How do I read current system variable into my Gcode program?

- waxelson

- Offline

- New Member

-

- Posts: 18

- Thank you received: 0

I can see the DRO value of u_pos_fb update accurately. However, when I try to read the same value using #<_u> or #5426, it does not update in real time. I can read it once and after that it always has the same value. Is there a way to read u_pos_fb directly into my code?

I have configured my ini.file ENCODER_SCALE so it reads 1 for each revolution. The HAL configuration watch screen displays u_pos_fb developing a cumulative total as it runs, incrementing by one each revolution. Then I try to convert the cumulative decimal reading to degrees using this block in my program, "#<Theta> = [#<_u> - FIX[#<_u>] * 360]. I capture the decimal "tail" of the current decimal angle and multiply it it by 360 degrees. This works.

However, it only works once. No matter how many other times the block is executed in my program, it always yields the same result, even though u_pos_fb has moved on to a very different value.

Please, what am I doing wrong?

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

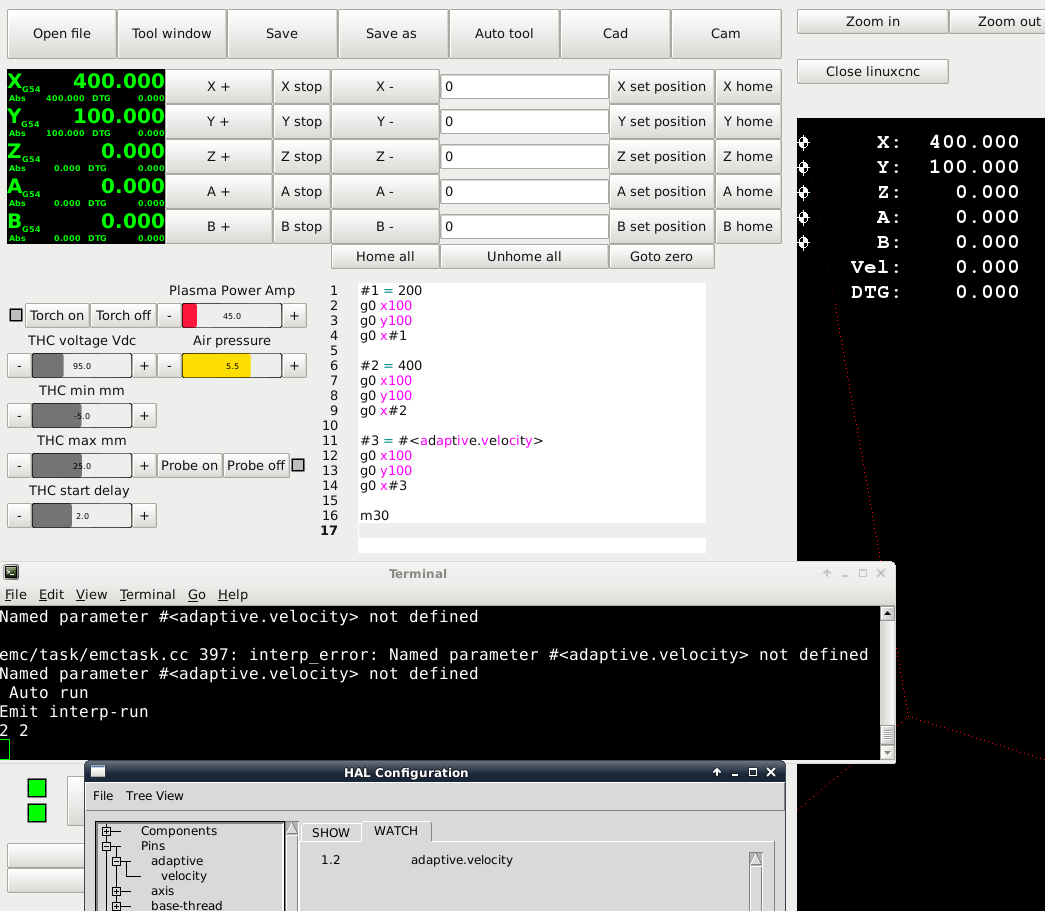

For your question, here you see a text entry box (variable) in glade. And later i write a g-code commando in python.

def on_y_set_position_pressed(self, widget, data=None):

self.entry2 = self.widgets.y_offset_label

self.y = float(self.entry2.get_text())

self.command.mode(linuxcnc.MODE_MDI)

self.command.wait_complete()

command = "G10 L20 P1 Y{0}".format(self.y)

self.command.mdi(command)

print " y position set " next example is spindespeed variable :

def on_torch_on_pressed(self, widget, data=None):

self.command.mode(linuxcnc.MODE_MDI)

self.command.wait_complete()

command = "M3 S{0}".format(self.widgets.plasma_power.get_value())

self.command.mdi(command)

print " Torch on "

#Now it is nice to turn a torch led on.

self.widgets.torch_on_led.set_active(True)Mostly g-code commands works only once. What i know i that for speed it wil change if you use a g-code variable.However, it only works once. No matter how many other times the block is executed in my program, it always yields the same result, even though u_pos_fb has moved on to a very different value.

In my project i am also testing different things with g-code variable.

Please Log in or Create an account to join the conversation.

- waxelson

- Offline

- New Member

-

- Posts: 18

- Thank you received: 0

Simply because I can see a parameter on the AXIS display being updated "rapidly", does not necessarily mean I can read that value in realtime and act on the value via gcode, right?

I was assuming LinuxCNC would run my gcode program like a PLC would run its program: looping continuously through the code as fast as the scan time will allow and branching to different sections of the code based on the value of the central realtime parameter, in this case the value of the U-axis, the rotating optics platform.

Is there anyway to access the realtime value of a parameter in the EMCMOT module and use it to guide the control another axis, like the Z-axis?

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

I did a few test's tonight. This is a button for go to home position with a variabele on the speed in the g-code.

For example, a normal user would do this for the button code : G1 X0 Y0 Z0 F5000

See example :

def on_goto_zero_pressed(self, widget, data=None):

self.command.mode(linuxcnc.MODE_MDI)

self.command.wait_complete()

self.widgets.program_speed.get_value()

command = "G1 X0 Y0 Z0 F{0}".format(self.widgets.program_speed.get_value())

self.command.mdi(command)

print " goto zero pressed "For the widget :

def on_program_speed_value_changed(self,widget,value):

self.command.maxvel(self.widgets.program_speed.get_value()/60)This code is interacting real time with command.maxvel.

So during the execution of this g-code mdi command it's real time changing.

So you can do it also on other commands.

Linux is running trough the code rapidly. But you have to use the right commands that are used for interacting with g-code.

I also mentioned, when you leave the widget's unchanged in glade you have the best output. When you describe the widget initial value's in python, you have to describe everething will it be interacting real time.

Maybe a idea for you :

I know your project is polishing mirror's. if you have a optical distance sensor like IFM sensors. (sometimes you can set the distance with a button on the sensor, this one is expensiver) then you can use also the THCUD function. I have tested this for a long time with

up and down signal. This works really good and is real time. If you need a special THCUD edition, I can compile something for you.

You can do that also yourself. The document's about that are good to do.

Is this info good for now? or not good info?

Here a list of things of what i think, you can manipulate real time without problems in your gcode :

set_adaptive_feed(int)

set adaptive feed flag

set_analog_output(int, float)

set analog output pin to value

set_block_delete(int)

set block delete flag

set_digital_output(int, int)

set digital output pin to value

set_feed_hold(int)

set feed hold on/off

set_feed_override(int)

set feed override on/off

set_max_limit(int, float)

set max position limit for a given axis

set_min_limit()

set min position limit for a given axis

set_optional_stop(int)

set optional stop on/off

set_spindle_override(int)

set spindle override flagMaybe there are more. you can search : linuxcnc.org/docs/2.6/html/common/python-interface.html

Please Log in or Create an account to join the conversation.

- waxelson

- Offline

- New Member

-

- Posts: 18

- Thank you received: 0

Thank you for your input. I haven't yet used any python code with my system; you have given me a lot to think about.

Do you think in python, code could be written to read the linuxcnc.stat object and parse it for the angular position of my rotating U-axis and then cause the Z-axis to move up and down fixed distances at specific angular trigger points?

Alternately, I could install flags on my rotating platform and then mount slot switches to trigger off the flags. One flag would make Z go up and the other would make it go down. Could I configure the Z-axis to be triggered into motion based on the state of a couple of digital inputs?

On a different topic: when I am using the AXIS GUI and I have a (PRINT, message) statement in my Gcode, where does the message show up? The documentation says it goes to "stderr", but where is that when I launched the program from a link on my Linux desktop?

Thanks for your help.

Wayne

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

In Python you can begin with : self.stat = linuxcnc.stat()

This will bring an first eye to the linuxcnc status channel.

I have posted a clean linuxcnc template yesterday. You can start with this to do some tests.

I can help you to set things up with a few command's and test's

After that you can ask the linux status channel for every command the status channel has in it's library.

So you can ask the current position for a certain axis and set this into variable, no problem so far.

The second thing you want is to move the rotating axis U, related to the stat input value.

Okey this is a realtime accident. So you have to use a THCud function, or something like that. There are expert's walking around here that can do huge more code writing than my tiny brains would do. Then your axis is rotating. You can tune this axis, no problem.

In Python you can do everething with i/o command's. You can make a interpolation to move the z axis up and down.

So in python you can make the www. (world wide web)

On a different topic: when I am using the AXIS GUI and I have a (PRINT, message) statement in my Gcode, where does the message show up? The documentation says it goes to "stderr", but where is that when I launched the program from a link on my Linux desktop?

What i think you want to have is a confirmation (good or not good) of your output code?

If you start halmeter of halshow you can see all the variable's you have made in python for your program.

If you start linuxcnc with terminal (linux startup icon, right mouse click) , you can also see message's. They are important for

fast program execution. If there are no errors you have fast program. If you have errors, program execution wil be slower, because program does not like bug's.

"stderr" This says me nothing, never seen before hihi.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4704

- Thank you received: 1443

You do realize python scripts are never real time. It probably isn't appropriate for controlling an axis. Maybe what you are trying would be better accomplished with real time hal components.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

- Posts: 11722

- Thank you received: 3968

Do you think in python, code could be written to read the linuxcnc.stat object and parse it for the angular position of my rotating U-axis and then cause the Z-axis to move up and down fixed distances at specific angular trigger points?

The other thing that might do this (on the bleeding edge of LinuxCNC development) is the experimental external offsets branch

github.com/LinuxCNC/linuxcnc/tree/dgarr/external_offsets

I would envisage you would write a component (in C, not python) that monitored the angular position of U and changed the Z axis position via an offset. There are several example sims for you to play with but you will need to compile from source.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

- Posts: 4704

- Thank you received: 1443

buildbot.linuxcnc.org/dists/wheezy/scrat...fsets~a764ff2.tar.gz

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

Please Log in or Create an account to join the conversation.