kinematics getting started for dummies?

- cncmark

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

02 May 2017 19:00 #92534

by cncmark

kinematics getting started for dummies? was created by cncmark

New to the linuxcnc, been using mach3, and considered converting several times. Now I have a new project.

Found a robot in scrap yard, Looks like a Faunc 510, SCARA arm.

I would like to get this running as a routing table, but am unsure of the kinematics.

Joint 0= base and is Z

Joint 1= base and rotates 360

Joint 2= first arm joint rotates 300

Joint 3= second arm joint, rotates 720

The 3 rotating axis are in same orientation.

I have looked at several KINS files that have been posted, but I have no idea what is going on in these, or what type of robot they are for.

Is there a "kinematics getting started for dummies" I am not good at trig, but given enough time, maybe.

Found a robot in scrap yard, Looks like a Faunc 510, SCARA arm.

I would like to get this running as a routing table, but am unsure of the kinematics.

Joint 0= base and is Z

Joint 1= base and rotates 360

Joint 2= first arm joint rotates 300

Joint 3= second arm joint, rotates 720

The 3 rotating axis are in same orientation.

I have looked at several KINS files that have been posted, but I have no idea what is going on in these, or what type of robot they are for.

Is there a "kinematics getting started for dummies" I am not good at trig, but given enough time, maybe.

Please Log in or Create an account to join the conversation.

- cncmark

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

03 May 2017 08:13 #92563

by cncmark

Replied by cncmark on topic kinematics getting started for dummies?

Found this at

MIT - Massachusetts Institute of Technology

The first robot described is close to what I am getting. "Planar Kinematics" Just have to add a Z to the base.

I have read this lecture note several times now, Think I am getting a grasp on the math involved.

Now to figure out how to program kinematics. Or is there a kinematics like this?

The first robot described is close to what I am getting. "Planar Kinematics" Just have to add a Z to the base.

I have read this lecture note several times now, Think I am getting a grasp on the math involved.

Now to figure out how to program kinematics. Or is there a kinematics like this?

Please Log in or Create an account to join the conversation.

- bkt

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1111

- Thank you received: 114

03 May 2017 13:27 - 03 May 2017 13:28 #92576

by bkt

Replied by bkt on topic kinematics getting started for dummies?

in master there is scarakins jet .... read the file for setting the right arm lenght ... than from your hal file remove

and read these doc first

Lcnc-KINS

regards

giorgio

#loadrt trivkins

loadrt scarakins /* control the exact name .... not shure*/

......

setp firstarmlenght etc etc ....and read these doc first

Lcnc-KINS

regards

giorgio

Last edit: 03 May 2017 13:28 by bkt.

The following user(s) said Thank You: cncmark

Please Log in or Create an account to join the conversation.

- cncmark

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

04 May 2017 06:32 #92619

by cncmark

Replied by cncmark on topic kinematics getting started for dummies?

Thanks. I was reading the docs, and didn't see the manual underneath. I was wondering why everything was so vague. Reading the manual now. I had many more questions, but now I think I may be OK.

Please Log in or Create an account to join the conversation.

- bkt

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1111

- Thank you received: 114

04 May 2017 07:38 - 04 May 2017 16:47 #92621

by bkt

Replied by bkt on topic kinematics getting started for dummies?

I am also a chatterer of course .... but here the thing is not very well seen, I think it's because whoever has all the answers has a lot to do so it only responds if the question is interesting.

Actually on the scaraKins question i also have many questions and no answer .... i also have a scara built by me .... the kinematics is identical to that of the fanuc 510, the engines a little bigger, so if you believe We could do experiments together.

For example, I on joint 4, while working on other joint, I have a slight oscillation that I have never been able to take away.

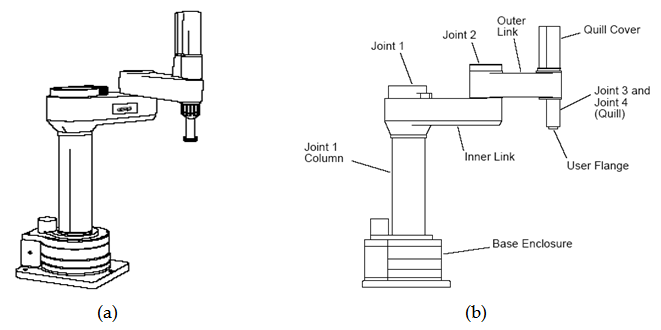

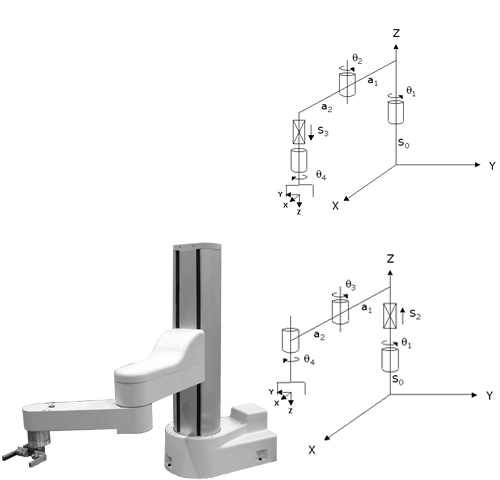

For better precision 2 image:

fanuc 510 have these config?

2 my scheme of scara, and fanuc 510 have these instead of nr.1?

I never see to work a scara fanuc so i do not know its functioning ... (correct after the andypugh intervention ... I think I could have created a misunderstanding).

I you use scarakins on master you are ready to start .... only need to insert as I suggest you the scarakins definition and call on your hal file (on top)... if you have other scarakins you must compile it with halcompile than insert the definition in your halfile as i suggest you.

We could do some experiments together to improve our knowledge. I hope you agree. Ciao.

regards

Giorgio

Actually on the scaraKins question i also have many questions and no answer .... i also have a scara built by me .... the kinematics is identical to that of the fanuc 510, the engines a little bigger, so if you believe We could do experiments together.

For example, I on joint 4, while working on other joint, I have a slight oscillation that I have never been able to take away.

For better precision 2 image:

fanuc 510 have these config?

2 my scheme of scara, and fanuc 510 have these instead of nr.1?

I never see to work a scara fanuc so i do not know its functioning ... (correct after the andypugh intervention ... I think I could have created a misunderstanding).

I you use scarakins on master you are ready to start .... only need to insert as I suggest you the scarakins definition and call on your hal file (on top)... if you have other scarakins you must compile it with halcompile than insert the definition in your halfile as i suggest you.

We could do some experiments together to improve our knowledge. I hope you agree. Ciao.

regards

Giorgio

Last edit: 04 May 2017 16:47 by bkt.

The following user(s) said Thank You: cncmark

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

04 May 2017 15:35 #92654

by andypugh

Replied by andypugh on topic kinematics getting started for dummies?

Both those robots should be able to use the same kinematics. This will work because the Z position is completely orthogonal to the arm joints in both cases. It doesn't matter from a mathematical point of view where the Z axis actuator is.

The following user(s) said Thank You: cncmark

Please Log in or Create an account to join the conversation.

- bkt

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1111

- Thank you received: 114

04 May 2017 16:44 - 04 May 2017 16:47 #92665

by bkt

Replied by bkt on topic kinematics getting started for dummies?

@andypugh ... the question was not kins related but mechanical configuration related ... only for know the phisical work of fanuc 510 robot and even make some friendship.

In any case I am always in debt with you for the help you gave me here on the forum..... and I correct my last post.

regards

giorgio

In any case I am always in debt with you for the help you gave me here on the forum..... and I correct my last post.

regards

giorgio

Last edit: 04 May 2017 16:47 by bkt.

Please Log in or Create an account to join the conversation.

- cncmark

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 0

04 May 2017 21:29 #92676

by cncmark

Replied by cncmark on topic kinematics getting started for dummies?

I have a long way to go. I have just now started understanding the scartkins file, Still not clear on the inverse, but think it is sinking in. I am thinking of some kind of router table, but not sure what I will use this for. It is big, about 9 foot reach, and when I put a tooling arm on?

Looks like I might be getting 2 of these, the second one has servo motors, but no drives and has the 3rd joint turned. As I am understanding this will be a different KINS. not going to figure that out for now. I have to figure out how to get these moving first.

Thanks k-1, I would be happy to help any why I can. I am learning by trial and error, I know there will be plenty of error. I am glad to see there is others with this type of machine.

Thanks Andy, I was wondering about Z location. The scartkins file has the z in different location from the 510. I didn't see this as a problem and help is always welcome. I have been drawing different positions figuring out the math and it works with Z any where in my figuring.

The names of the KINS is confusing to me. I don't know the types of robot configurations. Would be nice to see a picture of the different types of machines, I have been looking at other user machines as I find them, most don't say what it is using.

Thanks and looking forward to new things.

Looks like I might be getting 2 of these, the second one has servo motors, but no drives and has the 3rd joint turned. As I am understanding this will be a different KINS. not going to figure that out for now. I have to figure out how to get these moving first.

Thanks k-1, I would be happy to help any why I can. I am learning by trial and error, I know there will be plenty of error. I am glad to see there is others with this type of machine.

Thanks Andy, I was wondering about Z location. The scartkins file has the z in different location from the 510. I didn't see this as a problem and help is always welcome. I have been drawing different positions figuring out the math and it works with Z any where in my figuring.

The names of the KINS is confusing to me. I don't know the types of robot configurations. Would be nice to see a picture of the different types of machines, I have been looking at other user machines as I find them, most don't say what it is using.

Thanks and looking forward to new things.

Please Log in or Create an account to join the conversation.

- bkt

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1111

- Thank you received: 114

05 May 2017 11:19 - 05 May 2017 11:22 #92693

by bkt

Replied by bkt on topic kinematics getting started for dummies?

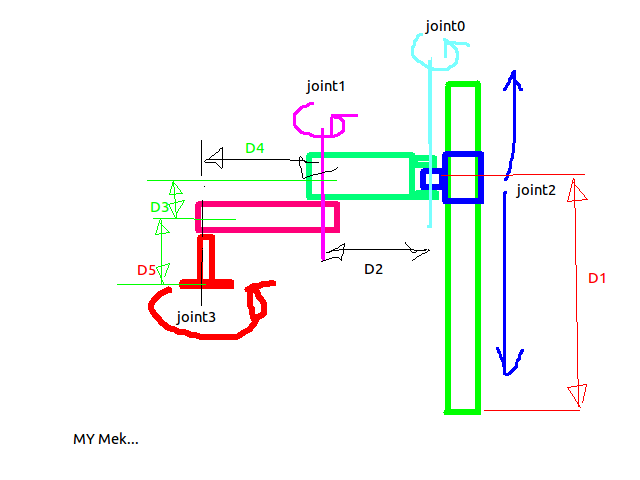

my mecanicals ... in the draw you see the right number and name of joint ....

.... Z location is not important because not influence the kins math .... only you see some difference on end effector if you not insert correctly ..

from scarakins.c ...:

Actually for more semplicity in my hal file I set D1/D5 and D6 to 0 .... in these way the working area of your scara and the arm orientation is determined by your ini file and the direction of rotation of the motors. No stress to detect real measures.

I hope these help.

Giorgio

.... Z location is not important because not influence the kins math .... only you see some difference on end effector if you not insert correctly ..

from scarakins.c ...:

/* key dimensions

joint[0] = Entire arm rotates around a vertical axis at its inner end

which is attached to the earth. A value of zero means the

inner arm is pointing along the X axis.

D1 = Vertical distance from the ground plane to the center of the inner

arm.

D2 = Horizontal distance between joint[0] axis and joint[1] axis, ie.

the length of the inner arm.

joint[1] = Outer arm rotates around a vertical axis at its inner end

which is attached to the outer end of the inner arm. A

value of zero means the outer arm is parallel to the

inner arm (and extending outward).

D3 = Vertical distance from the center of the inner arm to the center

of the outer arm. May be positive or negative depending

on the structure of the robot.

joint[2] = End effector slides along a vertical axis at the outer end

of the outer arm. A value of zero means the end effector

is at the same height as the center of the outer arm, and

positive values mean downward movement.

D4 = Horizontal distance between joint[1] axis and joint[2] axis, ie.

the length of the outer arm

joint[3] = End effector rotates around the same vertical axis that it

slides along. A value of zero means that the tooltip (if

offset from the axis) is pointing in the same direction

as the centerline of the outer arm.

D5 = Vertical distance from the end effector to the tooltip. Positive

means the tooltip is lower than the end effector, and is

the normal case.

D6 = Horizontal distance from the centerline of the end effector (and

the joints 2 and 3 axis) and the tooltip. Zero means the

tooltip is on the centerline. Non-zero values should be

positive, if negative they introduce a 180 degree offset

on the value of joint[3].

*/Actually for more semplicity in my hal file I set D1/D5 and D6 to 0 .... in these way the working area of your scara and the arm orientation is determined by your ini file and the direction of rotation of the motors. No stress to detect real measures.

I hope these help.

Giorgio

Last edit: 05 May 2017 11:22 by bkt.

Please Log in or Create an account to join the conversation.

Time to create page: 0.162 seconds