kl 5056 driver setings help

- sandman92k

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 0

09 Feb 2016 17:07 - 09 Feb 2016 17:08 #69862

by sandman92k

kl 5056 driver setings help was created by sandman92k

Last edit: 09 Feb 2016 17:08 by sandman92k.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

09 Feb 2016 17:34 #69865

by BigJohnT

Replied by BigJohnT on topic kl 5056 driver setings help

I would not set it higher than 16 microsteps. 2 microsteps is 1/2 step, 4 microsteps is 1/4 etc.

JT

JT

Please Log in or Create an account to join the conversation.

- sandman92k

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 0

09 Feb 2016 17:39 #69867

by sandman92k

Replied by sandman92k on topic kl 5056 driver setings help

so it is set at 50, what is that

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

09 Feb 2016 17:48 #69869

by BigJohnT

Replied by BigJohnT on topic kl 5056 driver setings help

Steppers take 200 steps to go one time around, when you use microstepping in a drive you multiply the full steps by micro steps to get the number of steps it takes to go one user unit. Say it takes 3 revolutions to move an axis 1" and your microsteps is set to 50 (which is way too much) then your scale for that axis is 200 x 3 x 50 = 30,000 step pulses to move 1". In the Stepconf Wizard you can play with the combinations and see the result.

JT

JT

Please Log in or Create an account to join the conversation.

- sandman92k

- Offline

- Senior Member

-

Less

More

- Posts: 42

- Thank you received: 0

10 Feb 2016 01:51 #69899

by sandman92k

Replied by sandman92k on topic kl 5056 driver setings help

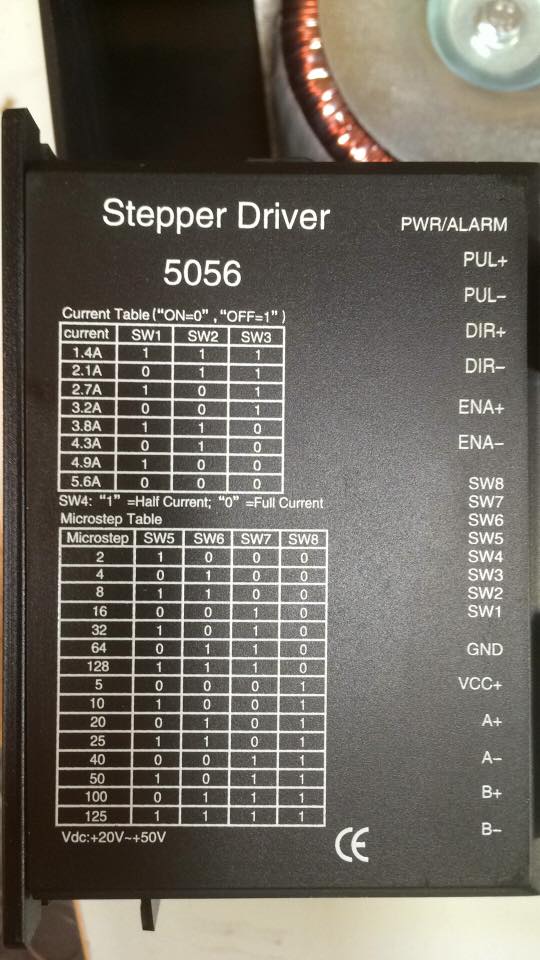

this page is the set up directions for my KL5056 driver, currently the drivers are set for 1/4 micro stepping, and according to this the motor steps per revolution should be set at 800, is this correct. any input

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

10 Feb 2016 12:02 #69921

by cncbasher

Replied by cncbasher on topic kl 5056 driver setings help

you don't say what machine your fitting out , however i would leave it at 1/4 step as you have it ( 800 steps per rev )

also beware the higher the microstepping the less torque you will have , a lot of people think microstepping is for resolution

it is not , it is mostly for overcoming resonance , fine for use on small motors such as used on 3d printers for resolution , but for any serious work , keep the microstepping to 1/2 ( 400 ) or 1/4 (800) , is more than ample for all jobs .

also beware the higher the microstepping the less torque you will have , a lot of people think microstepping is for resolution

it is not , it is mostly for overcoming resonance , fine for use on small motors such as used on 3d printers for resolution , but for any serious work , keep the microstepping to 1/2 ( 400 ) or 1/4 (800) , is more than ample for all jobs .

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

10 Feb 2016 17:37 #69943

by BigJohnT

Replied by BigJohnT on topic kl 5056 driver setings help

You might want to read this on microstepping...

www.micromo.com/microstepping-myths-and-realities

JT

www.micromo.com/microstepping-myths-and-realities

JT

Please Log in or Create an account to join the conversation.

Time to create page: 0.103 seconds