Fusion 360 CAM and linuxcnc touch off

- Desertboy

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

14 Apr 2018 10:21 - 14 Apr 2018 10:26 #108992

by Desertboy

Fusion 360 CAM and linuxcnc touch off was created by Desertboy

Last edit: 14 Apr 2018 10:26 by Desertboy.

Please Log in or Create an account to join the conversation.

- DanMN

-

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 10

14 Apr 2018 14:55 #108997

by DanMN

Replied by DanMN on topic Fusion 360 CAM and linuxcnc touch off

The following user(s) said Thank You: Desertboy

Please Log in or Create an account to join the conversation.

- Desertboy

- Offline

- Senior Member

-

Less

More

- Posts: 54

- Thank you received: 1

15 Apr 2018 12:20 #109063

by Desertboy

Replied by Desertboy on topic Fusion 360 CAM and linuxcnc touch off

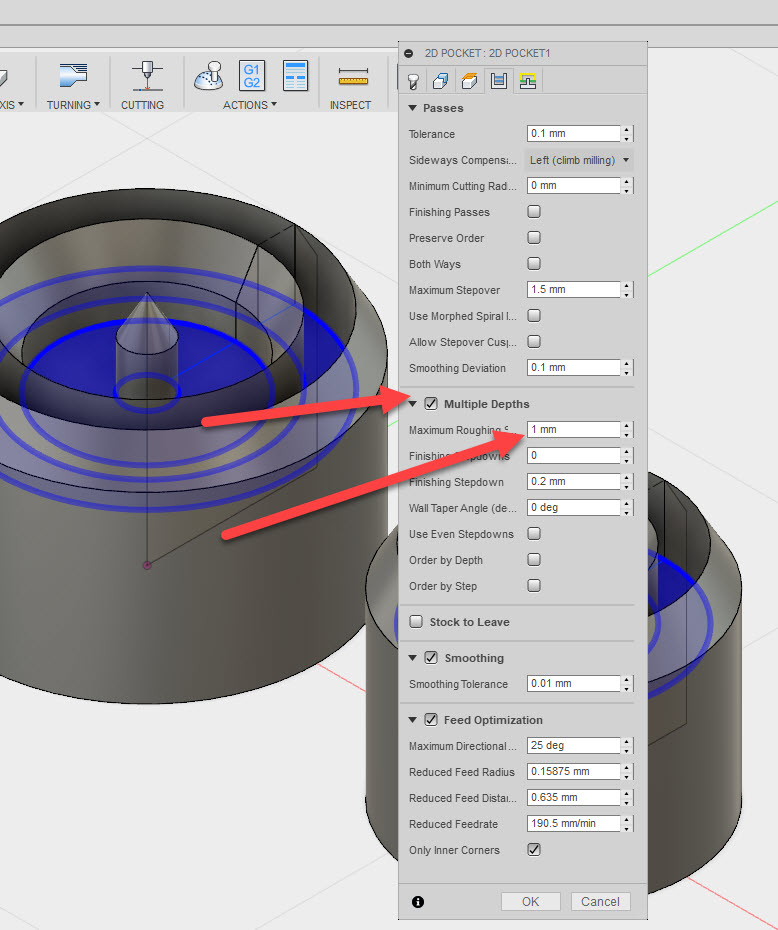

Hi thanks for the reply, I'm using 3d adaptive pocketing and then a parallel finish. I noticed today when I touch off, the G54 coordinates for X&Y set to 0 but the Z does not change is this something to do with how I have the tool setup?

Do the G54 Z coordinates have to read 0 if the tool is at the top of the material and I set the top of the material as 0?

Do the G54 Z coordinates have to read 0 if the tool is at the top of the material and I set the top of the material as 0?

Please Log in or Create an account to join the conversation.

- robh

- Offline

- Premium Member

-

Less

More

- Posts: 102

- Thank you received: 22

15 Apr 2018 22:05 #109099

by robh

Replied by robh on topic Fusion 360 CAM and linuxcnc touch off

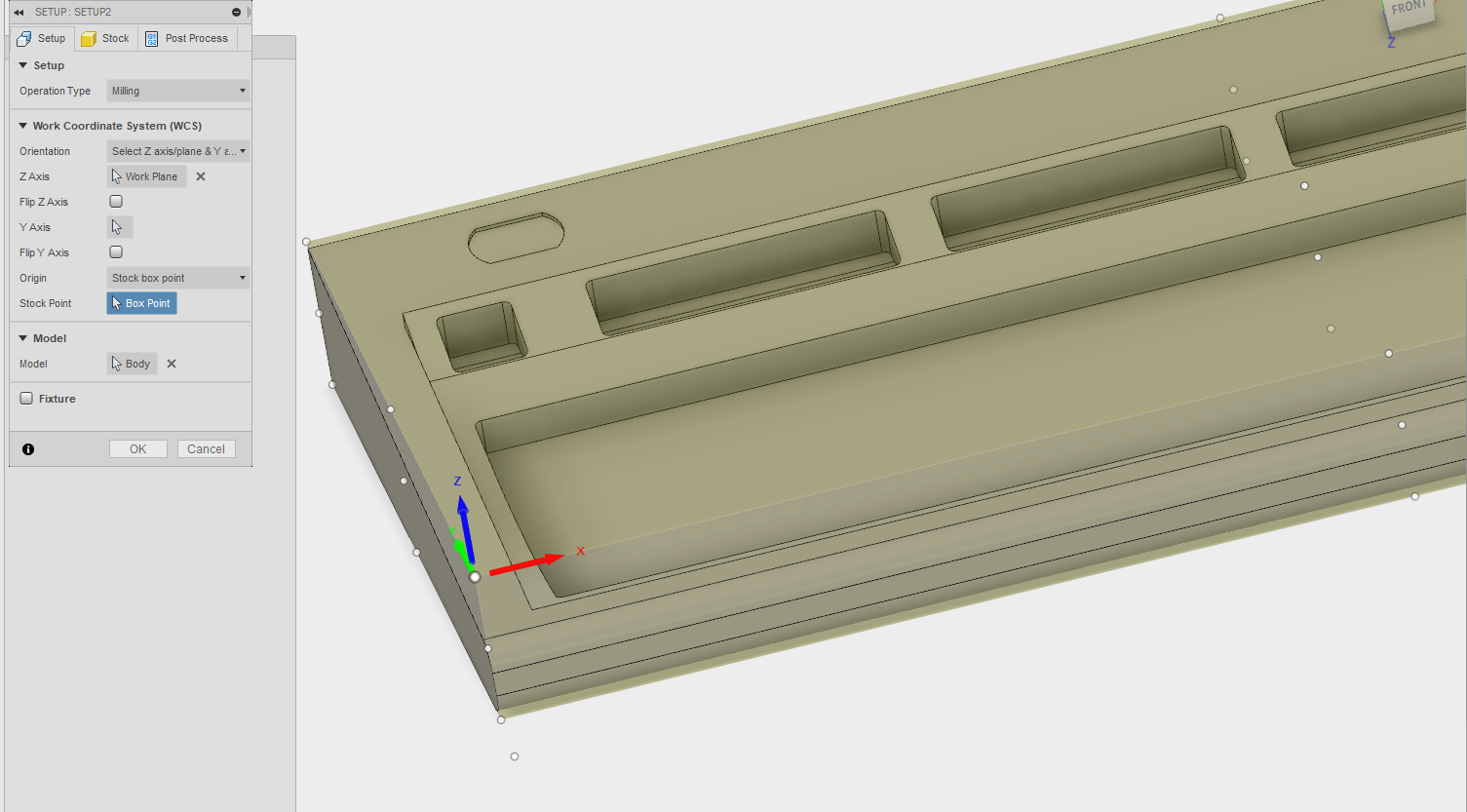

in fusion,you need to check what you have part zero, stock box or stock body.. or osmething else.. and you need to know what you want to set to on the machine, stock or model.

as this will effect where part zero is refferenced from.

if you want to touch off to part 0 with a known set tool..that has already been measured(known length)

make the tool you want to use active and in the spindle..

you will need to G43 the tool length on.

then toch on the surface and touch off the Z axis to 0

the dro should read the 0

you can use a known setting length block and do the same by bring the tool slowly into contact & entering in its distance

the DRO will show the distance above stock by the setting block hight.

hope it helps..

as this will effect where part zero is refferenced from.

if you want to touch off to part 0 with a known set tool..that has already been measured(known length)

make the tool you want to use active and in the spindle..

you will need to G43 the tool length on.

then toch on the surface and touch off the Z axis to 0

the dro should read the 0

you can use a known setting length block and do the same by bring the tool slowly into contact & entering in its distance

the DRO will show the distance above stock by the setting block hight.

hope it helps..

The following user(s) said Thank You: Desertboy

Please Log in or Create an account to join the conversation.

Time to create page: 0.109 seconds