HAL config for linear encoder and stepper motor

- mgadid

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

19 Feb 2017 19:50 #88288

by mgadid

HAL config for linear encoder and stepper motor was created by mgadid

Hello,

i'm newbe for linuxcnc. i'm trying to config HAL file thogh all the docomuntion are great. i find it hard to integret it all up.

and understand the internals.

i'm trying to config HAL file for linear encoder-with one wire puls. and creat a closed loop on the steeper baset on posion.

(stepper ruing with geackoG540).

i started to write the base and servo thread. but have doubts.

i know there is importents on the place a function is conected to thread.

i would appreciate your knowledge and experines with feedback on my work so far.

am i on the right track?

# Generated by stepconf and converted configuration to lathe stepper+encoder with PID

#

# Loading Real Time Generic components

loadrt trivkins

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hal_parport cfg="0 out"

setp parport.0.reset-time 3000

#config for charge pump

net estop-out charge-pump.enable iocontrol.0.user-enable-out

net charge-pump <= charge-pump.out

# Loading Real Time components

loadrt stepgen step_type=0,0

loadrt charge_pump

loadrt encoder num_chan=1

loadrt pid num_chan=1

#Adding fucntions to threads

addf parport.0.read base-thread

addf stepgen.make-pulses base-thread

addf charge-pump base-thread

####High speed function to count pulses (no floating point).

addf encoder.update-counters base-thread

addf parport.0.write base-thread

addf parport.0.reset base-thread

####To setup DoubleStep on the parallel port you must add the function parport.n.reset after parport.n.write

####and configure stepspace to 0 and the reset time wanted. So that step can be asserted on every period in HAL

####and then toggled off by parport after being asserted for time specificed by parport.n.reset-time.

####parport.0.reset-time to 3000

####Low speed function to update latches and scale position.

addf encoder.capture-position servo-thread

####Performs all calculations for a single PID loop

addf pid.0.do-pid-calcs servo-thread

####computes the stepgen's current position and makes it available to HAL.

####The position feedback information is normally connected (by HAL) to the motion planner.

####what that mean?? does pid need to come after in the thread???

addf stepgen.capture-position servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf stepgen.update-freq servo-thread

#Parametes taken from the ini file

setp stepgen.0.position-scale [AXIS_0]SCALE

#if steplen is changed from 1 to 2, then it there will be two periods between the beginning and end of the step pulse

setp stepgen.0.steplen 1

#Minimum spacing between two step pulses (step types 0 and 1 only), in nano-seconds. Set to 0 to enable the stepgen doublefreq function.

#To use doublefreq the parport reset function must be enabled.

setp stepgen.0.stepspace 0

#Minmum time from the end of a step pulse to a direction change (step type 0 only), in nanoseconds.

setp stepgen.0.dirhold 25200

#Minimum time from a direction change to the beginning of the next step pulse (step type 0 only), in nanoseconds.

setp stepgen.0.dirsetup 25200

#Maximum accel/decel rate, in positions units per second squared. If 0.0, has no effect.

#Parametes taken from the ini file

setp stepgen.0.maxaccel [AXIS_0]STEPGEN_MAXACCEL

i'm newbe for linuxcnc. i'm trying to config HAL file thogh all the docomuntion are great. i find it hard to integret it all up.

and understand the internals.

i'm trying to config HAL file for linear encoder-with one wire puls. and creat a closed loop on the steeper baset on posion.

(stepper ruing with geackoG540).

i started to write the base and servo thread. but have doubts.

i know there is importents on the place a function is conected to thread.

i would appreciate your knowledge and experines with feedback on my work so far.

am i on the right track?

# Generated by stepconf and converted configuration to lathe stepper+encoder with PID

#

# Loading Real Time Generic components

loadrt trivkins

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hal_parport cfg="0 out"

setp parport.0.reset-time 3000

#config for charge pump

net estop-out charge-pump.enable iocontrol.0.user-enable-out

net charge-pump <= charge-pump.out

# Loading Real Time components

loadrt stepgen step_type=0,0

loadrt charge_pump

loadrt encoder num_chan=1

loadrt pid num_chan=1

#Adding fucntions to threads

addf parport.0.read base-thread

addf stepgen.make-pulses base-thread

addf charge-pump base-thread

####High speed function to count pulses (no floating point).

addf encoder.update-counters base-thread

addf parport.0.write base-thread

addf parport.0.reset base-thread

####To setup DoubleStep on the parallel port you must add the function parport.n.reset after parport.n.write

####and configure stepspace to 0 and the reset time wanted. So that step can be asserted on every period in HAL

####and then toggled off by parport after being asserted for time specificed by parport.n.reset-time.

####parport.0.reset-time to 3000

####Low speed function to update latches and scale position.

addf encoder.capture-position servo-thread

####Performs all calculations for a single PID loop

addf pid.0.do-pid-calcs servo-thread

####computes the stepgen's current position and makes it available to HAL.

####The position feedback information is normally connected (by HAL) to the motion planner.

####what that mean?? does pid need to come after in the thread???

addf stepgen.capture-position servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf stepgen.update-freq servo-thread

#Parametes taken from the ini file

setp stepgen.0.position-scale [AXIS_0]SCALE

#if steplen is changed from 1 to 2, then it there will be two periods between the beginning and end of the step pulse

setp stepgen.0.steplen 1

#Minimum spacing between two step pulses (step types 0 and 1 only), in nano-seconds. Set to 0 to enable the stepgen doublefreq function.

#To use doublefreq the parport reset function must be enabled.

setp stepgen.0.stepspace 0

#Minmum time from the end of a step pulse to a direction change (step type 0 only), in nanoseconds.

setp stepgen.0.dirhold 25200

#Minimum time from a direction change to the beginning of the next step pulse (step type 0 only), in nanoseconds.

setp stepgen.0.dirsetup 25200

#Maximum accel/decel rate, in positions units per second squared. If 0.0, has no effect.

#Parametes taken from the ini file

setp stepgen.0.maxaccel [AXIS_0]STEPGEN_MAXACCEL

Please Log in or Create an account to join the conversation.

- mgadid

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

20 Feb 2017 19:58 - 20 Feb 2017 20:08 #88381

by mgadid

Replied by mgadid on topic HAL config for linear encoder and stepper motor

hi,

i'm trying to config HAL file for linear encoder-with one wire puls. and creat a closed loop on the steeper baset on posion.

(stepper ruing with geackoG540).

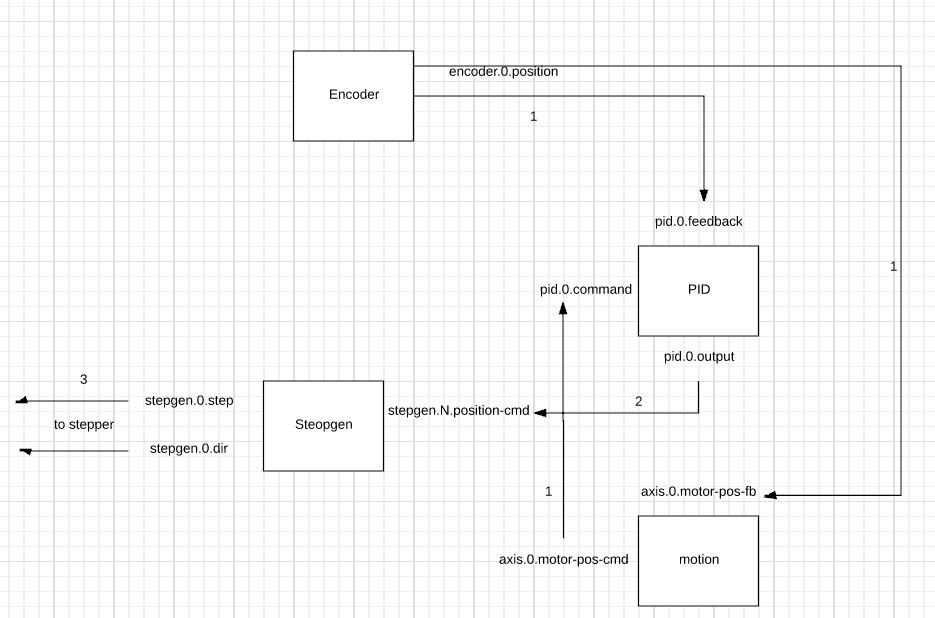

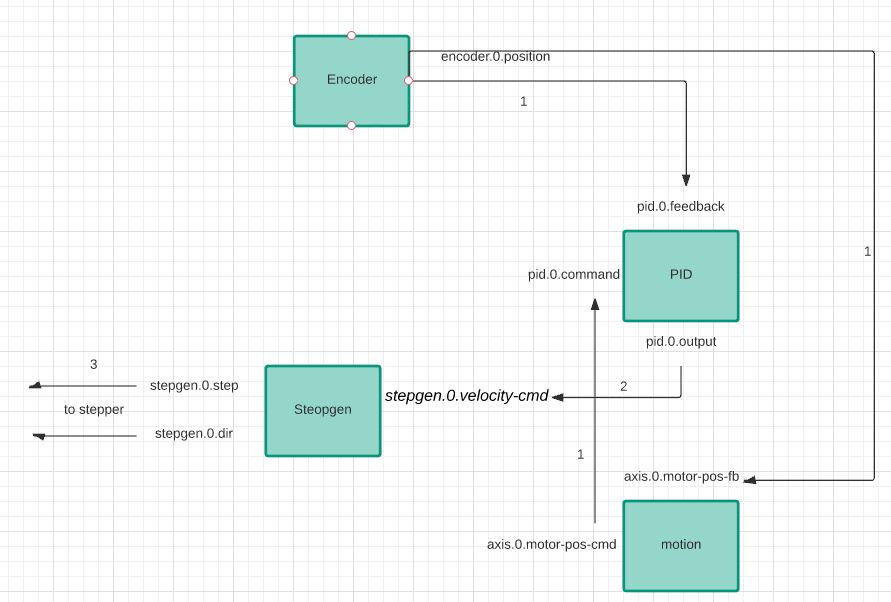

i tried to understand how to integreat HAL components -motion, encoder, stepgen and pid

i put it on diagram. is that how the componets realy conected??

forum.linuxcnc.org/media/kunena/attachme...atHAL_2017-02-20.JPG

i'm trying to config HAL file for linear encoder-with one wire puls. and creat a closed loop on the steeper baset on posion.

(stepper ruing with geackoG540).

i tried to understand how to integreat HAL components -motion, encoder, stepgen and pid

i put it on diagram. is that how the componets realy conected??

forum.linuxcnc.org/media/kunena/attachme...atHAL_2017-02-20.JPG

Last edit: 20 Feb 2017 20:08 by mgadid. Reason: double upload

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

20 Feb 2017 20:35 - 20 Feb 2017 20:37 #88386

by Todd Zuercher

Replied by Todd Zuercher on topic HAL config for linear encoder and stepper motor

No guarantees this will work as advertised (step motors are not servos and won't step faster when stalled).

But it is Motion sends position cmd to PID, PID sends velocity cmd to Stepgenerator, Stepgenerator sends pulses to motor drive.

Encoder sends feed position back to PID and Motion

But it is Motion sends position cmd to PID, PID sends velocity cmd to Stepgenerator, Stepgenerator sends pulses to motor drive.

Encoder sends feed position back to PID and Motion

Last edit: 20 Feb 2017 20:37 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

- mgadid

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

20 Feb 2017 21:05 #88395

by mgadid

Replied by mgadid on topic HAL config for linear encoder and stepper motor

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

20 Feb 2017 21:54 #88400

by Todd Zuercher

Replied by Todd Zuercher on topic HAL config for linear encoder and stepper motor

Close, the stepgen pin will be "stepgen.N.velocity-cmd" instead of position-cmd. But the basic gist of it is right.

Don't forget that the stepgenerator type needs to be set to velocity as well.

Pin names etc. will be different for a hardware step-gen.

Don't forget that the stepgenerator type needs to be set to velocity as well.

Pin names etc. will be different for a hardware step-gen.

Please Log in or Create an account to join the conversation.

- mgadid

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

21 Feb 2017 18:49 #88448

by mgadid

Replied by mgadid on topic HAL config for linear encoder and stepper motor

Thanks for pointing it out.

some how i missed the pid output is in vel units.

does step type 2 will work on steper motor? (there is no step and dir only phaze A and B . correct? )

some how i missed the pid output is in vel units.

does step type 2 will work on steper motor? (there is no step and dir only phaze A and B . correct? )

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

21 Feb 2017 19:26 #88452

by Todd Zuercher

Replied by Todd Zuercher on topic HAL config for linear encoder and stepper motor

What type works, will depend on your drives. Some drives can be configured for different input types, but the most common is standard type 0 step/dir.

A good description of how Linuxcnc's software step generator can be configured and how it works can be found here.

linuxcnc.org/docs/html/hal/rtcomps.html

A good description of how Linuxcnc's software step generator can be configured and how it works can be found here.

linuxcnc.org/docs/html/hal/rtcomps.html

Please Log in or Create an account to join the conversation.

- mgadid

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

21 Feb 2017 21:20 - 21 Feb 2017 21:23 #88464

by mgadid

Replied by mgadid on topic HAL config for linear encoder and stepper motor

Last edit: 21 Feb 2017 21:23 by mgadid.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

21 Feb 2017 21:39 #88466

by Todd Zuercher

Replied by Todd Zuercher on topic HAL config for linear encoder and stepper motor

PID and encoder settings can be set up only in hal. But they are usually set up in the ini, with the hal files using variables to reference the ini.

The following user(s) said Thank You: mgadid

Please Log in or Create an account to join the conversation.

- mgadid

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

21 Feb 2017 21:52 - 22 Feb 2017 18:41 #88468

by mgadid

Replied by mgadid on topic HAL config for linear encoder and stepper motor

so the next step is to fireup Linuxcnc and try the file?

Last edit: 22 Feb 2017 18:41 by mgadid.

Please Log in or Create an account to join the conversation.

Time to create page: 0.115 seconds