- LinuxCNC

- General LinuxCNC Questions

- Feature request: Different acceleration for rapid and feed moves

Feature request: Different acceleration for rapid and feed moves

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

15 Jan 2020 14:21 - 15 Jan 2020 14:22 #154921

by aleksamc

Replied by aleksamc on topic Feature request: Different acceleration for rapid and feed moves

Yes but there is present unlocated G-codes, for axample G0.1 etc.Remap G-code linuxcnc[/url] I G0 can't be remapped.

Last edit: 15 Jan 2020 14:22 by aleksamc.

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

15 Jan 2020 17:47 - 15 Jan 2020 18:16 #154939

by dgarrett

Inihal pins are part of the userspace task module ($ man milltask) and

sampled at the interval set by [TASK]CYCLE_TIME. If

unspecified, the default interval is

DEFAULT_EMC_TASK_CYCLE_TIME=0.100. Many sim configs use

0.001 (seconds), pncconf and stepconf use a value of 0.010

(seconds). The inihal pins are read continuously but they can

only affect trajectory planning when the interpreter is idle

_OR_ when the trajectory planner updates its plan after a

synchronization command (commonly called a queuebuster).

So, one can 1)change an inihal pin, then 2)force a

synchronization, and 3)have the updated ini value used for

the next trajectory calculation _provided_ that task has

read the updated pin value and propagated the change to

motion before the trajectory planner plans the

post-synchronization move(s).

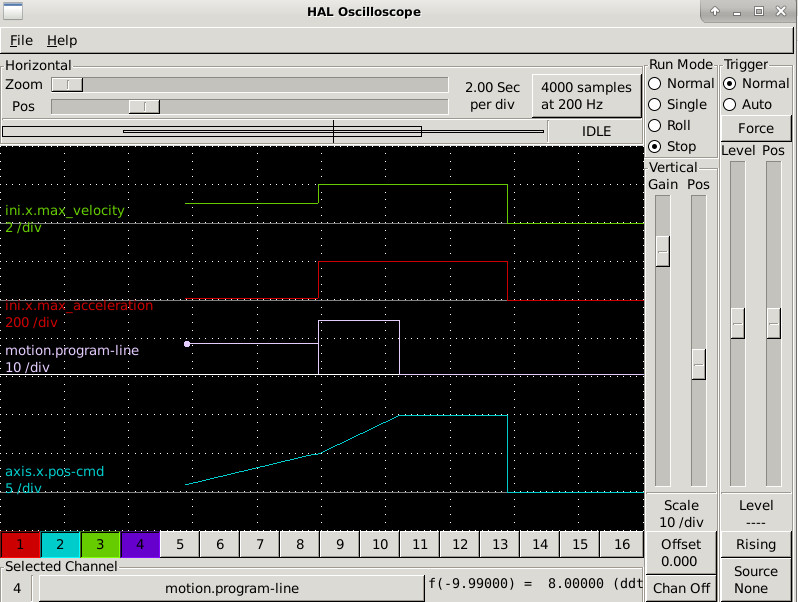

Example (attached sim config demo.tar shows altered max_velocity

and max_acceleration for the x coordinate during a simple program):

Notes:

1) Hal pin writes (M68) do _not_ synchronize but can be used

to set an inihal pin from gcode (or mcode) by netting the

inihal pin to a motion.analog-out-* pin

2) The simplest sync command is a hal pin immediate read:

M66 En L0. This synching read command can be used to read

the updated inihal pin (netting to a motion.analog-in-*

pin) to verify that the new value has been propagated from

the task module to the motion module.

3) As noted, response to inihal pins is _not_ realtime but using

an intervening synchronization read seems to always work in

my tests. To 'guarantee' acceptance of an updated ini hal

pin, the gcode should verify the updated inihal pin value

before continuing and if necessary issue additional sync

command(s) -- this is not done in the attached example, the

updated values are just printed with (debug,) commands.

4) With more testing (2.8 branch), i think that the mentioned

verification is not required but recommended as I tested only

simple programs with no subroutines or structured

code (loops etc).

Replied by dgarrett on topic Feature request: Different acceleration for rapid and feed moves

Note that the ini.pins are not sampled in realtime

or when G-code is running

Inihal pins are part of the userspace task module ($ man milltask) and

sampled at the interval set by [TASK]CYCLE_TIME. If

unspecified, the default interval is

DEFAULT_EMC_TASK_CYCLE_TIME=0.100. Many sim configs use

0.001 (seconds), pncconf and stepconf use a value of 0.010

(seconds). The inihal pins are read continuously but they can

only affect trajectory planning when the interpreter is idle

_OR_ when the trajectory planner updates its plan after a

synchronization command (commonly called a queuebuster).

So, one can 1)change an inihal pin, then 2)force a

synchronization, and 3)have the updated ini value used for

the next trajectory calculation _provided_ that task has

read the updated pin value and propagated the change to

motion before the trajectory planner plans the

post-synchronization move(s).

Example (attached sim config demo.tar shows altered max_velocity

and max_acceleration for the x coordinate during a simple program):

Notes:

1) Hal pin writes (M68) do _not_ synchronize but can be used

to set an inihal pin from gcode (or mcode) by netting the

inihal pin to a motion.analog-out-* pin

2) The simplest sync command is a hal pin immediate read:

M66 En L0. This synching read command can be used to read

the updated inihal pin (netting to a motion.analog-in-*

pin) to verify that the new value has been propagated from

the task module to the motion module.

3) As noted, response to inihal pins is _not_ realtime but using

an intervening synchronization read seems to always work in

my tests. To 'guarantee' acceptance of an updated ini hal

pin, the gcode should verify the updated inihal pin value

before continuing and if necessary issue additional sync

command(s) -- this is not done in the attached example, the

updated values are just printed with (debug,) commands.

4) With more testing (2.8 branch), i think that the mentioned

verification is not required but recommended as I tested only

simple programs with no subroutines or structured

code (loops etc).

Last edit: 15 Jan 2020 18:16 by dgarrett. Reason: note 4)

The following user(s) said Thank You: tommylight, Shu

Please Log in or Create an account to join the conversation.

- dgarrett

- Offline

- Platinum Member

-

Less

More

- Posts: 492

- Thank you received: 297

16 Jan 2020 00:53 #154987

by dgarrett

As mentioned, a remap (G0.n) would be a good method.

Alternately, a filter program can be used to find all lines

with G0 and surround them with the codes needed to alter the

inihal pin values for accel settings (with synching reads).

Ref: linuxcnc.org/docs/2.8/html/config/ini-config.html

2.3. [FILTER] Section

Example filter (lightly tested):

Ini file settings for g0filter.py in config directory:

Replied by dgarrett on topic Feature request: Different acceleration for rapid and feed moves

how to ditch m codes to change acceleration before and after

every g0 entirely?

As mentioned, a remap (G0.n) would be a good method.

Alternately, a filter program can be used to find all lines

with G0 and surround them with the codes needed to alter the

inihal pin values for accel settings (with synching reads).

Ref: linuxcnc.org/docs/2.8/html/config/ini-config.html

2.3. [FILTER] Section

Example filter (lightly tested):

$ chmod 755 ./g0filter.py # execute permissions

$ cat g0filter.py

#!/usr/bin/env python

#-------------------------------------------------------

# Note: create nets in a POSTGUI_HALFILE or APP file:

# net :xa motion.analog-out-00 ini.x.max_acceleration

# net :ya motion.analog-out-01 ini.y.max_acceleration

# net :za motion.analog-out-02 ini.z.max_acceleration

# set as required:

x_accel_pin = 00; x_accel_slow = 1; x_accel_fast = 100

y_accel_pin = 01; y_accel_slow = 1; y_accel_fast = 100

z_accel_pin = 02; z_accel_slow = 1; z_accel_fast = 100

#-------------------------------------------------------

import sys

infile = open(sys.argv[1],'r')

lines = infile.readlines()

infile.close()

g0_in_progress = False # handle consecutive g0 lines

# ensure slow accels at start:

print("M68 E%d Q%.2f (slow)" % (x_accel_pin, x_accel_slow))

print("M68 E%d Q%.2f (slow)" % (y_accel_pin, y_accel_slow))

print("M68 E%d Q%.2f (slow)" % (z_accel_pin, z_accel_slow))

print("M66 E0 L0") # read to synch

for line in lines:

line = line.replace("\n","")

has_g0 = line.replace(" ","").upper().find('G0') >= 0

if has_g0 and not g0_in_progress:

g0_in_progress = True

print("M68 E%d Q%.2f" % (x_accel_pin, x_accel_fast))

print("M68 E%d Q%.2f" % (y_accel_pin, y_accel_fast))

print("M68 E%d Q%.2f" % (z_accel_pin, z_accel_fast))

print("M66 E0 L0") # read to synch

print(line) # first G0 line

continue

if has_g0 and g0_in_progress:

print(line) # multiple consecutive G0 lines

continue

if not has_g0 and g0_in_progress:

g0_in_progress = False

print("M68 E%d Q%.2f" % (x_accel_pin, x_accel_slow))

print("M68 E%d Q%.2f" % (y_accel_pin, y_accel_slow))

print("M68 E%d Q%.2f" % (z_accel_pin, z_accel_slow))

print("M66 E0 L0") # read to synch

print(line)

continue

else:

print(line) # unalteredline

sys.exit(0)Ini file settings for g0filter.py in config directory:

[FILTER]

PROGRAM_EXTENSION = .ngc G0_filter

ngc = ./g0filter.pyPlease Log in or Create an account to join the conversation.

- cmorley

- Away

- Moderator

-

Less

More

- Posts: 7281

- Thank you received: 2124

16 Jan 2020 09:25 #155003

by cmorley

Replied by cmorley on topic Feature request: Different acceleration for rapid and feed moves

I'm curious - is it the high acceleration on feeds creates 'jerk' or creates following errors/missed steps?

What g64 setting do you use?

Chris

What g64 setting do you use?

Chris

Please Log in or Create an account to join the conversation.

- Shu

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 0

16 Jan 2020 09:58 #155006

by Shu

The head of the large moving gantry is flapping around while the servo thinks it's on point. The machine is just not stiff enough and has some wear.

Retrofit with a Beckhoff TwinCat (jerk can be limited) works well.

Replied by Shu on topic Feature request: Different acceleration for rapid and feed moves

Yes it's jerk. The following error is almost the same with low and high acceleration values. The machine has encoders at the servos, but no direct feedback. I'm not sure if there is any way to incorporate direct feedback on a moving gantry of that size. The jerk can be observed, e.g. bad surface quality when machining simple wooden test pieces, lots of overshoot and ringing when measured directly at the spindle head with a glass scale.I'm curious - is it the high acceleration on feeds creates 'jerk' or creates following errors/missed steps?

What g64 setting do you use?

The head of the large moving gantry is flapping around while the servo thinks it's on point. The machine is just not stiff enough and has some wear.

Retrofit with a Beckhoff TwinCat (jerk can be limited) works well.

Please Log in or Create an account to join the conversation.

- Shu

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 0

16 Jan 2020 10:05 #155008

by Shu

Replied by Shu on topic Feature request: Different acceleration for rapid and feed moves

here the open gantry with the large cantilever can be seen: www.instagram.com/p/B1Pipw6ACSN/?utm_sou...b_button_share_sheet

Please Log in or Create an account to join the conversation.

- Shu

-

Topic Author

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 49

- Thank you received: 0

16 Jan 2020 11:12 #155014

by Shu

I think the default of the machine and tool changing is run with G64 (no further parameter). Smooth

For actual programs G64 is in the post processor header with P0.04-P0.2 (in mm).

Replied by Shu on topic Feature request: Different acceleration for rapid and feed moves

What g64 setting do you use?

I think the default of the machine and tool changing is run with G64 (no further parameter). Smooth

For actual programs G64 is in the post processor header with P0.04-P0.2 (in mm).

Please Log in or Create an account to join the conversation.

- LinuxCNC

- General LinuxCNC Questions

- Feature request: Different acceleration for rapid and feed moves

Time to create page: 0.111 seconds