- LinuxCNC

- General LinuxCNC Questions

- CNC milling machine recrofit (pid tuning with analog servo) + digital servo

CNC milling machine recrofit (pid tuning with analog servo) + digital servo

- kavindu1

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 0

09 Nov 2019 02:46 #149959

by kavindu1

CNC milling machine recrofit (pid tuning with analog servo) + digital servo was created by kavindu1

hi everyone

during project im struck with some problems.

I tell what i done ,write my experience. im new to linux cnc.

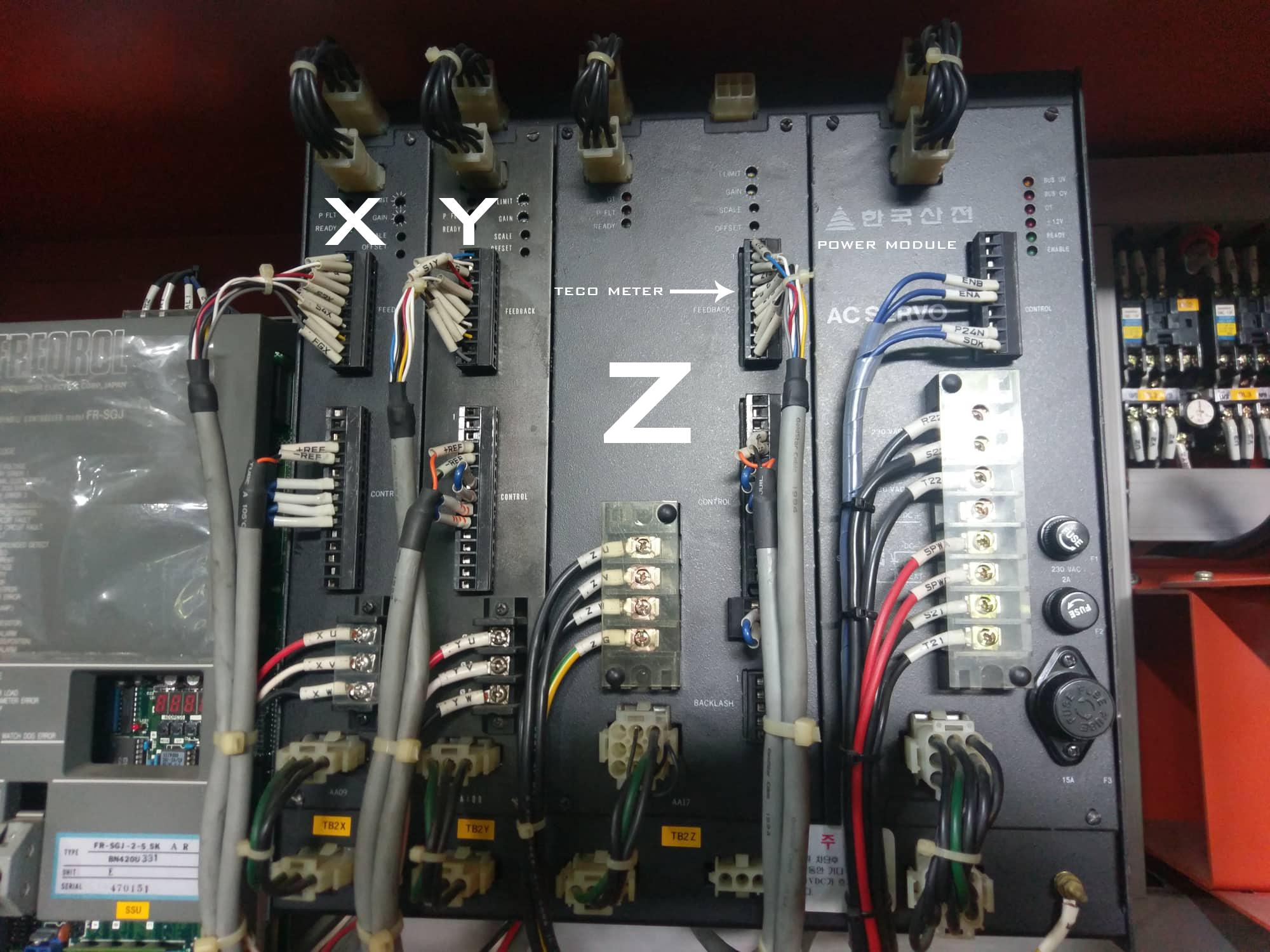

I'm retrofit cnc milling maching with linux cnc it has analog servo drive module with Z 18 NM , X 5.6 NM ,Y 5.6 NM servo motors (teco feed back get in to drive and motor has incrimantal encoder connect to controller)

i using 5i25+7i77 mesa cards.

this is drive module

in this module x drive card dead and we repair it replase igbt and some control circuit components

I Earth the machine properly with separate Earth rod wit 7 ft.

I wire drive module power cut off by series limit switch and emergency.

and remove motor from load.

wire the encoder, and make encoder calibrate with linux cnc system(encoder ppr 2500 / ball screw pitch 10 mm and direct couple to motor

first i tune motors from drive side remove the analog out and ground connector from drive and enable drive module with linux cnc

motor are rotate slowly.

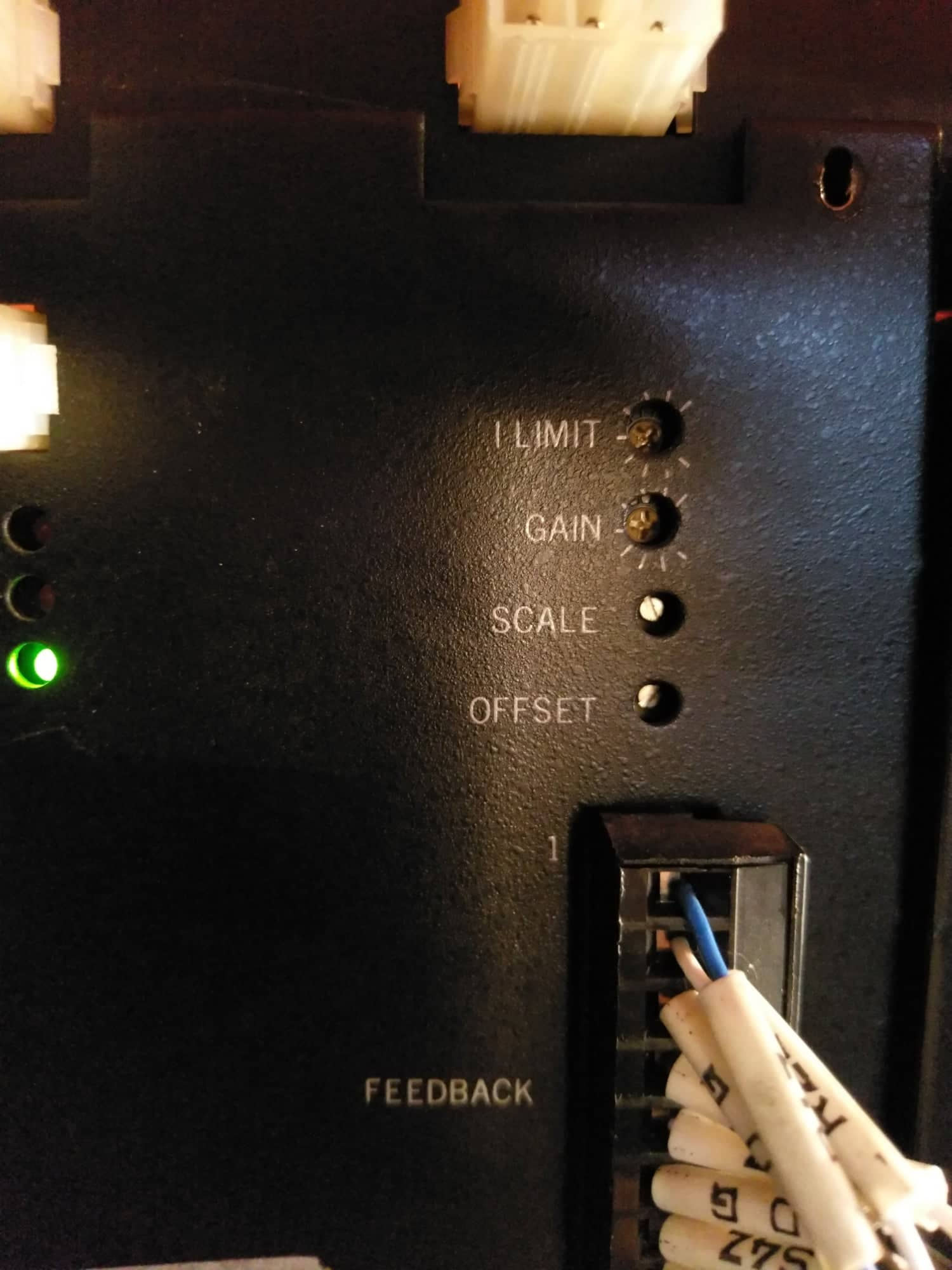

drive has scale and offset (variable resistors) rotate them and make motor to stop.stable

I put pid Value P=0 / I=0 / D=0 /FF1 = 0.01 / ff2 = 0 in all axis

connect analog out and ground connector to drive, and power up and enable drive module with linux cnc

but motor are running again I try to again rotate scale and offset (variable resistors) to stop rotate the motors Y is stop and other motor are not stop I rotate to max position to scale and offset (variable resistors) they are rotate very slow.

I remove analog out and ground connector to drive again make motor to stop at drive enable.

connect analog out and ground connector to drive, and power up and enable drive module with linux cnc motors rotate again I put PID value in P=1 ta all axis. then motor stop rotate and hold but motors are oscillating . I decrease P value but nothing happen

I put Pgain to X P=5 / Y P=7 / Z P=1.1 this are ok. higher than these value motor are highly vibrate and trying to jump not stable

I disable drive and enable drive it motors move little bit and hold and oscillating (it like steady state error)

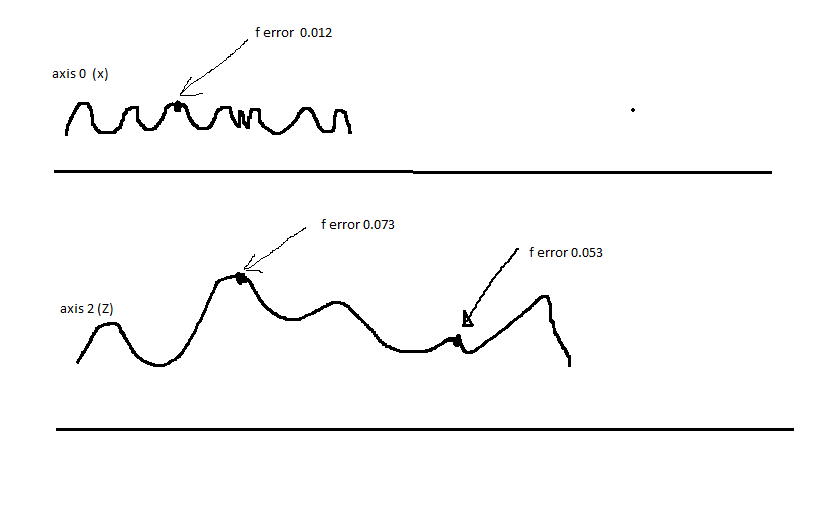

I zero the machine (home limit are not wire to system) it not come to 0.000 position X in 0.012 Y in 0.008 Z 0.058

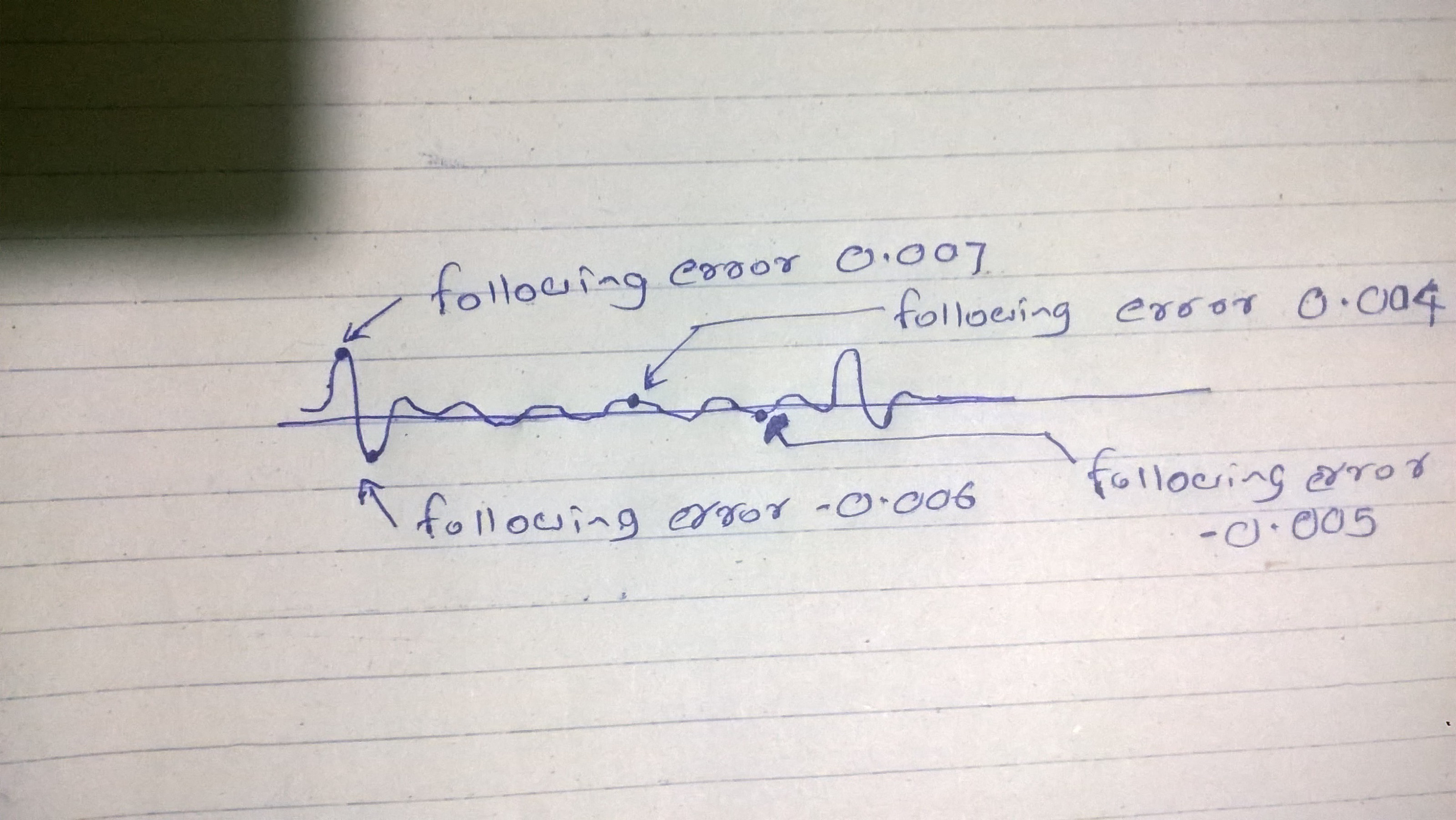

in hall scope show that like that

I move the X motor he not goes right position

EG ; i give comand in MDI X 20.000 motor goes to 20.015 and oscillating i give comand in MDI X 0.000 motor goes to 0.014

and oscillating

Tuning with I value put I=1 I zero the machine it with 0.014 and after few seond it came near to 0.000 but not in to 0.000 oscillating between -0.007 to 0.006

I move to motor to 20.000 it goes to 20.012 and try to come to 20.000 position. but oscillating between 19.993 to 20.006

Y is same like this Z error greater than X and Y

i try make this position from D but it is not work.

AND I TRY another way Put I=0 and D=0 P is same value. I tell motor to move 0.000 , it goes 0.013 I zero machine it value in 0.013

rotate offset (variable resistor) in each driver zero position came near 0.000 but oscillating is same .now it oscillate between -0.003 t0 0.004

we move motor to 20.000 it goes 20 .000 but oscillate between 19.993 to 20.004

hall scope chart show

Z is oscillating largely it position error cant get in near 0.000 by drive

I try lot but oscillating in same

3)And i try another way

remove X drive card and Z drive card from drive module and drive Module on with Y drive enable the drive Y Motor hold without

oscillation I ZERO the machine motor come 0.000 and move without position error

I connect the Z drive card on Drive module with Y and Z then problem came again Z and Y oscillating again

Z torque is very low

I power up drive module X drive card X little bit oscillate 0.001 to 0.000 some time goes -0.001

I on drive module with X and Z ,, Z and X oscillating again

Z torque is very low

I CANT THINK WHY THIS HAPPEN (in old system Y and Z work ok )

***I remove x and y drive card from drive module and power up with Z drive card then Z motor is stop oscillating and motor stable

Z torque is good now,

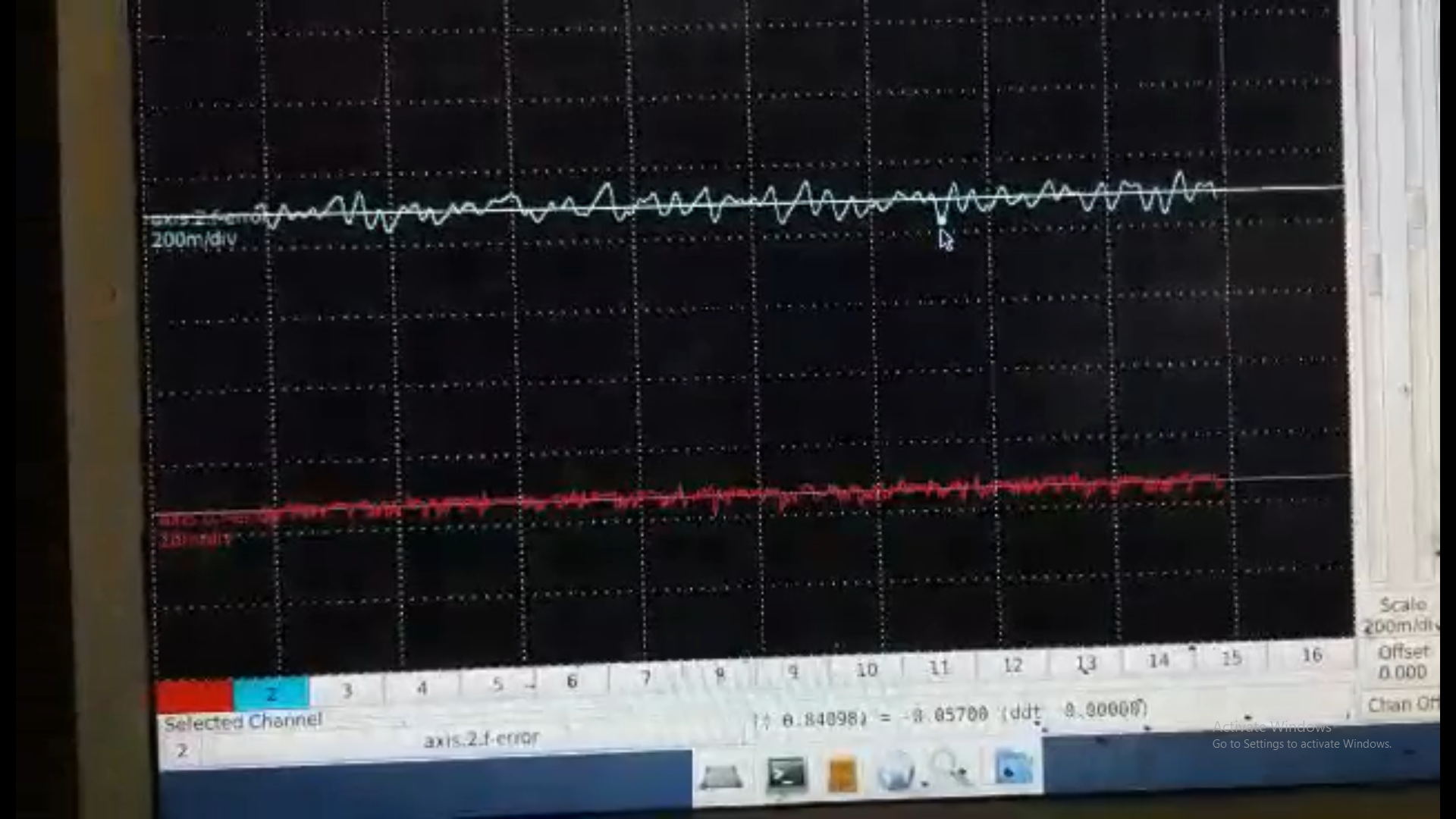

In MDI mode i run Z (g1 f 400 z-100) position is ok ,, motor moving with following error ( 0.018) use FF1 and FF2 low the followin

to 0..004

hall scope show like that

I connect motor to load power up and enable drive it hold Z axis without oscillate move very smooth position is ok I ZERO the machine axis in 0.000 position I move axis to 100.000 axis move to 100.000 I check movement in using dial gauge it ok with position

I again connect Y drive card enable drive Z fall -0.078 position error is also come and oscillating again 0.000 to 0.002 value

I remove Y motor power cables and enable drive module , then Z is working with out position error

I cant think what happen

@@ I have new 2 servo drive with motors im planing to run them in puls and direction

i have another 5i25 mesa card and write (5i25_prob_rfx2.bit) firmware to that card

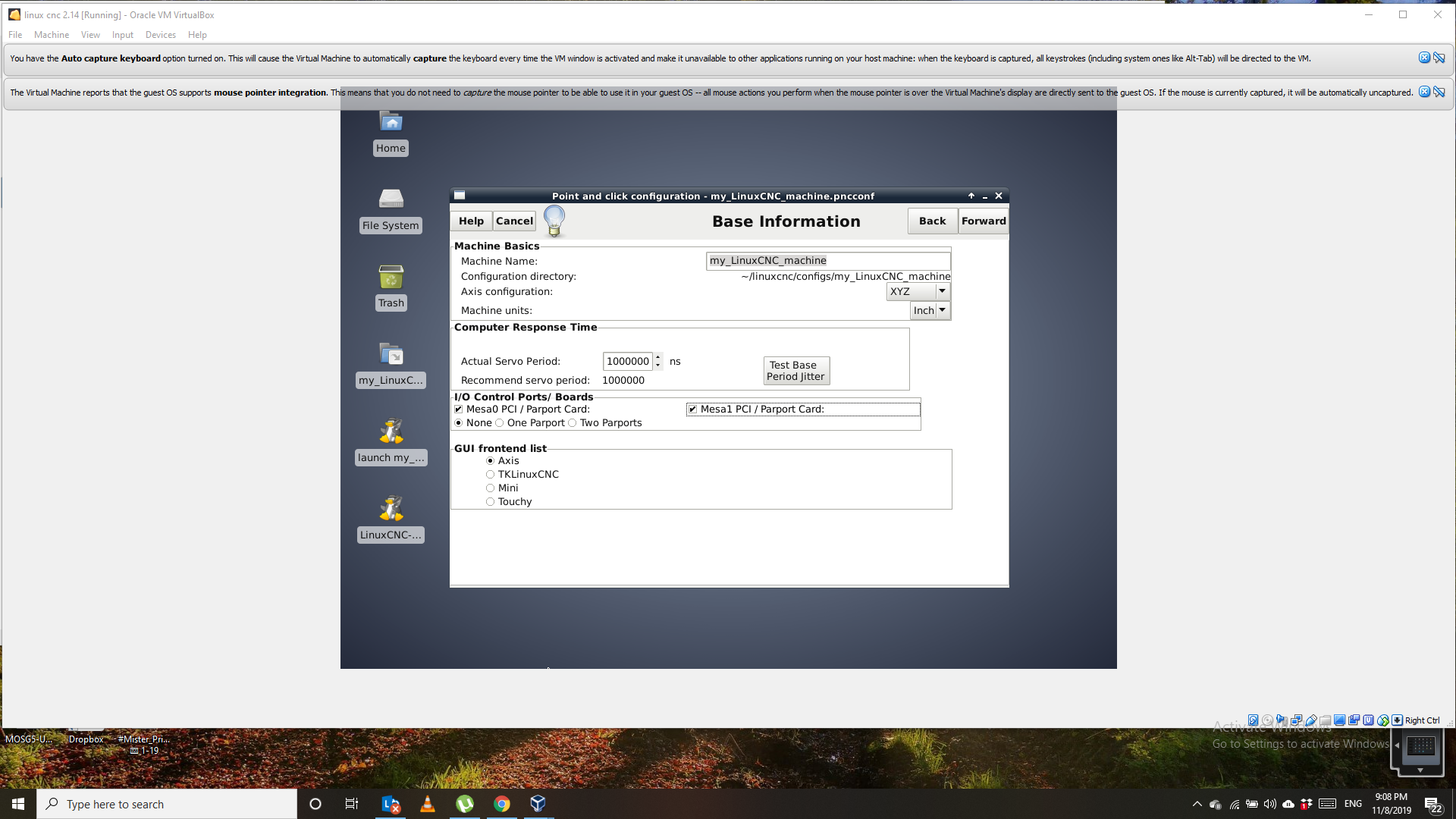

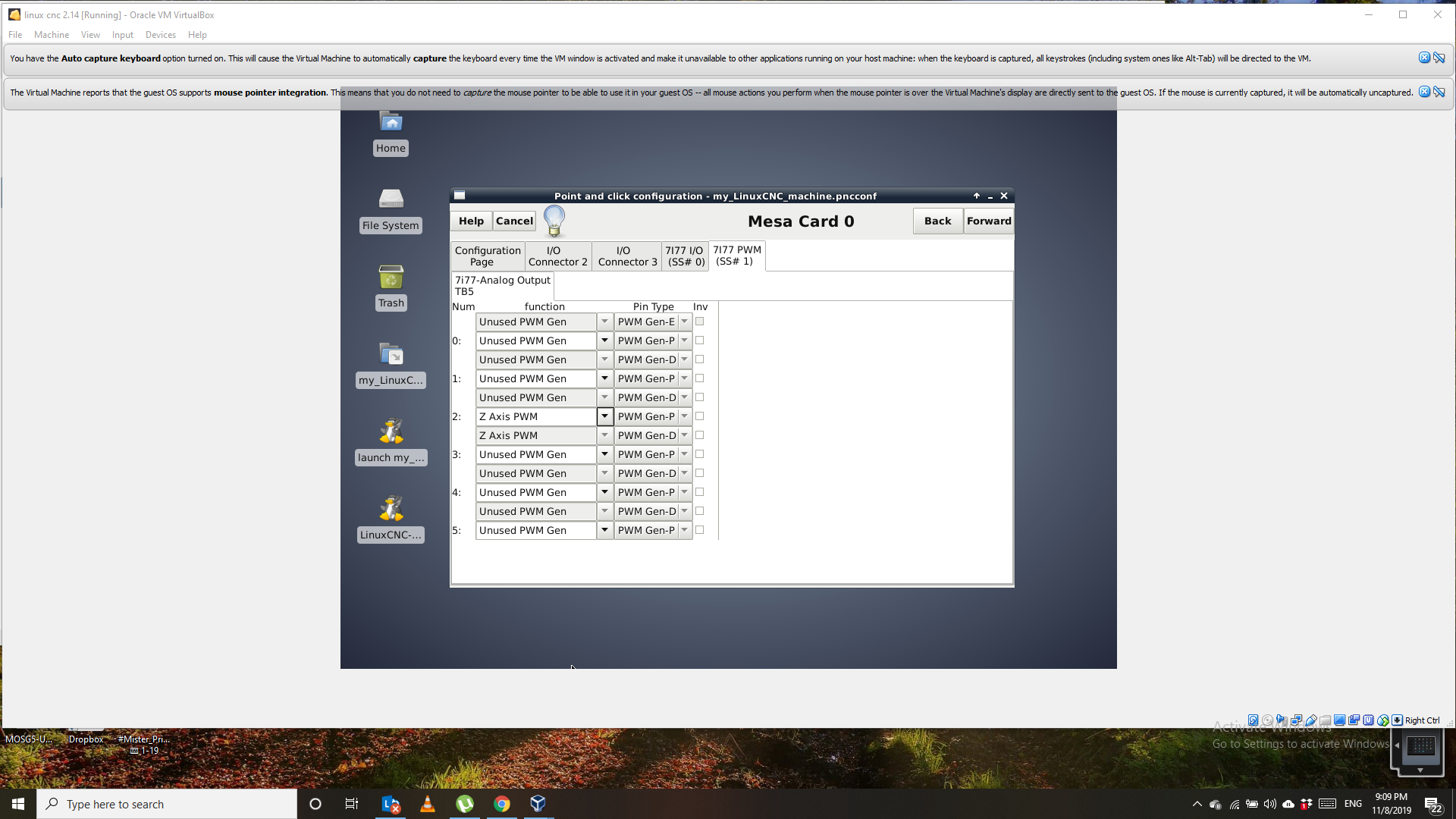

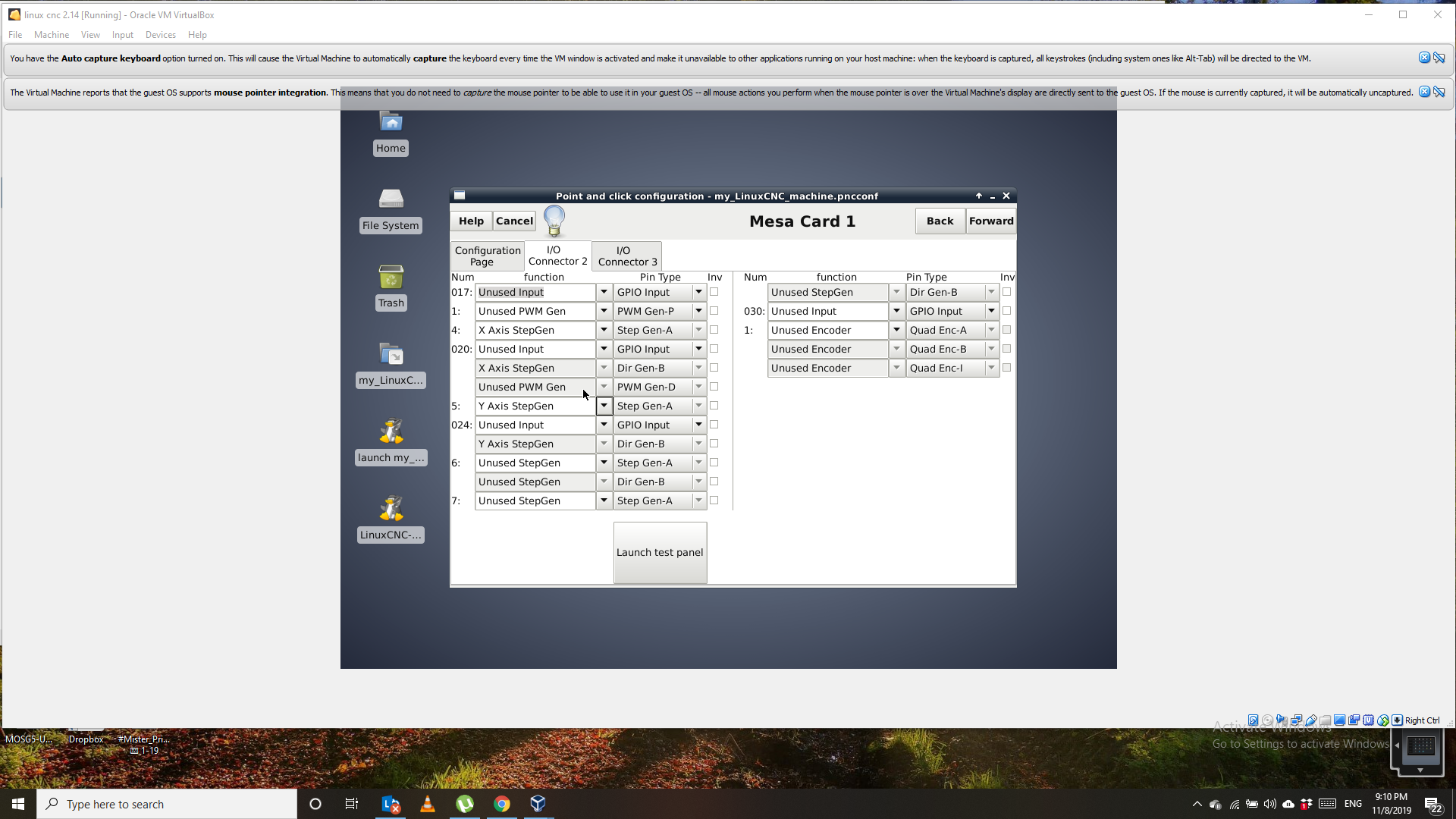

and i connect 2 mesa card to pc mesa 0 with 5i25+7i77

mesa 1 step direction

i configure pncconf wizard with like that

open this cnc file, i enable the machine with linux cnc my Z analog servo motor moving slowly.

i make another configure pncconf wizard for 1 mesa card (5i25=7i77) and enable machine from linux cnc Z analog servo is ok

motor is not moving.

then i open 2 mesa card cnc file and enable machine z moving slowly I Change P value of Z ,, put P=2 / P=10 / P=20

P=50 P=100 for p gain and nothing change.

are we cant use 2 mesa card to 1 pc

or power issue of pc

or other reason

i cant think what to do im struck in hear

during project im struck with some problems.

I tell what i done ,write my experience. im new to linux cnc.

I'm retrofit cnc milling maching with linux cnc it has analog servo drive module with Z 18 NM , X 5.6 NM ,Y 5.6 NM servo motors (teco feed back get in to drive and motor has incrimantal encoder connect to controller)

i using 5i25+7i77 mesa cards.

this is drive module

in this module x drive card dead and we repair it replase igbt and some control circuit components

I Earth the machine properly with separate Earth rod wit 7 ft.

I wire drive module power cut off by series limit switch and emergency.

and remove motor from load.

wire the encoder, and make encoder calibrate with linux cnc system(encoder ppr 2500 / ball screw pitch 10 mm and direct couple to motor

first i tune motors from drive side remove the analog out and ground connector from drive and enable drive module with linux cnc

motor are rotate slowly.

drive has scale and offset (variable resistors) rotate them and make motor to stop.stable

I put pid Value P=0 / I=0 / D=0 /FF1 = 0.01 / ff2 = 0 in all axis

connect analog out and ground connector to drive, and power up and enable drive module with linux cnc

but motor are running again I try to again rotate scale and offset (variable resistors) to stop rotate the motors Y is stop and other motor are not stop I rotate to max position to scale and offset (variable resistors) they are rotate very slow.

I remove analog out and ground connector to drive again make motor to stop at drive enable.

connect analog out and ground connector to drive, and power up and enable drive module with linux cnc motors rotate again I put PID value in P=1 ta all axis. then motor stop rotate and hold but motors are oscillating . I decrease P value but nothing happen

I put Pgain to X P=5 / Y P=7 / Z P=1.1 this are ok. higher than these value motor are highly vibrate and trying to jump not stable

I disable drive and enable drive it motors move little bit and hold and oscillating (it like steady state error)

I zero the machine (home limit are not wire to system) it not come to 0.000 position X in 0.012 Y in 0.008 Z 0.058

in hall scope show that like that

I move the X motor he not goes right position

EG ; i give comand in MDI X 20.000 motor goes to 20.015 and oscillating i give comand in MDI X 0.000 motor goes to 0.014

and oscillating

Tuning with I value put I=1 I zero the machine it with 0.014 and after few seond it came near to 0.000 but not in to 0.000 oscillating between -0.007 to 0.006

I move to motor to 20.000 it goes to 20.012 and try to come to 20.000 position. but oscillating between 19.993 to 20.006

Y is same like this Z error greater than X and Y

i try make this position from D but it is not work.

AND I TRY another way Put I=0 and D=0 P is same value. I tell motor to move 0.000 , it goes 0.013 I zero machine it value in 0.013

rotate offset (variable resistor) in each driver zero position came near 0.000 but oscillating is same .now it oscillate between -0.003 t0 0.004

we move motor to 20.000 it goes 20 .000 but oscillate between 19.993 to 20.004

hall scope chart show

Z is oscillating largely it position error cant get in near 0.000 by drive

I try lot but oscillating in same

3)And i try another way

remove X drive card and Z drive card from drive module and drive Module on with Y drive enable the drive Y Motor hold without

oscillation I ZERO the machine motor come 0.000 and move without position error

I connect the Z drive card on Drive module with Y and Z then problem came again Z and Y oscillating again

Z torque is very low

I power up drive module X drive card X little bit oscillate 0.001 to 0.000 some time goes -0.001

I on drive module with X and Z ,, Z and X oscillating again

Z torque is very low

I CANT THINK WHY THIS HAPPEN (in old system Y and Z work ok )

***I remove x and y drive card from drive module and power up with Z drive card then Z motor is stop oscillating and motor stable

Z torque is good now,

In MDI mode i run Z (g1 f 400 z-100) position is ok ,, motor moving with following error ( 0.018) use FF1 and FF2 low the followin

to 0..004

hall scope show like that

I connect motor to load power up and enable drive it hold Z axis without oscillate move very smooth position is ok I ZERO the machine axis in 0.000 position I move axis to 100.000 axis move to 100.000 I check movement in using dial gauge it ok with position

I again connect Y drive card enable drive Z fall -0.078 position error is also come and oscillating again 0.000 to 0.002 value

I remove Y motor power cables and enable drive module , then Z is working with out position error

I cant think what happen

@@ I have new 2 servo drive with motors im planing to run them in puls and direction

i have another 5i25 mesa card and write (5i25_prob_rfx2.bit) firmware to that card

and i connect 2 mesa card to pc mesa 0 with 5i25+7i77

mesa 1 step direction

i configure pncconf wizard with like that

open this cnc file, i enable the machine with linux cnc my Z analog servo motor moving slowly.

i make another configure pncconf wizard for 1 mesa card (5i25=7i77) and enable machine from linux cnc Z analog servo is ok

motor is not moving.

then i open 2 mesa card cnc file and enable machine z moving slowly I Change P value of Z ,, put P=2 / P=10 / P=20

P=50 P=100 for p gain and nothing change.

are we cant use 2 mesa card to 1 pc

or power issue of pc

or other reason

i cant think what to do im struck in hear

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17625

- Thank you received: 5157

09 Nov 2019 04:07 #149961

by PCW

Replied by PCW on topic CNC milling machine recrofit (pid tuning with analog servo) + digital servo

If those are metric numbers, that's not bad.

Small dithering can be reduced by adding some deadband

at the expense of following error

If reducing the P value (and D and I) to 0 doesn't stop the dithering, that

suggests a noise issue

If you need more output zero adjust you can set the PID bias pin to a small value

Note the you typically need rather large values of I for relatively quick response

( Caution! too high I values can result in slow large amplitude oscillations so set reasonable ferror values when tuning)

Small dithering can be reduced by adding some deadband

at the expense of following error

If reducing the P value (and D and I) to 0 doesn't stop the dithering, that

suggests a noise issue

If you need more output zero adjust you can set the PID bias pin to a small value

Note the you typically need rather large values of I for relatively quick response

( Caution! too high I values can result in slow large amplitude oscillations so set reasonable ferror values when tuning)

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21225

- Thank you received: 7247

09 Nov 2019 11:44 #149978

by tommylight

Replied by tommylight on topic CNC milling machine recrofit (pid tuning with analog servo) + digital servo

When tuning the drives ( no Mesa, nothing else ) you have to short the analogue input to it's ground, adjust it so it slowly moves in one direction.

When tuning the system ( with Mesa, after the above is tuned ), wire it properly so it will disable the drives if the motors move ( it has to cause a joint error ).

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Read this very carefully and do not do anything without fully understanding what it going on.

When tuning the system ( with Mesa, after the above is tuned ), wire it properly so it will disable the drives if the motors move ( it has to cause a joint error ).

forum.linuxcnc.org/10-advanced-configura...ning-detailed-how-to

Read this very carefully and do not do anything without fully understanding what it going on.

Please Log in or Create an account to join the conversation.

- kavindu1

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 0

09 Nov 2019 14:43 #149987

by kavindu1

Replied by kavindu1 on topic CNC milling machine recrofit (pid tuning with analog servo) + digital servo

hi pcw

thanks for your reply

today i try with power up Y drive card and Z drive card together ..

I put Y P = 1,

I = 0

D =0

ff1= 0.01

And Z values are not change and leave last time value

i enable drive through linux cnc Z not oscillating Y is also not oscillating

but z is move Z = -0.057 down direction in Y is also Y= 0.013 value .I ZERO the machine but position is not set in 0.000 it set Z for -0.057 Y for 0.013 .

in both axis with small oscillating change value between -0.057 to -0.058

I move Z in MDI (g1 f400 Z-20) it goes Z= 20.058 I move machine in MDI(g1 f400 Z0.000) machine came to Z=0.057 not came to 0.000

I change PID bias value and set ZERO to Z= 0.001

then i move machine it goes right position and came to 0.001

Then i start tune Y axis

I increase P value of Y P=2 P=3 like that

my Z axis Zero position is change again it came to -0.015 ( im not change any value of Z )

I set Y axis p gain to P=5

my Z axis zero position change to -0.042

Z position error is came again.

I again remove Y drive card from drive module and power up and Z pid bias to bias=0 problem solved .

With one drive card module is ok.

is this happen in some fault in drive module or some other thing.

thanks for your reply

today i try with power up Y drive card and Z drive card together ..

I put Y P = 1,

I = 0

D =0

ff1= 0.01

And Z values are not change and leave last time value

i enable drive through linux cnc Z not oscillating Y is also not oscillating

but z is move Z = -0.057 down direction in Y is also Y= 0.013 value .I ZERO the machine but position is not set in 0.000 it set Z for -0.057 Y for 0.013 .

in both axis with small oscillating change value between -0.057 to -0.058

I move Z in MDI (g1 f400 Z-20) it goes Z= 20.058 I move machine in MDI(g1 f400 Z0.000) machine came to Z=0.057 not came to 0.000

I change PID bias value and set ZERO to Z= 0.001

then i move machine it goes right position and came to 0.001

Then i start tune Y axis

I increase P value of Y P=2 P=3 like that

my Z axis Zero position is change again it came to -0.015 ( im not change any value of Z )

I set Y axis p gain to P=5

my Z axis zero position change to -0.042

Z position error is came again.

I again remove Y drive card from drive module and power up and Z pid bias to bias=0 problem solved .

With one drive card module is ok.

is this happen in some fault in drive module or some other thing.

Please Log in or Create an account to join the conversation.

- kavindu1

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 0

09 Nov 2019 15:36 #149989

by kavindu1

Replied by kavindu1 on topic CNC milling machine recrofit (pid tuning with analog servo) + digital servo

hi tommylight thanks for your reply

i tune the drive ( no Mesa, nothing else ) I short analog input to its ground but i adjust motor at stop not slowly move ( i done mistake in hear),

I will read your post and try again . and give you to feedback

in my drive variable resistors scale and offset that offset can adjust motor moving slow and high and turn direction

i have no idea about scale what for it.

i tune the drive ( no Mesa, nothing else ) I short analog input to its ground but i adjust motor at stop not slowly move ( i done mistake in hear),

I will read your post and try again . and give you to feedback

in my drive variable resistors scale and offset that offset can adjust motor moving slow and high and turn direction

i have no idea about scale what for it.

Please Log in or Create an account to join the conversation.

- Dinuka_Shehan

-

- Offline

- Platinum Member

-

Less

More

- Posts: 333

- Thank you received: 26

09 Nov 2019 17:58 - 09 Nov 2019 18:03 #149996

by Dinuka_Shehan

Replied by Dinuka_Shehan on topic CNC milling machine recrofit (pid tuning with analog servo) + digital servo

Hi Anushka ayya,

mesa boards tika awada?

Mn oyata dawasak katha kala.office eken katha kale.

Mokada wenne dan?

Hope to see you.

mesa boards tika awada?

Mn oyata dawasak katha kala.office eken katha kale.

Mokada wenne dan?

Hope to see you.

Last edit: 09 Nov 2019 18:03 by Dinuka_Shehan.

Please Log in or Create an account to join the conversation.

- kavindu1

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 0

12 Nov 2019 13:11 #150192

by kavindu1

Replied by kavindu1 on topic CNC milling machine recrofit (pid tuning with analog servo) + digital servo

hi dinuka

bord tika awa drive tune karaddi awl wagayak awa

oyage number eka wada nada

bord tika awa drive tune karaddi awl wagayak awa

oyage number eka wada nada

Please Log in or Create an account to join the conversation.

- Dinuka_Shehan

-

- Offline

- Platinum Member

-

Less

More

- Posts: 333

- Thank you received: 26

15 Nov 2019 08:46 #150409

by Dinuka_Shehan

Jaya wewa.

Dan wede goda da gaththa da!9

Board okkoma awada?

Ow mage 4n eka off wela thibuna dawas 2k 3k.

(+0094)0712992228

Thank you

Replied by Dinuka_Shehan on topic CNC milling machine recrofit (pid tuning with analog servo) + digital servo

hi dinuka

bord tika awa drive tune karaddi awl wagayak awa

oyage number eka wada nada

Jaya wewa.

Dan wede goda da gaththa da!9

Board okkoma awada?

Ow mage 4n eka off wela thibuna dawas 2k 3k.

(+0094)0712992228

Thank you

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- CNC milling machine recrofit (pid tuning with analog servo) + digital servo

Time to create page: 0.253 seconds