Servos and Drives questions..

- Lcvette

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 722

13 May 2016 01:06 - 13 May 2016 01:39 #74576

by Lcvette

Servos and Drives questions.. was created by Lcvette

Hey guys,

I recently purchased a Chinese VMC and it is being Built currently. there was a miscommunication regrading the servos, spindle motor and drives and I am now having to supply them for the machine. The main problem with that is I wasn't prepared research wise to do so.

I have found a few manufacturers in China who make the correct size motors and drives but I'm less familiar with Linuxcnc and what it requires in a drive, motor and encoder. I normally would spend the time reading and researching but the manufacturer needs the motors and drives by next week this time and most of the companies need a few days to configure, pack, and ship the drives.

The good news is I know all the sizes of the motors I need. But are there any special drive features I need to ensure are available for Linux CNC? I am happy to purchase whatever other hardware I will need to use with the drives but for now I just need to be sure what I am about to purchase is going to be compatible with Linux CNC be it the drive or encoder type etc.

Thanks so much in advance, I put the cheat sheets for everything below.

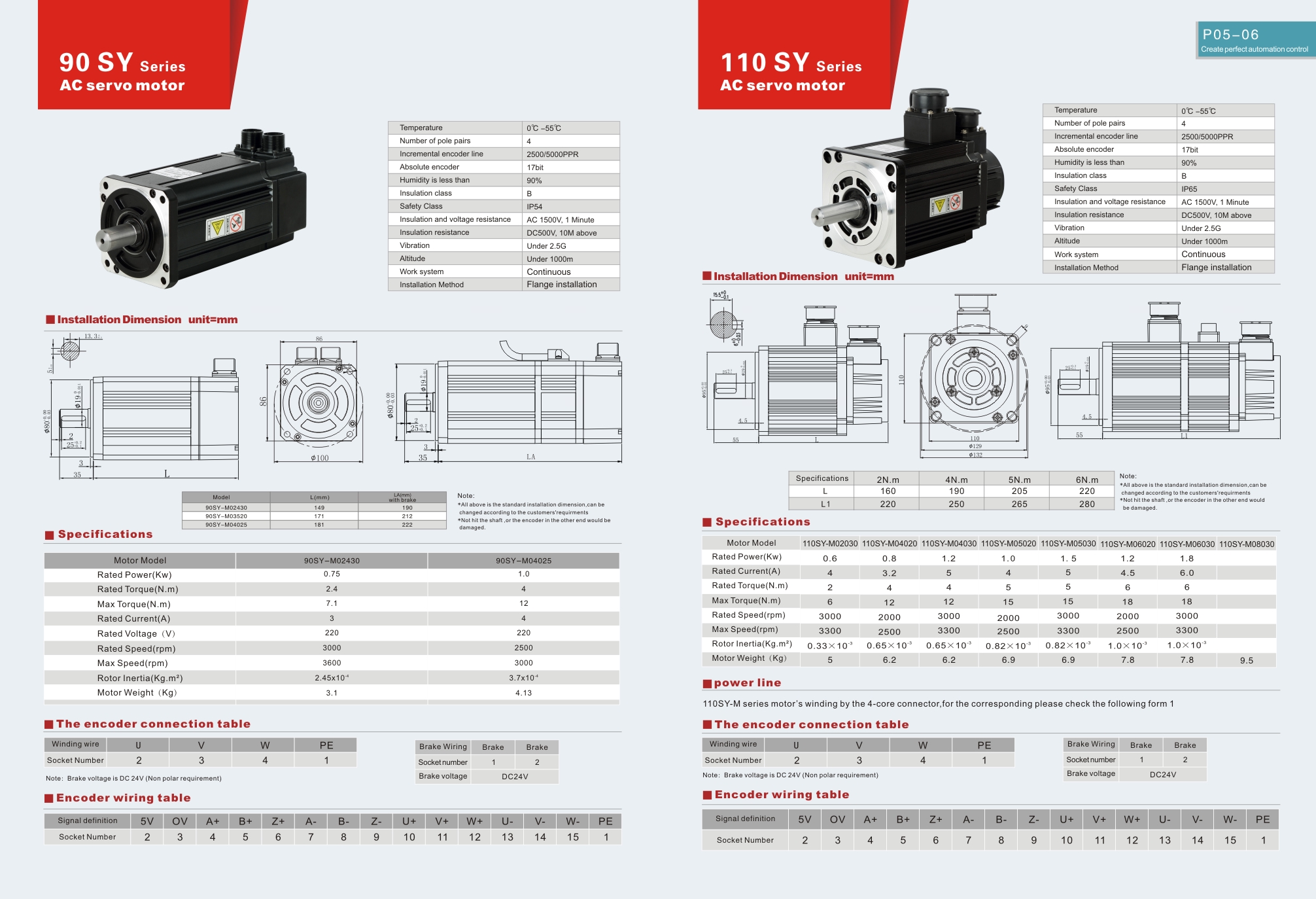

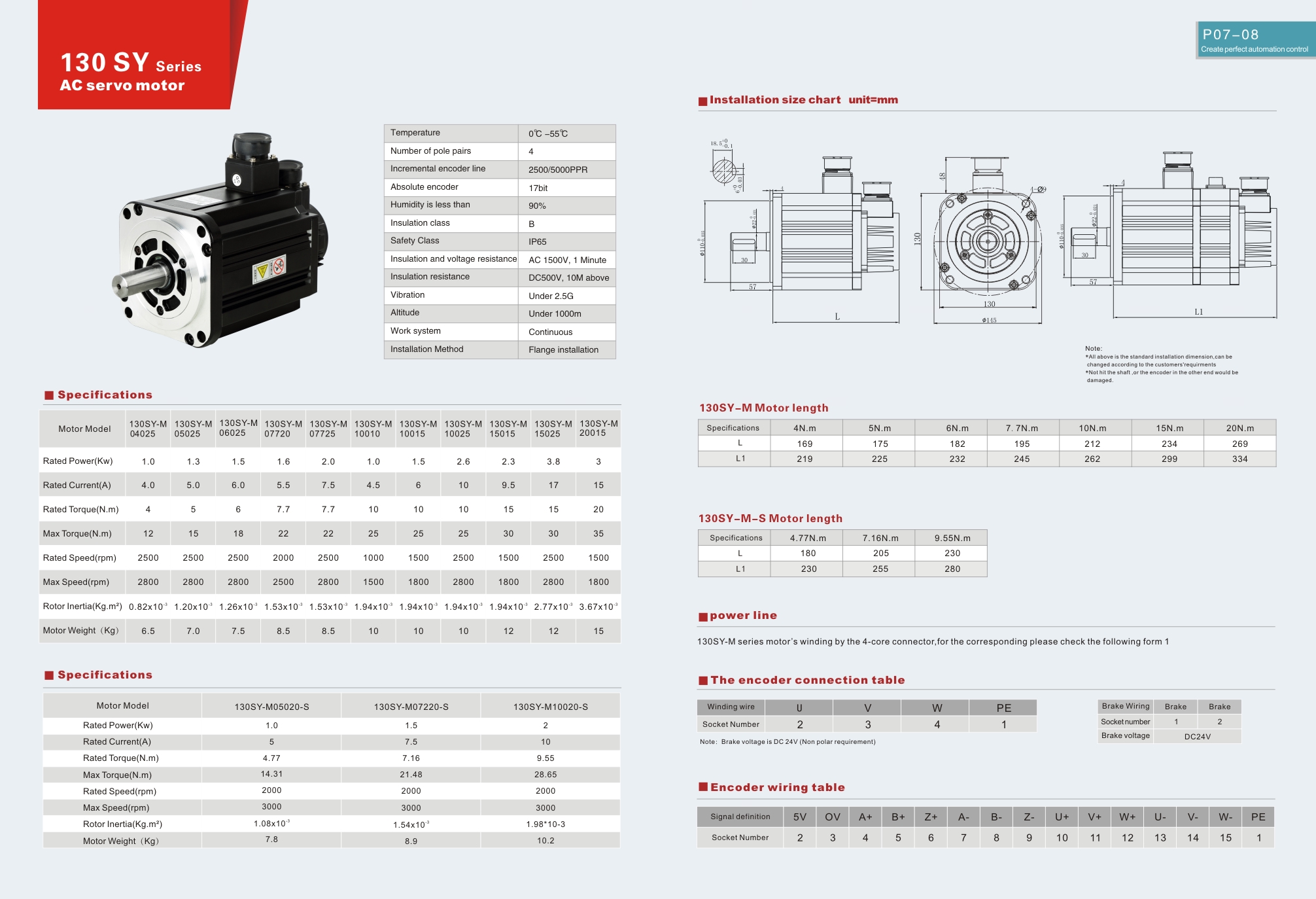

The motor sizes are as follows, x and y 110mm. 6n.m, Z axis is 130mm 10n.m, spindle motor is 5.5kw.

Spindle servo drive:

Spindle servo:

Axis servo motors:

Axis drive options:

I recently purchased a Chinese VMC and it is being Built currently. there was a miscommunication regrading the servos, spindle motor and drives and I am now having to supply them for the machine. The main problem with that is I wasn't prepared research wise to do so.

I have found a few manufacturers in China who make the correct size motors and drives but I'm less familiar with Linuxcnc and what it requires in a drive, motor and encoder. I normally would spend the time reading and researching but the manufacturer needs the motors and drives by next week this time and most of the companies need a few days to configure, pack, and ship the drives.

The good news is I know all the sizes of the motors I need. But are there any special drive features I need to ensure are available for Linux CNC? I am happy to purchase whatever other hardware I will need to use with the drives but for now I just need to be sure what I am about to purchase is going to be compatible with Linux CNC be it the drive or encoder type etc.

Thanks so much in advance, I put the cheat sheets for everything below.

The motor sizes are as follows, x and y 110mm. 6n.m, Z axis is 130mm 10n.m, spindle motor is 5.5kw.

Spindle servo drive:

Spindle servo:

Axis servo motors:

Axis drive options:

Last edit: 13 May 2016 01:39 by Lcvette.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4689

- Thank you received: 1433

13 May 2016 02:10 #74578

by Todd Zuercher

Replied by Todd Zuercher on topic Servos and Drives questions..

Linuxcnc can work with most anything that is suitable for cnc motion control, with the possible exception of some serial controlled devices. I think the best way to determine what to get, is to pick the control method you prefer to work with.

Please Log in or Create an account to join the conversation.

- Lcvette

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 722

13 May 2016 02:14 #74579

by Lcvette

Replied by Lcvette on topic Servos and Drives questions..

That is good news, when you say control method, I'm a little confused, bare in mind I'm coming from steppers and mach3 for the past 6 years and have no experience with servos.

So any guidance is greatly appreciated.

So any guidance is greatly appreciated.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4689

- Thank you received: 1433

13 May 2016 03:00 #74582

by Todd Zuercher

Replied by Todd Zuercher on topic Servos and Drives questions..

Linuxcnc can do most digital position types, (step/dir, cw/ccw, quadrature), most traditional analog control, (with the right interface hardware), and as of recently ethercat (but support is still a little sketchy).

What Linuxcnc doesn't do is work with usb motion controlers (like a Smoothstepper) and other non realtime interfaces.

So if you want to do software stepping, pick something that can do step scaling, and accept ttl inputs. If you want to use hardware stepping, look for high resolutions, with differential inputs (most hardware stepping stuff supports differential signaling). If you want to use analog +10/=10v, pick something that accepts an analog velocity signal.

Infact Linuxcnc can control a servomotor with just a simple H-bridge amp.

What Linuxcnc doesn't do is work with usb motion controlers (like a Smoothstepper) and other non realtime interfaces.

So if you want to do software stepping, pick something that can do step scaling, and accept ttl inputs. If you want to use hardware stepping, look for high resolutions, with differential inputs (most hardware stepping stuff supports differential signaling). If you want to use analog +10/=10v, pick something that accepts an analog velocity signal.

Infact Linuxcnc can control a servomotor with just a simple H-bridge amp.

Please Log in or Create an account to join the conversation.

- Lcvette

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 1523

- Thank you received: 722

13 May 2016 03:36 - 13 May 2016 03:38 #74584

by Lcvette

Replied by Lcvette on topic Servos and Drives questions..

You certainly know much about this, which would you select? This machine will be used for business, I know I needed something a bit more robust than steppers and the machine is fairly large which really needs servos. With that information which type would you select on a small size VMC for reliability, consistency ease of use etc..

Last edit: 13 May 2016 03:38 by Lcvette.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4689

- Thank you received: 1433

13 May 2016 12:59 #74598

by Todd Zuercher

Replied by Todd Zuercher on topic Servos and Drives questions..

I think my personal preference is for an analog velocity input control servo, using a Mesa 5i25 + 7i77 for the interface to the PC. But you might prefer using a digital position drive, with 5i25+7i76. One option is not necessarily better than the other, it's more about what you're comfortable with.

Please Log in or Create an account to join the conversation.

Time to create page: 0.154 seconds