Error message "Radius to end of arc differs....etc etc"

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

15 Jan 2025 22:01 #319056

by rodw

Replied by rodw on topic Error message "Radius to end of arc differs....etc etc"

Try setting the arc distance mode at the beginning of the program

linuxcnc.org/docs/stable/html/gcode/g-co...ml#gcode:g90.1-g91.1

some times the code is in absolute mode and QTplasmac is expecting relative mode or vice versa.

linuxcnc.org/docs/stable/html/gcode/g-co...ml#gcode:g90.1-g91.1

some times the code is in absolute mode and QTplasmac is expecting relative mode or vice versa.

Please Log in or Create an account to join the conversation.

- gekonko

-

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 3

15 Jan 2025 22:29 #319060

by gekonko

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

Thank you for your response, but I forgot to include it in the .ngc file - I have tested it before and it does not help in my case.

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

16 Jan 2025 00:23 #319065

by phillc54

Replied by phillc54 on topic Error message "Radius to end of arc differs....etc etc"

Some things look odd with your gcode file:

The first N12760 should be commented out.

The second N12760 should have a J value of -89.450, not -89.500

N12770 should not be commented out.

The second N12800 should have a J value of 89.450, not -89.400

This comment at the top ";File converted successfully;" hints that a conversion was done somewhere, I don't think that it was successful.

This gcode loads:

The first N12760 should be commented out.

The second N12760 should have a J value of -89.450, not -89.500

N12770 should not be commented out.

The second N12800 should have a J value of 89.450, not -89.400

This comment at the top ";File converted successfully;" hints that a conversion was done somewhere, I don't think that it was successful.

This gcode loads:

Warning: Spoiler!

;File converted successfully;

G90 G0 X10 Y10

#<keep-z-motion> = 1

G21

G64 P0.125

M52 P1

F#<_hal[plasmac.cut-feed-rate]>

G10 L2 P0 R90

G91 G00 X0 Y0

N12740 M3 $0 S1;ARC ON

N12750 G1 X0.000 Y-30.500

;N12760 G2 X0.000 Y-178.900 R90

N12760 G2 X0.000 Y-178.900 I-10.000 J-89.450

N12770 G1 X0.000 Y-30.600

N12780 G1 X-20.000 Y0.000

N12790 G1 X0.000 Y30.600

;N12800 G2 X0.000 Y178.900 R90

N12800 G2 X0.000 Y178.900 I10.000 J89.4500

N12810 G1 X0.000 Y30.500

N12820 G1 X20.000 Y0.000

N12830 M5 $0;ARC OFF

N13770 M2Please Log in or Create an account to join the conversation.

- gekonko

-

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 3

16 Jan 2025 09:14 #319102

by gekonko

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

@phillc54:

I really shouldnt post at midnight. You are right. Lines with R90 were added by me manually and should be commented out.

"The second N12760 should have a J value of -89.450, not -89.500"

- yes and no, really. From the CAM the precision is fixed to 0.1 so therefore it is "correct" in this case. I really just need to adjust tolerance in linuxcnc somehow, because no possibility to change presision in cam.

The source G-code is originally generated for esab NCE290. ";File converted successfully;" Means, it went trough parser which converts it to linuxcnc readable code without unknown command confilct (values are not checked).

If you are interested, there is complete program from CAM.

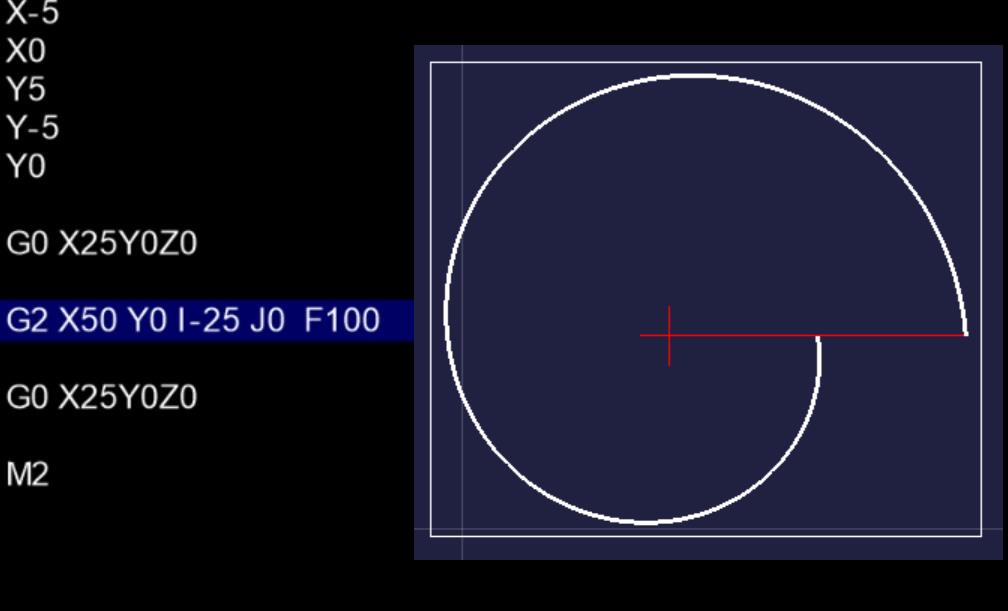

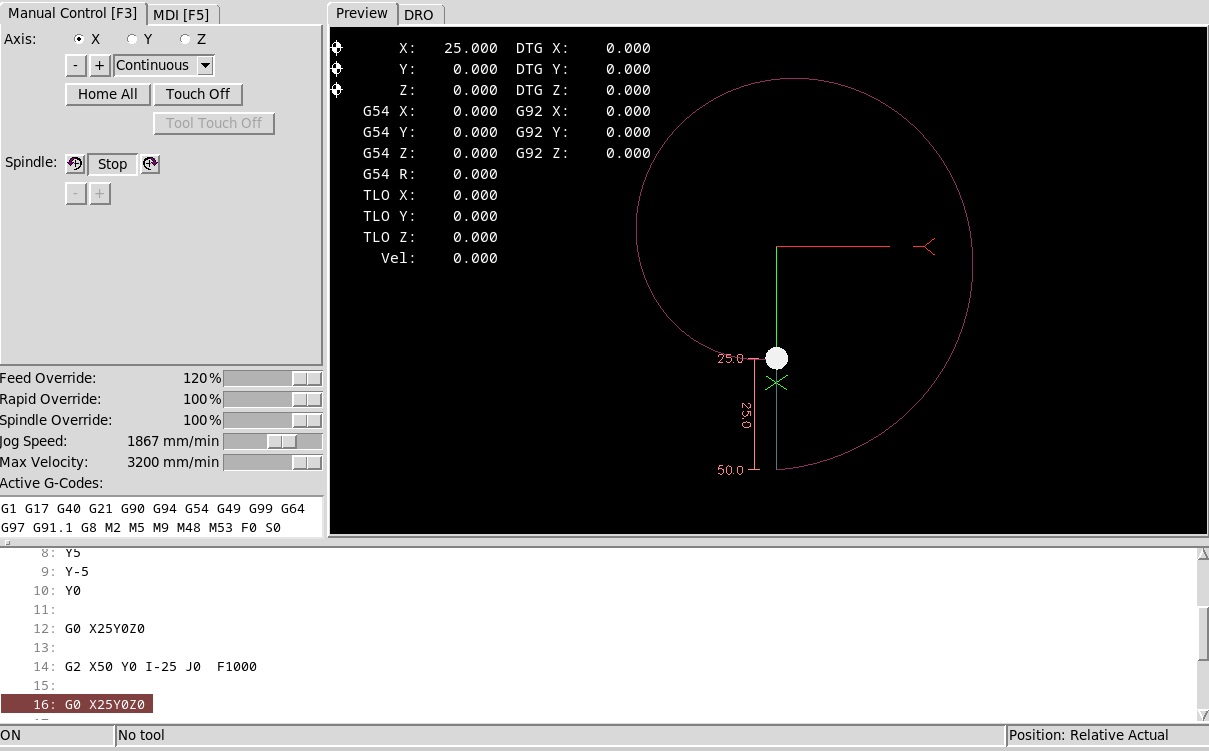

just to show you, how the code looks before

after converting to Linuxcnc readable code

I really shouldnt post at midnight. You are right. Lines with R90 were added by me manually and should be commented out.

"The second N12760 should have a J value of -89.450, not -89.500"

- yes and no, really. From the CAM the precision is fixed to 0.1 so therefore it is "correct" in this case. I really just need to adjust tolerance in linuxcnc somehow, because no possibility to change presision in cam.

The source G-code is originally generated for esab NCE290. ";File converted successfully;" Means, it went trough parser which converts it to linuxcnc readable code without unknown command confilct (values are not checked).

If you are interested, there is complete program from CAM.

just to show you, how the code looks before

after converting to Linuxcnc readable code

Attachments:

Please Log in or Create an account to join the conversation.

- phillc54

-

- Offline

- Platinum Member

-

Less

More

- Posts: 5711

- Thank you received: 2093

17 Jan 2025 00:48 #319151

by phillc54

Replied by phillc54 on topic Error message "Radius to end of arc differs....etc etc"

Please Log in or Create an account to join the conversation.

- hmnijp

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 45

17 Jan 2025 07:56 #319160

by hmnijp

Replied by hmnijp on topic Error message "Radius to end of arc differs....etc etc"

What a coincidence!

Just yesterday I was experimenting with this parameter and noticed that the value cannot be increased.

It's really only in the range of

#define CENTER_ARC_RADIUS_TOLERANCE_MM (2 * 0.01 * M_SQRT2)

#define MIN_CENTER_ARC_RADIUS_TOLERANCE_MM 0.001

rs274ngc_pre.cc

0.001 < tolerance < 0.0225

I wanted to disable the ARC_RADIUS_TOLERANCE constraint and see how interpolation works with a large difference between the start and end radius. This could be used to do spiral interpolation by extending the g-code to g2.1 / g3.1 - just copy interp_arc.cc, but there would be no radius difference check.

Just yesterday I was experimenting with this parameter and noticed that the value cannot be increased.

It's really only in the range of

#define CENTER_ARC_RADIUS_TOLERANCE_MM (2 * 0.01 * M_SQRT2)

#define MIN_CENTER_ARC_RADIUS_TOLERANCE_MM 0.001

rs274ngc_pre.cc

0.001 < tolerance < 0.0225

I wanted to disable the ARC_RADIUS_TOLERANCE constraint and see how interpolation works with a large difference between the start and end radius. This could be used to do spiral interpolation by extending the g-code to g2.1 / g3.1 - just copy interp_arc.cc, but there would be no radius difference check.

Attachments:

Please Log in or Create an account to join the conversation.

- hmnijp

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 45

17 Jan 2025 09:04 #319167

by hmnijp

Replied by hmnijp on topic Error message "Radius to end of arc differs....etc etc"

Attachments:

Please Log in or Create an account to join the conversation.

- gekonko

-

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 3

17 Jan 2025 16:51 #319191

by gekonko

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

hello hmnijp,

could you please elaborate on that?

I have tryed to comment out this section of the code in interp_arc.cc and then make the build, but I still get error message.

could you please elaborate on that?

I have tryed to comment out this section of the code in interp_arc.cc and then make the build, but I still get error message.

CHKS((abs_err > spiral_abs_tolerance * 100.0) ||

(rel_err > spiral_rel_tolerance && abs_err > spiral_abs_tolerance),

_("Radius to end of arc differs from radius to start: "

"start=(%c%.4f,%c%.4f) center=(%c%.4f,%c%.4f) end=(%c%.4f,%c%.4f) "

"r1=%.4f r2=%.4f abs_err=%.4g rel_err=%.4f%%"),

a, current_x, b, current_y,

a, *center_x, b, *center_y,

a, end_x, b, end_y, radius, radius2,

abs_err, rel_err*100);Please Log in or Create an account to join the conversation.

- gekonko

-

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 3

17 Jan 2025 17:17 #319194

by gekonko

Replied by gekonko on topic Error message "Radius to end of arc differs....etc etc"

ok, I got it, there is section for error generating with and without compensation.

thank you.

thank you.

Please Log in or Create an account to join the conversation.

- hmnijp

- Offline

- Junior Member

-

Less

More

- Posts: 30

- Thank you received: 45

17 Jan 2025 17:54 - 17 Jan 2025 17:57 #319196

by hmnijp

The simplest solution with minimal changes is to fix the upper limit in "interp_internal.hh" file:

#define CENTER_ARC_RADIUS_TOLERANCE_MM (2 * 0.01 * M_SQRT2)

for example

#define CENTER_ARC_RADIUS_TOLERANCE_MM 1.001

after that the setting in the ini file will allow to set a higher value than before

Replied by hmnijp on topic Error message "Radius to end of arc differs....etc etc"

hello hmnijp,

could you please elaborate on that?

I have tryed to comment out this section of the code in interp_arc.cc and then make the build, but I still get error message.

CHKS((abs_err > spiral_abs_tolerance * 100.0) || (rel_err > spiral_rel_tolerance && abs_err > spiral_abs_tolerance), _("Radius to end of arc differs from radius to start: " "start=(%c%.4f,%c%.4f) center=(%c%.4f,%c%.4f) end=(%c%.4f,%c%.4f) " "r1=%.4f r2=%.4f abs_err=%.4g rel_err=%.4f%%"), a, current_x, b, current_y, a, *center_x, b, *center_y, a, end_x, b, end_y, radius, radius2, abs_err, rel_err*100);

The simplest solution with minimal changes is to fix the upper limit in "interp_internal.hh" file:

#define CENTER_ARC_RADIUS_TOLERANCE_MM (2 * 0.01 * M_SQRT2)

for example

#define CENTER_ARC_RADIUS_TOLERANCE_MM 1.001

after that the setting in the ini file will allow to set a higher value than before

Last edit: 17 Jan 2025 17:57 by hmnijp.

The following user(s) said Thank You: gekonko

Please Log in or Create an account to join the conversation.

Time to create page: 0.737 seconds