Is it possible to compensate for offset tool path?

- uptown47

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 1

I'm completely new to the CNC world but had a go at making my first cut today!

I just had a thin MDF blank and wanted to carve my wife's name into it as a test.

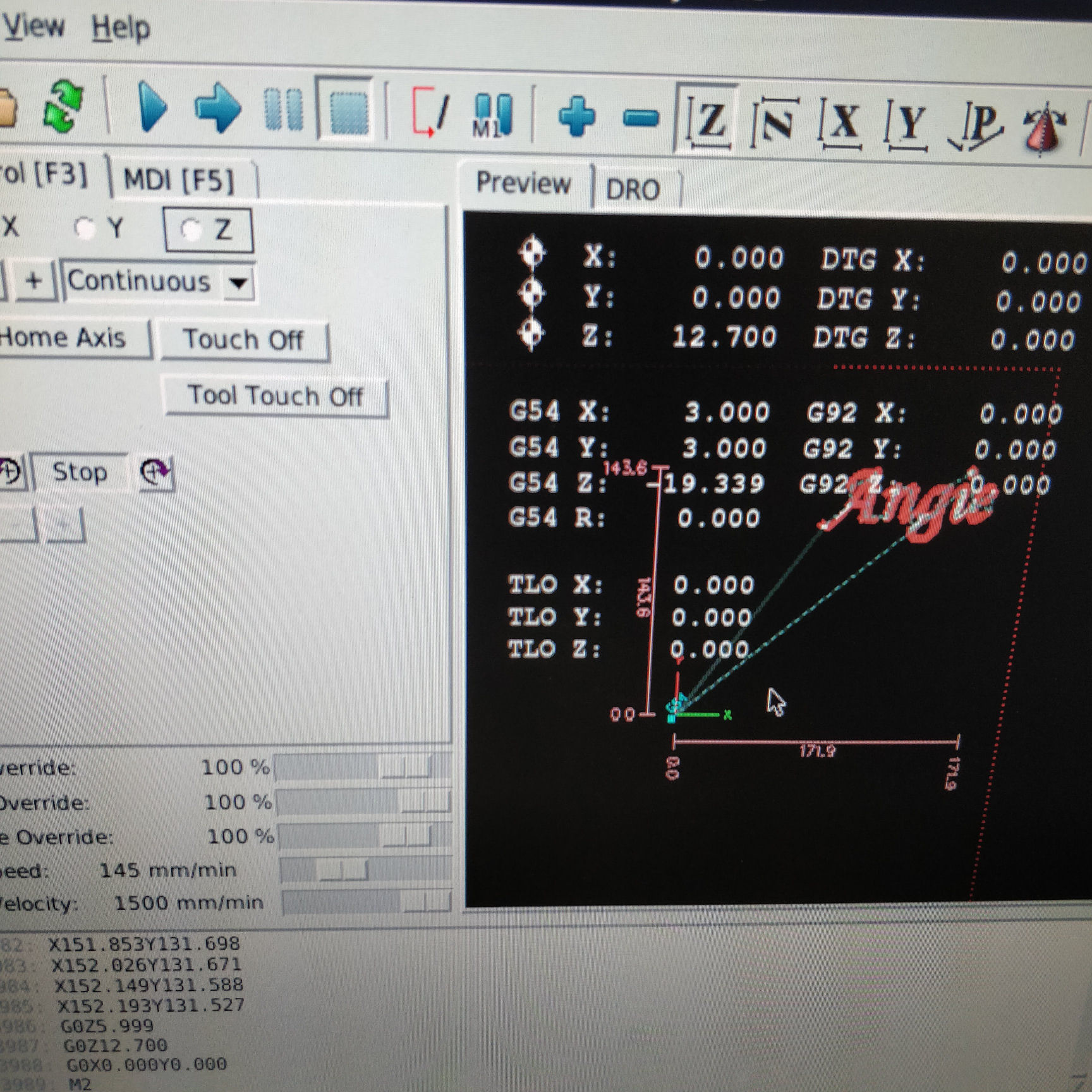

Unfortunately the tool path was a good way away from the 0 of X and Y (see photo)

I haven't got my 'home' switches working yet so I just took them out of StepConf for now. So I put the tool at the bottom left-hand position of the wood and 'homed' all the axis but when I run the machine it drives diagonally away (to get to the first cut).

I ended up manually offsetting the starting position just so it would cut the wood and I know that this is my cock-up in the software as I didn't start the cut at 0. However, I wondered if there was a way to compensate for this from within LinuxCNC?

I saw the "G54" variables and weren't sure if these were the first 'cut' position?? And, if so, if I could somehow tell LinuxCNC that the machine is already at the first cut position and to just lower the spindle and start the cut?

Thanks for any help you can give me.

Cheers

John

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

- Posts: 4696

- Thank you received: 1439

For example if you wanted something that would carve at X50 Y120 to be done at X10 Y10. You would set the G54 offset to X-40 Y-110. This can be done either with the touch off button or by using the g-code command G10L2P1X-40Y-110.

Please Log in or Create an account to join the conversation.

- uptown47

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 1

Using the machine coordinates is one way to move what will be carved to any position on the machine.

For example if you wanted something that would carve at X50 Y120 to be done at X10 Y10. You would set the G54 offset to X-40 Y-110. This can be done either with the touch off button or by using the g-code command G10L2P1X-40Y-110.

That's great Todd. Thanks for the info.

Just another couple of quick questions on the same/similar subject....

If the machine has completed part of the carving, is there a way through the software to get it to start again from the start?

Also, is there a way via the software to tell it to drive the machine back the position where you homed the machine?

Thanks again for all your help

Cheers

John

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

- Posts: 2419

- Thank you received: 2348

If the machine has completed part of the carving, is there a way through the software to get it to start again from the start?

This would be hit the start button again.

Also, is there a way via the software to tell it to drive the machine back the position where you homed the machine?

Yes, before your end of gcode M2, insert your home coordinates in G-code format, this will do the job for you.

In my user gui, you can insert your home coordinates in main screen. They stay present until you power off. So you click

go home and machine will go to your coordinates. It's like MDI input. But then pre programmed in the gui.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

- Posts: 4696

- Thank you received: 1439

If you press stop or escape, when you press start Linuxcnc should always start over from the beginning of the file.If the machine has completed part of the carving, is there a way through the software to get it to start again from the start?

If you are asking for a way to restart from some place other than the beginning, there is a way. But it is fraught with pitfalls and danger use with caution. There is the option to run from a specific line in your file.

But you have to be careful with it because any codes that configure the state of the machine earlier in g-code file will not be in effect. Things like starting the spindle, setting feed rates, tool offsets, other offsets, parameter values, sub routines... can all lead to unexpected behavior with potentially devastating consequences. To use it in Axis simply right click on the line in the g-code display where you would like to begin from.

Also, is there a way via the software to tell it to drive the machine back the position where you homed the machine?

Yes, the code would be G53... I would use it with the Z axis alone first G53 Z0 will move the Z to the original home position (on most machines this will be the top of the Z travel), Then G53X0Y0 would move the X and Y to their home positions.

If you are using homing like a tool or work coordinate touch off. (This is not recommended, but is often done by beginners.) Then you likely won't want to use G53Z0, in this case use Z=some value that moves Z to a safe height.)

Please Log in or Create an account to join the conversation.

- uptown47

- Offline

- Senior Member

-

- Posts: 48

- Thank you received: 1

Thank you both for your excellent replies.

Really appreciate the help. Will try this out over the weekend.

Cheers

John

Please Log in or Create an account to join the conversation.