Lathe spindle feedback

- rohit269

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 0

20 Jun 2021 05:09 - 20 Jun 2021 05:15 #212461

by rohit269

Lathe spindle feedback was created by rohit269

Sir,

Kindly tell us linuxcnc can work with single input (phase A or index) for spindle feedback regarding lathe threading.

Kindly tell us linuxcnc can work with single input (phase A or index) for spindle feedback regarding lathe threading.

Last edit: 20 Jun 2021 05:15 by rohit269.

Please Log in or Create an account to join the conversation.

- scotth

- Offline

- Elite Member

-

Less

More

- Posts: 241

- Thank you received: 61

20 Jun 2021 15:12 #212490

by scotth

Replied by scotth on topic Lathe spindle feedback

The problem is you can't tell the direction of rotation, with a single input.

Please Log in or Create an account to join the conversation.

- rohit269

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 0

21 Jun 2021 02:50 #212532

by rohit269

Replied by rohit269 on topic Lathe spindle feedback

Thanks for your reply, but sir, which reason mach3 can work only index signal input for spindle feedback regarding lathe threading.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17581

- Thank you received: 5142

21 Jun 2021 03:16 - 21 Jun 2021 04:39 #212533

by PCW

Replied by PCW on topic Lathe spindle feedback

You can use a single input for threading with LinuxCNC

You would connect it to the A and Index input of LinuxCNC

encoder component.

The disadvantage of course is that LinuxCNC is basically guessing the spindle

position between between index signals, so any speed variation in the time between

index signals (say due to varying load) is not accounted for in the Z motion

You could gain a small advantage by using a 1/2 disk rather than a hole since you

could get 2 counts per turn with a small modification of the encoder component.

You would connect it to the A and Index input of LinuxCNC

encoder component.

The disadvantage of course is that LinuxCNC is basically guessing the spindle

position between between index signals, so any speed variation in the time between

index signals (say due to varying load) is not accounted for in the Z motion

You could gain a small advantage by using a 1/2 disk rather than a hole since you

could get 2 counts per turn with a small modification of the encoder component.

Last edit: 21 Jun 2021 04:39 by PCW.

Please Log in or Create an account to join the conversation.

- rohit269

- Offline

- Senior Member

-

Less

More

- Posts: 63

- Thank you received: 0

21 Jun 2021 07:34 #212540

by rohit269

Replied by rohit269 on topic Lathe spindle feedback

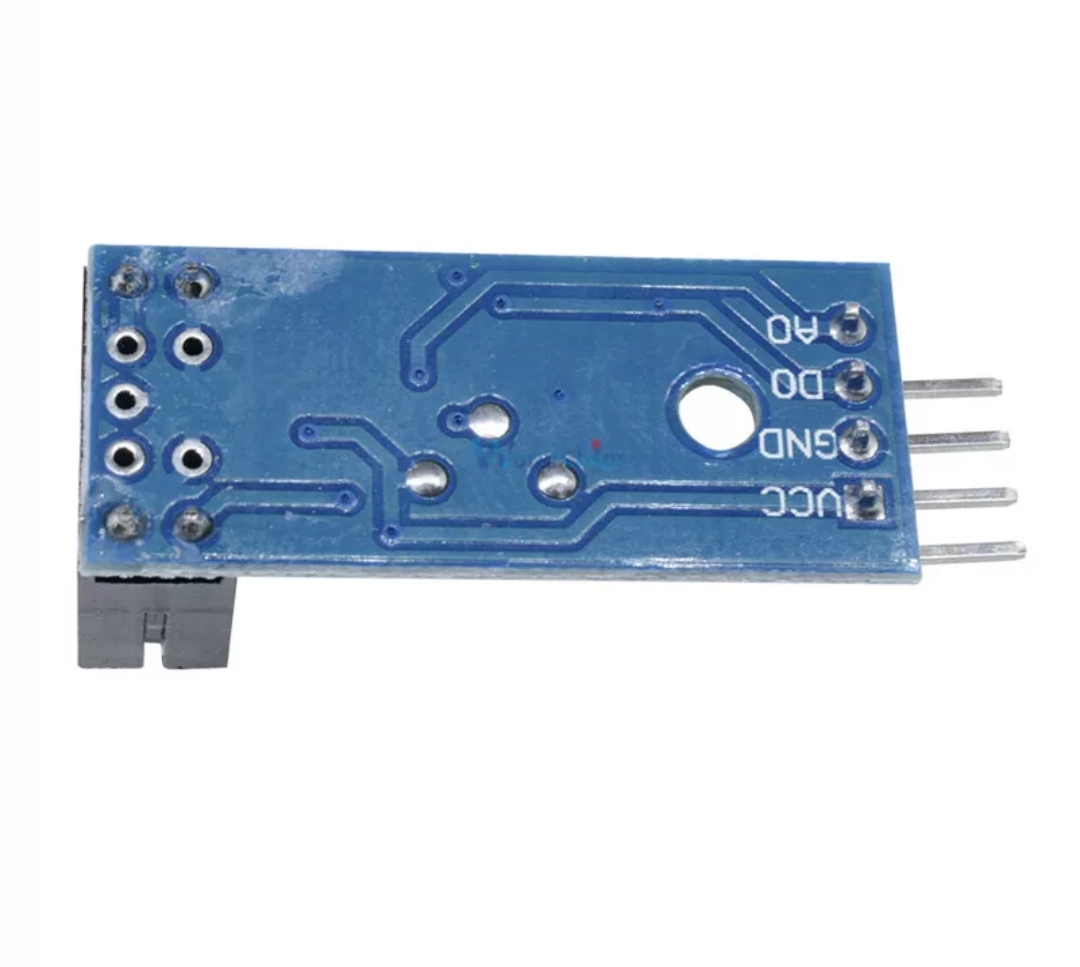

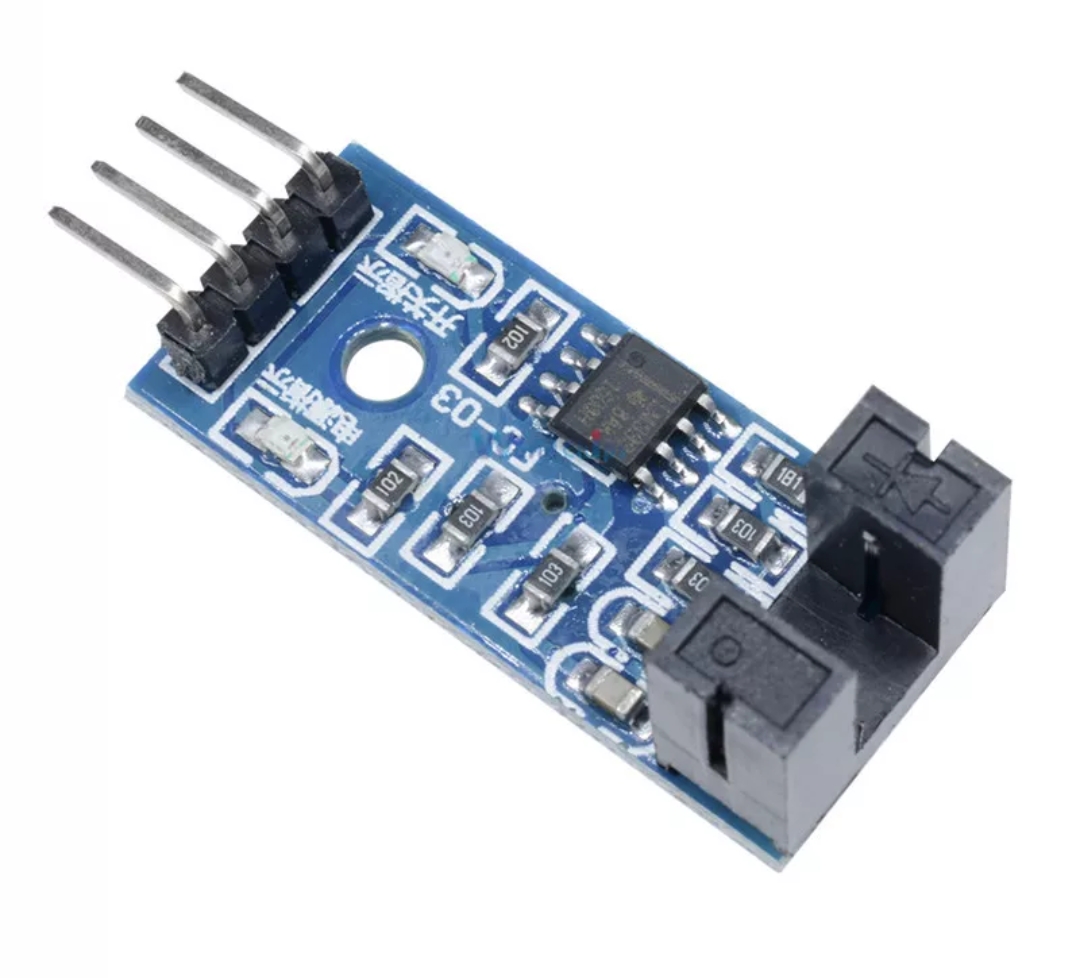

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4600

21 Jun 2021 23:43 #212616

by andypugh

Replied by andypugh on topic Lathe spindle feedback

The connection of the single pulse to both A and Z encoder phases is purely a HAL connection, ie in the software. A single sensor channel and a single IO pin is all that is needed.

(I really must get round to adding missing-tooth index to the encoder component)

(I really must get round to adding missing-tooth index to the encoder component)

Please Log in or Create an account to join the conversation.

Time to create page: 0.194 seconds