645 G2 X-34.014 Y108.209 I0. J-11.52

N650 G3 X-29.192 Y106.733 I3.495 J2.803

N655 G2 X-6.48 Y90. I5.192 J-16.733

N660 G1 Y74.5

N665 G2 X-18. Y62.98 I-11.52 J0.

N670 G1 X-19.

N675 G3 X-23.48 Y58.5 I0. J-4.48

N680 G1 Y31.856

N685 G2 X-29.24 Y21.88 I-11.52 J0.

N690 G3 X-31.471 Y18.28 I2.24 J-3.88

N695 G2 X-42.969 Y7.48 I-11.497 J0.72

N700 G1 X-107.

N705 G2 X-118.497 Y18.28 I0. J11.52

N710 G3 X-120.737 Y21.885 I-4.472 J-0.28

N715 G2 X-126.52 Y31.874 I5.737 J9.99

N720 G1 Y42.69

N725 Y63.115 Z-6.

N730 Y65.347

N735 G3 X-128.014 Y68.687 I-4.48 J0.

N740 G2 X-121.72 Y96.831 I11.013 J12.313

N745 G3 X-118.52 Y101.089 I-1.28 J4.294

N750 G2 X-107. Y112.52 I11.52 J-0.09

N755 G1 X-43.

N760 G2 X-34.014 Y108.209 I0. J-11.52

N765 G3 X-29.192 Y106.733 I3.495 J2.803

N770 G2 X-6.48 Y90. I5.192 J-16.733

N775 G1 Y74.5

N780 G2 X-18. Y62.98 I-11.52 J0.

N785 G1 X-19.

N790 G3 X-23.48 Y58.5 I0. J-4.48

N795 G1 Y31.856

N800 G2 X-29.24 Y21.88 I-11.52 J0.

N805 G3 X-31.471 Y18.28 I2.24 J-3.88

N810 G2 X-42.969 Y7.48 I-11.497 J0.72

N815 G1 X-107.

N820 G2 X-118.497 Y18.28 I0. J11.52

N825 G3 X-120.737 Y21.885 I-4.472 J-0.28

N830 G2 X-126.52 Y31.874 I5.737 J9.99

N835 G1 Y63.115

N840 Y65.347 Z-6.109

N845 G3 X-128.014 Y68.687 Z-6.294 I-4.48 J0.

N850 G2 X-133.512 Y81.531 Z-7. I11.013 J12.313

N855 X-121.72 Y96.831 I16.512 J-0.531

N860 G3 X-118.52 Y101.089 I-1.28 J4.294

N865 G2 X-107. Y112.52 I11.52 J-0.09

N870 G1 X-43.

N875 G2 X-34.014 Y108.209 I0. J-11.52

N880 G3 X-29.192 Y106.733 I3.495 J2.803

N885 G2 X-6.48 Y90. I5.192 J-16.733

N890 G1 Y74.5

N895 G2 X-18. Y62.98 I-11.52 J0.

N900 G1 X-19.

N905 G3 X-23.48 Y58.5 I0. J-4.48

N910 G1 Y31.856

N915 G2 X-29.24 Y21.88 I-11.52 J0.

N920 G3 X-31.471 Y18.28 I2.24 J-3.88

N925 G2 X-42.969 Y7.48 I-11.497 J0.72

N930 G1 X-107.

N935 G2 X-118.497 Y18.28 I0. J11.52

N940 G3 X-120.737 Y21.885 I-4.472 J-0.28

N945 G2 X-126.52 Y31.874 I5.737 J9.99

N950 G1 Y65.347

N955 G3 X-128.014 Y68.687 I-4.48 J0.

N960 G2 X-133.512 Y81.531 I11.013 J12.313

N965 X-121.918 Y96.771 Z-8. I16.512 J-0.531

N970 X-121.72 Y96.831 I4.918 J-15.771

N975 G3 X-118.52 Y101.089 I-1.28 J4.294

N980 G2 X-107. Y112.52 I11.52 J-0.09

N985 G1 X-43.

N990 G2 X-34.014 Y108.209 I0. J-11.52

N995 G3 X-29.192 Y106.733 I3.495 J2.803

N1000 G2 X-6.48 Y90. I5.192 J-16.733

N1005 G1 Y74.5

N1010 G2 X-18. Y62.98 I-11.52 J0.

N1015 G1 X-19.

N1020 G3 X-23.48 Y58.5 I0. J-4.48

N1025 G1 Y31.856

N1030 G2 X-29.24 Y21.88 I-11.52 J0.

N1035 G3 X-31.471 Y18.28 I2.24 J-3.88

N1040 G2 X-42.969 Y7.48 I-11.497 J0.72

N1045 G1 X-107.

N1050 G2 X-118.497 Y18.28 I0. J11.52

N1055 G3 X-120.737 Y21.885 I-4.472 J-0.28

N1060 G2 X-126.52 Y31.874 I5.737 J9.99

N1065 G1 Y65.347

N1070 G3 X-128.014 Y68.687 I-4.48 J0.

N1075 G2 X-121.918 Y96.771 I11.013 J12.313

N1080 X-121.72 Y96.831 Z-8.01 I4.918 J-15.771

N1085 G3 X-118.52 Y101.089 Z-8.289 I-1.28 J4.294

N1090 G2 X-110.439 Y111.995 Z-9. I11.52 J-0.09

N1095 X-107. Y112.52 I3.439 J-10.995

N1100 G1 X-43.

N1105 G2 X-34.014 Y108.209 I0. J-11.52

N1110 G3 X-29.192 Y106.733 I3.495 J2.803

N1115 G2 X-6.48 Y90. I5.192 J-16.733

N1120 G1 Y74.5

N1125 G2 X-18. Y62.98 I-11.52 J0.

N1130 G1 X-19.

N1135 G3 X-23.48 Y58.5 I0. J-4.48

N1140 G1 Y31.856

N1145 G2 X-29.24 Y21.88 I-11.52 J0.

N1150 G3 X-31.471 Y18.28 I2.24 J-3.88

N1155 G2 X-42.969 Y7.48 I-11.497 J0.72

N1160 G1 X-107.

N1165 G2 X-118.497 Y18.28 I0. J11.52

N1170 G3 X-120.737 Y21.885 I-4.472 J-0.28

N1175 G2 X-126.52 Y31.874 I5.737 J9.99

N1180 G1 Y65.347

N1185 G3 X-128.014 Y68.687 I-4.48 J0.

N1190 G2 X-121.72 Y96.831 I11.013 J12.313

N1195 G3 X-118.52 Y101.089 I-1.28 J4.294

N1200 G2 X-110.439 Y111.995 I11.52 J-0.09

N1205 X-107. Y112.52 Z-9.171 I3.439 J-10.995

N1210 G1 X-90.067 Z-10.

N1215 X-43.

N1220 G2 X-34.014 Y108.209 I0. J-11.52

N1225 G3 X-29.192 Y106.733 I3.495 J2.803

N1230 G2 X-6.48 Y90. I5.192 J-16.733

N1235 G1 Y74.5

N1240 G2 X-18. Y62.98 I-11.52 J0.

N1245 G1 X-19.

N1250 G3 X-23.48 Y58.5 I0. J-4.48

N1255 G1 Y31.856

N1260 G2 X-29.24 Y21.88 I-11.52 J0.

N1265 G3 X-31.471 Y18.28 I2.24 J-3.88

N1270 G2 X-42.969 Y7.48 I-11.497 J0.72

N1275 G1 X-107.

N1280 G2 X-118.497 Y18.28 I0. J11.52

N1285 G3 X-120.737 Y21.885 I-4.472 J-0.28

N1290 G2 X-126.52 Y31.874 I5.737 J9.99

N1295 G1 Y65.347

N1300 G3 X-128.014 Y68.687 I-4.48 J0.

N1305 G2 X-121.72 Y96.831 I11.013 J12.313

N1310 G3 X-118.52 Y101.089 I-1.28 J4.294

N1315 G2 X-107. Y112.52 I11.52 J-0.09

N1320 G1 X-90.067

N1325 X-69.641 Z-11.

N1330 X-43.

N1335 G2 X-34.014 Y108.209 I0. J-11.52

N1340 G3 X-29.192 Y106.733 I3.495 J2.803

N1345 G2 X-6.48 Y90. I5.192 J-16.733

N1350 G1 Y74.5

N1355 G2 X-18. Y62.98 I-11.52 J0.

N1360 G1 X-19.

N1365 G3 X-23.48 Y58.5 I0. J-4.48

N1370 G1 Y31.856

N1375 G2 X-29.24 Y21.88 I-11.52 J0.

N1380 G3 X-31.471 Y18.28 I2.24 J-3.88

N1385 G2 X-42.969 Y7.48 I-11.497 J0.72

N1390 G1 X-107.

N1395 G2 X-118.497 Y18.28 I0. J11.52

N1400 G3 X-120.737 Y21.885 I-4.472 J-0.28

N1405 G2 X-126.52 Y31.874 I5.737 J9.99

N1410 G1 Y65.347

N1415 G3 X-128.014 Y68.687 I-4.48 J0.

N1420 G2 X-121.72 Y96.831 I11.013 J12.313

N1425 G3 X-118.52 Y101.089 I-1.28 J4.294

N1430 G2 X-107. Y112.52 I11.52 J-0.09

N1435 G1 X-69.641

N1440 X-49.216 Z-12.

N1445 X-43.

N1450 G2 X-34.014 Y108.209 I0. J-11.52

N1455 G3 X-29.192 Y106.733 I3.495 J2.803

N1460 G2 X-6.48 Y90. I5.192 J-16.733

N1465 G1 Y74.5

N1470 G2 X-18. Y62.98 I-11.52 J0.

N1475 G1 X-19.

N1480 G3 X-23.48 Y58.5 I0. J-4.48

N1485 G1 Y31.856

N1490 G2 X-29.24 Y21.88 I-11.52 J0.

N1495 G3 X-31.471 Y18.28 I2.24 J-3.88

N1500 G2 X-42.969 Y7.48 I-11.497 J0.72

N1505 G1 X-107.

N1510 G2 X-118.497 Y18.28 I0. J11.52

N1515 G3 X-120.737 Y21.885 I-4.472 J-0.28

N1520 G2 X-126.52 Y31.874 I5.737 J9.99

N1525 G1 Y65.347

N1530 G3 X-128.014 Y68.687 I-4.48 J0.

N1535 G2 X-121.72 Y96.831 I11.013 J12.313

N1540 G3 X-118.52 Y101.089 I-1.28 J4.294

N1545 G2 X-107. Y112.52 I11.52 J-0.09

N1550 G1 X-49.216

N1555 X-43. Z-12.304

N1560 G2 X-41.055 Y112.355 Z-12.4 I0. J-11.52

N1565 X-34.014 Y108.209 I-1.945 J-11.355

N1570 G3 X-29.192 Y106.733 I3.495 J2.803

N1575 G2 X-6.48 Y90. I5.192 J-16.733

N1580 G1 Y74.5

N1585 G2 X-18. Y62.98 I-11.52 J0.

N1590 G1 X-19.

N1595 G3 X-23.48 Y58.5 I0. J-4.48

N1600 G1 Y31.856

N1605 G2 X-29.24 Y21.88 I-11.52 J0.

N1610 G3 X-31.471 Y18.28 I2.24 J-3.88

N1615 G2 X-42.969 Y7.48 I-11.497 J0.72

N1620 G1 X-107.

N1625 G2 X-118.497 Y18.28 I0. J11.52

N1630 G3 X-120.737 Y21.885 I-4.472 J-0.28

N1635 G2 X-126.52 Y31.874 I5.737 J9.99

N1640 G1 Y65.347

N1645 G3 X-128.014 Y68.687 I-4.48 J0.

N1650 G2 X-121.72 Y96.831 I11.013 J12.313

N1655 G3 X-118.52 Y101.089 I-1.28 J4.294

N1660 G2 X-107. Y112.52 I11.52 J-0.09

N1665 G1 X-43.

N1670 G2 X-41.055 Y112.355 I0. J-11.52

N1675 X-37.233 Y110.973 Z-12.6 I-1.945 J-11.355

N1680 X-34.014 Y108.209 I-5.766 J-9.973

N1685 G3 X-29.192 Y106.733 I3.495 J2.803

N1690 G2 X-6.48 Y90. I5.192 J-16.733

N1695 G1 Y74.5

N1700 G2 X-18. Y62.98 I-11.52 J0.

N1705 G1 X-19.

N1710 G3 X-23.48 Y58.5 I0. J-4.48

N1715 G1 Y31.856

N1720 G2 X-29.24 Y21.88 I-11.52 J0.

N1725 G3 X-31.471 Y18.28 I2.24 J-3.88

N1730 G2 X-42.969 Y7.48 I-11.497 J0.72

N1735 G1 X-107.

N1740 G2 X-118.497 Y18.28 I0. J11.52

N1745 G3 X-120.737 Y21.885 I-4.472 J-0.28

N1750 G2 X-126.52 Y31.874 I5.737 J9.99

N1755 G1 Y65.347

N1760 G3 X-128.014 Y68.687 I-4.48 J0.

N1765 G2 X-121.72 Y96.831 I11.013 J12.313

N1770 G3 X-118.52 Y101.089 I-1.28 J4.294

N1775 G2 X-107. Y112.52 I11.52 J-0.09

N1780 G1 X-43.

N1785 G2 X-37.233 Y110.973 I0. J-11.52

N1790 X-37.184 Y110.933 I-0.099 J-0.171

N1795 G3 X-37.136 Y110.892 I0.153 J0.135

N1800 G2 X-34.03 Y108.196 I-5.864 J-9.892

N1805 G3 X-29.186 Y106.714 I3.51 J2.816

N1810 G2 X-6.5 Y90. I5.186 J-16.714

N1815 G1 Y74.5

N1820 G2 X-18. Y63. I-11.5 J0.

N1825 G1 X-19.

N1830 G3 X-23.5 Y58.5 I0. J-4.5

N1835 G1 Y31.856

N1840 G2 X-29.25 Y21.897 I-11.5 J0.

N1845 G3 X-31.491 Y18.281 I2.25 J-3.897

N1850 G2 X-42.969 Y7.5 I-11.477 J0.719

N1855 G1 X-107.

N1860 G2 X-118.477 Y18.281 I0. J11.5

N1865 G3 X-120.727 Y21.902 I-4.492 J-0.282

N1870 G2 X-126.5 Y31.874 I5.727 J9.972

N1875 G1 Y65.347

N1880 G3 X-128. Y68.702 I-4.5 J0.

N1885 G2 X-121.714 Y96.812 I11. J12.298

N1890 G3 X-118.5 Y101.089 I-1.286 J4.313

N1895 G2 X-107. Y112.5 I11.5 J-0.089

N1900 G1 X-43.

N1905 G2 X-37.136 Y110.892 I0. J-11.5

N1910 G3 X-37.071 Y110.868 I0.102 J0.172 F600.

N1915 G1 X-36.874 Y110.831

N1920 X-36.823 Y110.821 Z-12.593

N1925 X-36.776 Y110.812 Z-12.573

N1930 X-36.735 Y110.805 Z-12.541

N1935 X-36.704 Y110.799 Z-12.5

N1940 X-36.684 Y110.795 Z-12.452

N1945 X-36.678 Y110.794 Z-12.4

N1950 G0 Z15.

N1960 M9

N1965 G53 Z0.

N1970 M30

%Please Log in or Create an account to join the conversation.

- alan_3301

- Offline

- Premium Member

-

- Posts: 136

- Thank you received: 22

If you are having a Z issue, is your linuxcnc setup with a tool table for length compensation? if not, line N60 is going to mess you up.

as far as Y, are you setting your part origin at the same location in fusion as in reality?

Please Log in or Create an account to join the conversation.

- yoshimitsuspeed

- Offline

- Premium Member

-

- Posts: 95

- Thank you received: 0

Yes the origin is on the corner of my stock. It shows it's proper location in both F360 and in the view in linuxcnc.

It's just trying to start very far away from the part.

If I go out and mess with it today I'll see if I can get a screen grab where you can see the toolpath starting very far away from the part. But there is nothing in the code that would cause y to want to start ver far away from the part is there?

I am a noob at code but it seems to me it is saying to start at +22 which in this case would be directly over the part.

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

- Posts: 1021

- Thank you received: 202

or a shortened version again full gcode so that it can be run and show the errors

this is difficult without seeing the full code , so that it can be simulated and tested

Please Log in or Create an account to join the conversation.

- ArcEye

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 240

There are all sorts of things I am suspicious of, this bit for a start

N10 G90 G94 G17 G91.1

N15 G21

N20 G53 G0 Z0.

(2D CONTOUR1)

N25 M9

N30 T13 M6

N35 S8000 M3

N40 G54

N45 M8

N55 G0 X-27.759 Y22.695

N60 G43 Z15. H13Why is it moving Z to machine 0 and how does it know that is safe?

Normally the tool is touched off at G54 Z0 and a safe G54 height set for start and inter cut moves

G40 was not called on startup, so any existing compensation could persist

G43 is only applied AFTER a linear move has been made with the new tool installed but adjustment not made

The toolchange is unnecessary anyway, you can just touch off with the tool you will be using throughout and know it is right.

Where is your machine programmed to do its toolchange?

What is the tooltable like?

(Why do you have a toolchange at all, when you use the same tool throughout?)

As you can see from the screen shot, the origin seems quite sensible and everything is within limits on my sim.

regards

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 19762

- Thank you received: 4589

N65-70 drops down outside the machines travel and then N75 is a long line on the visual display going from 100mm away from the part over to the part.

Is there by any chance a Y-offset in your tool table?

Please Log in or Create an account to join the conversation.

- yoshimitsuspeed

- Offline

- Premium Member

-

- Posts: 95

- Thank you received: 0

First I'll report on the problem then try to answer a couple of the other questions.

It was in fact an offset in the tooltable. It is strange because over a period of time I had added tools into it manually with more information in the tooltable but when I opened it today there was only one tool that had the tool info like I had added manually for many others in the past. Then tool 13 had a 154mm offset on y or something with no other information. Had I manually added it then it would have had more information in the comments section but it just had a date like all the rest.

I am a little confused though because if it was a y offset then wouldn't the whole toolpath have been moved in that direction as opposed to just the starting point of the z drop?

Attached is a pic of the toolpath in my system.

A couple other things. I removed the offest in the toolpath, opened another toolpath, acknowledged the tool switch then opened the problem file again and it still showed this messed up toolpath. So I closed linuxcnc, ran system updates, re opened linuxcnc and then opened this file and it showed up fine and started a dry run and everything looked normal. For troubleshooting purposes I probably should have tried restarting linuxcnc without updating so I don't know if the update had any effect. Something about the linuxcnc toolpath something or another was updated.

So whatever the case it does appear to be fixed. It does seem like it must have been related to the offset in tool 13. I just can't figure out what happened to my manually entered tools or how, why or when that offset would have gotten there.

I wouldn't have suspected that because as said above I would have expected it to move the whole toolpath. Is that not correct?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Away

- Moderator

-

- Posts: 19762

- Thank you received: 4589

No, the machine bounding box will move, but the toolpath stays in the same place.I am a little confused though because if it was a y offset then wouldn't the whole toolpath have been moved in that direction as opposed to just the starting point of the z drop?

You can try this by using the touch-off button in the Axis GUI. Touch-of Y to 150 After selecting T for tool table in the drop-down and the tool will move, the bounding box will move, but the tool path will stay in the same place, because the actal XYZ numbers stay the same. You then need to re-edit and re-load the tool table, though.

I removed the offest in the toolpath, opened another toolpath, acknowledged the tool switch then opened the problem file again and it still showed this messed up toolpath. So I closed linuxcnc, ran system updates, re opened linuxcnc and then opened this file and it showed up fine and started a dry run and everything looked normal. For troubleshooting purposes I probably should have tried restarting linuxcnc without updating so I don't know if the update had any effect. Something about the linuxcnc toolpath something or another was updated

After editing the tool table you have to explicitly re-load the tool table (option in the File menu).

Please Log in or Create an account to join the conversation.

- yoshimitsuspeed

- Offline

- Premium Member

-

- Posts: 95

- Thank you received: 0

I cannot see a problem with the code per se, albeit there is a lot in there that is far from ideal, typical CAM output.

There are all sorts of things I am suspicious of, this bit for a startN10 G90 G94 G17 G91.1 N15 G21 N20 G53 G0 Z0. (2D CONTOUR1) N25 M9 N30 T13 M6 N35 S8000 M3 N40 G54 N45 M8 N55 G0 X-27.759 Y22.695 N60 G43 Z15. H13

Why is it moving Z to machine 0 and how does it know that is safe?

Normally the tool is touched off at G54 Z0 and a safe G54 height set for start and inter cut moves

Unfortunately this is the gcode straight out of fusion360. There was a thread on here a while back where someone from f360 was trying to get input on their software and gcode generation. There wasn't much interest or response from this community and the few suggestions that were made like changing the name from EMC to linuxcnc in F360 were ignored.

As to moving Z to 0 I have no idea. This actually messed me up good and crashed my machine initially. I don't know why but while setting up my machine I couldn't get Z to be up. Presumably just didn't get the right combination of inputs in the settings as I do have it corrected now. It ran fine with the first few CAM programs I ran though, then first time I ran Gcode from F360 it drove the cutter straight into the bed trying to go to Z0 at the bottom. I did have a thread on here about that a while back and you or someone else brought up the same concern. I brought it up on the F360 forum and they insisted this is normal behavior and a fairly standard way of doing it. So I just fixed my machine and set it up to work with their way of doing it.

G40 was not called on startup, so any existing compensation could persist

G43 is only applied AFTER a linear move has been made with the new tool installed but adjustment not made

The toolchange is unnecessary anyway, you can just touch off with the tool you will be using throughout and know it is right.

No idea on that either. Perhaps for auto tool changers?

I don't know but I can be a bit of a space cadet sometimes so honestly I don't mind it stopping and saying to insert the tool at the beginning. It makes me double check my tool and whether I touched off everything properly.

Once it requests the tool switch once it doesn't again until I run a program with a different tool.

If anyone is interested in checking out F360 CAM or it's gcode output you can get f360 as a private user for free.

Or if we should start a thread discussing it or even if you had general notes that I could pass on to their dev team to be ignored by them I am happy to do so.

Please Log in or Create an account to join the conversation.

- yoshimitsuspeed

- Offline

- Premium Member

-

- Posts: 95

- Thank you received: 0

After editing the tool table you have to explicitly re-load the tool table (option in the File menu).

Okay thanks. I didn't do that so that would explain why it didn't work till I restarted.

Please Log in or Create an account to join the conversation.