Plasma Cutting aluminum question...

- BlueManRising

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 3

26 Jan 2020 03:31 #155773

by BlueManRising

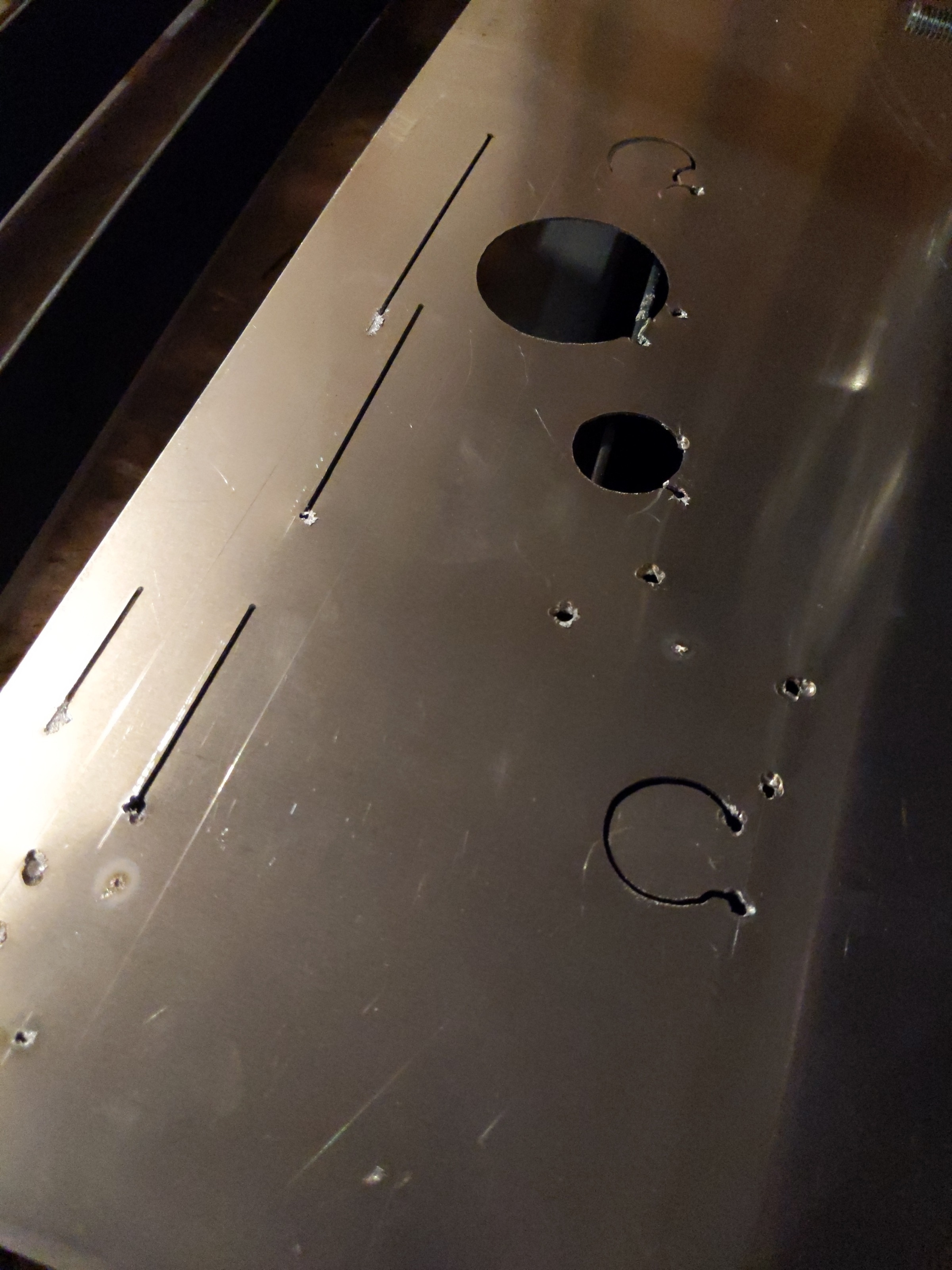

Plasma Cutting aluminum question... was created by BlueManRising

Need some help... Or maybe my search skills are lacking.. anyone have success cutting aluminum? I've notice a few things when I cut, voltage starts off great, but slowly depreciates to the point where the plasma just cuts off, error with voltage comes up, cut stops and then will not continue. (Just tries to restart but no success) I tried to increase the delay time for the Mesa THCAD, but never gets going unless I move the unit completely, it looks and almost feels like it's not able to maintain a arc. I'm assuming my feed rate is maybe the culprit, I did speed it up and saw a drastic increase of performance, but didn't know if anyone else has the same issue. It's about 1/8 thick aluminum plate, cutting at 45amps and 50-60 psi... Also delay THC at 2 seconds. I did keep the guard on my plasma, could be too far away from the material? I will remove it tomorrow and run more line and circle tests.. just racking my brain here..

Attachments:

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

26 Jan 2020 16:53 #155818

by bbsr_5a

Replied by bbsr_5a on topic Plasma Cutting aluminum question...

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20611

- Thank you received: 7013

26 Jan 2020 21:19 #155857

by tommylight

Replied by tommylight on topic Plasma Cutting aluminum question...

Since you reminded me, to all : Please red the plasma source manual !

Several times i see users here trying to cut and fine tune the plasma machines using 30 to 60 PSI, and that is wrong hence giving very bad results. All Plasma sources need 4.5 to 5.5 Bar (67 to 82 PSI i think, please check this ) and some high end/industrial plasma sources will not turn on if under 7 Bar ( 105 PSI ).

For cutting Alu, you will have to do some ( well plenty ) of test cuts as there are plenty of alu types and that will change the cut parameters a bit.

Several times i see users here trying to cut and fine tune the plasma machines using 30 to 60 PSI, and that is wrong hence giving very bad results. All Plasma sources need 4.5 to 5.5 Bar (67 to 82 PSI i think, please check this ) and some high end/industrial plasma sources will not turn on if under 7 Bar ( 105 PSI ).

For cutting Alu, you will have to do some ( well plenty ) of test cuts as there are plenty of alu types and that will change the cut parameters a bit.

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Clive S

- Offline

- Platinum Member

-

Less

More

- Posts: 2247

- Thank you received: 483

26 Jan 2020 22:40 - 26 Jan 2020 22:46 #155865

by Clive S

Yes. A big thanks to Tom for putting me right on the air pressure. photos.app.goo.gl/dNT9vWYgYdHAa22K7

This was 2.4mtr/min 80psi 40amp 3.1mm and I recon I will get it faster.

Edit: 6mm at 4.5mm/min 40A photos.app.goo.gl/S3fLSXVPvZE5fwN38 The disc is 3mm as above

Replied by Clive S on topic Plasma Cutting aluminum question...

Since you reminded me, to all : Please red the plasma source manual !

Several times i see users here trying to cut and fine tune the plasma machines using 30 to 60 PSI, and that is wrong hence giving very bad results. All Plasma sources need 4.5 to 5.5 Bar (67 to 82 PSI i think, please check this ) and some high end/industrial plasma sources will not turn on if under 7 Bar ( 105 PSI ).

For cutting Alu, you will have to do some ( well plenty ) of test cuts as there are plenty of alu types and that will change the cut parameters a bit.

Yes. A big thanks to Tom for putting me right on the air pressure. photos.app.goo.gl/dNT9vWYgYdHAa22K7

This was 2.4mtr/min 80psi 40amp 3.1mm and I recon I will get it faster.

Edit: 6mm at 4.5mm/min 40A photos.app.goo.gl/S3fLSXVPvZE5fwN38 The disc is 3mm as above

Last edit: 26 Jan 2020 22:46 by Clive S.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- BlueManRising

- Offline

- Junior Member

-

Less

More

- Posts: 29

- Thank you received: 3

26 Jan 2020 23:07 - 26 Jan 2020 23:08 #155867

by BlueManRising

Replied by BlueManRising on topic Plasma Cutting aluminum question...

I realized my cup guard needed to be removed from the torch, figured it was the right hight preset but I was wrong, cutting like a champ now.

Thanks!!

Thanks!!

Last edit: 26 Jan 2020 23:08 by BlueManRising.

Please Log in or Create an account to join the conversation.

- bbsr_5a

- Offline

- Platinum Member

-

Less

More

- Posts: 544

- Thank you received: 105

27 Jan 2020 08:25 #155875

by bbsr_5a

Replied by bbsr_5a on topic Plasma Cutting aluminum question...

can you tell others here Your DATA in USE to cut like a CHAMP

this will help people like beginners to don't waste cost intensive Material

this will help people like beginners to don't waste cost intensive Material

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.100 seconds