Can LinuxCNC meet the needs of my growing small shop?

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 4

23 Sep 2020 14:53 - 23 Sep 2020 15:57 #183476

by wiremonkey

Can LinuxCNC meet the needs of my growing small shop? was created by wiremonkey

Hey folks,

I'm hoping the LinuxCNC titans on here will weigh in on this. We have very specific needs for our next upgrade and want to know if LinuxCNC is the right platform. So far, I think yes, but I'm not a strong programmer and there don't seem to be any plug an play solutions.

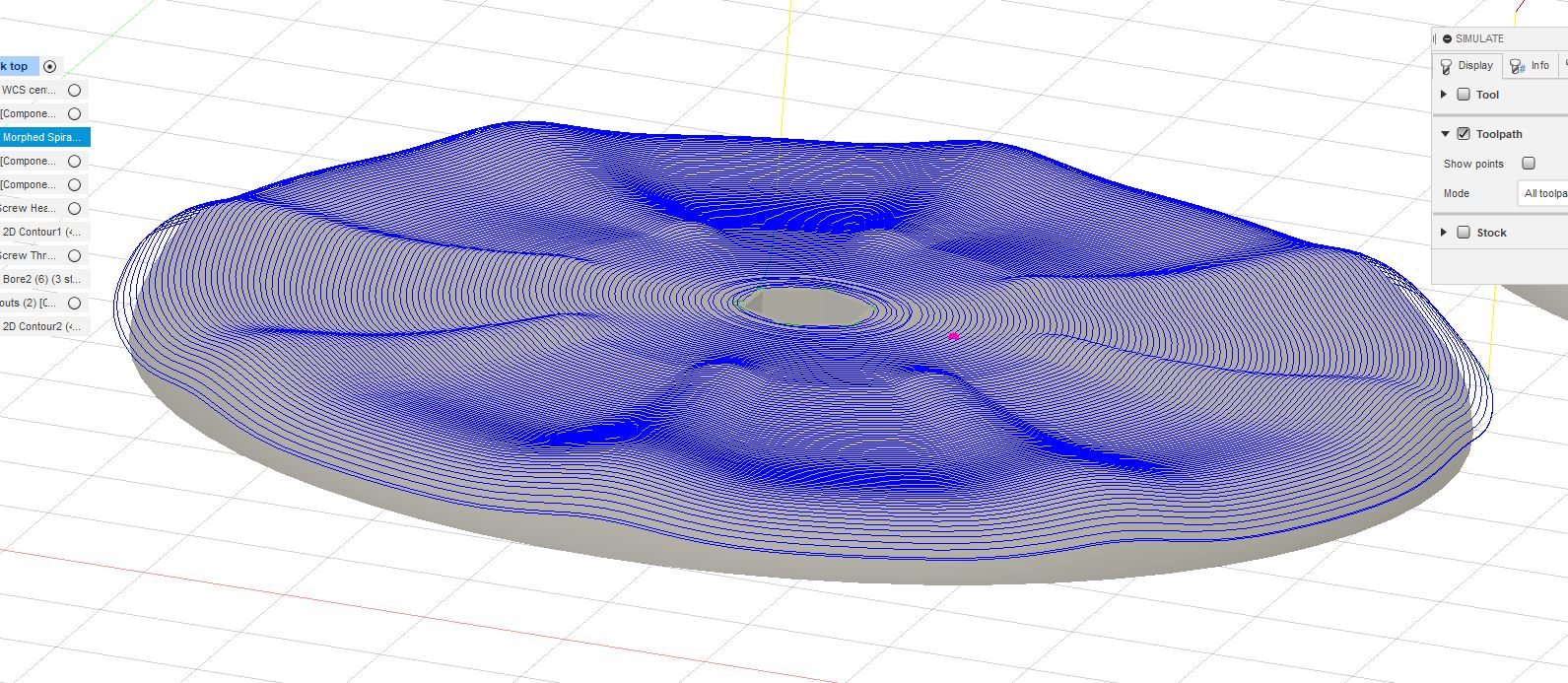

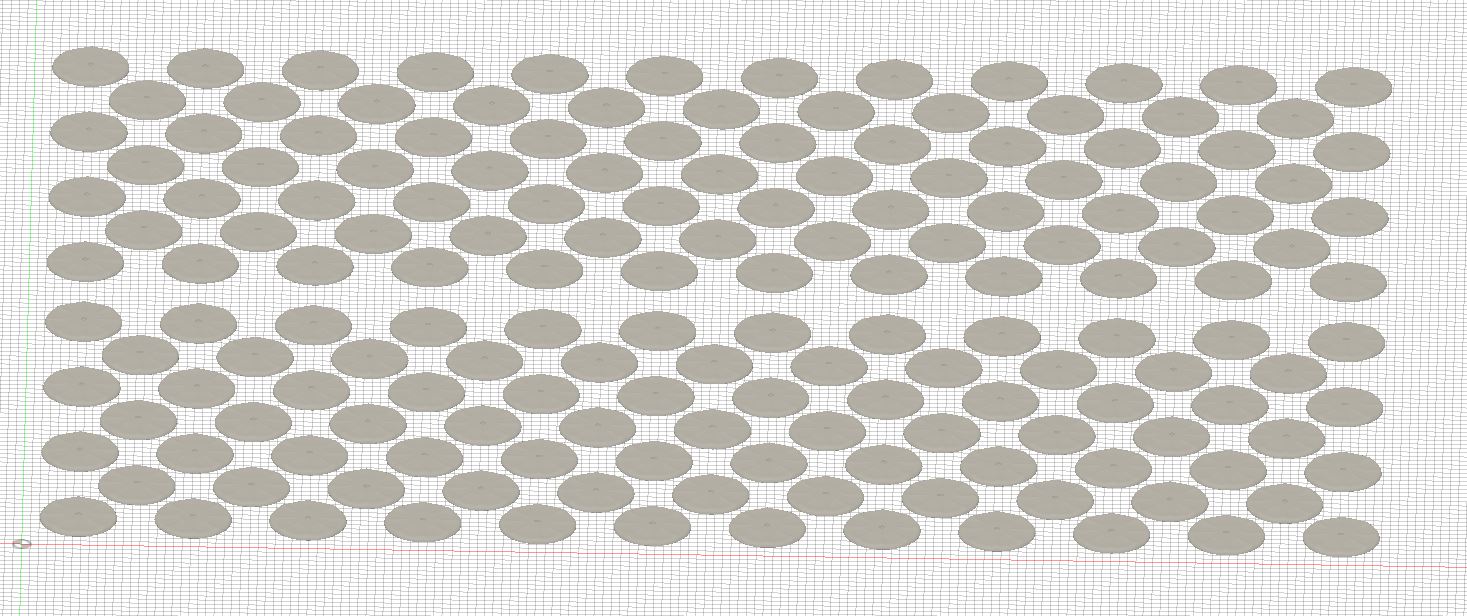

We are dealing with large g-code files, 1.4+million lines of code, combined with a need for autoleveling and over 160 of the same objects being carved on one large piece of wood.

Maybe using g-code ripper autolevel? But this is complicated by the fact that we're dealing with huge files! If we use subprograms, subroutines, remapping, etc, will that play nicely with an autolevel subroutine? Probekins?

The single objects are quite complicated, the surface is almost entirely made up of curves and arcs, so shrinking the code isn't really an option.

And there are a lot of them on two sheets of wood held flat on vacuum tables.

We are currently able to do this with a grbl based machine on the less complex objects using bCNC, but it only works with smaller files and the machine clearly has data starvation, stuttering when cutting, which slows things down and isn't ideal.

I just joined and the community here is great!

Thoughts?

Thanks!

T-

I'm hoping the LinuxCNC titans on here will weigh in on this. We have very specific needs for our next upgrade and want to know if LinuxCNC is the right platform. So far, I think yes, but I'm not a strong programmer and there don't seem to be any plug an play solutions.

We are dealing with large g-code files, 1.4+million lines of code, combined with a need for autoleveling and over 160 of the same objects being carved on one large piece of wood.

Maybe using g-code ripper autolevel? But this is complicated by the fact that we're dealing with huge files! If we use subprograms, subroutines, remapping, etc, will that play nicely with an autolevel subroutine? Probekins?

The single objects are quite complicated, the surface is almost entirely made up of curves and arcs, so shrinking the code isn't really an option.

And there are a lot of them on two sheets of wood held flat on vacuum tables.

We are currently able to do this with a grbl based machine on the less complex objects using bCNC, but it only works with smaller files and the machine clearly has data starvation, stuttering when cutting, which slows things down and isn't ideal.

I just joined and the community here is great!

Thoughts?

Thanks!

T-

Attachments:

Last edit: 23 Sep 2020 15:57 by wiremonkey.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 20992

- Thank you received: 7158

23 Sep 2020 15:44 #183484

by tommylight

Replied by tommylight on topic Can LinuxCNC meet the needs of my growing small shop?

Did you by any chance try the dmap2gcode by ScorchWorks ?

It does this type of stuff very nicely and it is very simple to use.

www.scorchworks.com/Dmap2gcode/dmap2gcode.html

It does this type of stuff very nicely and it is very simple to use.

www.scorchworks.com/Dmap2gcode/dmap2gcode.html

Please Log in or Create an account to join the conversation.

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 4

23 Sep 2020 15:53 #183487

by wiremonkey

Replied by wiremonkey on topic Can LinuxCNC meet the needs of my growing small shop?

Hmmmm, I hadn't realized Scorch had another autoleveling option. Once I get the machine up, I'll give it go.

Thanks again!

Thanks again!

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11527

- Thank you received: 3860

23 Sep 2020 20:29 #183511

by rodw

Replied by rodw on topic Can LinuxCNC meet the needs of my growing small shop?

I don't think there is any reason fro Linuxcnc not to be able to handle the Gcode. The screen display preview might not. I don't know.

I think if I had this auto level problem, I would try and map the surface in a grid and use a custom component that read the current X & Y position and then calculated the Z external offset to apply in real time so there was no gcode used at all.

But if your router base is level, why can't you take an initial levelling pass over each disc with your router?

I think if I had this auto level problem, I would try and map the surface in a grid and use a custom component that read the current X & Y position and then calculated the Z external offset to apply in real time so there was no gcode used at all.

But if your router base is level, why can't you take an initial levelling pass over each disc with your router?

Please Log in or Create an account to join the conversation.

- wiremonkey

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 4

23 Sep 2020 22:54 #183526

by wiremonkey

Replied by wiremonkey on topic Can LinuxCNC meet the needs of my growing small shop?

Thanks for weighing in.

The material is 1/8" thick wood and tolerance is less than 0.1mm. even with a perfectly flat vac table, which we have, the variations in stock thickness make enough of a difference. We also do engraving, which is even less forgiving.

It shouldn't be a tall order to make this happen: autolevel a surface and apply to said g-code file. What makes it challenging is the large file sizes involved.

I admit that I'm seeking perfection.

The material is 1/8" thick wood and tolerance is less than 0.1mm. even with a perfectly flat vac table, which we have, the variations in stock thickness make enough of a difference. We also do engraving, which is even less forgiving.

It shouldn't be a tall order to make this happen: autolevel a surface and apply to said g-code file. What makes it challenging is the large file sizes involved.

I admit that I'm seeking perfection.

Please Log in or Create an account to join the conversation.

Time to create page: 0.083 seconds