System Identification for control

- jang

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

21 Aug 2021 08:34 #218314

by jang

System Identification for control was created by jang

Hello

I'm student want to study CNCcontroller

I'm using LinuxCNC 2.8. on commercial gantry(H-type) CNC system was consist of dual servo motor

And I can run LinuxCNC with commercial gantry system

but, I can just run it.

Now, I want know about my system Identification

So I have to run the CNC with sine wave with various sine wave.

But, I can't command sine wave to LinuxCNC

I think I can use siggen or G-code for direct command similar with sine wave

How can I position or velocity command with sine wave to LinuxCNC ????????????

help me pleaseeeee

I'm student want to study CNCcontroller

I'm using LinuxCNC 2.8. on commercial gantry(H-type) CNC system was consist of dual servo motor

And I can run LinuxCNC with commercial gantry system

but, I can just run it.

Now, I want know about my system Identification

So I have to run the CNC with sine wave with various sine wave.

But, I can't command sine wave to LinuxCNC

I think I can use siggen or G-code for direct command similar with sine wave

How can I position or velocity command with sine wave to LinuxCNC ????????????

help me pleaseeeee

Please Log in or Create an account to join the conversation.

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

21 Aug 2021 17:39 #218335

by aleksamc

Replied by aleksamc on topic System Identification for control

As for me, your topic is unclear.

1. It doesn't matter what gantry property is..

2. what is system identification do you mean?

"So I have to run the CNC with sine wave with various sine wave."

3. Do you know how many sine waves you need? I even not ask for what purpose you need them.

1. It doesn't matter what gantry property is..

2. what is system identification do you mean?

"So I have to run the CNC with sine wave with various sine wave."

3. Do you know how many sine waves you need? I even not ask for what purpose you need them.

Please Log in or Create an account to join the conversation.

- jang

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

23 Aug 2021 06:45 - 23 Aug 2021 06:49 #218462

by jang

Replied by jang on topic System Identification for control

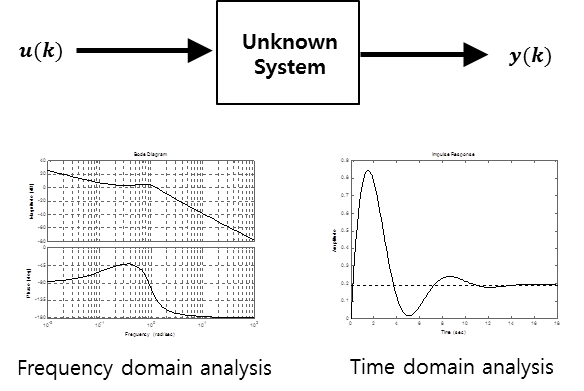

System Identification is required to see the dynamic characteristics of the system.

I want to get the ability to respond according to commands (for drawing bode plot)

this is mean system identification

To do this, I have to change the frequency of the sine wave according to time and apply it to the velocity(or position) command

finally I can get response ability from data.

I want to get the ability to respond according to commands (for drawing bode plot)

this is mean system identification

To do this, I have to change the frequency of the sine wave according to time and apply it to the velocity(or position) command

finally I can get response ability from data.

Last edit: 23 Aug 2021 06:49 by jang.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4457

- Thank you received: 1997

23 Aug 2021 12:47 #218505

by Aciera

Replied by Aciera on topic System Identification for control

This is really just a stab in the dark:

If you make a gcode that commands a circle to be cut then one axis moves according to the sine and the other to the cosine. If you need to adjust the frequency of that then you would need to adjust the feed rate. If you need to adjust the frequency dynamically then you can use feed override while the machine moves.

Amplitude would be adjusted by making the circle bigger or smaller.

How do you measure the response of your router?

If you make a gcode that commands a circle to be cut then one axis moves according to the sine and the other to the cosine. If you need to adjust the frequency of that then you would need to adjust the feed rate. If you need to adjust the frequency dynamically then you can use feed override while the machine moves.

Amplitude would be adjusted by making the circle bigger or smaller.

How do you measure the response of your router?

Please Log in or Create an account to join the conversation.

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

23 Aug 2021 18:47 #218534

by aleksamc

Replied by aleksamc on topic System Identification for control

Aciera It seems to me that he wants to analyze mechanical devices by analyzing op amps method.

Please Log in or Create an account to join the conversation.

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

23 Aug 2021 18:52 #218536

by aleksamc

Replied by aleksamc on topic System Identification for control

I studied at university such subject as jang.

I must say, that with sine wave you will nothing see.

It should be anylized to the step responce.

I must say, that with sine wave you will nothing see.

It should be anylized to the step responce.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 19042

- Thank you received: 5255

23 Aug 2021 19:21 - 23 Aug 2021 19:22 #218540

by PCW

Replied by PCW on topic System Identification for control

Well theoretically they are interchangeable via a Fourier transform

I suspect the main issue will be that the response to either

Step or Bode plot will be dominated by nonlinearities

I suspect the main issue will be that the response to either

Step or Bode plot will be dominated by nonlinearities

Last edit: 23 Aug 2021 19:22 by PCW.

Please Log in or Create an account to join the conversation.

- jang

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

24 Aug 2021 10:14 #218607

by jang

Replied by jang on topic System Identification for control

I don't know router sorry,,, but I got data using ethercat. and so I can watch the data with halscope.How do you measure the response of your router?

Please Log in or Create an account to join the conversation.

- jang

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

25 Aug 2021 05:42 #218677

by jang

Replied by jang on topic System Identification for control

thank you for your reply

I got some data about step command already

but I think the data can't be used for bodeplot

because bode plot require dynamic command and response like sine wave(in various frequency)

If I get the bode plot then I can know resonance(?) frequency or response which reached at -3dB

I have dual servo gantry system

Can I use stepgen in my linuxcnc ?? Or can I give velocity command with siggen???

First, I'll try with sim.axis example

I got some data about step command already

but I think the data can't be used for bodeplot

because bode plot require dynamic command and response like sine wave(in various frequency)

If I get the bode plot then I can know resonance(?) frequency or response which reached at -3dB

I have dual servo gantry system

Can I use stepgen in my linuxcnc ?? Or can I give velocity command with siggen???

First, I'll try with sim.axis example

Please Log in or Create an account to join the conversation.

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

25 Aug 2021 20:05 #218733

by aleksamc

Replied by aleksamc on topic System Identification for control

As for me you will never get resonance freaquency in gantry system.

With increasing of the freaquency change, you will get decay of responce of your motor, it will overheet and may be, will give some smell. It all depends on your persistence.

Resonanse freaquency could be only in systems that has big PID regulator gains. You can increase this values - and resive resonance. I had such things. But if your gains in safe zone, you will never had problems with your gantry system because it's very inertial and has counterforces, if we spoke about cnc.

About stepgen I think it's witten in manual.

linuxcnc.org/docs/html/man/man9/stepgen.9.html

You need siggen set to the input of te stepgen, possibly.

With increasing of the freaquency change, you will get decay of responce of your motor, it will overheet and may be, will give some smell. It all depends on your persistence.

Resonanse freaquency could be only in systems that has big PID regulator gains. You can increase this values - and resive resonance. I had such things. But if your gains in safe zone, you will never had problems with your gantry system because it's very inertial and has counterforces, if we spoke about cnc.

About stepgen I think it's witten in manual.

linuxcnc.org/docs/html/man/man9/stepgen.9.html

You need siggen set to the input of te stepgen, possibly.

Please Log in or Create an account to join the conversation.

Time to create page: 0.111 seconds