CNC Tig welding

- SSP

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 2

31 Dec 2017 13:45 #103896

by SSP

CNC Tig welding was created by SSP

Hello all !

I have managed to put together a single axis TIG welding CNC machine for seam welding using Arduino & GRBL, using a GUI to send G code to the Arduino . The only hiccup is that the USB connection between the Arduino & the Laptop sometimes freezes when initiating the arc by HF initiation. When that happens , the g code that follows does not get executed, & the rest of the commands ( such as turning off the arc etc) have to be manually dealt with.

Can this problem be avoided by using Linux CNC & its supported hardware? If so , then how?

I have never used LinuxCnc before .

Hope this is the right place to post since, I did not see a CNC welding category anywhere.

Appreciate your help.

I have managed to put together a single axis TIG welding CNC machine for seam welding using Arduino & GRBL, using a GUI to send G code to the Arduino . The only hiccup is that the USB connection between the Arduino & the Laptop sometimes freezes when initiating the arc by HF initiation. When that happens , the g code that follows does not get executed, & the rest of the commands ( such as turning off the arc etc) have to be manually dealt with.

Can this problem be avoided by using Linux CNC & its supported hardware? If so , then how?

I have never used LinuxCnc before .

Hope this is the right place to post since, I did not see a CNC welding category anywhere.

Appreciate your help.

Please Log in or Create an account to join the conversation.

- chimeno

- Offline

- Elite Member

-

Less

More

- Posts: 295

- Thank you received: 125

31 Dec 2017 17:28 #103905

by chimeno

Replied by chimeno on topic CNC Tig welding

hello SSP,

the problem you have with high frequency will not solve linuxcnc, it is a problem of environmental noise, it is much easier, separates the control circuits further away from the TIG machine and isolates the masses of the two machines and put them to different lands , I also advise you that the control circuits are inside a metal box and connected to the ground, I hope I can help you.

the problem you have with high frequency will not solve linuxcnc, it is a problem of environmental noise, it is much easier, separates the control circuits further away from the TIG machine and isolates the masses of the two machines and put them to different lands , I also advise you that the control circuits are inside a metal box and connected to the ground, I hope I can help you.

Please Log in or Create an account to join the conversation.

- ozzyrob

-

- Visitor

-

31 Dec 2017 22:14 #103913

by ozzyrob

Replied by ozzyrob on topic CNC Tig welding

This is something I'd like to see a vid of, sounds very interesting.

But the environmental noise advice is very sound indeed.

But the environmental noise advice is very sound indeed.

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7286

- Thank you received: 2125

02 Jan 2018 08:04 #103944

by cmorley

Replied by cmorley on topic CNC Tig welding

Linuxcnc can use ethernet cards which are better suited to noisy environments.

USB is not so good at noisy environments and or course are not realtime to begin with.

Hard to say without more idea what the actual problem is.

linuxcnc has been used with plasma cutters so can work well in that environment.

Chris M

USB is not so good at noisy environments and or course are not realtime to begin with.

Hard to say without more idea what the actual problem is.

linuxcnc has been used with plasma cutters so can work well in that environment.

Chris M

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

02 Jan 2018 20:00 - 02 Jan 2018 20:01 #103962

by Grotius

Replied by Grotius on topic CNC Tig welding

Hi,

I have also done a project with Inox Tig welding on CNC. The problem is indeed the HF ignition start of the Tig welding inverter.

Also HF plasma inverters have the same problem and are not usable for CNC. Only the expensive plama machine's with HF start are

good insulated to work with CNC. Then we talk about branches Hypertherm or Thermal Dynamics.

To reduce the problem you can try :

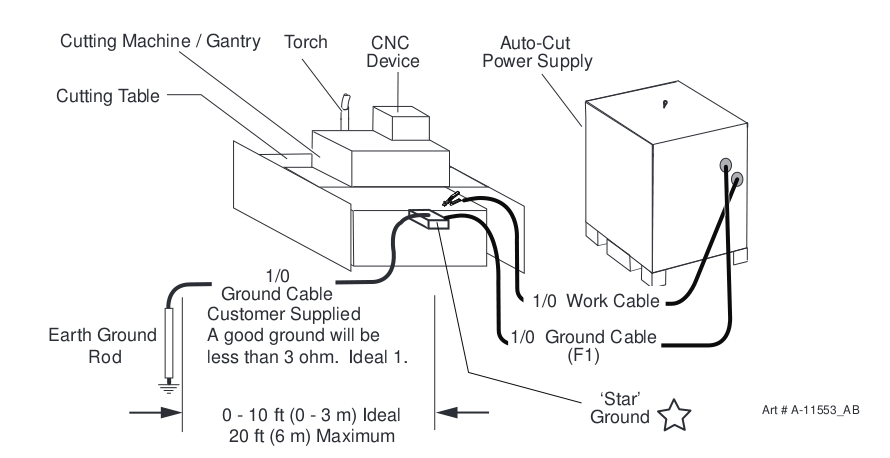

1. Make a good ground connection => machine to earth cable and ground

2. Use a opto isolated break out board.

3. Use mosfet relais (torch start) in stead of mechanical click relais.

4. Isolate your cnc hardware into a metal box

5. Use a differtent power connection for your tig inverter.

6. If your computer screen is flickering you know it's not good.

7. My experence is that after a time (can be a few weeks) your computer i/o can be broken.

SSP :

Have luck !!

I have also done a project with Inox Tig welding on CNC. The problem is indeed the HF ignition start of the Tig welding inverter.

Also HF plasma inverters have the same problem and are not usable for CNC. Only the expensive plama machine's with HF start are

good insulated to work with CNC. Then we talk about branches Hypertherm or Thermal Dynamics.

To reduce the problem you can try :

1. Make a good ground connection => machine to earth cable and ground

2. Use a opto isolated break out board.

3. Use mosfet relais (torch start) in stead of mechanical click relais.

4. Isolate your cnc hardware into a metal box

5. Use a differtent power connection for your tig inverter.

6. If your computer screen is flickering you know it's not good.

7. My experence is that after a time (can be a few weeks) your computer i/o can be broken.

SSP :

No no no hihiCan this problem be avoided by using Linux CNC & its supported hardware? If so , then how?

Have luck !!

Last edit: 02 Jan 2018 20:01 by Grotius.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21290

- Thank you received: 7267

04 Jan 2018 11:44 #104014

by tommylight

Replied by tommylight on topic CNC Tig welding

HF interference is a pain to deal with, but with some attention to details can be awoided always.

Proper grounding is the main part of the equasion, plasma cutter must have proper grounding, cables for torch ignition must be shielded and that shield connected only on the electronics side. All other cables and electronic must be as far as posible from the plasma, all power supplyes must be grounded to the mains ground.

Do not connect ground wires from plasma to electronics. Never.

Awoid daisy chaining ground wires, all should be on a single spot.

You should also use better usb cable, cheap ones have no shielding and some have straight data wites, they should be twisted inside.

Proper grounding is the main part of the equasion, plasma cutter must have proper grounding, cables for torch ignition must be shielded and that shield connected only on the electronics side. All other cables and electronic must be as far as posible from the plasma, all power supplyes must be grounded to the mains ground.

Do not connect ground wires from plasma to electronics. Never.

Awoid daisy chaining ground wires, all should be on a single spot.

You should also use better usb cable, cheap ones have no shielding and some have straight data wites, they should be twisted inside.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2348

04 Jan 2018 23:06 #104036

by Grotius

Replied by Grotius on topic CNC Tig welding

Please Log in or Create an account to join the conversation.

- SSP

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 2

05 Jan 2018 06:16 #104043

by SSP

Replied by SSP on topic CNC Tig welding

The following user(s) said Thank You: chimeno

Please Log in or Create an account to join the conversation.

- chimeno

- Offline

- Elite Member

-

Less

More

- Posts: 295

- Thank you received: 125

05 Jan 2018 08:06 #104045

by chimeno

Replied by chimeno on topic CNC Tig welding

Hello SSP,

I think it's great that it works for you at last! I am also a welder and I have a tic machine to weld steel and stainless steel, but I did not have time to test it. I hope I can someday get it done, I have a question, how did you make the metal wire welding device?

thanks

Chimeno

I think it's great that it works for you at last! I am also a welder and I have a tic machine to weld steel and stainless steel, but I did not have time to test it. I hope I can someday get it done, I have a question, how did you make the metal wire welding device?

thanks

Chimeno

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21290

- Thank you received: 7267

14 Jan 2021 00:10 #195274

by tommylight

Replied by tommylight on topic CNC Tig welding

@PrincessJasmW

You spam, you get banned, no more warnings.

I did remove the links you added to other topics.

You spam, you get banned, no more warnings.

I did remove the links you added to other topics.

The following user(s) said Thank You: CORBETT

Please Log in or Create an account to join the conversation.

Time to create page: 0.133 seconds