Analog Servo runs at maximum speed at start

- tommylight

-

- Offline

- Moderator

-

- Posts: 21164

- Thank you received: 7228

Bumped into that issue back in 1991 !honestly it looks a bit like Coca-Cola...

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

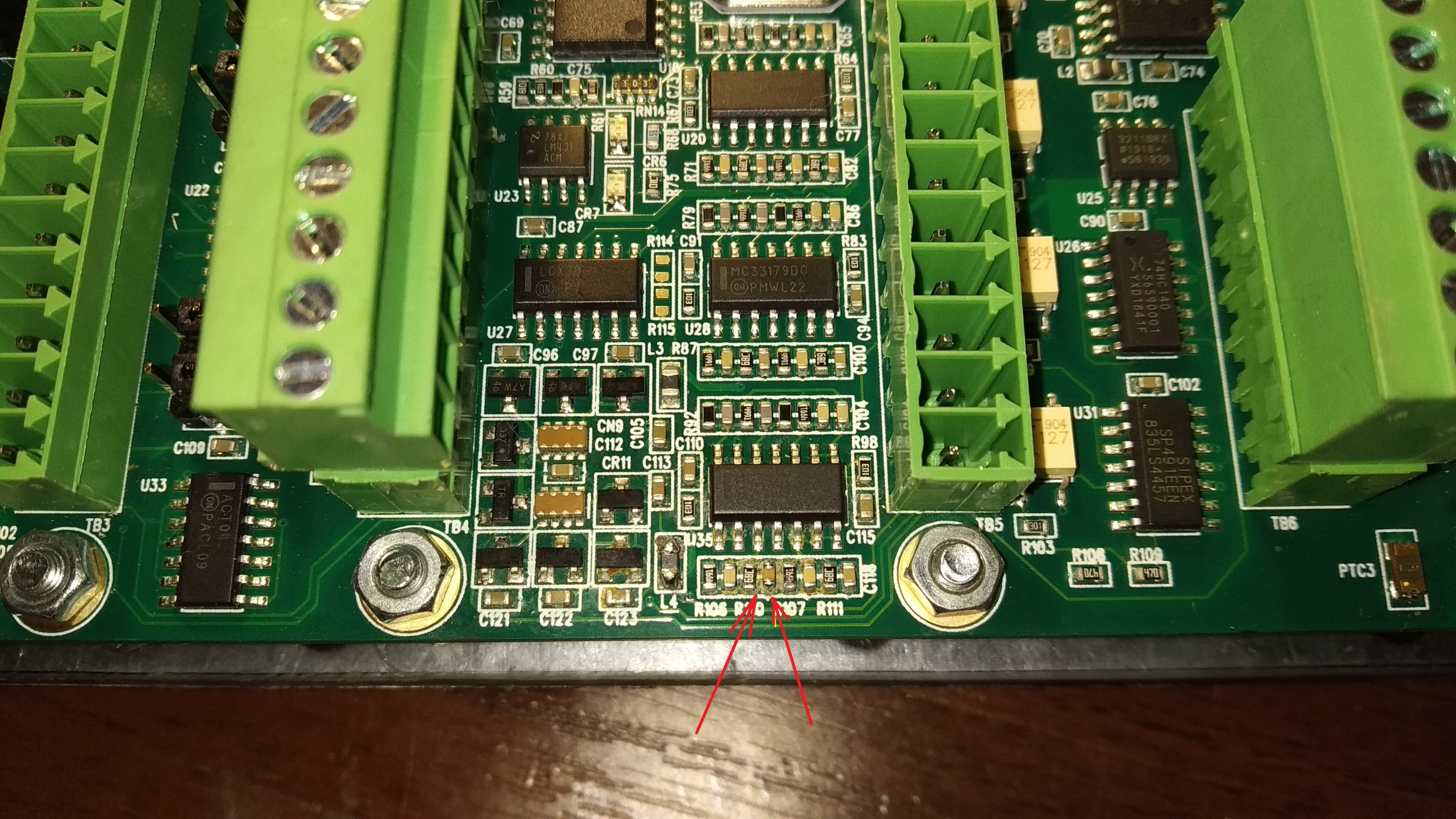

If it will be clean than it will work fine or I need to renew with new solder?

As for me I didn't have Coca Cola in the house for a year at least, so it's not me. Board was in packet from time I received it to be installed.

As for me, it's look like it was resoldered manualy.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17590

- Thank you received: 5145

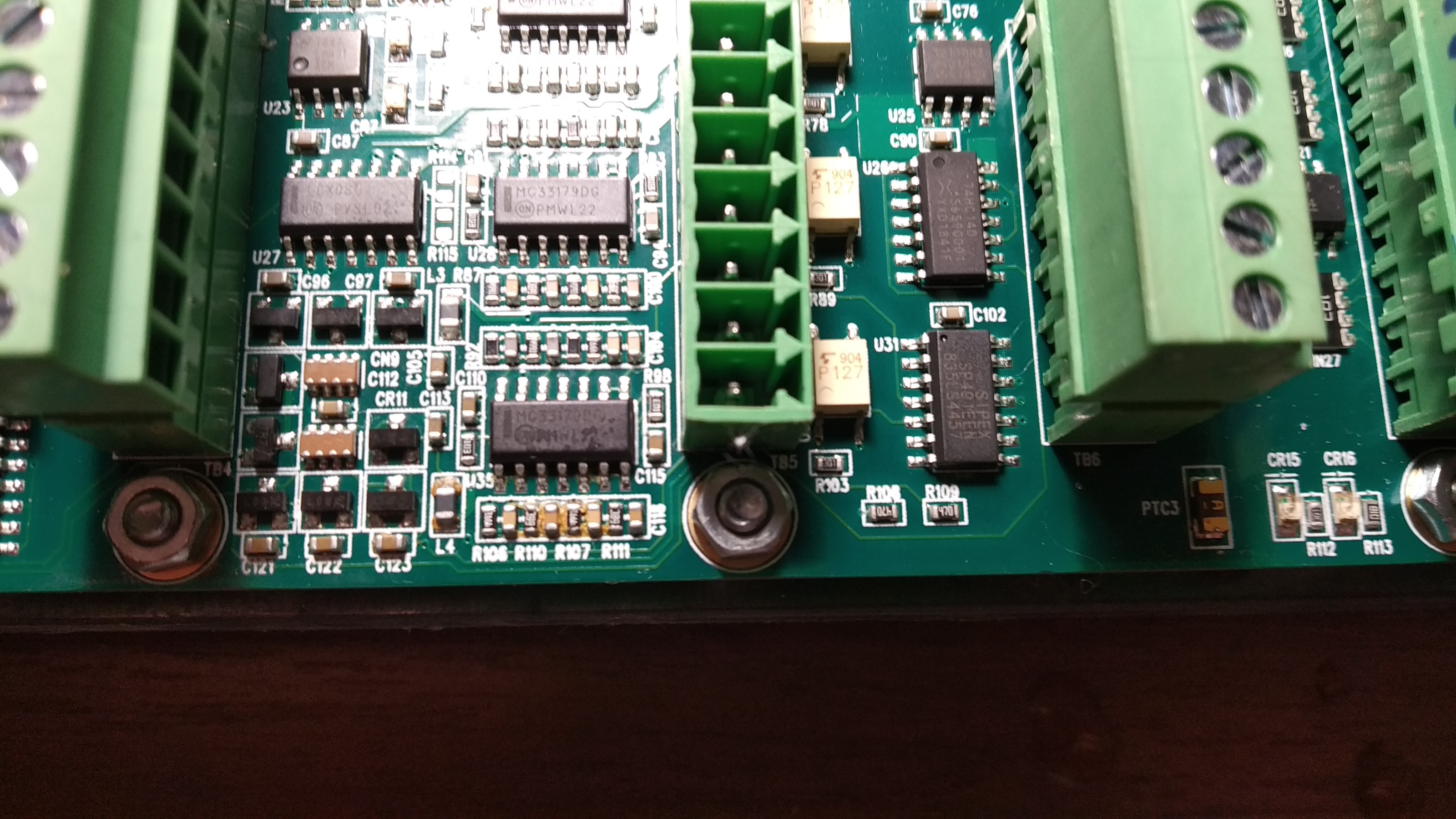

based material which will cause leakage and eventually corrosion. In this case

it would be best to wash the entire board and brush the contaminated

area with something like a toothbrush. If its an oily material, I would use

some detergent in the water. and the rinse many times until the detergent

is gone. When clean I would dry in a 65C oven for a few hours.

If its flux (which would be odd since I have never seen card from out assembly

house with a large amount of flux residue) that should not be harmful but can be

cleaned with isopropyl alcohol

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

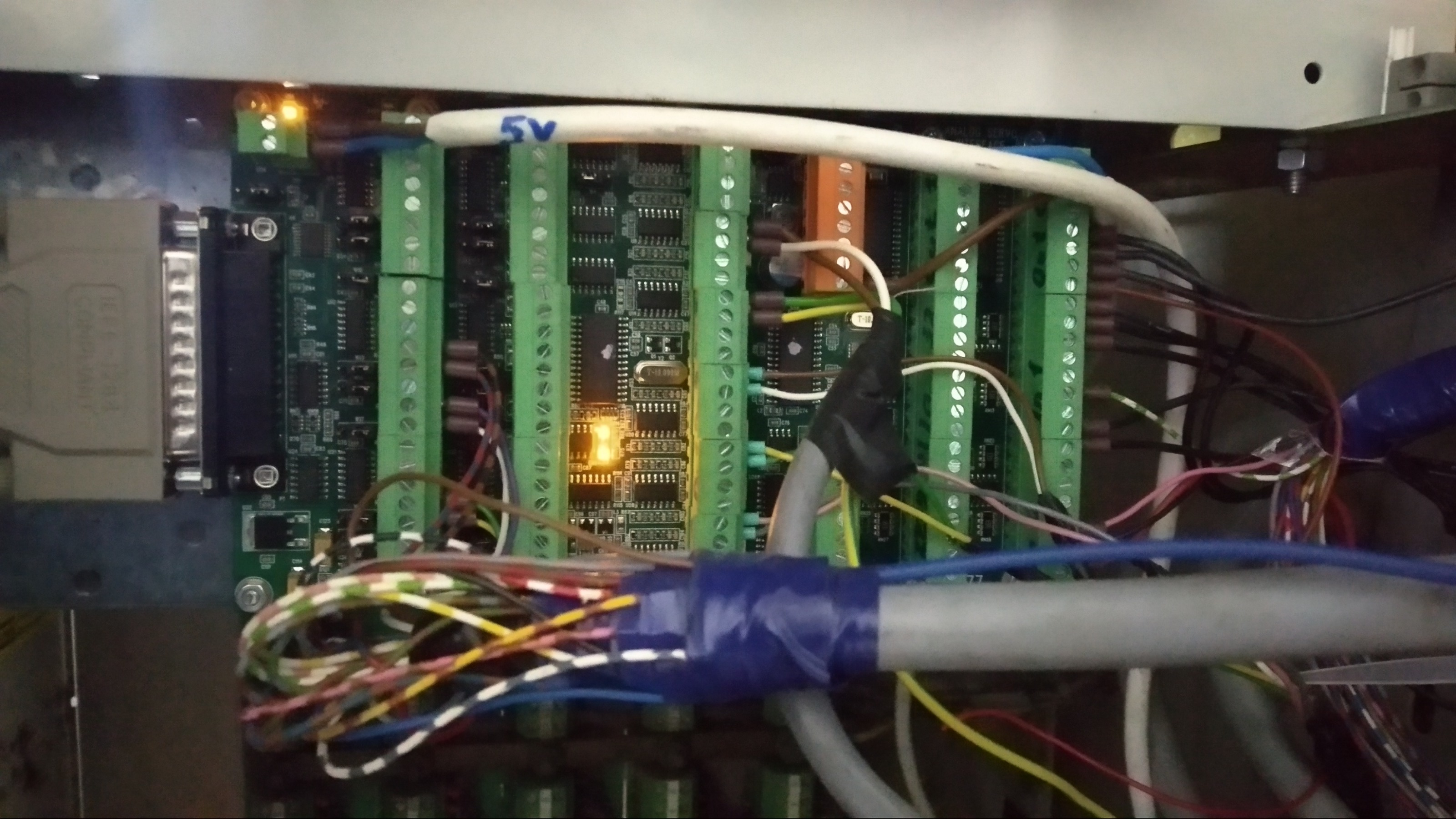

Not the best resault. I checked if capsitor have electrical contact and assembled it back on machine.Now chanel works very nice. It tried run on cold, it works very good. I will try after few days one more time to start on cold if it doesn't change it's quality.

Attachments:

Please Log in or Create an account to join the conversation.

- Mike_Eitel

-

- Offline

- Platinum Member

-

- Posts: 1052

- Thank you received: 183

Not only when it's freezing cold....

Like it was when we have been scubadiving in Petropawlowsk.

Mike

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

But they are the same.

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

I have some brake in working with cnc machine.It was stopped and turned off.Today I turn it on and get errorERROR: Pin 'hm2_5i25.0.7i77.0.0.output-01' doesn't existWhat problem could be in?I tried to set it tighter bot same resault.Supply is added t0 7i77 board.Log of error when I start linuxcnc

Information from MesaFlash PSCable connected to Mesa, not to Parallel Port.

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

Previously I had problem with chanel.0 in this topic.

Now I have problem with chanel 1 (axis Y).

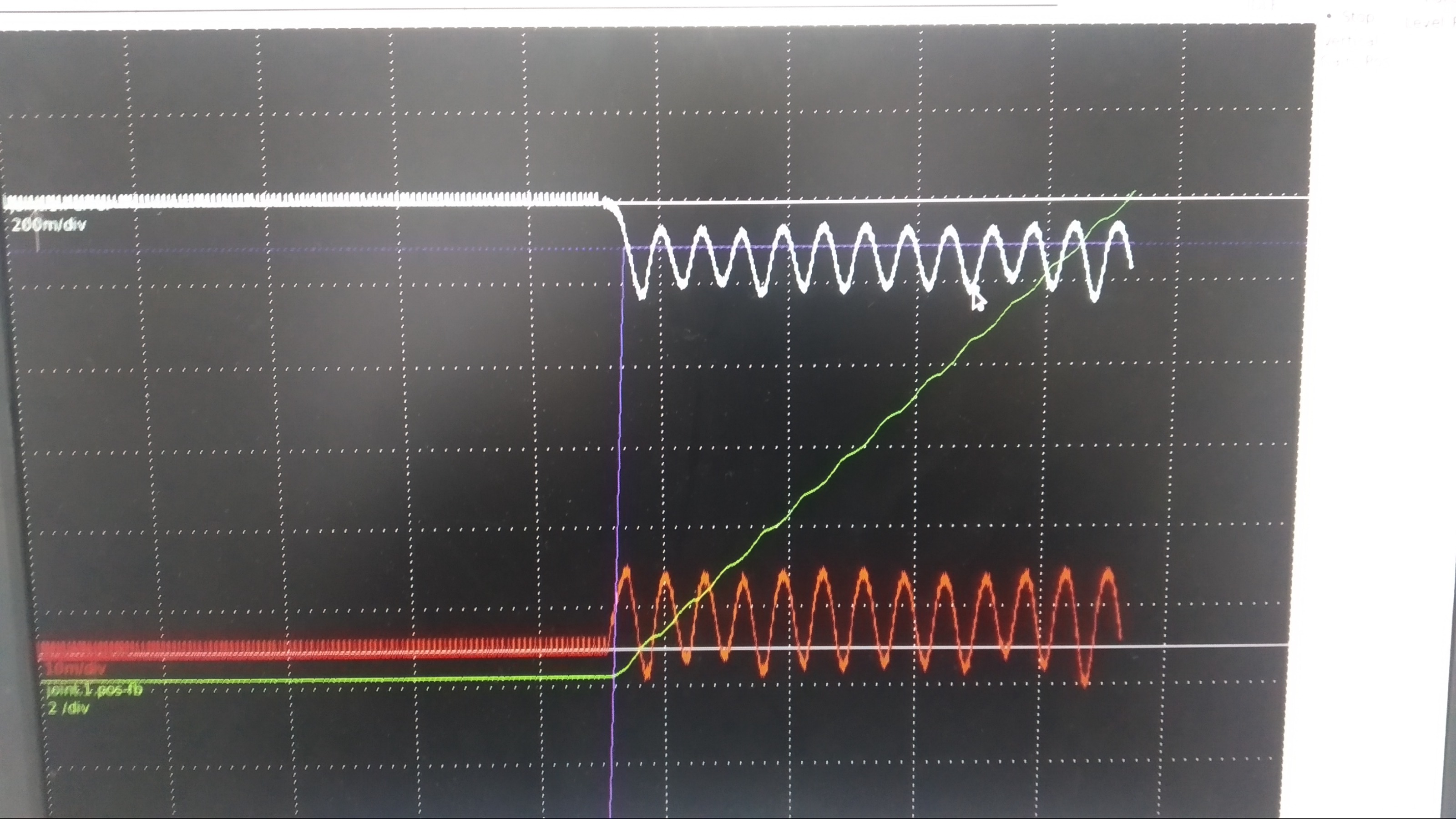

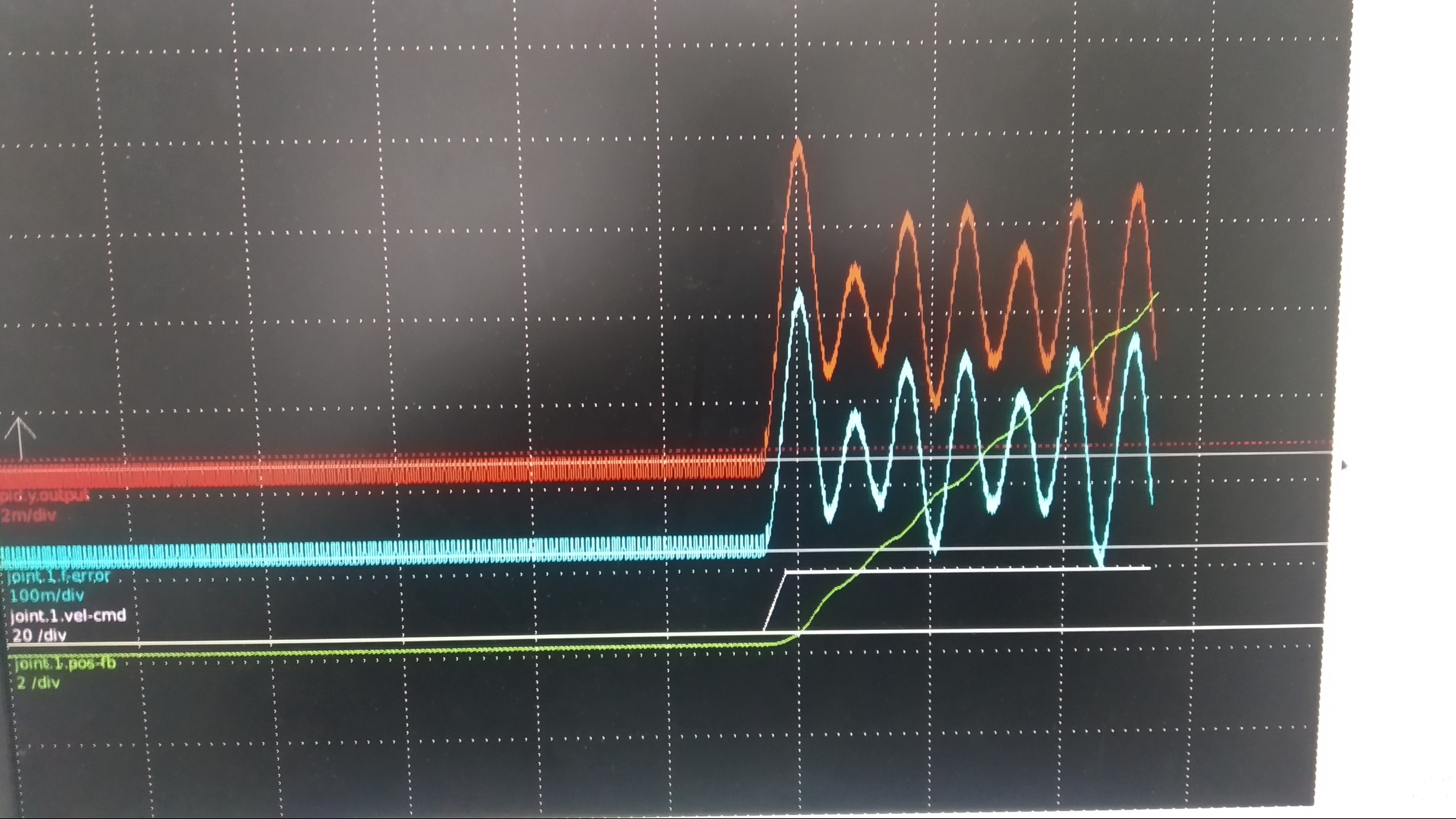

I add transitional process graphs.

I must say that I decreesed P-gain to very slow value.

Also previously I supposed that mechanic is problematic, because belts are move this axis And I supposed that it's very springin. I add one more mechanical joint to stabilize it. But it doesn't solved my problem complitly.

What do you think about this transitional process, PCW?

Other axis X also has belt joints but it's fine now.

I change analog chanel to another to check if problem not in MESA, but it doesn't changed anything, so MESA chanel is good

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17590

- Thank you received: 5145

If you get oscillations with very low (or even 0) P gain,

you probably need to tune the velocity loop on the drive

With halscope pictures, can you take a screen shot rather than a picture

and include the halscope settingspart of the image so that the oscillation

frequency can be determined.

It would also be helpful for diagnosis if you showed the current PID parameters

associated with halscope images

Please Log in or Create an account to join the conversation.

- aleksamc

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 568

- Thank you received: 67

With changing of servodrives I defined that this one was bad.

Also I saw that P=0.003 for another servodrive give much better results (previous value was P=0.08)

I think this problem is solwed.

Please Log in or Create an account to join the conversation.